Flat roofs, open terraces and balconies - the choice of architectural solutions, materials, technologies.

Service such complex technique on the pitched roof is unsafe

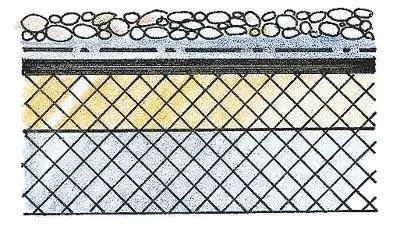

A- primer Indever,

Barprooolator DIFBAR,

The anti-coronary membrane Defend Autoots,

G-geomembrane Protefon Tex

Waterproofing, drainage and anticorval material TEFOND DRAIN PLUS

Polyethylene waterproofing membrane Tefond Plus

We continue to discuss the topic of flat roofs, raised in the past issue of the magazine. Today you want to equip a flat roof in your home, an open terrace and a lot of balconies. What architectural solutions to choose? What materials will take advantage of? What kind of company prefer? We tried to answer these and other questions in our new publication.

Pie Slavny Stuffley

Prompt into the device of modern roofs, you are striking how mankind is far away from the primitive primitive canopy. The evidence of progress is, in particular, a variety of terms adopted in roofing construction. What is worth at least a culinary definition of "root pie", used to designate a multilayer design, crowning the construction!Doing the roof of a residential building flat makes sense in two cases: when its operation is assumed (let's say, for dilution of colors or maintenance of the external split system unit) and when it requires artistic intent. The experience of the construction of open architectural and engineering structures with a small bias has been accumulated in large companies producing insulating and roofing materials. For example, in the French company Siplast, in American Carlisle Syntec, Firestone and Genflex, Italian Tegola and General Membrane S.P.a, in the German Industrial Group Schomburg, in the European Solvay Corporation, in Russian companies "TechnoNIKOL" and "Sovintachprom" and others.

Completely flat roofs are not there. They usually have small slopes (B1-4) to the center of the house. This ensures the directional movement of water in the funnel of the inner drainage. The main waterproofs are usually heated (electric heating cable) so that they do not freeze in winter. There are also additional stormwater drains through which excessive water flows are reset.

The plane roof is experiencing increased atmospheric loads not only in summer, but in the winter. It regularly moistened to snow that melted under the influence of heat outgoing from the house. The more efficient the layers of heat and vaporizolation, the less the threat of leaks.

But first of all, the roof resistance determines the roof reliability. Our magazine has already published an overview of the roofing materials of various types and gave them a comparative analysis ("Modern roofing materials: what are they?").

Currently, the main waterproofing carpet is increasingly manufactured from bitumen-polymeric materials on a non-burning basis. The most qualitative is the rolled coatings on the substrate from elastic polymer fibers with a top layer of an oxidized bitumen, modified by the APA and SBS-polymers. The range of these materials includes hundreds of names. The selection of the brand is determined by many factors: the features of the roof design, the location of the house, climate, etc. Rolls are welded to the surface with a burner or a construction dryer. There are also self-adhesive coatings. Bituminous polymer materials are relatively cheap, can be used on surfaces with any bias. But here for the operated roofs such a coating is not enough, one more, a more durable protective layer (tile, gravel, cement screed, etc.) is needed. However, after the "strengthening", the material will give way to strength, durability and simplicity of laying more expensive polymer membranes.

The EPDM membrane (ethylene-propylene-diene-monomer) is a modern elastomer. It allows in a short time to cover large surfaces of the roof. Width of the floor-from3 to 15m, length - from 15 to 61m. They are connected to each other using a special bilateral self-adhesive tape. The EPDM membrane has a high elasticity (relative elongation of 300%) and low weight (1m2 with a thickness of 1.15mm weighs 1,4kg). The calculated life of the material is not less than 50 years. Some are already operating more than 40 years. The rest of the membranes are applied relatively recently, so European manufacturers still do not provide a guarantee for them more than 10 years. The service life of PVC membranes and membrane "Resortiks" from the moment of their first use is already more than 25 years. Specialist characters confirm that these materials can be operated for another period.

The largest membrane manufacturer is CARLISLE SYNTEC Incorporated (USA). The membrane of the TEPK (from a triple ethylene propylene rubber) with a thickness of 1.14mm is stacked on any basis by all known methods. Ideal for waterproofing of flat surfaces with small slopes. For the operation of roofs and engineering structures covered with such membranes, the manufacturer offers a lot of auxiliary materials. For example, such as the pre-waterproofing bitumen polymer membrane CCW-711, the polyethylene drainage membrane Sure-Drain-HD, Walkway tracks from modified rubber, ensuring the convenience of movement on the membranes surfaces.

In our country, the EPDM membrane produces the company "Sovirthprom". The material "polycom" produced by it has two varieties - P (ordinary) and APG (sponden by combustion). According to its physical and mechanical and operational characteristics, this coating is comparable to American counterparts, but it is twice as cheaper.

TPO-polymer material of the last generation based on thermoplastic polyolefins. The use of TP-membranes is suitable where they have a complex configuration or where the risk of mechanical damage to the roofing carpet (i eat on the operated roofs). The material comes in rolls 95 cm wide and 1.8m. The seams are connected by welding. TPO more racks to mechanical and chemical influences than EPDM, but less flexible and elastic, especially at low temperatures. That is why it finds use mainly in the southern regions. The most famous manufacturer, and since 1998 and the supplier of this material to Russia, the American Corporation Genflex. Similar membranes are manufactured and supplied to our country Carlisle.

PVC (PVC-P) is a high-quality elastic material from polyvinyl chloride. Welded with hot air just like TPO. The PVC membrane reinforced polyester mesh is characterized by high strength to the puncture, a wide color scheme (9 sets), has a good deformation ability. For the roof type "Green Lawn" produced material with fungicidal additives. There is a PVC membrane similar to Linoleum. It is able to simultaneously play the role of finishing coating and waterproofing. The use of PVC membranes is justified in cases where it is impossible to align the underlined surface for some reason. The material is good and with a combination of areas of the exploited and non-exploitable roof. The Belgian company Alcor Draka, which is part of the International Solvay Chemical Corporation, produces and supplies Alkorplan PVC membrane to Russia. They are equally suitable for waterproofing new roofs and for the repair of old, and with any bias. Alkorplan comes in rolls, has a width of 1.6 or 2.1 m, length 20m and a thickness of 1.2 mm.

Well, will not the membrane turn into an improvised carpet and the aircraft and will not be quenching from the impulse of the wind? There are three basic ways to fix material on the plane. The choice depends on the design of the roof, the material used and the operational features of the coating.

The most economical and universal is the method of attaching ballast. Freely lying on the base of the membrane is fixed only around the perimeter and in places of adjustment to vertical surfaces. Based on it is held with the help of ballast: pebbles, gravel, concrete blocks or (if there is a member of the operated roof, balcony, terrace) paving slabs. A variant of the ballast system is an inversion roof in which a layer of waterproof thermal insulation (polystyrene foam) is laid on the membrane. The staplening materials of the new generation, suitable, among other things, and for flat roofs, our magazine is also acquainted with the reader ("New 'Clothing" for home "). The method is suitable for roofs with a solid base, withstanding an additional mechanical load of about 700Pa (in addition to the weight of the roof itself).

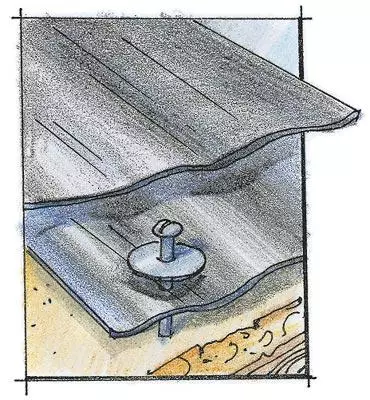

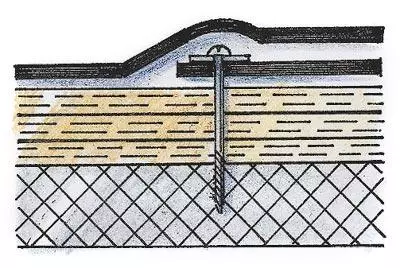

The mechanically fixed membrane is recommended in cases where additional load on the bearing structures is unacceptable when parapets or organized plums are missing. Of the roofing materials for these purposes, the TPO or PVC membrane is preferable. Fixing the coating on the surface is made in seams with special self-draws.

Finally, the roofing membrane can be completely glued to the base. This method is recommended mainly for roofs with complex outlines, as well as strong mechanical loads (incomprehensible wind). Grilled (cooked) canvases are attached to the base with special mounting glue. Choosing this way of installation, it is important to know whether glue with thermal insulation materials and membranes is compatible.

Methods for fastening roofing systems

| Mechanical on screw screws | ||

|---|---|---|

|

|

|

| Ballast | ||

|

|

|

As for the prices of the proposed rolled materials and polymer membranes, then the simple comparison is able to introduce a buyer to delusion. Consider, more expensive polymer membranes are stacked in one layer and do not require significant installation costs, while the roofs of cheaper rolling-bitumen materials are mounted in two layers using gas burners, sealing mastic and other auxiliary compositions. As a result, the polymer membrane costs the customer no more expensive. The average cost of 1M2 high-quality rolled bitumen materials modified by polymer additives is $ 4; EPDM-membranes with components - from $ 8.5; TPO and PVC membranes with components - from $ 9.5; Membranes "Resortiks" with components - from $ 18. Work on the installation of polymer membranes costs the customer of $ 3-5 per 1 m2. The cost of the insulation from the extrusion polystyrene foam firms BASF or DOW CHEMICAL is an average $ 175 for 1m3. Depending on the configuration of the roof, the terrace, the balcony, the passages, the funnels, the add-ons, etc., the costs of materials and carrying out works can significantly increase what should be prepared.

About tastes argue

In the struggle for the buyer, the company not only constantly expand the range of roofing materials and improve their properties, but also develop systems of materials and technology of their cumulative use in various construction situations. That is, the choice of the most effective and coordinated components makes the manufacturer. The designer remains only to apply the system correctly. Again, an analogy with cakes is applied: apple, cherry, meat ... Choose to taste.Various systems intended for the device of flat roofs offer companies such as Siplast, Index, Tegola, Icopal, Schomburg. Since a private developer is closer to the idea of the cottage, we give as an example an option of the system of the operated roof type "green roof" on a concrete base.

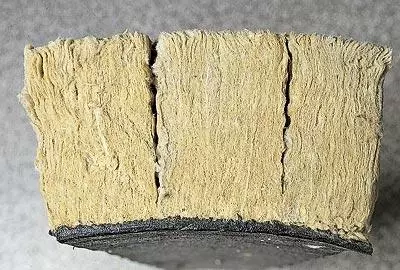

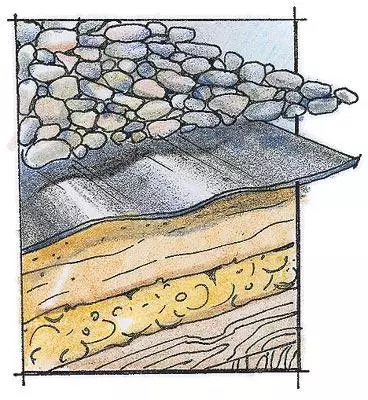

The base can be both heat-insulated (perlite or polystyrene foam plates, polyurethane foam) and non-flared. For the next case, the mandatory components of the "roof pie" become layers of vapor insulating, heat insulating, waterproofing, drainage materials and external earth grounds. The thickness and composition of the latter are due to the selected type of green plantings. Ombolis of materials of the company contributes their additions.

Of course, the construction company can compile its composition of materials from different manufacturers. For example, a Paroc vaporizolytor, insulator IsOver, hydroelector "Hydrotect-y". But the result of such combination is unpredictable.

The French company SIPLAST offers for green roofing coatings. GRAVIJARDIN system with double waterproofing protection. This is a combination of GRAVIEFLEX materials with special mechanical additives that guide the roots of plants in parallel with the surface of the waterproofing layer (securing its destruction), and the waterproofing of Preflex. The main advantages of the proposed solution are:

- Simplification of the system. The strength of the materials avoids the traditional method of protecting waterproofing with a concrete screed and refuse a heavy gravel drainage layer (which sometimes reaches thickness 100mm).

- High resistance to mechanical damage, loads and aging.

This anti-corporate coating applies Index. But it offers to apply it to the heat insulating layer with the polymer-bituminous film already put on it. Utemola in the "Pie" The highlight is the TEFOND DRAIN PLUS material performing the function of waterproofing and drainage. It is a membrane of PVD with a double mechanical lock, waterproofing seam and geotextile (polypropylene).

The constant component of the "green" roofing polymer geomembrane. It is formed from cloths with rounded spikes up to 8mm and filtering textiles. Textiles prevents the system with particles of soil, and rounded spikes form drainage channels for which the filtered water is sent to the drain. Isaoy main thing, such a solution allows you to unload the waterproofing carpet from the impact on the side of the soil and ballast (which could lead to ruptures, scratches and punctum). Such membranes are widely used for waterproofing and drainage of various building structures.

The price of 1 m2 of the polymer membrane with geotextiles from different manufacturers ranges from $ 4 to $ 8. The total cost of its laying depends on the specific task.

One of the most common is the operated system for the terraces on a concrete basis. Of course, the anti-coronary membrane here is nothing. Heat insulators are rarely used. SIPLAST, for example, provides in the structure of the terrace floor layer of vapor insulation, separation and reinforcing gaskets, waterproofing.

In the construction of the floor of the terrace on a concrete basis, methods of sealing of adjoins (Kstenam, pipelines) and waterfronts, as well as the execution of deformation seams are extremely important.

This system uses freely stacked rolled material with self-adhesive joints of Teranapjs and Bande Teranap (Band tape for welding joints). As a rule, the floor is trimmed with facing tiles on adjustable supports or covered with wooden flooring. Supports make it possible to ensure the safety of a two-layer system at a price of one-layer. It simplifies the design of the adjoints and thresholds.

The German company Schomburg offers its own technology based on the use as a waterproofing layer (coating cement waterproofing) of a thin-layer plasticized cement solution. The universal waterproofing material Aquafin-2k is used to protect against moisture terraces and balconies with a small and zero slope. The advantage of the technical solution of Schomburg in the ease of installation of the waterproofing layer (the composition is applied with a roller, brush or splashing in 2-3 layers). The versatile material Aquafin-2K is elastic, has good adhesion to many surfaces, vapor permanent, resistant to UV radiation, cold, quickly acquires resistance to atmospheric precipitation. Directly on the waterproofing layer with the help of elastic waterproof glue with a particularly high plasticity of UNIFIX-2K, capable of providing a long-term repayment of the peeling stresses, the floor tile is stacked.

Finally, the third version of the open architectural construction structure with a small bias-balconies on a concrete or wooden base with a two-layer waterproof isolation and a decoration of ceramic tiles. The waterproofing of the balconies is performed by two layers of self-adhesive rolled materials (polymer-bitumen or based on plasticized cement mortar). They fit into the joint with alternating seams, decorated self-adhesive sealing ribbons. The finish is made by facing ceramic tiles for floors on various technologies.

Siplast in such cases applies Paradiene35SR4 waterproofing material, which is placed in two layers. Schomburg offers the same technical solution as for the terraces.

Modern materials and technologies provide us today, about which the fathers of architecture and builders of the past could not even dream. Open terraces that were once one of the seven wonders of the world are becoming everyday reality in Russia today. Hospital, solve complex and high-tech architectural and construction problems are often trying not enough individuals. Even who is going to build a structure with a flat operated roof, an outdoor terrace and a balcony, should be prepared for the design, construction and operation of the object will be in a penny. But the advantages are apparent: a rooftop garden and ternscourt, a magnificent view of the surroundings at any time of the year, the uniqueness of the architecture of your home ... Do not be afraid of flat surfaces, gentlemen! If you do everything right, they will definitely be beautiful, reliable, durable and deliver a lot of pleasures to you and your family members.

Examples of geomembran

| Name | Manufacturer |

|---|---|

| "DRENZ" | Russia |

| "Fundalin" | "Ondulin", France |

| Delta. | Dorken, Germany |

| Protefon Tex. | Index, Italy |

| Tefond Drain. | TEGOLA CANADEESE, ITALY |

| Blackline | Monarflex, Denmark |

The editors thanks the company "Tryples" for help in the preparation of material.