Manual masonry fireplaces. Device and classification, installation, materials for chimneys, furnaces and cladding, masonry technology.

Island Fireplace, created from elements commonly used for wall appliances

Fireplace with tiles longer saves heat

Basic structural elements of a used fireplace:

a - smoke collector;

b - fireplace shelf;

in - portal;

r - heat chamber;

d - leafy shelf;

E - Drovnitsa

In the interior trying to reproduce the AR-Deco era, the fireplace has a laconic, strict form

The huge portal brings the spirit of medieval castles to the modern house. But soak such a fireplace must be careful not to shoot the room

Portals of modern fireplaces sometimes have very fantasy forms

Parade fireplace for interior living room in colonial style

High-Tech Corner Fireplace

How from rectangular bricks folded a hemispherical fiber - secret of the master

Fireplace is better laying up to the device of floors and ceiling structures

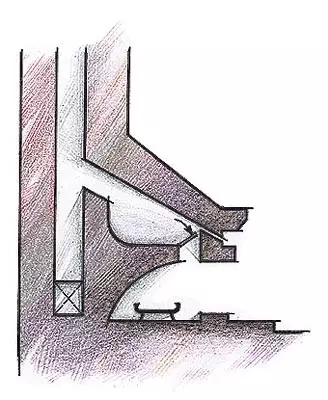

Transverse cuts of fireplaces with various shape of gas feeding channels. Their outlines and sizes and make up the main secret of successfully working devices:

According to statistical data, from 80 to 90% of the owners of country mansions would like to have or already have a fireplace in their home. Higherine of this thrust to "Resellers of the past" most often consists by no means in problems with heating. The fireplace is primarily a symbol of life, stability, home comfort. If you please, he reflects the epicorean approach to everyday life.

The evening spent at the open fireplace fire in the whimsical chopping languages of the flame is simple, but sophisticated pleasure. In addition, a qualitatively performed fireplace is an excellent ventilating device, well drying the air into the dwelling (this is especially important for locality with a raw climate). It is not surprising that the number of fireplaces and fireplaces in houses grows every day.

But at the same time, the fireplace device is quite complex and "gentle", requiring accurate calculations and scrupulous construction execution. In the opposite case, the "focus of living fire" can turn into a constantly chadeing and fatigue furnace. Finally, fireplaces, like any other sources of open flame, are fire-hazardous and in non-compliance with the rules of construction and operation are able to deliver major trouble to their owners. In other words, if you decide to acquire a fireplace, problems associated with its installation, you need to pay maximum attention.

Device and classification of fireplaces

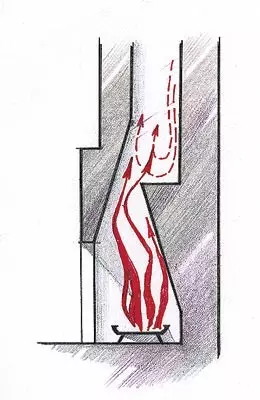

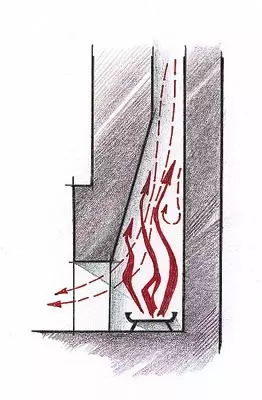

Every fireplace consists of three parts: firebox, portal and chimney. Furnaces are distinguished by firebox design. The depository fireplaces is open, wide, but shallow. This is a kind of niche made of refractory material (brick, stone, metal). Due to its design, fireplaces are able to heat the room only with the radiant energy generated during the combustion process of fuel. Simply put, they give heat only when fire burns in them. They do not need time to warm up their massive corps, as in the case of furnaces, but they quickly cool. In general, the fireplaces do not relate to highly efficient heating devices: their efficiency is 10-25% (the efficiency of the fireplace is determined by the ratio of the amount of thermal energy given to the room, to the energy that could be obtained with full combustion of fuel). For comparison: the efficiency of modern heating furnaces reaches 70-80%, the efficiency of the Russian furnace is 20-30%.To increase the heat transfer of the device, the inner walls of the furnace must have a high reflective ability. For this, they are made as smooth and even as possible, and sometimes we are lined with brass or stainless steel sheets. Firecate heat pumping scholars The side walls of the furnace are performed tapping to the rear wall. In this case, heat is reflected in the room not only from the rear wall, but also from the side walls, and the efficiency of the device rises by 7-10%. An open furnace is laid out of a smooth refractory brick with a width of 5-6mm wide. The thickness of the wall is the half of the Polkirpich.

In the upper part of the furnace chamber, a gas porch is usually manufactured ("tooth"). He prevents the ejection of the sparks from the pipe, protects the furnace from counter-air flows capable of causing a smoke of the room and the emission of soot, and also improves the chain when inciting the fireplace. The gas threshold is a place where the soot is settled, so a tray-sage tray can be installed here. However, in many designs "tooth" there is no and the furnace is connected with the chimney of the inclined channel (sometimes very bizarre geometry). In general, each firewall has its secrets. Easy (the lower part of the fireplace) is a deepening for collecting ash- pushed. In addition, it was confused serves as an additional source of air supply for the furnace (loving furnaces with a closed firebox).

Recommendations SNIPA 2.04.05-91 * "Heating, ventilation and air conditioning" approved in 1997.

Paragraph 3.84. Building designs should be protected from ignition:

a) the floor from combustible and hard-scale materials under the metering door - a metal sheet of 700500mm, located its long side along the furnace;

b) the wall or partition from non-combustible materials adjacent at an angle to the frontal oven, - with plaster with a thickness of 25mm on a metal grid or a metal sheet on an asbestos cardboard 8mm thick from floor to a level of 250mm above the top of the coil.

Paragraph 3.86. The floor from combustible materials under frame furnaces, including legs, should be protected from the ignition sheet steel on the asbestos cardboard with a thickness of 10mm, while the distance from the bottom of the furnace to the floor should be at least 100mm.

All models of fireplaces can be divided into two groups: with open and closed firebox. Closed furnaces are cameras equipped with a quartz glass door that withstands the heating to 800c. These doors open either only to the side, or to the side and vertically up. In the end, they are supplied with a special lifting mechanism. Of course, it complicates and increases the design of the construction, but the doors are cleaned from the eye from the eye and allow you to get full pleasure from living fire.

Fireplaces with a closed firebox are capable of working in two modes: disappeared or with an open door. The closed firebox with an open door is no different from the open firebox without the door. Avota With a closed door, you can adjust the stream of air entering the fireplace, overlooking the bottom holes. The smaller the amount of air flows, the slower will go burning processes. Accordingly, one portion of firewood can be stretched for a weighty night. The economy of such a fireplace is essentially higher, it can already be used as an alternative heating.

What masonry fireplace is better-woven or closed firebox? Chermannia and Scandinavian countries, where a rational approach to the use of fuel resources is prevalent, fireplaces with doors are popular. Proszia, for reasons of aesthetics, is given preference to open structures. Fireplaces with a closed metal furnace are conveniently installed in homes with existing chimneys, so the installation of such devices is substantially simpler. Through houses, the chimney pipe is usually constructed with the fireplace. Here it is appropriate for the construction of a large masonry fireplace that can withstand heavy tube (its mass can reach 2t). Metal furnace on such "feats" is not capable. To unload it (the Acan meter of the chimney weighs about 200-250kg), you will have to erect some additional supporting structure. Incase, the cost of the fireplace with a closed firebox may be significantly (1.5-2 times) above the value of a conventional masonry fireplace, the average price of which, depending on the size and decoration, is $ 2000-5000.

Of course, the question of the effects of the fireplace and its smoke pipe on the overlap of the building or the foundation is not solved on the eye, but on the basis of engineering calculations. They must be obtained from builders before the start of work. According to the specialists of the company "Kfelvit", if the mass of the fireplace itself exceeds 900kg, it is always wiser to put it on the first floor and for a separate foundation. On the second floor there are simpler and lightweight designs, otherwise the cost of work increases sharply.

Depending on the location, the fireplaces are divided into fully built into the wall; partially built into the wall (sprayer); confined angular; confused; corner; Island (located in the middle of the room).

Installation of fireplaces

The location of the fireplace is determined by the architectural solution of the designed premises, the design of the walls, the ventilation scheme and, of course, fireproof requirements. Depending on the design of walls, fireplaces can be located next to them or embedded in them. It is recommended to use the inner walls or partitions from non-combustible materials intended for the placement of smoke channels. For each fireplace requires a separate chimney. "To plant" two fireplates located on different floors, one chimney is theoretically, but practically problematic. In any case, it will only be possible to use them. The size of the external opening of the furnace must correspond to the size of the room in which the fireplace is installed (the area of the opening is usually correlated with the area of the room in the proportion of 1:75).

An open fireplace from a brick is a very massive structure, it is often necessary for it. A separate foundation is often required (it will be discussed below). It is also necessary to take into account the features of the ventilation of the room. Fireplaces are poorly tolerant, therefore it is advisable to have them away from the doors, windows and ventilation plants. Solid side, fire is needed a permanent and large air flow, which can prevent hermetic double-glazed windows. If you do not fulfill these requirements, the fire in the fireplace will burn unstable and even smoke. Special problems with drafts arise when designing island fireplaces, "open to all winds" from four sides. In place in the room it is desirable to organize forced ventilation controlling the chimney, with the possibility of regulating its parameters.

And yet the priorities in the construction of fireplaces should be considered fire requirements. The fireplace should be securely wasolate from gender, partitions and other building structures made of combustible materials.

Fire safety issues are particularly relevant when installing fireplaces in wooden houses. It is important to remember: fireplaces and chimneys must be removed at a sufficient distance from all structures from combustible materials! Distance This should be at least 250mm. The walls made of combustible materials located in close proximity to the fireplace, it is necessary to isolate with non-combustible material, such as asbestos sheet or asbestos-cement, impregnated with felt clay or a thick math of silica fiber.

The smokers for a homely focus having a view of a high vertical exhaust channel first entered into use in the V-III centuries. BC e. By Rome. Similarly, large ovens for heating water in Roman baths were equipped with such chimney. The mild climate allowed the Greeks, the Romans and representatives of other civilizations of the ancient world without the "capital" furnaces and fireplaces - for warming the premises of even a large area, portable foci or pots with coals were common.

Chimney

The chimney is a vertical channel that serves to remove the combustion and inflow products to the fuel of fresh air. The thrust in the chimney occurs due to the fact that the density of the heated flue gases in it is less than the density of the outer air. The movement speed of flue gases depends on the difference in the temperatures of heated and cold air, as well as from the height of the pipe. Therefore, the chimney, despite the seeming simplicity of the design, is a technically difficult structure, the correct calculation of which - the vaccinal meaning of the task with many unknowns. Here are their brief list: dimensions of the opening of the furnace and the depth of the portal; The width and height of the throat of the smoke collector; height and cross-section of the pipe; Selection of the required cap for the pipe; Individual features of the terrain and landscape (lowland, elevation, open place, climate, wind rose, the presence of buildings in the neighborhood) ... Solve such a task for only a highly qualified specialist with extensive experience, and in this field of construction. As the builders themselves say, "Bricklayer and the Fireplace are different specialties." Fireplaces must fold the fireplace, and not a master of renovations.Most often, the pipes of fireplace chimneys are made up of specially burned bricks. The masonry should be as smoother as possible, with a thickness of the seams, a maximum of 5mm. The thicker of the seam, the faster it is destroyed under the action of hot gases. Bricks, going to the manufacture of chimney, are selected smooth, without protrusions or chosel. The cross-sectional area of the fire channel is several times more than the smoke channel area of the furnace of similar power. Therefore, the fireplace is impossible to somehow "attract" to the already existing chimney. The minimum channel cross-section is one brick, or 130260mm. The height of the flue pipes (seeds of the grate to the mouth) should be at least 5m. It is desirable that the pipe leaves as close as possible to the rod of the roof and at the same time towering over the roof level by at least 500mm (when the skate is removed to 1.5 m). The height of the pipe should be increased (in order to avoid tipping the thrust), if high buildings or trees are very close.

Excessively long chimney will create too strong air craving. Vtaka firewood firewood will instantly be lit. To compensate inside the chimney, the traction stabilizer is set. It is a valve, the flap of which opens due to strong air vacuum and provides cold stream access in automatic mode. If the smoke canal, on the contrary, is too short, the thrust will be insufficient. In this case, it is possible to install a forced system of smoke removal - a special heat-resistant fan, mounted on the mouth (whitage) of the pipe. Such a fan will create additional vacuum, increasing the thrust of the chimney.

The smoke canal should be vertically. It is allowed to deviate from vertical to an angle of no more than 30 with a given no more than 1M.

No less strict firefire requirements are presented to chimneys than to fireboxs of fireplaces. The minimum distance "outflow" (that is from the inner wall of the smoke tube) to elements of structures from combustible materials should be 380mm. Inside the passage of pipes through the overlaps, the "roller" is made - thickening from the brick, which is manufactured in the process of masonry pipe. The clearance between the "roller" brick and the ceiling overlap is isolated by mineral wool or silica fiber.

Chimney must be protected (as far as possible) with thermal insulation from exposure to low temperatures. It should not be wrapped in the winter so that condensate formed on the interior walls. In the opposite case, problems may not only with the fireplace of the fireplace, but also with the integrity of the pipe itself. After using the condition, the fireplace pipe is closed with a valve to prevent the outlet of warm air from the room.

To facilitate the breeding and maintenance of fire, as well as cleaning the furnaces, many centuries have been used by various accessories, and interest in which they have become especially erected lately. The books include: a kocherga to break coal into small pieces; buckets and fuel boxes; Tongs and a special fork for grilling firewood; Brush on a long handle; scoop. Protective screens are used to protect the wooden floor of the room from burning coals. Also, the fireplace accessories include various decorations and baubles located on the fireplace shelf. The most characteristic decoration is special flat fireplace watches.

Materials

Recently, the so-called "sandwiches" are widely used as a material for fireplace and furnace chimneys. Sandwich is a design consisting of two metal pipes invested in each other. The gap between them is filled with fireproof thermal insulation. The pipes themselves are made of stainless steel.

Modern chimneys "sandwich" designs have some benefits compared to their bricks. They are much easier, their walls are of greater smoothness. Kednostoks should include high cost and small self-supporting ability. That is, "sandwiches" need additional supports, the external load is not recommended. Despite the high degree of heat shields, these chimneys require (according to the bottom) of the same fire safety measures as brick tubes: they should be removed to the safe distance from combustible structures (380mm minus the wall thickness of the sandwich wall) and isolated from overlaps. This sometimes "forget" sellers, but never-fire inspectors.

A much more traditional material for chimneys and focus-brick. Burnes are the most stringent requirements. For masonry of the furnace part of the furnaces, in which a stone coal, giving the strongest heat, is used by refractory chamotte brick from the burnt and grinding refractory clay. It is able to withstand temperatures up to 1200s. Fireplace, which is token by firewood, can be folded from an ordinary red brick (designed for temperatures up to 800C). In love case, the brick should be high quality, well burned, without a fault or negligent, with a brand is not lower than M200 (the brick is marked depending on its ability to withstand the load on the compression in kilograms per square centimeter; there are brands from M50 to M300). A well-burned brick has a smooth red color, it is easy to rally and gives up to dazonia, it splits into large pieces. The checked brick, the so-called Zheleznyak, is distinguished by darker, almost brown, in places in the vitreous surface. It is very durable, badly ourselves and weakly binds to the solution. The inexpensive brick, on the contrary, pale, falling, crumbles into small pieces, absorbs water well. The furnace brick should have the shape of a rectangular parallelepiped with clearly smooth faces and smooth surfaces, without chipping and through cracks. Brick size - 25012065mm, chamotte bricks - 25012365mm. Separate instances may differ from each other by several millimeters: in length - 3mm, in width and height, 2mm. To masonry the furnaces and the lower part of the chimney, it is recommended to select a brick with minimal deviations from standard sizes to get the most subtle and uniform masonry seam. Among the manufacturers of high-quality bricks, it is possible to mention Oboli, Ryazan, Borovichi and Serpukhovsky brick plants, as well as Lode (Latvia), Terca and Aseri Tellis (Estonia). The average cost of ordinary domestic chimney brick is 7-8 rubles. a piece; Imported brick costs about a dollar apiece.

The secondary use of the brick obtained after the disassembly of buildings is allowed, for the masonry of the "irresponsible" parts of the fireplace (foundation, sidewall). But only provided that the material is not damaged and purified from the old solution. The same parts can be spread out of the inexpensive or depleted brick. Hollow, silicate and hole brick use for masonry fireplaces is not recommended.

As a binder solution, a mixture of clay, sand and water is used. On its plastic properties, solutions are divided into "skinny", normal and fat. In "skinny" above the percentage of sand, and in "fatty", on the contrary, clay. "Skinny" solutions do not possess the necessary plasticity, and cracks are formed in "fatty" during drying. Therefore, for masonry fireplaces, normal solutions are better. It is possible to determine the quality of the solution, making a harness or strip with a thickness of 1-2 cm and a length of 15-20 cm. If you are harvested when trying to bend it not stretching, but it is cleaned, it means that the solution is "skinny". The harness from the "fatty" solution is well stretched and does not give cracks when flexing. The harness from a normal solution with bending forms small cracks, and when stretched it is lengthened by 15-20%.

For a solution, it is necessary to use water, clay and sand without any impurities, especially organic, which will subsequently collapse under the influence of high temperatures. Sand is best to take small quartz, with grains with a diameter of not more than 1 mm (the smaller the particle, the thinner the seams are obtained). Water is desirable to use as clean, not rigid (not containing calcium and magnesium salts). Clay applies the same as for the manufacture of bricks. For masonry, a chamotte clay is needed for masonry from chamotte bricks. To increase the strength of the solution, Portland cement is added in the calculation of 1l Portland cement on the bucket of the solution.

Laying the fireplace

Fireplace, like the oven, - the structure is sufficiently massive, often requiring a separate foundation. Therefore, it is best to lay the fireplace to the device of floors and ceiling structures, immediately after the construction of capital walls. Foundations for fireplaces and smoke pipes are made of waterproof rail-iron bricks, boob stone or concrete. The depth of the occurrence is determined by the depth of the primer of the soil. Between the foundations of the building and the fireplace requires a gap in 50-55mm filled with soil. It is forbidden to bandage these foundations, as they can give different precipitations, which is fraught with cracks in the masonry. The size of the foundation in the plan should be wider the base of the fireplace (pipes) by 10-15 cm. To protect the fireplace masonry from the soil moisture in the foundation, horizontal waterproofing from a bitured coating reference.The need to erect a separate foundation significantly complicates the installation of the fireplace in the ready-made room. It is more profitable and easier to do it simultaneously with the construction of the house. The construction of fireplaces on the upper floors is limited by the carrier abilities of overlaps. For an accurate answer to the question, whether the construction of the fireplace is possible in this case, the engineering calculation of the entire building structure is needed. Masonry fireplaces require a preliminary compilation by a specialist-builder of all masonry decents, indicating the exact location of the bricks of various types and other elements of the design - the door, coopers, ashniks, etc. According to composed orders, you can calculate the required number of building materials. As a rule, about a thousand bricks take place on the masonry fireplace of small sizes.

The masonry of fireplaces requires careful lining of bricks in all directions. To facilitate this work, a mobile formwork is used on vertical racks. Before laying bricks in the next row, they are selected in size and necessarily check the dressing of the seams. The seams should be as thin and completely filled with a solution (the so-called suture "violation"). In the intra-propelled and intracerene space, convex seams are not allowed, the surplus is necessarily removed. In the "invisible" places where the outlet of gases is possible through the seams, they can be performed "inlet" (not more than 10 mm) - for further plastering. The narrowings and turns of the chimney and the gas threshold are closed, for which the bricks are attached to the round form.

All metal structural elements (doors, grate grids) must be installed with regard to their thermal expansion (5-10mm szor). In contrast, the metal will destroy the masonry. In general, it is desirable to use as few metal parts as possible.

It is necessary to overlap the fireplace of the fireplace, metal beams cannot be used for this. The number of bricks in the arch and rows in the arch should be odd. Vaults are high and low, semi-curvous, gentle or three central. The overlap of the fuel is often decorated with a specially selected portal. For laying backs and devices of fixing "locks", bricks need to give some complicated form or reduce their dimensions. Professional of the old hardening is able to split a brick in any direction with the help of hammer or blades; Modern wizards for this procedure are more often used by saw-"Bulgarian". Slap brick has a smoother cut surface, so the second method is preferable. It is forbidden to pay the bricks with a slot or spinal side inside the furnace or chimney, since the strength of these faces is lower than others, and the masonry will be faster.

Traditions of pipeline

The design of modern fireplace portals amazes its diversity, it reflects all the styles and architectural directions from the stone to the Space Age. Of course, in most cases, the fireplace is associated in our consciousness with the old Good England of Sherlock Holmes. Especially unexpected design solutions of such recognized masters of the fireplace avant-garde, as the Frenchman Dominic Imber or the Dutchman Hari pain ...

As for the Russian tradition, it involves the design of furnaces by tiles. They are a thin tile of burned brick, covered with the front of the face. The articles of the furnace are not facing, as a tile, and laid out during the construction process - the finished fireplace will not decorate them. The tiles are put on the solution and are attached using wire segments and metal crutches. Released a tiled brick brick manufacturers ordinary, the above-mentioned Oboli and Borovichsky factories, as well as the firms of Germany, Baltic countries and Scandinavia. In addition to decorative, the tiles solve the practical problem of the accumulation of thermal energy of the furnace. Therefore, the laying of the fireplace portals are practiced infrequently (if it comes to the fireplaces, and not about the furnaces - fireplaces). It is much more convenient for this purpose to use ready-made portals from specialized manufacturers.

Order a solid portal made in a particular style, the manufacturers are stunned by the variety of proposals. The only difficulty is to accurately determine the dimensions of the product. Most manufacturers of fireplace portals produce them in the form of ready-to-install rectangular blocks with a clearly defined step (usually 5-10 cm). If necessary, the company will be on the order portal of any size, but its cost will be 20-30% higher. In general, the price of fireplace portals varies in very wide limits and depends primarily on the material from which they are made. Thus, country-style portals can cost several hundred dollars, and the portal of the Spanish company ARRIAGA from complexly processed onyx is already several thousand dollars. Moreover, some of our manufacturers, all the details of the fireplaces are manufactured according to the drawings of foreign firms, but from domestic materials and assemble at the installation site. At the same time, the customer can choose a model according to the catalog and contribute to the design of the change. Vitoga stylish exquisite thing is cheaper. Let's say the elegant fireplace from the French company Deville, the "cloned" company "WORLD SOUN" will cost the buyer at $ 2000-3000, depending on the material (shell, marble, etc.).

Continuing the conversation about the fireplace portals, we note that classicism, Ampir and Country (or "Rustic") are allocated among traditional styles. The very first fireplaces foci were out of the untreated stone. Simplicity, idleness, powerful energy "the era of barbarism" makes the style of "Rustic" very popular and now. Fireplace portals in this spirit are produced by Rene Brisach and Europe Chemines (France), Arriaga (Spain), Piazzetta (Italy). Portals are decorated with a chipped marble, a sewer, a tuff, sandstone. These products are easy in production, and therefore relatively cheap. But consider: than the stone is softer, the faster it is polluted by the soot and the more difficult it will remove the sage and dirt from it. In classic products, simple and elegant forms are dominant, harmoniously combined with each other. Wangli fireplaces Flat P-shaped portal is usually performed from wood of various, more often dark shades. The portal can be decorated with a decorative cafenel. An indispensable attribute of the English camp-fire regiment, which should be located at such a height so that it is convenient for it to learn. The furnace in English fireplaces is open and relatively shallow, which allows the use of chimneys of a small cross section. The Kclassic campuses include most of the products of Stovax (United Kingdom).

Ampire style originated during Napoleon Bonaparte. Fireplaces portals are made of marble and distinguished by some pomp. Frections of appeal to antique mythology. Caryatids, columns, sphinxes, griffins reigned in a diplomacy throughout the XIXVEK. Such fireplaces are produced today by Arriaga (Spain), Piazzetta (Italy).

Modern fireplace styles are extremely diverse. Here is modern, and the ar dece, and even High Tech. The battle of the most famous "fireplace avant-garders" can be attributed to Boley (Holland), Bordelet, Arkiane, Focus (France). Modern designers boldly experiment with the shape and material of the furnace, creating sometimes the most bizarre structures. There are still no less cozy and trembling "homemade gloves" yet living ...

The editorial board thanks the company "Art-tone", "KaminspetsStroy", "Kfelit", "Mirsown", "Agroproekt" for help in the preparation of material.