Overview of modern facade panels. Manufacturers, technical specifications of panels of various species.

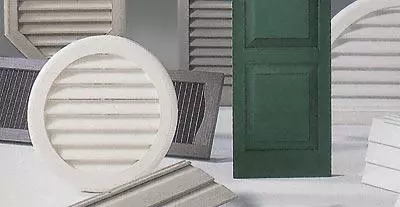

One of the most rational ways to solve the problem of protecting facades of the already constructed buildings is the use of various types of walls, or as they are often called facade panels. The facades of wooden buildings were published with wooden clap, which was carefully painted. It is the lining and can be viewed as a prototype of front panels. But over time, the tree began to rot, so natural and synthetic materials, the protective characteristics of which are much higher than the tree began to use the facade panels.

Siding It has highly both decorative and moisture protection properties and is a typeset panels made of steel, aluminum or vinyl polymers, the outer surface of which is painted into different colors or textured under the tree.

The most durable, durable and, naturally, dear ($ 25-45 m2) type of siding-steel. However, the main area of its use is the finishing of facades of buildings in cities.

The technology of facing at home siding is not more complicated by the procedure for the covering of its wooden carbon panel - the polymer panels are easily cut with a hacksaw. The profile of the panels is designed in such a way that they need to be mounted horizontally, flashes. For which the holes for nails are made in the upper edge of the panels, and the holes have an extended shape that allows you to compensate for the thermal expansion of the panels. To attach siding, you should use nails from aluminum alloys to avoid subsequently rusty drills on the surface of the panels.

To make the building finish finished type, there are additional components, such as a variety of corners, drainage, decorative elements. Interesting Facade panels from rigid polyvinyl chloride with stone facing . In Chermannia, they are already produced more than 25 years, but the Russian market began to conquer only recently. The incidence of the carrier layer is the rigid polyvinyl chloride foam of volumetric mass (density) of about 700 kg / m3, on the surface of which the stone crumb is applied at high temperatures. The Russian market presents the products of Deltken (Germany), which has already gained great popularity. Standard length panel - 6m, but it is possible to separately select from2.5 to 9.0 m. To finish the surface of the panels, the company "Delken" uses marble crumb. The price of such facade panels is $ 45-55 m2.

Wood fiber composite slabs Synthetic or natural resins are presented on the Russian market in several manufacturers, among which Canexel products are allocated (Canada). The basis of such wood panels split into fibers and pressed at high temperatures and pressure. The binding component is a natural lignin (an organic polymeric compound contained in the plant tissue), released during the hot chopping of wood. The resulting material is environmentally friendly, since it does not use phenol formaldehyde resins. High density does not allow panels to deform, crack and split. Each panel in the manufacturing process is covered with five layers of paint, which create a reliable protective layer. Installation of the wall coating is no different from the finishing of the building with the clapboard. Largely a variety of additional elements are available, which will significantly facilitate installation.

Facoon panels from fiber cement Have a high hardness and good vapor permeability. An example of fiber-cement panels can serve facing boards from a fine-grained color concrete Colorock of Lemminkäinen (Finland) and Eternitag construction panels of ETERPLAN-N of Eternitag (Germany). In addition, Eternitag produces low-informant finishing tiles of 127 sets and the most diverse form Polycolor and ColorFlex, designed specifically for low-rise construction.

Last 25 years of great success in Europe enjoy Ceramic plates . Permissible water absorption of about 3% guarantees their high frost resistance. The surface of the facade ceramic plates is polished or applied to her glaze.

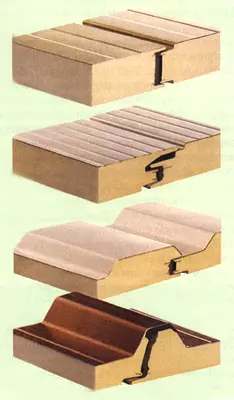

Of particular interest are the front panels of the second group, which have in addition to decorative and moisture protection properties with good thermo- and sound insulation properties. They got the name Sandwich type panels . One of the first such materials was developed in Germany more than 30 years ago is the Polyalpan panel of Herbert Heinemann. Such a panel consists of an outer metal sheet with a thickness of 0.5 mm, a layer of polyurethane foam 25 or 50mm thick for the thermal insulation of the facade and the internal vapor insulation layer of aluminum foil thickness 0.05mm. The lacquered and dried by a hot layer of aluminum alloy, manganese and magnesium can have a surface molded under decorative plaster, wood and other texture. Changing the physical parameters of panels when the ambient temperature change is so insignificant that the manufacturer firm guarantees their use in the range from -180sdo + 100 ° C for 30 years. The panels have high chemical and fire resistance (a group of hardly combed materials), environmentally friendly, are not affected by fungus and mold. The acoeffer of their thermal conductivity is 0.02 W / (MK). Price panels Polyalpan- $ 55-75 m2. Prosossia Material represents the Inteko Zoon.

Recently, three-layer facade panels of ISOPanel Ateriti Turkish company Karaca Dis Tika-Ret appeared on the Russian market. Punching the thermal insulation layer between the two metal layers is placed fire-resistant polystyrene foam.

One of the newest variants of decorative-insulating facade material are the Gebrick panels. Each block of this system has an area of 1m2 with a thickness of only 60mm, which makes it relatively easy- 25kg. The GEBRICK panel looks like a brickwork area. It is made of natural bricks fixed on a monolithic panel of polyurethane foam. The thickness of the brick facing is 19 mm, and the thickness of thermal insulation is 44mm. The rear side of the block is protected by kraft paper. The thermal conductivity of the wall, trimmed outside with such panels, is reduced by three times and sometimes more. GEBRICK panels are attached to the wall on the dowels. The panel panels numbers 40 sets and shades. For ease of installation, special angular elements have been developed. In the Russian market, the GEBRICK panel represents the company M-Holding.

Comparison of the technical characteristics of the most common "sandwich" - Panels are given in the table.

| Panel | Dimensions | Coating | Insulation | Weight, kg / m2 | Coefficient Cenage thermal Water, W / (MK) | ||||

|---|---|---|---|---|---|---|---|---|---|

| Length, see | Width, see | Thickness, see | Outdoor | Domestic | Material | Thickness, mm. | |||

| Polyalpan. | 120. | 42; 55. | 2.5; five | Aluminum magnifying sheet 0.5mm, | Aluminum foil 0.05mm | Polyurene Foolder | 25; fifty | 3.5 | 0.020 |

| Rannila | 120. | 60; 90; 120. | 8-20. | Hot-dip galvanized steel sheet 0.6mm, polyester varnish | mineral wool | 80-200. | 19-33. | 0.044. | |

| Trimoterm SNV. | 200-1400 | 6; eight; 10; 12; fifteen; twenty | Hot-dip galvanized steel sheet 0.6mm, polyester varnish | mineral wool | 60-200. | 16.2-23.6 | 0.045 | ||

| Isotermsc. | 1200. | 110. | four; 6; eight; 10 | Hot-dip galvanized steel sheet 0.6mm, polyester varnish | Polyurene Foolder | 40; 60; 80; 100 | 10.9 13.6 | 0,022 | |

| Pflaum. | 1000. | 61-91.5 | 3,512. | Hot-dip galvanized steel sheet 0.55-0.75mm, polyester coating | PUR foam | 35-120 | 11.3-14.8. | 0.055 | |

| PW8 / B-U1 | 240-1600. | 119. | 4.5; 6; eight | Hot-dip galvanized steel sheet 0.6mm, polyester varnish | Polyurene Foolder | 45; 60; 80. | 11.7-12.9 | 0,025 | |

| Isopanel Aterit. | 1220. | 100 | five; eight; 10; fifteen; twenty | Hot -Cincike steel sheet 0.45mm, polyester varnish | polystyrene foam | 45-200. | 8.7-9.3 | - | |

| Gebrik. | 140. | 70. | 6. | Brick facing 19mm | Kraft paper | Polyurene Foolder | 44. | 25. | - |

| Thermobick. | 122. | 40. | five | Ceramic facade tile | Waterproof | Polyurene Foolder | - | 22. | 0.033 |