How to choose "your" dishwasher? Functional features of various models, power consumption and washing quality.

The variable position of the upper box in the "dishwashers" allows you to install large items upstairs

($ 600)

Glass spiral in the Optosensor sensor on the dishwasher door imitates the walls of the glasses through which the beam is passed

If it falls on the surface of the spiral, then the infrared beam is dissipated and a weaker Bosch signal arrives on the photocell ->

Everyone knows that washing dishes is a time-consuming and not very pleasant occupation. But the dishwasher has not yet become in Russia the same full "family member", as, say, washing. Meanwhile, the world manufacturers of "dishwashers" offer to the domestic buyer more and more fascinating functions, put on crimped names, compete in the efficiency of technical solutions ... Today we will try to decipher some of them.

First of all, let's try to build dishwashers sold in Russia, in a row, so to speak, descending, from the most advanced Hi-End models to economy class. The first will be the instruments of manufactured by Gaggenau, Miele, AEG (Germany), Asko (Sweden); Following the Nimi-Ariston (Italy), Bosch and Siemens (Germany), Electrolux (Sweden); Then Indesit, Whirlpool, Zanussi (Italy) and, finally, available to most residents of our country, Candy and Ardo (Italy). This division does not apply for a rigor, because reflects the opinion of manufacturers about themselves, and most of the European companies have in the line of household appliances all possible options for configuration, from the most complex to the most simple as possible. For example, the "dishwashers" of economical execution from Electrolux compete in the lowest price segment with Whirlpool and Ariston, whose premium models are comparable to Siemens. Now, BOSCH produces low-cost units with a pali-ax (polinox) pallet, but does not sell them in Russia because of other positioning in our country.

What to do to the buyer who conducts a complex analysis of numerous parameters trying to choose his own "dishwasher"? It's no secret, which he wants to achieve as a result of the purchase: pure-well-washed and dry-dry dried dishes at the lowest cost (for the entire life of the device). For example, in the apartment where the electrical heating system is installed, the washing machine, audio and video equipment, string lighting systems are stretched under the ceiling, and the hydromassage bath is brown in the bathroom, it's time to take care of savings (because the energy tariff has already begun to grow and do not think about This is as about tomorrow). There will be a majesty ecolebel (Ecolabel- EU), or an energy consumption sticker, on a dishwasher.

AAA!

This is not a combat cry of apaches, but just a standardization system introduced by all European manufacturers with 1995. So they tried to alleviate for consumers of household appliances the task of choice. On the ecoleeble of dishwashers are displayed by the 3-eyed "environmental" indicators: an energy consumption class, a car wash class and a class of drying. The characters are added, indicating water consumption and the number of tableware sets treated at the same time. Usually the sticker indicates the exact noise level in the dBA.Why are these indicators called environmental? Yes, because they all somehow reflect the impact of "dishwashers" on human health (through the purity of dishes and the environment). Behind the AAA or ABA characters, which are known today, there are serious instrument tests. Methods of these tests for all "dishwashers" are the same, although there are some features here.

When determining Class power consumption The manufacturer chooses one of the regulated standard washing modes, which, in his opinion, is most suitable for measurement of electricity consumption. As a rule, this is a standard washing at a temperature of 50-55s without prior rinsing. The maximum amount of dishes are involved, which is calculated by the machine. The dishes are laid out in baskets according to the scheme specified in the instruction instruction. On the measurement values of the consumption of electricity, the class of energy consumption is determined. If the value falls into the interval defined for a specific class, or does not exceed its upper boundary by more than 10%, the machines of this model are assigned classes A, B or C. For example, for a class of power consumption of full-term machines, 1,056-1,254 kWh with tolerance is given. % to the large side (in case of the case, the upper border of the class rises to 1.38 bills). If the measured value goes beyond the frame of a class by 10-15%, 2 more prevents are additionally tested. The average-parent three dimensions can be met in the framework of valid values and the machine will assign a class. Which of all this suggests?

First, one-sole measurement can immediately satisfy the conditions, and the second and third that did not spend due to a successful result, fall out of the specified boundaries. For reference: Any experiment implies an acceptable accuracy of at least five attempts. Meanwhile, according to manufacturers, the process of technical content "dishwashers" to the designed designers of the energy consumption of the energy consumption is not easy. As a rule, it takes not one test with subsequent revision. Therefore, it is unlikely that the device will overcome the "barrier" by chance.

Secondly, the manufacturer can from the very beginning to choose a program of an economical sink, when the minimum amount of electricity is consumed, although it is not achieved by high-quality washing. For example, a cost-effective washing-andpribor has acquired an energy consumption class. But at the same time, test pollution washed not completely and was appointed class washing. Thus, one product can be designated as a supereconomic, and the other as superfunction (luster, when they came with the principles of energy efficiency and received a class, and the classroom was worked on washing and drying). This path elects are elective to transnational companies that belong not to one brand. In addition, when testing for the European Ecoleybla, they are mainly going to enhance the class of energy efficiency, because for Europe, the issue of saving costs more acutely than, for example, for North America. Many European manufacturers are chosen for the Economy Program test (if they are implemented in the machine) at 50-60 ° C, the exact mode is indicated in the prospects and technical description of the model. The buyer should clarify this, otherwise, when using other programs, much more energy and water will be spent.

In total, there are 7 skills of power consumption of DPG. Not so long ago, the Class has become extreme for "dishwasher". Instruments Classd, E, F, G (if there are generally in nature) are recognized as non-economic and prohibited for the production and import to the European Union countries. This restriction is associated both with an attempt by universal economy and with additional obstructions on the path of Asian competitors, which in technical "achievements" do not catch up with "Europeans".

In addition to the general division of energy efficiency, there is still intracelave division according to the sidelines for cars with a width of 60, 45 cm and compact. It is that smaller limits are installed for smaller devices. For example, in the classroom, with a width of 60cm, the flow rate is not more than 1.05 kWh, and for the instrument with a width of 45cm, not more than 0.75 kWh. In addition, the values for the classes with a width of 45cm (0.90-1.03 kWh) are fully fitted in the range of a class for devices 60cm wide. Let us buy a smaller machine of one class with more, you automatically get savings, and almost independently of the manufacturer's selected programmer.

Class of washing dishes . To determine this parameter, a standard set of dishes is taken and for each subject, according to its purpose, the most common food "Pollution" is applied: mince, spinach, oatmeal, milk, tea and coffee. Next, the entire kit is placed in the oven and for two hours is dried at a temperature of 80c. The result is a solid and durable crust on the surface. Then the same program "Dishwashers" is chosen, as if tests for energy efficiency, and the dishes are clean. After that, for each subject, the effectiveness of the washing efficiency is from0 to5 (5Tupports completely clean dishes). It is determined by the amount of spots and an area of pollution. The instrument index is calculated as a medium-tariff indicator (for example, 4.01) and is compared with the reference (for example, 2.85), which meets the 40s dishwasher from Miele. The difference is calculated (1,16- corresponds to the class) and is assigned a car wash class at the calculation A> 1.12> B> 1> C> 0.88> D> 0.76> E. The testing process passes through the same rules as When determining the class of energy efficiency, but with smaller tolerances of deviation (4-6%).

And finally Index Dushka Determined in the range from0 (several droplets of water on the surface) to 2 (no drops or moisture zones). The result of drying is calculated by the same principle as the result of washing.

As you guide the letters on the elalaeble there is a competitive struggle, which is not one decades with varying success. Suspicious consumers that they are "somewhere can inflate, but it is unknown where," they are not completely groundless. Here is the conclusion of analysts held in 2001. A study for one of the departments of the European Commission on the revision of the euro-collectible parameters for dishwashers (quoting): "There is one problem that requires consideration. It is the likelihood that tests conducted by various laboratories can show different results for one machine. This is It is possible in view of the fact that in the process of the experiment, some tolerances are made that apply to factors such as ambient temperature, the temperature of the water at the entrance and the constancy of the temperature in the chamber. Deviations from accepted constants can lead to differences in one class (Aiseki and two) In addition: no production errors are not taken into account, which make up 10-15%. They can lead to a change in one class. "But it should be recognized that most of the companies are following the innovations of the neighbors in the market and, if suspicious of uncleanness arise, conduct an independent investigation and Quickly fed to court.

Battlefield: Dishes

The battle for three people among the producers of "dishwashers" in the absolute majority of cases is not carried out by means of methodological tricks, but by technical innovation. Here are some of the main directions of progress in this area:

- improving the quality of washing and drying with small energy consumption;

- improving hygienic indicators of washed and dried dishes;

- safety instruments starting from water supply hose and ending with adaptations that restrict children's access;

- Full automation, the use of sensory systems with control processors that support complex programs for selecting the modes of the unit;

- Noise absorption.

And several secondary areas of development:

- an increase in the volume of the washing chamber by changing the layout of the dishwasher;

- Introduction of cost-effective half-loading programs allowing you to use the machine, for example, when filling only the top basket;

- As a result, the appearance of rearranged baskets and baskets transformers, allowing to put large dishes at the top;

- Develop new design.

Quality washing

As a rule, dirty dishes are laundered by not strong jets of water, but splashes that are produced by rotating sprayers-rockers. For a good result, the wash is very important that the car does not have the so-called "dead zones", where the intersecting jets are "collapsed", and the detergent solution fell to the maximum area of the dishes. For this, many manufacturers use plastic rockers in which small holes (nozzles) are made, because the smaller the hole, the more "point" will enter the jets on the dishes. So do Electrolux and AEG. Bosch and Siemens, in addition, are used in all devices plastic rockers wave-like form. The nozzles are placed in such a way that the jets of water do not crosses and do not "quench" each other. Therefore, water freely falls into all the corners and on all surfaces of the washing chamber. Whirlpool engineers came further. They set up the upper stainless steel sprayer on the rotating bracket. So it was possible to achieve complex trajectories of water jets, dishwashes. The lower rockers with holes on the underside are widespread, the jets of which are constantly washed by a mechanical cleaning filter. When analyzing the water spraying system, an important parameter is the number of directions. The more directions, the better. For example, Asko has7, ELECTROLUX, BOSCH, WHIRLPOOL and SIEMENS- 5.Another way to improve the quality of washing is based on a pulsating change in the pressure of the water supplied in the rocker. This is due to the use of a two-speed motor in the supply pump: under weak pressure dirt fades, and it is finally washed under severe. Such a solution is implemented in AEG, Electrolux, Ariston, Whirlpool, Candy machines. Extract models of Candy (for example, CD798Smart) similar processing (designated abbreviation) is combined with heating of water to 70c, which allows you to remove even the most resistant dirt.

In Ariston machines equipped with the Duo Wash function, the water is distributed over two levels in different ways: for the top basket pressure and temperature below (delicate washing), for the node, above (washing pan, saucepan, etc.). This makes it possible to simultaneously wash the fragile and severely polluted dishes. The Siemens Avnted Machine SIEMENS technology allows you to reduce water consumption while maintaining the pressure. Through the rotary valve, the water is redistributed to the top, then at the lower level. While stands up the top rocker and the detergent affects the dishes, there is an intensive washing under high pressure at the bottom. Then the baskets "change places", and the pressure appears at the top.

Filtration

Under the three or four-step filtration system of the dishwasher, all manufacturers are understood by mechanical filters that are located at the bottom of the washing chamber. They cover the pump inlet, which pumps water to either into the sewer (we lose the replacement) or back to the rocker. Mechanical filters in most cases are located equally. They consist of a small grid that occupies 10-30% of the pallet area, one or two mesh glasses with different calibers of cells and plastic liner with the largest holes. Large waste is delayed in the first liner and fall into the so-called bunch, smaller remain in the second and third glasses and on the grid, which acts as a grater. In the "dishwashers" with self-rotational filters (Bosch, Miele, Siemens, Ariston, Asko, Whirlpool, Candy, etc.), soft food waste is packed under the influence of water jets emanating from the directional injectors. The resulting mesh is constantly washed and require additional purification only in case of solid waste (type of cartilage or bones) in them, which in most cases are removed before installing the dishes in the basket. The use of similar filters makes it possible to reduce the total water consumption and save electricity, which is at its heating, due to the recycling of heated water.

To optimize the filter and improve the hygiene of the washing chamber, some manufacturers (Bosch, Siemens, Brand) increase the area of the upper grid, thereby increasing the useful area of the grater. Others (for example, Asko) make a special hole in the grid itself, which prevents the deposition of pollution under it as a result of stagnant phenomena. Whirlpool sets a special electronic pulse formation device, which at the plum stage sends pulses to water accumulated at the bottom of the washing chamber. These impulses create a wave that lifts and moves all the dirt tempered on the bottom and transfers it to the filter block.

In the meantime, manufacturers who do not trust the filter self-resistant ability or do not provide its irrigation from the lower rocker, necessarily indicate the instructions on the mandatory manual flushing of the filter (equipped for this with a special handle) after each use. The battery of such firms includes AEG, Ardo, Electrolux, Zanussi, etc.

Sensors on guard

Sensors "Ecolesor" (Miele), Aqua-Sensor (Bosch, Siemens), Water Sensor (Electrolux, AEG) and Sensor System (Ariston) consist of light sources and photocells installed on a dishwasher recycling water line. Designed to determine the instead of water after pre-rinsing and during the operation of the machine. Transmit a signal to the controller, which compares readings with extremely valid values embedded in the detergent programs. Based on this data, the car in the first stage of the program decides whether to launch fresh water or continue washing dishes in the old one.The main difference between the sensors consists in their sensitivity not only to the muddy, but also to painted water. AQUA-SENSORII sensors are installed in the most expensive models with additional sources of green spectrum, which are with the greatest reliability distinguish between pollution. This year, Miele also appeared the second generation sensors "Ekosencessori", allowing to distinguish air bubbles in water. Previously, these bubbles were taken for dirt particles.

In the latest series of models Bosch, Electrolux and Siemens, appliances appeared, which simultaneously with the determination of water purity independently evaluate the number of dishes in the chamber. It is done on two different methods, but one principle. The principle is as follows: the more dishes, the greater the number of droplets will not reach the bottom of the washing chamber and the less water in relation to the launched from the water supply system will return to the recirculation system. Ubosch and Siemens are installed "Rotation sensor on pump", which determines the amount of glass with water dishes by the impeller of the pump. The competitor applied the method of measuring the pressure of the water column above the deepening, where the pump is located.

It is difficult to say which technique is more accurate. But at first glance, the aeration of water, that is, its saturation with air bubbles, the thing variable and depends on the type of flow (laminar or turbulent). Solid side, the amount of water in the pallet is a constantly changing value, and a suspension is required to measure, and its necessary and sufficient duration is difficult to predetermine in advance. After the controller receives relative data on the number of dishes and pollution after pre-rinsing, it decides on the choice of the program is intensive, standard or economical. WeT and consists of the essence of the intellect of modern "dishwashers", which decide everything for you.

Half loading, pre-rinsing

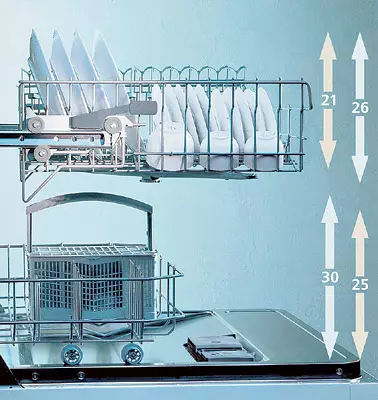

Cheaper dishwashers are not equipped with such complex systems, although they give the user a choice. Depending on the contamination and the number of dishes you yourself can choose the "Pre-rinse" option without heating and detergent in order to clean the most contaminated areas, after which the device will be released on one of the selected cycles. Listening to a small amount of dishes Many devices from model rows of all companies support half-loading mode. Then less electricity and water is consumed, which comes only in the upper rocker (extraction models; if there is a system of redistribution of pressure from the lower rocker to the upper and back, the lower rocker is not blocked). To accommodate a small amount of large plates and a saucepan at the top of the washing chamber, it is planned to lower the upper basket on 5cm.

Heat

Previously, the box is rearranged in those models, where the heating element was used by TEN, it was not available. This is due to the fact that with the open position of the heaters, right in the washing chamber there is a sharp drop of temperatures in the lower zone, on the boundary of cold air and hot water. The thin-walled glassware from glass or porcelain, which does not withstand such differences, was placed in the upper basket, as far as possible from the Tannes, and the probability of permutation was not even considered.Today, many companies removed the aggregates with a similar layout with production and began to set the machine the so-called hidden heating element. What does he represent? TEN, which is installed under the bottom of the washing chamber in the field of water fence pump. Water is heated when the recess is inserted to the bottom, before passing the pump, and does not have direct contact with the hot surface. It turns out a kind of flowing heater. Such a scheme is more economical compared to open by the open, since heat is transferred to a small amount of water and it is immediately discharged into the recycling system nozzle, so that energy is not spent on convection. But if earlier the open heater made it possible to quickly dry the dishes, not the caustav, then the speed requires special technical solutions. About them next time.

Optimal rigidity

It is no secret that in the waterways of Moscow, the Moscow region and many other regions of Russia is tough. To mitigate it, there is a special device for ion exchanger, where Ca2 + and Mg2 ions are replaced + Na + ions. We wrote about the principle of the operation of the ion exchanger in the article "Almost to whiteways").

The most sensitive glass dishes are most sensitive to this indicator, for which the rigidity from 2 to 5 mg. / l is optimal. At large values, a lime flare appears, and the detergent becomes inefficient, the diffusion of Ca and Mg ions from the glass itself begins. Over time, this is manifested in the form of characteristic scratches and clouds on the surface of the dishes.

By its technical nature, the ion exchanger is not capable of adjusting the rigidity. It is a chemical reaction that cannot be controlled. The device softens the water as much as it can, and only a certain number of ions replaces. The performance of the ion exchanger is laid at the calculation of the maximum stiffness of tap water so that optimal indicators are obtained at the output. If initially water in the plumbing is soft, then its impact is redundant and at the output we will get too low concentration of SA and MG ions. What will lead to corrosion of glass.

Previously, the rigidity of water falling into the washing chamber was not regulated. The user was allowed only to establish a ion exchanger regeneration cycle depending on the known rigidity. With the help of an interactive display, a division on a rotary scale is exhibited in the worst-screwdriver. And at a certain point, despite the fact that regeneration is needed or not, it was conducted. Salt was spent, water rigidity was not controlled in any way. Today, the premium class of model rows of Bosch, Siemens, Miele appeared. They can control the regeneration process of resin and indirectly maintain optimal rigidity in the washing chamber. Why indirectly? Because the essence of the option is that with a delicate sink, a small amount of uncooked water from the water pipeline is mixed.

How do sensors act? Bosch engineers have developed a system for determining the content of waterfront. The dishes replaces the spiral from the laboratory glass installed on the door of the machine. The spiral is skipped infrared beam. If there is no wave of scale on the glass, the infrared beam passes without loss and the photocell detects the maximum light intensity. If there is a flare on the spiral, with each reflection, part of the light is lost due to the dispersion and the photocell comes into a less intense light. Then, at the next load, the system sends a regenerating salt into an ion exchanger. Measurements are carried out after each washing cycle. Due to repeated reflections of the beam in a glass spiral, the accuracy turns out to be many times higher than it distinguishes the eye of a person who considers glasses on the lumen. When the formation of scale is based, the machine at the rinse stage overlaps the feed of the rigid water and the scale in the flow heater ceases to form.

In MIELE devices, a sensor defines the electrical conductivity of the resin. This indicator changes when calcium and magnesium ions replace sodium ions. Upon reaching the thresholds, the system gives a command to regeneration. In addition, the "brain" of the machine can estimate the rate of saturation of the ion exchanger. A high speed means that water is tough and, therefore, will not be able to change. A small speed indicates that the water at the entrance is not tough, therefore, after passing the softener, it will remain completely without calcium and magnesium. In this case, a certain amount of water from the water pipe is added to the chamber. As you can see, different approaches give, essentially the same result.

We will tell about all other technical solutions that are embodied in the metal engineers of manufacturing companies of dishwashers, the next time. It will be about drying the dishes, about systems that prevent leakage, about effective noise absorption and new trends in the design of the dishwasher.