Features of national double-glazed windows: quality determining factors; What affects heat and sound insulation; How to achieve the extension of the warranty period.

Nii), heating, heat-saving, multilayer (laminated), tempered, reinforced

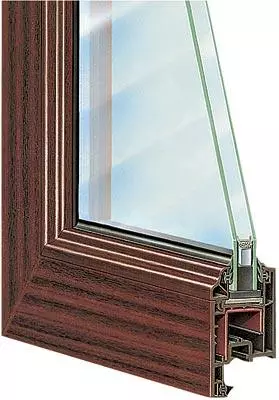

The remote frame between the glasses is often made from an aluminum P-shaped profile.

Between the glass and the binding, heat and soundproofing gaskets are installed

To improve the soundproofing package, the camera width should be made unequal

Thermoplast.

Single-chamber (a) and two-chamber (b) double-glazed windows

To absorb water vapor in cameras, remote frames are often filled with silica gel

We have to admit that we have with you, with the exception, maybe a small group of owners mansome, there are no real incentives to improve the thermal insulation of their housing. Accurate, due to high-quality windows. Because of this, the Russian market remains unclaimed much of the new developments not only to specialized systems, but also glasses used for the manufacture of double-glazed windows.

It is known that the share of glazing accounts for almost 70% of the area of the entire window block. ITHO double-glazed binding cheaper. It would seem that the manufacturers and consumers should pay more attention to glazing. After all, it is wiser to make the window warm, improving the performance of glazing. For example, the use of low-emission glass allows you to create packages with good thermal insulating properties (the resistance of the heat transfer Rapuck = 0.6-1.0 m2c / W).

If you compare the indicators of two single-chamber windows of the same design, one of which is made of conventional glass, and the second - from I-glass and filled with argon, you can make sure that the rise in the latter one and a half times more than justified. Even in comparison with a two-chamber double-glazed glass of the usual glass of its thermally insulating ability to third above.

In industrialized countries with climatic conditions similar to our construction, only low-emission glass is used in construction. There, the share of I-glasses in the total volume of glazing every year increases and today is 70-90%. However, in Russia, the majority of firms manufacturing windows are not used.

Even despite the fact that, in addition to famous global Pilkinton and Saint-Gobain manufacturers, it is C1999. Releases St. Petersburg Architectural Glass Plant. Most manufacturers in most cases can offer the consumer only a single-chamber bag with K-glass. Avteda he has almost the same indicators as a two-chamber package from ordinary glass of M1 brand production of a boric plant, and almost a quarter is inferior to the characteristics of a single-chamber design with I-glass!

Low-emission glass has the ability to reflect thermal radiation. The actual period, it "returns" to the apartment from 70% (K-glass) up to90% (I-glass) heat waves isolated by heating devices. Alet reflects thermal, infrared (IR), part of solar radiation. Travel in winter in the room becomes warmer, in the summer, more cooler.

K-glass-low-emission glass, which causes a coating of metal oxides. We are talking about a "solid" coating, resistant to mechanical exposure.

I-glass-low-emission glass with a multi-layer coating (in total silver) deposited by plasma spraying in vacuo. This is a "soft" coating. The sheet with such a spraying should be addressed only inside the glass package.

Unlike profile systems, double-glazed windows are almost always manufactured in Russia. Their part of them is produced by the manufacturers of windows. Having equipped in low-cost equipment, they successfully serve the market, without bothering themselves with delights like argon, K-glass and especially I-glasses. With complex products, they are not able to cope or not for the pocket.Contrary to a problem, a glass-barker is a rather complicated product. In its manufacture, on which the thermal insulation properties of the final product depend on the thermal insulation properties of the final product. Books include, for example, the accuracy of the cutting of glass (the grader permissible deviations should not exceed 1mm); the absence of microcracks in the most distant climbing zone of sealing and installing a remote frame with a dryer; The need to remove a narrow strip of a special coating on K-or I-glasses along the sealing sites (in order to avoid corrosion). We are not talking about the automation of the processes of washing and drying the glass and the use of high-quality sealants.

All these requirements can only be respected when using modern automated lines. This service, in addition to high quality products, it is possible to achieve a relatively low cost, due to the mass production. But such equipment is available only to large firms. With the handicraft production, the risk of rapid depressurization of the package is high. The same consumer will be difficult to distinguish in the finished product K-, I-glass or usual. Equally, how to find out if there is an argon inside. Therefore, when buying double-glazed windows, random sellers are possible a direct cheating (when the product from ordinary glass is issued for the heat saving).

And one more note about high-quality packages. It is believed that a two-chamber product has higher sound insulation properties. However, there is one subtlety. At the same intervals between the glasses, the two-chamber package has the same soundproofing ability, as well as a single-chamber (28-30 dB). Therefore, in order to increase the soundproofing level up to 32-40 dB, you need to make these gaps in different ways, for example, by type: 4-12-4-8-4.

Warranty

The modern window is subject to the opposite requirements. In order to improve the heat-insulating properties of the design and prevent drafts, it is necessary to maximize its tightness. But at the same time it is necessary to ensure admission to the premises of fresh air. The glass should reflect the thermal radiation and at the same time skip light. In general, the manufacturers of quality windows are faced with the task of finding a reasonable balance between different requirements using the design developments of profiles, accessories and glasses. From how technically, it will be done technically, it will ultimately depend on whether the new design will reveal all its capabilities or put the consumer in front of a number of difficult problems.In such conditions, the issue of guarantees provided by manufacturers of windows is fundamental importance. Usually, the warranty period does not exceed 2-3 years, in very rare cases reaches 5 years. At the same time, managers are not without pride report that their company produces windows from components to which the manufacturer gives a guarantee of other duration: 10-year-old and double-glazed accessories and 15-40-year-old profile. The ones of EPDM (artificial rubber) (artificial rubber) are the most minor, 5-year warranty period.

Well, and if in a year after the expiration of the warranty period, the double-glazed windows are depicted or accessories will fail, then to whom to contact the consumer? PC producer profile, double-glazed accessories, fittings or processing company, which makes the installation and installation of the window and is obliged to calculate its strength and temperature characteristics? Part of the processors in such a statement of the issue agrees to note in the contract concluded with the consumer, its responsibility and extend to the consumer of the manufacturer's warranty. Judgerate all in such a way that the processor becomes the first and last instance to present claims. Other firms offer paid post-warranty service. In general, the consumer should show more perseverance, common sense, and besides, to be attentive when drawing up a contract (after all, he has the biggest rights at this stage).

Ideally, the window should have a passport with the indication of its characteristics: heat transfer resistance (RO) - to the profile and double-glazed windows, as well as on the entire window as a whole (ROPR); sound insulation; parameters of ventilation devices, etc. Yvsa is Sgarentia to preserve the specified values for 5-10 years.

Characteristics of double-glazed windows

| A type | Thickness, mm. | Rapkin, m2c / w | Svetopropuska,% | Mass, kg. | Price 1m2, $ |

|---|---|---|---|---|---|

| 4-16-4 | 24. | 0.36 | 81. | twenty | 19-23 |

| 4-16Ar-4i | 24. | 0,68. | 75. | twenty | 30-36 |

| 4-16Ar-4k. | 24. | 0.55 | 74. | twenty | 30-36 |

| 4-10-4-10-4 | 32. | 0.50 | - | thirty | 29-33 |

| 6-12-4-6-4 | 32. | 0.50 | 72. | 35. | 31-35 |

| 6-12-4-6AR-4I. | 32. | 0.71 | 67. | 35. | 38-44. |

| 6-12-4-6Ar-4K. | 32. | 0.65 | 66. | 35. | 38-44 |

Note. The encoding of the package parameters will explain on the example of the model 4-14AR-4I, where: 4- thickness of the outer glass, 14Arr- width of the gap between the glasses of the camera filled with argon, 4i- thickness and type of low-emission glass.

The editorial board thanks the company "KBE window technology", "Httroplast", Rehau AG + CO., NPO Plasma, Palace Windows for help in preparing the material