Chiller-Fencoal systems as an alternative to traditional split systems. Points for and against".

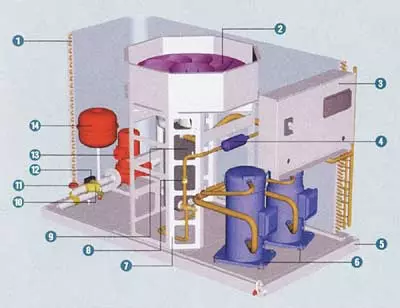

1. Condenser

2. Axial fan

3. Pro-Dialog Plus controller

4. Filter Desiccant

5. Rama

6. Spiral compressors

7. Vibroging column

8. Viewing glass

9. Evaporator

10. Water purification filter

11. Three-way valve

12. Relay of Duch

13. Pump

14. Expansion Bako of many air conditioners working on Freon, we have already told in our magazine (

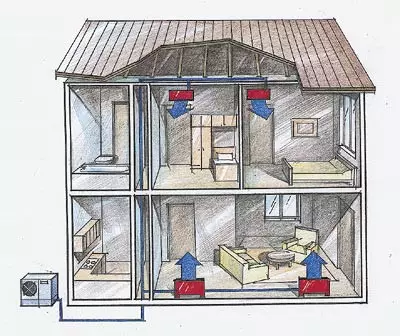

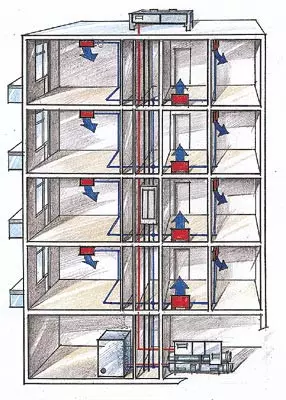

"Home atmosphere", "climate for every taste", "atmosphere of your taste"). An alternative to the widespread split systems on Freon can be the Chiller-Fencoal system. The English Chiller is a refrigerator, and Fancoil consists of two words: fan fan (or just a hairdryer) and a coil heat exchanger, which together can be translated as a water-free heat exchanger with water. Chiller and fenquies are connected by a pipeline, along which ordinary water flows as a coolant. Its circulation performs a pump, which is the third, undeservedly ignored in the title, but the mandatory component of the system. So, at first, Chiller will cool the water, then it will go into fenquies located in the rooms and intended for cooling air.If you do not delve into technical details, the chiller in the most common design can be compared with the home refrigerator. Its main parts are the evaporator, the capacitor and the compressor connected by the pipeline by which the freon circulates. Freon goes into a gaseous state, selecting heat in a water-washing evaporator. In this case, it can be cooled to 5-7c. The accompanier, on the contrary, the refrigerant pairs turn into a liquid with heat isolation, so the capacitor must be cooled. For which this part of the chiller is either carried to the street, or in the room, where heat is needed from.

As with a split system, a system with a chiller can be 2 executes of operation: or only cooling, or cooling plus heating (in the last case, the chiller is called reversible, and the thermal pump mode is also reversible). When the first, the water is first cooled using an evaporator to 5-7c, after which it enters the phenkyl, where the air is cooled by the fan. The waterproof water pump is directed to the condenser, where she, selecting heat from him, heats up to a temperature of 45-55С and the pipeline is supplied to a phenkyl through which the air is heated in the room.

With a two-circuit pipeline, everything else. One contour is allowed cold water from chiller, and on the other, hot from the boiler. Naturally, its pump must be installed in each circuit. An absolute phenkyle is served either that or other water and thereby cooled or heated each room independently of others.

Several phenkilites are connected between the supply and return branches of the pipeline - usually one in each room. The air temperature is changed by increasing or decreasing the flow of water coming from the chiller (or cycotla). The authentant intensively mixes the air layers and levels the temperature indoors. But since the efficiency of heat transfer in 1.2 regrace, and the air and water temperature drop in 1.03rd is less than the freon system, then the performance of the phenkole is almost 50% lower than the performance of the internal unit similar to the size of the split system.

Finally, another inconvenience, capable of delivering a lot of trouble to the designer, there may be 5 rubles connected to each phenkyle when using a double-circuit pipeline (submissing on the cold and hot water plus another one for the drainage of the accumulating condensate). True, their laying in the wall will completely remove the problem. And the pipes themselves may not be copper, as in the case of a freon system, and metal-plastic or steel.

However, the chiller system has positive qualities:

- You can connect more phenkoles to one chiller than the internal blocks to one outer block of the split system at the same cooling capacity;

- permissible any distance between chiller and phenkims, if only enough power of the pump yes, the pipeline was well insulated (so that the water did not have time to warm or cool on the way to the phenkyle);

- It is possible to adjust the thermal regime as a change in the water temperature in the chiller and the change in the heat transfer speed in the phenkyle, and, if necessary, each phenkival is easily turned off at any time;

- Connecting the pipeline circuit boiler allows you to abandon water heating batteries and use phenkly instead (having about the same heat transfer).

The performance of the air conditioning process is estimated at the rate of 0.1kW / m2. Thus, with a cottage area in 300m2, a chiller with a cooling capacity of 30kW will be required. Heat production of any chiller above its cooling capacity. Therefore, it is not necessary to fear the lack of heat in the winter, if the cooling capacity in the summer was sufficient. The capacity of 30kW is quite enough for the air conditioning of most cottages, and we are limited to it when reviewing the Chiller-Fencoal systems. The chillers used in this case will be called (backrest) mini-chillers to separate them from industrial devices whose productivity hundreds, thousands of kilowatt and even dozens of megawatt.

The electrical power consumed by the system can be determined by dividing the nominal performance on the performance coefficient (equal to 2.5-3 in cooling mode and 3-3.5 in heating mode). So, during the cooling capacity of 30kW, it will be 10-12kW. When choosing a system, it should be borne in mind that most of the chiller models work from a three-phase electrical circuit.

Consider the possibilities of the systems of interest to us on the example of products of fifteen foreign firms supplying this product to the Russian market: American York, Carrier, Trane, Lennox, McQuay, Dunham-Bush, Italian Bluebox, Clivet, Emicon, Dölonghi (Climaveneta compartment), French ACSON, CIAT, Japanese Daikin, German Al-Ko and Israeli Electra (French Wesper Branch).

Differences between models are concluded not only in oversized sizes and appearance, but also to the degree of influence on the climate of the room.

Chiller varieties

The main parts of the chiller - evaporator, the condenser and the compressor included in the single chain of the refrigerant circulation. Distinguish 2 Capacitor Cooling: Aerial and Water. More common to the air, created by an electric fan, which can be axial or radial (centrifugal). The first one is quieter and cheaper, but less productive. With the radial fan, the air is usually closed from the room (the attic, basement, the chulad) and is thrown under pressure up to 250p. The frequency of rotation of each fan can be a constant or variable. Thus, in the LSH30 chiller model, CIAT firms are installed two axial fans with a constant rotational frequency and 180W each; They provide air consumption 3100m3 / h. The Lennox PRA6D amodenel is equipped with fans with variable rotation frequency. In addition models, you can order the desired fan type.

Water has greater thermal conductivity than air. Water cooling is cheaper, but it can only work at ambient temperature above + 4C. Therefore, it is necessary or installed a chiller with water cooling of the capacitor indoor, or turn off the system and merge water from it with the onset of cold. In addition, it is desirable that the water is flowing.

There are several constructive solutions of water cooling systems. Calin-chillers are most often used by a plate capacitor (such a device of EUW5-20F models of the company Daikin or HRH-HRHN by Climaveneta).

At the location of all Chillers divide into two groups:

- intended for installation outdoors in which air cooling is carried out using an axial fan;

- Installed indoors:

- monoblock, in which air cooling is carried out using a radial fan;

- composite, with a remote capacitor;

- Water cooling of a plate capacitor.

At the street in the street below + 5C, the efficiency of the chiller work as a heat pump decreases, and with a further decrease in temperature, serious problems arise. So optimally use this mode at a temperature of order -10С - late spring or early autumn with a disconnected central heating system.

Basic requirements for the compressor, "chasing" refrigerant inside chiller between evaporator and capacitor, - compactness, reliability and low noise. There are several options for the design of the compressor, but for mini-chillers, almost all firms prefer a spiral type (SCROLL) corresponding to all three requirements at a minimum of costs. However, in some models (for example, MC050AR McQuay) can also be found and piston design. To increase reliability, two compressors are sometimes used (as in the model ranks of the company Lennox or RAE company EMICON). Each of them interacts only with its part of the evaporator, but at the failure of one device, the other will take on all loads. In addition, electrical heating of oil in the crankcase is also provided, which allows devices to work with a decrease in the ambient temperature up to -20c (CIAT model of CIAT, CWP-RC 06 of Wesper, CXA036ND firm and others).

However, despite all sorts of tricks and constructive finds, Chiller remains a very noisy car. Even the least "sonorous" models LSH35 (CIAT) or WSAN71 (CLIVET) the noise level, judging by the results of the Eurovent European Organization's certification tests for 2002, not lower than 70DB, which is comparable to the roar of the street highway. It is clear that such installations are away from residential rooms.

Special conversation of chillers. No company offers price lists, referring to the individuality of the execution of each order. Let's just say that the price can range from $ 3,000 to 5000, and waiting for the execution of the order will have to be from 30 to 60 days.

Examples of mini-chillers working only in cooling mode| Manufacturer | Model | Performance, kW * | Number of compressors | Fan Type ** | Length, depth, height, mm |

|---|---|---|---|---|---|

| Carrier. | 30RA 021. | 21.6 (5.5-240.0) | one | Oh or R. | 13284781383. |

| Trane | CGA 075RD. | 19.1 (5.5-61.8) | one | ABOUT | 10609501050 |

| Lennox. | Ecoleaneac | 20.0 (8.0-96.0) | 1 or 2 | ABOUT | 1600800935 |

| McQuay. | M4Ass 050A. | 10.0 (8.8-14.0) | one | ABOUT | 10325581342. |

| York. | Ecofrio YCSA 18T-TP | 17.2 (5.9-35.7) | one | ABOUT | 14304951260. |

| Dunham-bush. | ACDI 125ZC. | 25.0 (5.6-73.0) | one | R | 11507501250. |

| Clivet. | WSAT 71. | 16.7 (4,6-16.7) | one | ABOUT | 13105421212. |

| Climaveneta. | HRAT 0101. | 26.8 (4,7-32.4) | one | ABOUT | 14505501700. |

| Emicon. | RAE 191. | 18.2 (5.1-163.7) | 1 or 2 | Oh or R. | 11107501100. |

| ACSON. | Amac 075V. | 23.4 (8.8-36.6) | one | ABOUT | 108912881739. |

| CIAT. | Ciatcooler LSH 35. | 10.3 (7.7-18.6) | one | ABOUT | 10584851010. |

| Daikin. | EUWA-12HDZW1S. | 26.5 (10.1-79.5) | one | ABOUT | 12907001444. |

| Al-Ko. | C-O3H1-5N. | 4.9 (4,9-176) | one | Oh or R. | 8703201100. |

| Blue Box. | Alfa / HP 81 | 16.8 (4.9-51.9) | one | ABOUT | 1200400950. |

| Wesper | CWP-RC 06 *** | 21.6 (7.6-33.3) | one | ABOUT | 900700910. |

* - in brackets shows the range of cooling capacity of the entire model range;

** - o-axis, R - radial;

*** - remote capacitor.

Examples of reversing mini chillers with cooling and heating modes| Manufacturer | Model | Performance, kW * | Number of compressors | Fan Type ** | Length, depth, height, mm | |

|---|---|---|---|---|---|---|

| Cooling | Heat | |||||

| Carrier. | 30RH 021. | 21.6 (5.6-240.0) | 25 (6.4-256.0) | one | Oh or R. | 15034781587. |

| Trane | SHA 036ND. | 8.4 (5.5-60,6) | 9.8 (6.8-70.3) | one | ABOUT | 1018360795 |

| Lennox. | Ecolean Ear0151 | 14.5 (8,8-89) | 10.7 (9.5-84) | one | ABOUT | 11956601375. |

| McQuay. | Mak 058ar | 14.1 (8.8-14.1) | 14.7 (9.4-14.7) | one | ABOUT | 10315561341. |

| York. | YCSA-H 26T-TP | 24.4 (6.0-34.7) | 26.2 (6.3-38.0) | one | ABOUT | 15108951340. |

| Dunham-bush. | ACDS 125Zh. | 25.0 (5.5-97.0) | 27.8 (6.4-99.8) | one | ABOUT | 12005831330. |

| Clivet. | WSAN 71. | 19.1 (6.7-19.1) | 21.1 (6,8-21.1) | one | ABOUT | 13105421212. |

| Climaveneta. | ERAN / P 0071 | 19.0 (5,8-32.0) | 21.0 (6.9-36.0) | one | ABOUT | 14505501200. |

| Emicon. | PAE 191. | 17.9 (5.0-157.4) | 20.5 (6.0-182.5) | 1 or 2 | Oh or R. | 11007501100. |

| ACSON. | Amac 040ar. | 8.8 (8.8-36.6) | 9.4 (9.4-42.5) | one | ABOUT | 10325581342. |

| CIAT. | Aurea ILA 50. | 11.3 (5.5-17.7) | 12.8 (5.9-20.3) | one | ABOUT | 5005001349. |

| Daikin. | EUWY 10HDW1 | 21 (9.1-63.4) | 32.0 (11.9-75.2) | one | O. | 12907001444. |

| Al-Ko. | C-O3H1-5WP | 4.9 (4,9-39.8) | 5.8 (5,8-43.7) | one | Oh or R. | 8703201100. |

| Blue Box. | Alfa / HP 91 | 20.8 (4.9-51.9) | 22.8 (5.6-55.2) | one | ABOUT | 15005001100. |

| Wesper | CWP-HP 06 *** | 23.1 (6.4-27.3) | 31.2 (8.9-37.4) | one | ABOUT | 900700910 |

* - In brackets, the performance range of the entire model range in the cooling and heating modes.

** - O - axial, r - radial.

*** - remote capacitor.

Varieties of fenquilkFenocyl is also called a fan closer. Obviously, because it is in him that the room air served as a fan on the heat exchanger is gradually cooled, taking the cold in the flow water from the chiller. Although the externally phenkyl is similar to the inner block of the split-system, it is much simpler, because it contains only a heat exchanger in the form of finned pipes and a fan. Fenocylas are also outdoor, suspended, ceiling, cassette or channel. In many cases, it is possible to connect pipes both to the left and on the right, and sometimes below (for example, in CARRIER 42nm models, CLIVEVENETA PCSVA firms).

Almost all phenkyls have a three-stage change in the speed of rotation of the fan electric motor, and, for example, in the Wesper-smooth CWP model range. This allows you to provide a more comfortable output mode to a specified temperature.

The structure of the phenkoe can also be provided for the substitution of fresh (outdoor) air. For example, using a special camera connected to the installation of the supply and exhaust ventilation. This camera allows changing the cooled air supply mode with recycling on the direct-flow (FWH3C pixels from Daikin, 42nm from Carrier and others). The incoming air passes through the light grapple air filter of reusable. The part of the fenquet body is a pallet for collecting and draining condensate that flows from the heat exchanger. At the output of a row of phenkilov, to increase the efficiency of operation in heating mode, an electric heater with a power of 0.5 to 3 kW is installed. Phencoal control can be performed manually or automatically (autonomously or from a single remote control).

On the level of noise created by a fenquil, which is located directly in the residential premises, one can say that it, according to Eurovent, does not fall below 36DB and does not exceed the similar characteristics of the inner block of the split system. Carrier and Delonghi in the latest models are installed low-noise bearings, and the screw design of the fan blades supply a special profile. This reduces the noise level created by the phenkom, to the sounds of a quiet street.

Examples of low-performance fenkyloves| Produced Velivity | Model | A type | Maximum performance, kW | Number of fittings | Input sizes for fresh air submeece, mm | Power electrical heater, kw | Length, depth, height, mm | |

|---|---|---|---|---|---|---|---|---|

| Cooling | Heat | |||||||

| Carrier. | 42nm 25SF. | Universal | 2,1 | 3.0. | 2. | 100467. | - | 1030220657. |

| Trane | FHK02. | Ceiling | 0.8. | 3.7. | 2. | - | 1.0 | 1100529230. |

| Lennox. | RGL 20. | Floor | 3,2 | 6.0 | 2. | 120 * | 1,7 | 973225630. |

| McQuay. | VAC | Floor | 1,3. | 2.9 | four | 100* | 0,7 | 768231430. |

| York. | Low Body 114. | Floor | 1,8. | 2,3. | 2. | - | 1-2 ** | 900254430. |

| Dunham-bush. | DBF-02-4V. | Floor | 2.0 | 4,2 | 2. | - | 2.0 | 880220520. |

| Clivet. | PCC VA 9. | Cassette | 3,3. | 6.3. | 2. | 120. | 1-2 ** | 580580213. |

| Climaveneta. | FC 30. | Floor | 2.0 | 3.9 | 2. | - | 2.0 | 1100529230. |

| Emicon. | FSR 3. | Floor | 2.0 | 4.5 | 2. | 74. | 1.2-3 ** | 985475183. |

| ACSON. | AWM010FV. | Floor | 2.8. | 3.0. | 2. | - | - | 815290179. |

| CIAT. | Major2 426. | Suspension | 1,4. | 2.9 | four | - | 1,2 | 740575243. |

| Daikin. | Fwh3cf6v1 | Suspension | 2.9 | 3.7. | four | 80690 * | 1.6 ** | 985560228. |

| Al-Ko. | GV 031. | Floor | 1,3. | 2.9 | four | - | 0.5 | 648224538. |

| Blue Box. | SV-N 03 | Floor | 1,6 | 3,1 | 2. | - | 0.6 ** | 650225517. |

| Wesper | WSW / XLM 7EH | Suspension | 1.5 | 2.0 | 2. | - | 1.0 | 815160270. |

* - The fits block of fresh air is set to order;

** - The electric heater is set to order.

Easiness - the key to reliabilityThe chiller-fencoal system resembles the construction of a plumbing or plumbing network, therefore it is assembled and mounted quite simple. A results of the cost of installation work, at least 2 times lower than when installing the split system. Chiller can be diagnosed and repairing separately from the entire network as the usual refrigerator refrigerator unit.

Most modern systems contain a hydraulic module in their pipeline circuits. It combines a water pump, accumulative (if present) and expansion tanks, duct relays, locking valves, valve for selecting the optimal water consumption (conversation with installation characteristics), thermostatic valve, filter-desiccant, high and low pressure relays and many other Useful elements. Such a module greatly simplifies the installation of the system, because it is only necessary to pave pipes to combine chiller, phenkyl and hydraulic module into a single chain. It is clear that the probability of installation errors is sharply reduced, and the reliability of the device increases. For example, Carrier managed to provide a 23-year resource of the system.

Comparison of the positive characteristics of two systems| Type of characteristics | View of the system | |

|---|---|---|

| Freonovaya | Water | |

| Consumer | Less ratio "Performance-dimensions" | The possibility of a phased increase in the number of air conditioning zones |

| Cheaper for housing from 1-4 rooms | Easy installation and maintenance | |

| When connected to the boiler, the phenkyle plays the role of water heating radiator | ||

| Operating | Fast mode for mode | Ecology |

| Less ratio "Electricity-performance consumption" | It is possible to generate hot water (technical) | |

| Above the guaranteed resource | ||

| Independence of the connection of chiller and fenquets to the mains |

The diagnostic mode contains 10 software that allows you to quickly and unambiguously detect a malfunction and save the algorithm to its search in the instrument's memory. The control panel is applied to the holo-ditch circuit panel with the control buttons and the digital LCD display. The user can immediately find out the meaning of any operating parameter: water temperature (in use or return circuits), its pressure and flow, the time of exit mode, etc. The controller can be connected to a local monitoring network of the entire building and to the Internet.

The Wesper Micronet Controller can be programmed for all occasions: recycling air exchange is provided without tributary and with partial fresh air inflow, single-circuit or double-circuit pipeline, cooling and heat pump modes. Using the switching tire allows you to connect new e-cards and thereby increase the degree of intelligence systems. Dunham-Bush uses TEF-Control microprocessor control, based on two modulus and power and power. The first consists of a controller and control panel (it can be embedded in a phenkyle or mounted on the wall); The second controls the pump and the valves of the water circuit of the device. Such control allows you to smoothly adjust the fan rotation speed, increasing the accuracy of maintaining a given temperature when saving electricity and reduce noise.

Optimal choice: split-system or chiller-fencoalBoth types of systems are used in almost all countries. Identia there are your advantages and disadvantages that we tried to tell. Evaluation of the economy of systems is more complicated, since domestic firms do not disclose the cost data and offer only the most general recommendations. All unanimous only in one thing: efficiency depends on the number of rooms.

With one-four-room urban apartment and central heating, the Chiller-Fencoal system will cost 1.5-2 times more than split systems. True, in some houses of the most modern design, there are still powerful central chillers and pave pipelines - it remains only to acquire and connect fenquies. In this case, it is better to consult with the specialists of a climate firm, which preferred whether to pay for the connection of its phenkolov to the general system and to further pay the costs of its centralized service or still equip the autonomous multi-zone split system. For the first case, the consolation can serve as the fact that the connection of fenquilk will cost cheaper than the installation of the usual split system.

To create a home climate in the cottage, in the presence of a central heating network, it is better to first consult with specialists. In the absence of such a network (which happens more often) and the availability of air conditioning area over 300m2 is almost always more attractive by the "Chiller-Fencoal" system. According to Ventrade's specialists, the relative cost of the equipment for the production of 1kW of cooling capacity for the water system will be $ 700-800, and the cost of installation work- $ 200 / kW, which is 1.5-1.8 times lower than for freon. Daikin even developed a special program for a personal computer, with which you can choose the chiller model, depending on the area of the room, the necessary performance on cooling or heating and other specific operating conditions.

Several practical recommendations

- Since some devices of the Chiller-Fencoal system are part of a conventional water supply network, specialized firms themselves do not produce them, and the guarantee is given only to their products. Note that the warranty on the entire system is provided only when it is installed by a specialized climate firm.

- Each model of reversing chiller (modes of cooling and heating) during operation in the heat pump mode is characterized by the minimum permissible temperature of the outer air. At a lower temperature, the device may turn off or even fail. The temperature parameters of Chiller is better to ask before purchasing it.

- The dimensions and the mass of some chillers are significant, so they are easier to mount them to the final design of interior partitions.

- The launcher of Chiller is superior to the working more than in the 4th. So the fuse of the electrical circuit must be calculated at least, on the double value of the operating current.

- To prevent increasing the noise level of working fans due to the accumulation of dust on heat exchangers, approximately once every six months change or clean air filters.

- After a long downtime, the system should not be launched instantly. A few hours before the start, you need to connect the chiller to the electrical network to warm the thickened oil in the crankcase pallet and facilitate the launch of the compressor.

The editors thanks the company "Evroklimat", "Evistreid", Ventrade, "Nimal", "Pacific Eir", "Termoservis", "Elektostar", "Genesis-VENT", as well as representative offices of Carrier, Daikin, Delonghi, McQuay, Ciat, Lennox and York for help in preparing the material.