Review of the sewing machine market.

A variety of selection of household sewing machines in our market provides companies such as American Singer, German PFAFF, Swedish Husqvarna, Swiss Bernina and Elna, Japanese Brother, Jaguar, Janome, Podolsky Mechanical Plant (PMZ) and other major manufacturers. They supply a large number of models: simple and complex, standard dimensions and compact, with electromechanical and microprocessor control. In the latter case, the processor is built into the machine housing and controls all operations performed on it. For the most promising models, you can develop assignments on a personal computer (PC). For example, create your own line with the help of the applied program.

We compare the most popular sewing machine models available on the counter and provided by the certificate of the Russian State Standard, warranty and post-warranty service. Along the way, let's try to figure out the differences between these difficult devices from each other. But under one condition: the final choice of the most convenient model you must do yourself. And also: today it is hardly worth buying a sewing machine, as inserted, for life. Get ready for the fact that in 10-15 years your favorite will obstruct morally and requires replacement.

"Heart" of a sewing machine

Swinging shuttle - simplest. It is used in cheap machines by all firms except Husqvarna. Sewing speed when using it is the lowest, it works worse with low quality threads. Stitch length does not exceed 5 mm. The bobbin with a wound thread has to be installed on the bottom of the platform.

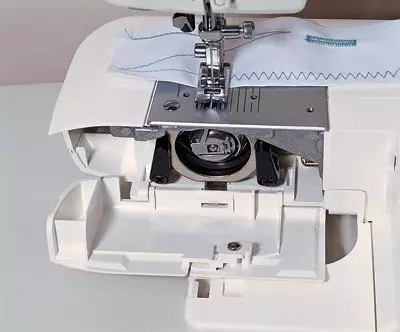

Horizontal shuttle - most convenient to refuel bobbing. It is inserted from the top side of the platform and closed with a transparent lid, through which the amount of the remaining thread can be seen (if the bobbin is also transparent). The bobbin can not get out without removing the thread from the needle's ear. But here to adjust the tension of the lower thread is convenient not in all designs of the machines. This kind of shuttle is the most popular. Used by all firms, except PFAFF and BERNINA, in sewing machines of the middle and highest value categories.

Vertical shuttle - The most reliable and expensive, almost eliminating thread content. The bobbin can not get out without removing fabric from under the foot. This shuttle is used in industrial sewing machines, as well as in expensive models from PFAFF and BERNINA.

"Heart" of a sewing machine - a shuttle - commits or oscillatory, or rotational motion. In domestic machines, it either swings in the vertical plane or rotates in the horizontal or vertical plane. For simplicity, we will denote: swinging, horizontal and vertical shuttle (the last two are also called double-circuit shutouts).

The tension of the upper thread must be somewhat larger than the bottom. Yes, and the upper thread is selected more carefully, since its strength in the sewing process is reduced by 15-20%. This is due to the multiple passage of each section back and forth through the needle's ear in the formation of stitches. Moreover, to obtain a high-quality seam it is necessary that both threads intersect inside the material, and not on its surface. It depends on the tension of each of them. The tension of the upper thread is regulated by turning a special disk located on the front panel of the machine, with a lowered presser foot. The average position of the disk is usually indicated as "Auto", it corresponds to the most commonly used stretch.

As for the lower thread, its tension is changed by turning the screw in the machine's shuttle, which is less convenient than adjusting the upper thread, but it is required less frequently. For example, when replacing the lower thread number 50 to the number 10 in the horizontal shuttle shuttle shutter, Decor 5018 sewing machine (Janome) must be slightly weakened by a flat spring. It is not necessary to remove the tiploader from the car.

Reception "Quick Start" simplifies the operation of the extraction and laying on the node-thread needle plate with a length of 5-8 cm. This is done before the start of each seam so that the first stitches are not blocked. In Brother's cars with a horizontal shuttle, it is enough to carry out the lower thread through a slot specially provided in the needle plate with a sharp blade, leaving after the bobbin, just the necessary 5-8 cm of the thread.

Muscles and Head Sewing Machine

Sewing machines differ from each other not only by the "heart" - shuttle, but also "muscles" - drive and "head" - control.

The machine drive is mechanical (manual or foot) and electric. Our grandmothers are accustomed to the first, monotonically rotating the handle handle or swing a sewing machine pedal (not because, according to statistics, the female half of the last generation turned out to be more lively than men?). In modern models use electrical drive. It allows not only to free both hands, but also influence the sewing speed with a slightly pressing foot on a special pedal. For household vehicles use electric motors with a capacity of 50 to 90 W, but in most models it is 60 or 70 W. Consider, the case indicates not this value, but the installed power of the entire machine.

You can control sewing on the sewing machine using electromechanical or electronic devices. Thus, elements of electronics will ensure the stop of the engine, even when the pedal is pressed in the case of a solid subject (pins, fasteners). And, for example, the Fantasy 977 or Fantasy 979 models of Jaguar at the same time, and three times "wept". In the case of sewing interruption, for any reason (let's say, due to the surveillance of the foot pedal), the needle will standard stop in the extreme upper position, which is considered optimal in terms of safety. However, if desired, you can set the stop and in the extreme lower position.

Electronics not only expanded the circle of managed operations, but also allowed to control the correctness of their execution. Thus, the most "advanced" sewing-embroidery machines with microprocessor controls are able to perform programs drawn up on a PC with the involvement of information from the Internet.

To facilitate a description of a variety of machines, we are concerned about two types: I - with electromechanical control and II - with microprocessor control.

Almost all type I machines set an AC motor, calculated on voltage 220 V. In type II models, only low-voltage (12, 24 or 28 V) DC motors are applied. With their help, it is much easier to expand the capabilities of the machine. For example, to ensure maximum needle pressure on the fabric even at low sewing speed. This greatly facilitates work with thin silk, leather things folded in a few layers of denim cloth, the approach to the thick drape.

We emphasize that there is no single classification of household sewing machines yet. Thus, the Firm PFAFF divides potential buyers according to the degree of preparation for two groups: beginners (Hobby) and professionals (Professional). Each of them offers sewing machines with their capabilities. Moreover, some of our buyers are mistakenly used by the English word Professional not to the possibilities of the sewing machine, but to the sphere of its operation. As a result, the model of this discharge is used for the present mass production, such as bed linen. What is absolutely not provided by the manufacturer of machines.

For Electromechanical control Change the strength of the tension of the thread and pressure of the paws on the fabric, set the stitch size, to choose a view of the line is manually. This is carried out either by turning the control disk or the slider displacement, or the lift and lowering the lever. Part of the movements can be carried out by electronics after pressing the corresponding key located on the front panel of the machine (for example, the needle stop in the extreme upper position).

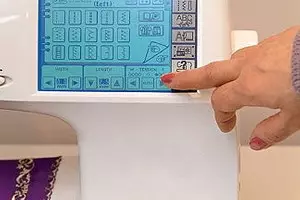

Microprocessor control It happens both autonomous and compatible with PC. However, any of them allows you to coordinate most of the functions of the sewing machine, and almost all procedures are performed by pressing the corresponding key. External sign of this type of control - the presence of a liquid crystal information display. It can not only highlight the values of the parameter installed (for example, the view and size of the stitch being executed), but also specify a possible error and even give the hint. It is convenient both with the initial development of the machine and in the presence of sufficient experience. Let's say, in the case of a raised paw in the recording hinge mode on the display of the sewing machine MEMORY Craft 4800, a message will appear: "Lower the paw foot."

Further improvement of microprocessor management led to the creation of a sewing and embroidery machine compatible with a PC. It can already be forced to make a needle to do any line. I just need to first come up with a special program on your home PC, and then rewrite into the microprocessor memory (directly through the connector or with a floppy disk).

On the recommendation of Ellefort LLC, which trading in household sewing machines of almost all of the above companies, in the preparation of a table from a large number of characteristics, only eight is selected.

| Manufacturing firm | Model | A type | Characteristics | Price, $ | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| one | 2. | 3. | four | five | 6. | 7. | eight | ||||

| Pfaff | Hobby 1020/1030/1040 | I. | to | 4 (5) | 7/15/23 | - | - | - | four | - | 60/180/200. |

| Varimatic 6085/6091 | I. | in | 6 (5) | 21. | - | - | - | four | - | 330/410 | |

| TipMatic 6122/6152. | I. | in | 6 (5) | 30/70 | +. | +. | +. | one | +. | 420/500. | |

| Tiptronic 2020/2040. | II. | in | 6 (6) | 47/180. | +. | +. | +. | one | +. | 600/850 | |

| Creative 7570. | II. | in | 6 (9) | Over 500. | +. | +. | +. | one | +. | 1840 * | |

| Singer. | Alpha 342/343/345 | I. | to | 4.5 (5) | 2/5/5 | - | - | - | 4/1/4 | - | 140/160/152. |

| Omega 9810/9818/9836 | I. | G. | 5 (6) | 10/18/36 | - | - | - | four | - | 168/180/195 | |

| Chic 4662. | I. | G. | 5 (6) | 10 | - | - | - | four | - | 230. | |

| CONCERTO 9217/9224/9240. | I. | G. | 5 (6) | 17/24/40 | - | - | +. | one | +. | 295/320/354. | |

| Brother. | Px 100/200/300 | I. | to | 4 (5) | 15/17/30 | - | - | - | one | - | 155/185/190. |

| PS 31/33/35 | I. | to | 4 (5) | 12/15/20 | - | - | +. | 4/1/1. | - | 160/166/172. | |

| STAR 120E / 130E / 140E | I. | G. | 4 (5) | 26/37/37 | +. | - | +. | one | +. | 300/330/370 | |

| M-955 / M-965 | II. | G. | 5 (7) | 300/400 | +. | - | +. | one | +. | 600/850 | |

| Super Galaxie 2100/3000 | II. | G. | 9 (7) | 1000/1500. | +. | - | +. | one | +. | 1890 * / 2600 * | |

| Jaguar. | 415 Super | I. | to | 4 (5) | 12 | - | - | - | four | - | 150. |

| 383/386. | I. | to | 4 (5) | 21/26 | - | +. | - | five | - / +. | 176/195 | |

| Fantasy 970. | I. | G. | 5 (6.5) | 12 | - | +. | - | five | - | 172. | |

| Fantasy 972/976. | I. | G. | 5 (6.5) | 14/28. | - | +. | - | one | +. | 188/240 | |

| Fantasy 977/979 | I. | G. | 5 (6.5) | 28/39 | +. | +. | - | one | +. | 250/275 | |

| Janome. | J 394. | I. | to | 4 (5) | 21. | - | +. | - | four | - | 174. |

| J 540. | I. | to | 4 (5) | fourteen | - | - | - | four | - | 138. | |

| US 2014/2022. | I. | to | 4 (5) | 14/22 | - | - | - | 4/1. | - | 185/210 | |

| JEM GOLD. | I. | G. | 4 (5) | 12 | - | - | - | four | - | 150. | |

| Decor 5124. | I. | G. | 4 (6) | 24. | +. | +. | - | one | +. | 363. | |

| Memory Craft 3500/4800. | II. | G. | 5 (7) | 50/99 | +. | +. | +. | one | +. | 500/630 | |

| Memory Craft 10000. | II. | G. | 5 (7) | Over 1000. | +. | +. | +. | one | +. | 2000 * | |

| Bernina. | Bernette 50/60 | I. | to | 4 (5) | 11/15 | - | - | +. | four | - | 160/185. |

| Bernette 70/75 | I. | to | 4 (5) | 13/21 | - | - | +. | one | - / +. | 200/220 | |

| Bernina 1008. | I. | to | 5 (5) | 17. | - | - | +. | 6. | - | 400. | |

| Activa 140. | II. | in | 5 (5.5) | 23. | - | +. | +. | one | - | 610. | |

| Virtuosa 160. | II. | in | 5 (5.5) | 48 (+180) | +. | +. | +. | one | +. | 825 * | |

| ARTISTA 180. | II. | in | 5 (9) | 500. | +. | +. | +. | one | +. | 1550 * | |

| Elna. | 2003/2005/2007 | I. | to | 4 (6) | 11/15/20 | - | +. | - | 4/1/1. | - / + / + | 198/224/240. |

| 3003. | I. | G. | 4 (6) | sixteen | +. | +. | - | one | +. | 275. | |

| 6005. | II. | G. | 5 (7) | 238. | +. | +. | +. | one | +. | 665. | |

| Husqvarna. | Daisy 325/335 | I. | G. | 6 (5.5) | 15/25 | - | +. | +. | four | - | 340/380 |

| Freesia 415/425 | II. | G. | 6 (6) | 16/30 | - | +. | +. | one | - | 470/520. | |

| Lily 535. | II. | G. | 6 (6) | thirty | - | +. | +. | one | - | 600. | |

| Lily 545/555. | II. | G. | 6 (6) | 80/240. | +. | +. | +. | one | - | 650/730. | |

| ROSE 605. | II. | G. | 6 (6) | 120. | +. | +. | +. | one | - | 1390. | |

| Desiner 1. | II. | G. | 6 (6) | Over 500. | +. | +. | +. | one | +. | 3200 * |

* - compatible with PC (cost without software)

Explanations to the table:

1 - Type of Shuttle ( to - swinging, G. - horizontal, in - vertical);

2 - Maximum length of direct stitch (width of the shaped stitch), mm;

3 - the number of types of lines (operations);

4 - sewing speed range switch;

5 - pressure regulator foot on fabric;

6 - reception "Quick Start";

7 - the number of steps when the slotted loop rift; 8 - the tip of the top thread.

Management of main performance

The location of the control mechanisms should be convenient or at least not to annoy. That is why the same type of models of different firms are distinguished primarily by the position of the control panel. Each user gets the opportunity to choose a convenient placement of keys, disks and levers.Types of line You can choose from the sewing machine menu. They are depicted using characters either on the front panel, or under the top folding lid or on the display. Calculate the number of stitch options is not always easy, because some firms are recorded not lines, but operations. In the second case, one and the same line is taken into account several times, for example: straight line, straight with a needle-left needle, straight with a needle displacement to the right. For example, in the machine model PS-35 company BROTHER, the number of lines 20, and operations - 35. In type II machines, only the number of operations consider the implementation and shaped seams, and the rubber loop of different forms (with rounded corners, with the "eye" etc.), and embroidery letters of several alphabets in different designs.

The usual line of shuttle stitches is almost not stretched in length. Therefore, for sewing elastic tissues, such as knitwear, resort to the so-called multicolor line. Performing them, the needle performs down-up moves more often - the more injections when performing a line, the more elastic. In the menu of type II machines such lines is always enough. But purchasing a cheap type I machine, be sure to ask their number in the menu.

Length and width The stitch on all machines can be "edited", but their maximum absence of the regulator, and in type II machines, the pressure in the sewing process really changes. Note that the electronic regulator is provided only in the most expensive models. Purchases to design the sewing machine were made in Europe since the time of Leonardo da Vinci. However, I truly solved the problem of Austrian J. Madersmanger, proposed in 1814: to cast an eye to inventing the thread closer to the needle's edge, and not like a needle for manual sewing. The initiative passed to the Americans, and in 1845, E. Khow invented the mechanism of shuttle, which allowed to automatically delay the thread loop at a speed of up to five stitches per second. It was E. Khow that is unofficially considered the father of the first sewing machine. In 1851, A. Wilson and I. M. Zinger improved the mechanism, using a clamping paw and a gear rail, rising and lowering in the rosets of the needle plate. Thus, intermittent fabric feed was provided at sewing. Later, the rail was transformed into a fabric advancement mechanism, which is more often called the conveyor.

In 1862, the sewing machine was produced in Germany I. M. Pfaff, in 1872 - in Sweden on the Husqvarna weapon plant. In Russia, the first domestic sewing machine was released in 1902 in the Moscow region of Podolsk under the Singer brand and called the family.

Maximum litter lift It is important when sewing such thick materials like a drape, tarpaulin, leather. In all modern models, the paw can be lifted above the standard height of 5 mm (for example, at 7, 8, 11, and even 12 mm). For those buyers who intend to sew denim fabric and quilting products (Quilting), form applications or fragments from patchwork), the higher the boost lug - the better.

Speed change pedal Sewing is provided in all models of machines for influence on the rotation frequency of the shaft. In more expensive models for convenience there is also a sewing speed range, located on the machine itself. Janome cheap machines can be purchased for $ 30 Sewing speed change with built-in two-position ("fast" and "slowly") switch of ranges.

Rubber Button On a modern sewing machine, one of two ways is performed: a few steps (more often than 4) or one. In the first case, the loop is formed by consistent steps without turning the fabric: sewing ahead - fixing - sewing back - pinning. The exclusion is the model of the company Singer Alpha 342 and Alpha 345, in which the fabric after each step is rotated. In the second case, a button is required to install a button for which the loop is designed, and the machine will remove the size and consistently perform all the steps without any participation. However, large loops (longer than 50 mm) on machines of both types make only a few steps.

Since when moving forward and forth, a markup with a different density of stitches is obtained, then in many machines a device is provided for adjusting their density. But there are nuances here. So, in the three models of Jaguar cars, the mark is performed in 5 steps, and in the Bernina 1008 car, Bernina - 6 steps. In this case, both sides of the loop are processed only when the material moves forward. As a result, the density of stitches is the same, which eliminates the need to install an additional special device.

The reverse of the engine is used at the end of each seam to fasten the thread, so the reverse key is on any machine. This key should always be at hand, you just need to press it with your finger. In all type I machines to stop the reverse, it is necessary to simply remove the finger from the key. But in a number of type II machines - for example, Husqvarna - the operation will be stopped only after it is repeatedly pressed.

Additional useful devices

The overall dimensions and the appearance of the modern sewing machine almost completely took shape in the consciousness of consumers and manufacturers. Therefore, some of the same type of models of different firms look like twin sisters. But here are additional devices that provide ease of use of the machine, there are not in each case or differ.

Fetching The needle is designed to facilitate one of the most "low-altitude" procedures, which is particularly annoying, if you are in a hurry, or difficult if you don't see too well. As a result, more and more models are supplied with a small refueling. The thread after the pyrechivator needs to hook behind the hooks of the teller and turn a special lever. The thread will push the needle's ear, and you will only have a slightly pulling the resulting loop.

Platform All sewing machines are able to transform. One of its parts is extended, removed or folded down, opening a device called a free sleeve. It is a narrower support on which you can wear a sleeve, cuff, sock or other part of a sewing product that requires processing around the circle. The minimum diameter of the worn element is usually 8.5 cm, and the distance from the needle to the rack from different models is different: from 7 to 18 cm (maximum - at the machines of Husqvarna).

Removable part of the platform Perform a drawer for storing spare accessories: additional paws, replaceable bumps, needles, brushes, screwdrivers, etc. In some models, Janome and Elna firms also have special cells under the top folding lid.

Metal-ceramic supports For the main rotating parts of the mechanism, they are installed in many models, so the owner may not worry about periodic lubrication. The window of the machine is always made metal, but its closing decorative body can be plastic, metallic or combined (plastic front panel, and the reverse side is metallic).

Plastic case Closing the type I machine is offered in a hard or soft version, and sometimes you can replace soft to hard, paying $ 5-7. Type II machines are equipped with rigid covers.

Threads, needles and legs

The quality of the thread should be paid to close attention, especially with the system of automatic tension in microprocessor control machines. It is better to exclude from the use of "shaggy" threads, which score a shut and overload the engine. According to experts, LLC "Grazi-F" supplying sewing fittings, it is quite suitable for threads with a small friction coefficient and uniform forces: polyester, cotton with polyester or silk (for example, German from GUTERMANN, MADEIRA and AMANN, Chinese - Strong and Rainbow, Polish - Talia and Era).The type and thickness of the needle for each type of matter, plus recommendations for the choice of the appropriate number of the threads are given in the manual for the use of the sewing machine. It is also explained that to work with leather, knitwear, denim and other specific materials need needles with a special sharpening of the tip. In any sewing machine, a double needle can be applied to two parallel seams. You just need to use another rod to install the second coil. The guide explains the features of additional paws attached to the car (from 3 to 9), as well as the methods of their installation. Some firms even provide the opportunity to choose some of them when buying a car. By the way, in the store, ask the seller compatibility of the car with paws supplied by other firms. Today, all manufacturers make paws quick-consuming - the replacement is carried out literally in 2-3 seconds.

Branded "Summies"

A number of firms offer additional original engineering solutions that are kind of business cards manufacturers. Without these "trifles", of course, it is possible and can do, but how not to use the "row" designed to simplify the use of a sewing machine! True, any such "row" somewhat increases its value. Let us dwell on some of them.

Singer cars can be equipped with an inclined needle, which creates optimal needle pressure due to its entry into the material at an angle, and not vertically. As a result, according to the statement of the company, thick tissues are easier than when the needle is right. The second feature can be pneumopedal (instead of the usual sewing speed with electronic control). Especially such a device is suitable for concrete people who fear the dangers of damage to the current, for example, as a result of accidental damage to the electric pipe, because the supply voltage to the pneumatal is not supplied. The inclined pool and pneumopedal is equipped with the COC 4662 models and the Concerto series.

Multiple models of PFAFF machines are equipped with an IDT conveyor (Integraierter Dyal-Trasport, or a synchronous dual conveyor). It has a second built-in paw with teeth, which additionally presses the fabric and eliminates the offset of one layer of its relative to the other. This is especially important when sewing thin materials (silk, viscose), for the perfect coincidence of the drawing of striped and checkered tissues or sewing without prior leisure. IDT system is installed on Varimatic 6091 models, TipMatic 6122, Tiptronic 2020 and Creative 7570. To sewing machines of other firms, the upper conveyor will have to buy for $ 20 and establish if necessary instead of a presser foot.

Husqvarna and Bernina supplied with a sewing machine working table, allowing to increase the platform area. It is attached directly to the platform.

Some Bernina machines are equipped with a FHS mechanical device (Free Hands System, or "Free Hands") in the form of a lever. It allows one knee movement to lift the presser foot and at the same time lower the conveyor, while both hands remain free. This system is available on Activa 140, Virtuosa 160 and Artista 180 models.

All of the above devices are not installed on each company's product. Thus, the VARIMATIC 6091 of the PFAFF firm is equipped with the IDT system, and the variatic model varimatic 6085 is not, thanks to which $ 80 is cheaper.

PC compatible sewing machine

The microprocessor will remember the necessary information and removes it from the command on the team. For example, when repetition, after a while, the sewing of any tissue does not need to be selected by the selection of the thread, the size of the line, the strength of the tension of the upper thread, the speed of the procedure. All this can be restored on the display, and the machine will automatically fulfill the task.If you decide to purchase a machine with a liquid crystal display, ask how information is presented on it - symbolic or symbol-letter. In the second case, the display must be Russified. If not, the owner will have to learn a number of sewing terms in English. The lines are made up of a plurality of individual stitches that can be shuttle or chain. Accordingly, the first are used in the racial sewing machines, and the second - in the stimples (overlock).

For the formation of a shuttle stitch, two threads are used - upper and lower. The needle with the upper thread moves down-up, and the shuttle with the bottom wound on the bobbin fluctuates or rotates under the needle plate on which the fabric lies. When moving down the needle pierces the fabric and stretches through it the upper thread, creating a loop from the wrong side. The shuttle captures this loop and drives around the spitcher and bobbins, binding both threads. Then the pylidewriter wars the upper thread from the coil, pulls the loop from the bobbin and delays the stitch, after which the conveyor moves the fabric to the stitch length. The work of all mechanisms is consistent with the help of the main rotating shaft.

SUPER GALAXIE 3000 Model Display, Memory Craft 10000 and Desiner 1 not only reproduces everything in color, but also contains a number of sensory control keys - a sufficiently easy touch to any of them.

The advantage of this method of controlling the machine is especially noticeable when it is used for embroidery. At any time, you can take a floppy disk with the right plot, rewrite the machine into memory of the microprocessor, and it will push it with threads of those colors that are alternately refilled in the needle. Therefore, the most promising models of type II are equipped with a device for recording information on a floppy disk to save in a kind of library. For each of the Desiner 1 models, Super Galaxie 3000, Super Galaxie 2100, Creative 7570, Memory Craft 10,000, Artista 180, you can create an extensive library of such plots on diskettes.

Warranty obligations

Some firms provide a two-stage guarantee for their sewing machines: 6 months with the right to replace the machine and the next 12 or 18 months - without such a right, but with free repairs. Husqvarna gives one-stage warranty for 2 years, and Jaguar - on 3. True, in the event of a repair on the third year, only the work of the master will be free, but not spare parts. The Bernina 1008 model Bernina supplies a guarantee for as many as 5 years.

The warranty is valid only if the homely sewing workshop served members of one family, and not tenants of the whole house.

The sewing machine can be made both directly in the country of the manufacturer and in another region, most often asian. For those who are interested in how this affects the quality of products, LLC Firm Zinmost leads such an example: the Bernina 1008 sewing machine with the maximum warranty period of 5 years is manufactured in Thailand.