Once again about warm floors. Cable electrical heating systems: "narrow" places, basic technologies, characteristics of heating sections, cables and thermostats.

Modern cable floating systems of the floor are safe from the point of view of both temperatures (24-28C) and electromagnetic radiation (10MKTL) ->

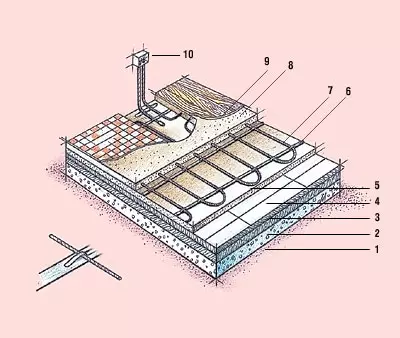

1. Soil.

2. Sealing gravel.

3. Thermal insulation.

4. Plastic film.

5. Reinforced concrete plate.

6. Mounting plank.

7. Heating cable.

8. Alignment concrete.

9. Surface material.

10. Thermostat

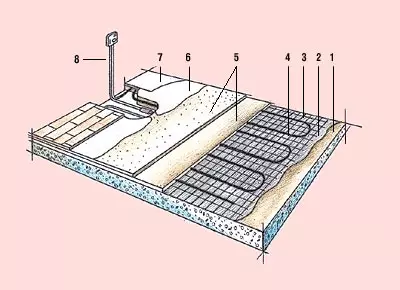

1. Old surface material.

2. Coupling layer.

3. Grid (for example, a thin wire chain, approximately 2525mm).

4. Heating cable.

5. Putclone and, if necessary, surface putty.

6. Attaching the coating.

7. Surface material.

8. Thermostat

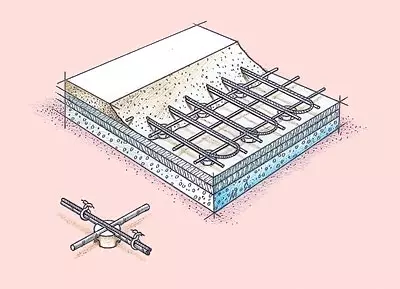

1. Carpet.

2. Aluminum foil (optional).

3. Fastening grid.

4. Heating cable.

5. Poland flooring.

6. Passage of gap.

7. Thermostat

Rushing heating cable roads, however, it is not afraid of migratory loads and does not cord a parquet due to overheating even under furniture

The idea of home heating with heating of floors arose in ancient times. In the 70s. XXV, with the appearance of relatively inexpensive and affordable electricity, for these purposes began to use heating cables located in a sand-cement screed. So the era of electrical heating of floors began.

Warm floor for a warm house

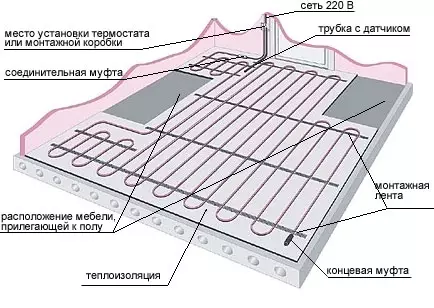

Electric heating of the floor (warm floor) is able to become both the main and optional (used together with other heating devices) of the heating system that can be included at any time of the year, regardless of the operation of the CHP. The heat source is the heating cable. It turns the floor into a large panel, evenly emitting heat. The cable is connected to the automatic thermostat (thermostat), controlling air temperature in the room. This device is fixed on the wall and is the only visible part of the system. The temperature information in the room is coming to it from the thermal sensor installed in a special corrugated tube (so that it can be changed in the breakdown) in the plane sealing the cable, directly in the body of the thermostat or in any place convenient for the host.As the main (main), the warm floor system is usually used in separate buildings (cottages, cottages), including those that cannot be connected to central heating. In this case, the designer remains a greater space for the embodiment of its designs, since there is no need to seek places for heating devices and pipes and somehow decorate them. Punching the top layer of a warm floor can be used natural or artificial stone, concrete, tile, tube, linoleum, carpet, well-dried tree (parquet or floorboard).

As an additional system, the warm floor is designed to achieve the highest comfort in rooms with cold floors (bathrooms, kitchens, pools), on the first floors of buildings, as well as in any other residential and non-residential areas. Place for an additional system Customer chooses at its discretion. For example, you can warm up the floor in a children's, living room, bathroom, a small space under a writing desk or in the hallway. The system of the system finds the preferred application in urban apartments, since the water heated floors in them are difficult to implement.

Electric floor heating systems have a number of indisputable advantages. The main system in each room can be automatically maintained with high accuracy to maintain individual temperatures. In this case, the floor will be only 2-3C thermal air. Touching the feet heated to a physiologically comfortable temperature (24-28C) surfaces causes a feeling of comfort and bliss unattainable when using other heating systems, and relatively cool air at the head level gives a feeling of freshness. In addition, there are no drafts in heated in this way of room, and dust, even if it was not removed on time, almost does not rise upward by convective flows of air and does not make allergies. It does not fall below the norm and the level of air humidity, since the temperature of the floor surface, as already mentioned, is low.

When repairing the electrical heating system, there is no need to open the entire floor. It is enough to determine the place of damage to the cable and open the floor only at this point. The ends of the cable are connected using special repair couplings, after which it is again poured by cement. The repair of the thermostat or replacing the sensor will not be difficult if the latter was installed in the corrugated tube.

As for statements on the dangers of electrical heating systems, there are no objective data on this account. According to many experts, the ecological safety of such heating is not doubtful. According to the sanitary standards and rules of Russia (SanPiN) 2971-84, the electric field strength in residential premises cannot exceed 500V / m, and the level of induction of the magnetic field of industrial frequency (SanPine 2.1.2.1002-00) should be below 10MKTL. The actual values of these parameters of electromagnetic fields above the gels with shielded cables are lower than those specified several times. Manufacturers referred to the electrofolting tension from 10 to 300V / m. APO testimony of the employees of the Electromagnetic Security Center Ministry of Healthcare, spent in the residential measurement premises showed that the values of tension and induction created by the floors do not exceed the background. It is also important that materials used in the creation of warm floors are less susceptible to fire than the usual electrical wiring.

Speaking of lack of electrical heating, an increased energy consumption should be noted. Especially a lot of electricity consumes the main system. For example, for heating a house with thermal loss of about 30kW during the heating season, the system requires approximately 500 billion energy. "Electric" heat every year costs the owner in 20 times more expensive than the resulting system on the main gas. Connecting this main system of outdoor electric heating is costly justified only in areas where there is no main gas supply, and even if the house is built in compliance with the latest energy saving standards.

In urban buildings, which were erected more than 10 years ago and where substations, eyeliner to homes and apartments are designed for old standards (approximately 2,5kW per apartment), you can only talk about the heating of floors only as an additional heating. Yes, and it should be used carefully, since there is a possibility of overloading the feed cable (if all neighbors simultaneously include numerous electrical appliances). But even if the electrical power required to connect electrical installation is available (dondrone apartments are 7kW), it is necessary to check whether the existing wiring is allowed to connect the warm floor to the current load. If not, you can recommend installing a system with a power of more than 2kW through a separate wiring and a separate machine.

Permissible electrical hardware loads (according to PEU)

| Explorer material | Section, mm2 | Maximum load current, and | Maximum total power, kW |

|---|---|---|---|

| Copper | 21. | nineteen | 4,1 |

| 21.5 | 27. | 5.9 | |

| 22.5 | 38. | 8.3 | |

| Aluminum | 22.5 | twenty | 4,4. |

| 24. | 28. | 6,1 |

All serious problems with the system arise as a result of improper installation. "Narrow" place of half-overheating cable and, as a result, burnout, if the heat removal from its surface is insufficient. Therefore, in a concrete screed, in which the cable is immersed, there should be no emptiness around it. Mechanical burning of heating veins over the permissible limit is fraught with a violation of the crystal structure of the metal and also burns out the cable. Therefore, do not twist and do not bend cables with a radius smaller than the manufacturer allows. A thermal zebra may appear on the floor surface, that is, the alternation of cold and hot plots. It is also possible to occur areas of local overheating, due to which the resource of the system is significantly reduced, the material of the floor covering (especially parquet) is spoiled. All this happens if the cable laying step is incorrect. However, with a clear compliance with the laying technology, the cable will serve at least 25 years (idle up to 50 years of calculations). Although the guarantee on it is given a much smaller. For example, 15 years-ceilhit (Spain) and 10let- Alcatel (Norway).

Popular recipes

In the section, the warm floor is heterogeneous and resembles a puff cake, "baked" using one of the five basic "recipes" (depending on the main purpose). You can create a system of basic heating for accumulating and direct heating, a traditional system of additional heating, an additional heating system in a thin screed or on a wooden floor. Each "cook" (cable manufacturer) seeks to make a "dish" (screed creation technology) something self. Customer should not refuse this "highlight" to the customer in no case so as not to lose the right to warranty service and repair. We limit ourselves to the description of basic technologies.Let's start with the fact that the main system of electrical heating can be arranged directly on the ground. At the same time, its base serves a pillow of carefully tumped gravel. Listening to the main system on the already arranged concrete floor in the premises of any types of gravel, naturally, is not used, and the base is well purified and aligned slab overlap. Over the base lay a layer of a hard heat-insulating material with a thickness of 50-100mm, which serves the first screed. The segments of the mounting ribbon or the reinforcing design of the wire that have not yet frozen until the end of the concrete surface are located, which significantly facilitates the fixation of the cable. Next, the cable is laid on the intended route. Then there is a second concrete screed, the thickness of which with direct heating is 30-70 mm, and in the case of the device of the accumulating heating system, 100-150mm. On the perimeter of the room in the lower part of the walls, heat-insulation strips are laid, which prevent the floor deformation as a result of a thermal expansion of concrete. Over the screed is the finish coating. With direct heating, it is a hard, well conductive heat material, such as a ceramic tile.

In the accumulating system, the cable is recommended to lay closer to the central plane of the screed body, for which the supply of heat floors includes special guides or grid. Under the grid nodes are laid round plastic backups with rods for rods, its step corresponds to the step of laying the cable. The cable is attached to the grid with plastic bracket or wire. In this case, the floor covering is better to use a plug, wood, carpet and other materials with low thermal conductivity so that the heat is saved longer in the concrete layer.

The traditional additional heating system is assembled, as a rule, on top of the old floor, laying the cable to the guide or reinforcing mesh directly on the heat insulation without an intermediate screed. Such a system can be used in the premises of different types, both in the cottages and in urban apartments. True, a concrete screed is located on top should have a thickness of from 30 to 70mm, to be sufficiently liquid and homogeneous to tightly contend the cable from all sides. Avota in the device of an additional heating system on top of an old tiled or concrete floor with a cable installation in a thin screed (0.5-1.5 cm) in bathrooms, toilets, hallways and other rooms of the modern urban apartment from the use of thermal insulation, as a rule, refuse. Without it, heating, of course, will be less economical, but it will not be necessary to sacrifice 5-10 cm of the height of the room. The cable is folded by a snake or spiral and fixes directly on the old floor covering. From above, instead of a screed, a layer of tiled glue is applied to dry for 1-2 days. Then there are finish coating or put the tile directly to the just applied glue.

Now about the design of a very cunning (forward queue, due to its fire hazard in the event of an installation error) - a preheating of wooden seats of country cottages. When it is created on the wooden floor, thermal insulation is placed in the gap between lags, on top of which aluminum foil and the mesh for fastening the cable are placed. Inside, where the cable passes through wooden lags, arrange the isolated fooles, the cable is passed through metal tubes. Punching of the finish coating is used by the flooring of 20-30 mm thick. You can put the cable and directly on the wooden floor and pour the screed.

Heat runs on ... Wires

Single-core heating sections

Two-housing heating sections

Heating mats based on single-core and two-housing heating sections

|

The only veins of a single-core shielded cable can be performed from nichrome, galvanized steel, brass or other material that makes up the know-how of the firm. The insulation of the veins make two-, three- and four-layer. PVC, stitched polyethylene, teflon (fluoroplast), silicone rubber are used for it. The temperature of the heating vein with the correct installation and operation of the system does not exceed 80c, while the insulation is withstanding more than 100 ° C. The smaller the calculated value of the vein temperature (say, 50c), the easier it is the insulation withstands overload and the cable longer serves. True, the specific power of it decreases and has to buy it more and stacked the slower.

On top of the inner isolation, a screen of steel or copper wire, aluminum foil or lead, serving, primarily, security goals are mounted. It protects insulation and core from mechanical damage and is grounding wire. But the main screen significantly reduces electromagnetic radiation created by the cable. Extracting systems with shielded single-core cable, the screen is used both as a feed (reverse) wire, but only located coaxially with a heating residential, due to which the resulting electromagnetic radiation decreases very much. At the same time to use additional Teflon isolation (as, for example, in Spyheat), the cable will successfully withstand and twice loads. Outside of the screen, a protective shell is applied, as a rule, from PVC. The heating section from a single-core cable contains two couplings and two cold end. When laying on the floor, both ends of the heating core should be approached to the thermostat (network connection point).

In two-core cables, depending on the design, two heating or one heating and one feed vein (feed-from copper wire) are used. A nucleation section of a two-tier cable at one end All wires are securely connected and reinforced with an end cap, and on the other are completed with clutch and cold ends to connect to the network. Thanks to this design, the section has a number of advantages. First, the magnetic fields of both wires with current closes each other and are partially mutually compensated (especially in the case of a double twist - firm KIMA, Sweden). The screen around the veins additionally reduces this radiation to neglecting small values that practically do not affect human health (magnetic induction in the range of 0.1-1MKTL). Secondly, laying the heating section from a two-housing heating cable is simpler than from one-core, since it is not necessary to bring the second end back to the thermostat.

The booting envelope reliably protects cables from mechanical damage, which allows them to operate them in the harshest conditions (for example, when heating the steps of the fever house). The most important technical parameter of cables is the power supply (specific heat generation). The most common heating sections with a rapid power of 15-21 W / m are most common. They are supplied to the consumer rolled into the bay. Several major foreign and domestic firms are engaged in the production of such sections, each of which uses its own technological developments and adheres to their views on which cables are better to use for heating residential and auxiliary premises. For example, in the range of companies Ceilhit, Alcatel, Kima, Ensto (Finland), CST, Eltech Electronics (Russia) are presented both single-core and two-housing cables of various power, with which it is possible to heat the room of any size. De-VI (Denmark), "Terma" (Russia), Siemens (Plant in Israel) and "Chuvashkabel" (Russia) For heating of residential and auxiliary premises, offer to use a two-housing cable produced by them.

In principle, in the range of those listed firms, of course, you can find more powerful cables - from17 to 21 W / m (with a diameter of 5-10mm for mounting in a concrete screed with a thickness of 30-100mm). But when using them, it should be borne in mind that they are more "sensitive" to errors when laying a large probability of appearance on the surface of the heated floor "heat zebra" (cables are too far from each other). It is also possible to premature damage to the cable as a result of overheating (invalid rapprochement or crossing cables). Cables with a diameter of 2-3mm for additional heating, installed in thin concrete screeds (up to 3cm) or in wooden floors, have a circuit power in the range of 5-12 W / m.

One of the most important criteria for the successful selection of the cable is the quality of the coupling. It should ensure the tightness of the connecting unit and reliable electrical contact for many years. Different firms use different options for compounds (soldering, welding, crimping) and sealing (the use of heat shrink plastic, filling with polymerizing compounds). Reliability and durability are determined by the perfection of the used technology, and the quality of the assembly. Therefore, the best criteria for reliability are the long experience of the manufacturer's manufacturer in the market of warm floors and the period of free warranty service.

Thin low-power cables are sold or also in bays, or in the form of mats. The latter are a stamped cable attached to carrier fiberglass grids 50cm wide and a length corresponding to the selected system power. Heating mats are manufactured specifically for additional comfortable heating in rooms where it is impossible to raise the floor level by more than 0.6-1 cm (excluding the thickness of the floor covering). As a rule, these are bathrooms, toilets and hallways with low ceilings in residential buildings of urban building. The grid can be cut into separate fragments, of course, without disturbing the integrity of the cable, and lay out on the plane of any configuration (say, bypassing the obstacle).

Heating mats and sections based on thin cable-protected cables produce the above-mentioned company DE-VI, CST, Ceilhit, Alcatel, Ensto, Siemens, Kima, as well as Stiebel Eltron (Germany). When choosing a model, you should pay attention to the warranty period during which cables will be serviced and replaced for free, as well as for certificates of environmental and fire safety. Note that even for the purpose of saving, you should not use one section in rooms with floors of different designs. It is better to resort to the installation of independent heating sections with separate thermostats. Laying the cable can only be carried out in those areas of the room, where there are no flat base furniture (without legs) and carpets.

Assess the required power of the heating section, the customer may, based on the area of the room. The specific power of the outdoor heating system in the central part of Russia is taken, depending on the thermal insulation of the house: when creating an additional electrostropriation system, the channel 110-130 W / m2 and the device of the main system of direct heating (in the case of the case, the cable must be laid out at least 70% of the surface. The floor of each heated room!) - Vdiapazone 120-150 W / m2. The power of accumulating systems sometimes reaches 240W / m2. When installing in wooden floors, permissible power should not exceed 80W / m2. In order not to buy too powerful or, on the contrary, there is not enough powerful heating section, it is better to entrust the choice of the model of a competent specialist of the organization selling such equipment.

Connecting the electrical heating system to the network is made stationary connections (forks and sockets) is not allowed.

The shielding braid is necessarily grounded that in the case of a breakdown of insulation ensures the safety of people.

Depending on the purpose of the system, the thermostat must have a conventional or moisture-proof design and installed either directly in the heated room or in electrical protection.

To protect against a short circuit in the system, automata or protective shutdown devices (UZO) are included.

Electronic "Kochegar"

The thermostat with the floor temperature sensor, along with the heating cable, is an essential element of the electrical heating system. Such thermostats are manufactured by OJ Microline (Denmark), Eberle (Germany), DE-VI, ENSTO, CST, Elek Electronics and others.

In the simplest cable heating systems (for example, for a bathroom or toilet), unprogrammed thermostats cost from $ 40 to $ 120 are most often used. By sposing floor temperature or air relative to 0.1-2 ° C (depending on the model), the unprogramable thermostat commutes the system, with an increase in temperature to the same value, turns off. Installing the desired temperature parameters is made step, using a multi-position switch, or smoothly, using a variable resistor. From that that the heating system is under voltage, the user reports the LED.

Programmable thermostats worth $ 100-200 and more allow not only to maintain the specified temperature, but also change it according to a user-defined algorithm. For example, you can heat the floor to a given temperature only in the morning, from 7 to 9, and in the evening, from 18 to 23 hours. Increased time the system will be in the disconnected state. Programmable thermostats are usually equipped with digital displays to set the desired temperature. Have some standard programs with different temperature indicators for the day and night, workers and weekends. Each of the programs may often be modified, adapt to the needs of the user. Instruments of this type are often used in country houses, at dachas and other objects with a periodic visit. Capable to heat the room to the arrival of the hosts on the weekend, lower the temperature or turn off the heating at night or in the absence of the hosts (antifraizing function). In addition, it is these thermostats that make it possible to extract the maximum benefit from the two-timing system of payment of electricity, automatically including thermostat and accumulating in the "cheap" time of the day. Programmable thermostats easily fit into the Smart Home system.

According to the method of installation of the thermostats of both types (unprogrammed and programmable) are housemate or embedded in the walls, as well as intended for installation in the automation closet (DIN-rail), etc. Rooming devices for overhead or installation in the wall are located in the most convenient place at home so as not to interfere with the placement of furniture. Instruments that control the heating of rooms with high humidity (bathrooms, toilets and others) and have no appropriate protection against moisture, it is necessary to have out these premises.

The switched power of thermostats, as a rule, does not exceed 3kW. If the total power installed in the heating sections is larger, their connection to the supply network is carried out through a special power relay (magnetic starter) controlled by the thermostat. Another option is to use several devices, one for each section.

Sometimes due to the installation error, it is not possible to replace the failed gender sensor. To bring an electrical heating system to a working condition, you have to open the floor. But you can not resort to destructive actions. It is enough to connect to the thermostat instead of the floor temperature sensor, the air temperature sensor attached to the wall at an altitude is no more than 40cm in a place where there are no drafts. Some thermostats are equipped simultaneously and the floor temperature sensor and air temperature sensor, which increases their reliability.

Take care heat!

According to most professionals, the correct selection of thermal insulation leads to a noticeable economy of electricity during the operation of the floor heating system, and the initial cost of the system increases slightly. The thermal insulation reduces the useless heat loss to heating overlaps and other designs underlying the premises serviced. You can buy heat insulation both from sellers of heating cable and in specialized construction stores.If the floor heating system is arranged as the main one, as thermal insulation, it is recommended to use solid polystyrene varieties with a thickness of 50-100mm. Material is greater thickness choose when you need to heat the floor on the ground floor and on the ground. We often use thermal insulation materials with a foil layer and with a polymer coating. Builders assure that the foil in contact with the concrete screed, due to thermal conductivity, effectively redistributes heat from the cable over the entire floor surface, and also reflects part of the heat back to the room. The selection of heat-insulating materials is quite wide, for example Styrodur, Floormate, Hanalon, "Fomisol", "Penofol", "Folgoisol-F" and others. The average price is 1m2- from $ 2 to $ 10.

I must say that the practice of the device of such floors makes it constantly clarify some provisions of technology. For example, according to experts from Eltech Electronics LLC, the use of thermal insulation in floors above the heated (residential) premises gives more minuses than pluses. The heat loss through the base is insignificant, and the first screed has to be done quite thick to ensure its strength and high bearing ability of the floor. A results of an unjustified increase in the cost of work.

Unnecessary company specialists consider the use of foil materials under the screed, since unprotected foil quickly (for 3-5 years) and completely destroyed under the action of an alkaline medium of a cement mortar (especially in rooms with high humidity). The same opinions hold the masters of the first supplier of electric floors to Russia - the company DE-VI. By the way, the last thing is about being ready to release a set of recommendations on the installation of heating systems on a new form of floors with a dry tie, which began to be embedded in the recentations in houses built according to individual projects.

The so-called self-regulating cables are implemented in practice. They are not afraid of local overheating, they can be laid directly under parquet and even thin laminate. Furniture above them can be placed, without fearing the intake of the flooring. It will evidence, these warm floors allow us to update the interior more often, which impresses many owners. True, it is worth such equipment quite expensive (1pog.m- $ 5-10). You can even perform a thin heating film (FloorFilm) that is suitable for laying directly under a laminate coating or parquet.

Installation of heating sections and pouring screed

- The layout section is usually starting from the place where the wiring from the thermostat will be descended.

- The permissible deviation of the step from the estimated is no more than 10mm. But it should not violate the manufacturer's recommendations for the minimum radius of cable bending and the minimum possible approach of its threads among themselves.

- When laying a cable, it is necessary to bypass areas on which furniture, household appliances, sanitary equipment will be installed.

- The temperature sensor "Steam" is placed in a corrugated plastic or copper tube in the middle between adjacent cables. One end of the tube with an output of the connecting wire from the sensor should end in a dispensary box or at the thermostat, the other where the sensor itself is located, should be displayed in the floor and closed with a tightly fitted plug. This design will help to easily replace the sensor without opening the floor or wall. Horizontally, the distance from the wall to the end of the tube (sensor installation site) should be 50-60cm. The thermostat is connected in strict accordance with the instructions attached to it.

- After installation, the entire surface of the floor is carefully swept, processed by a vacuum cleaner and ground.

- To search for the location of the cable, in the future, you should draw a section of laying a section of the section with an indication of the couplings location points.

|

|

|

|

The editors thanks CJSC "De V", "Arkads", LLC "SST", "Eltech Electronics", "Warm floors" for help in the preparation of material.