Thermal insulation materials: the advantages and disadvantages of various materials, the field of application, the level of thermal conductivity.

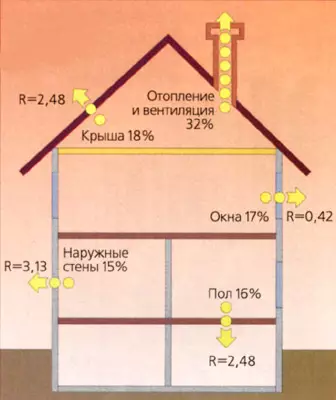

Recently, new regulatory documents on heat saving and during the reform of housing and communal services are extended by the principle of the bottomless payment of thermal energy. That is why the thermal insulation of residential buildings becomes one of the most important problems of construction.

Thermal insulation materials are divided into several large groups:

Glass and fiberglass;

Mineral wool;

Gas-filled polymers (foam): polystyrene and polystyrene foam, polyurethane and polyurethane foam, polyethylene, polyester, from phenol foam;

Thermal insulation from natural materials and products of their processing (traffic jam, peat blocks, paper, etc.);

Thermal insulation panels and structures;

Modified concrete: cellular concrete (foam concrete), polystyrene bauton;

Heat insulation based on synthetic rubber;

Heat insulation from silicon production waste.

About 240mln is spent on heating in our country. Ton of conditional fuel. This is 20% of the total energy consumption of the country

First of all, the number of highly efficient belongs Glass and mineral wool materials The share of which in the production of thermal insulation in recent years is 40-60%. Their advantages are fireproof, chemical resistance, size stability, low moisture absorption and good sound-absorbing properties. It has long been known glass gambled of domestic production, which, despite all its shortcomings, it rushes, inconvenient in the work, is still applied to the most part for external work or for the insulation of non-residential premises. Recommend glasswater for the insulation of residential premises is impossible, but if it has already been done, it should be very thoroughly isolate it from the room itself.

Scope of main thermal insulation materials

| Type of insulating material | Walls | Roof | Floor | Ceiling | Foundation, Cocoln. floor | ||||

|---|---|---|---|---|---|---|---|---|---|

| Facades | Outdoor | Internal | Masonry (medium layer) | Three-layer panels | |||||

| Fiberglass and fiberglass URSA, ISOVER | +. | +. | +. | +. | - | +. | +. | +. | - |

| Mineralovate | +. | +. | +. | +. | - | +. | +. | +. | - |

| Prestimal expanded polystyrene PSB | +. | +. | +. | +. | +. | +. | +. | - | |

| Extrusion polystyrene foam | +. | +. | +. | +. | +. | +. | +. | +. | +. |

| Foil polyethylene foam | +. | +. | +. | - | - | +. | +. | +. | +. |

| Corkboard corkboard | +. | +. | +. | - | - | - | +. | - | - |

| Paper Equouth Makron. | +. | +. | +. | - | +. | +. | +. | - | |

| Peat-free blocks "Geocar" | +. | +. | +. | +. | - | - | +. | +. | - |

| Cheat foam concrete | +. | +. | +. | - | - | - | +. | +. | - |

| Polystyrevbeton NIIZB | +. | +. | - | - | - | - | - | ||

| Based on synthetic rubber (*) | - | - | - | - | - | - | - | - | - |

| From silicon production waste | +. | +. | +. | - | - | +. | +. | +. | +. |

* - Synthetic rubber-based thermal insulation (ArmaflexHT and AC) Applicable only for pipelines

Now high-quality thermal insulation are widely represented on the Russian market. Materials from fiberglass Several foreign and domestic manufacturers. These materials are somewhat more expensive, but with them much easier and more convenient, and most importantly, it is safer to work. Forward the queue you need to mention the two largest manufacturers of thermal insulation materials. Isoveroy (Finland) is a subsidiary of the largest and oldest glass manufacturer in the world concern Saint- Gobain (France). Isoveroy produces glass gamble C1941g. and is the largest manufacturer of building heat-insulating in Finland (trading march Isover ) and acoustic ( Akusto. ) Materials. The annual production of glass gambles exceeds 40000 tons. This company is one of the largest suppliers of thermal insulation materials to Russia.

The manufacture of fiberglass occurs at almost 1500s. The molten glass is pressed through plates with holes with a diameter of 4-5 microns. The resulting glass fibers have a thickness of approximately 6micron, which B20 is less than the thickness of the human hair. Then, to clean them between themselves, special binders are sprayed onto the aerosol. Of the resulting glass mass, the products of the desired thickness and density that come to heat treatment are molded. At a temperature of 250 ° C, polymerization of binders occurs, and the material acquires the necessary rigidity. At the same time, various facing materials can be applied to the surface of the material: kraft paper, aluminum foil, fiberglass, nonwoven materials, etc.

Domestic fiberglass thermal insulation materials are produced in the form of rolls (101.6 m and 50mm thick) under the brand name "Termavoyozol" (Chant. = 0.036 W / (MK).

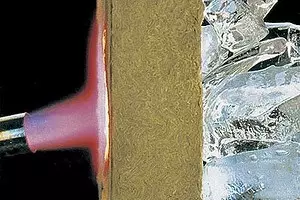

Recently, the largest competition is the "stone", and more precisely as familiar glass insulating materials. Basalt, wats Rockwool. (Denmark) and Paroc of PARTEK (Finland). This is a non-aggravated environmentally friendly material with water-repellent properties, but at the same time vapor-permeable. In its heat-insulating properties, basalt materials are superior to glass gambles, however, they are more expensive. These materials refer to the group of non-aggravated. Thermal insulation products made of polymers or paper in the fire are burned for 5 minutes. Heaters made of glass grooves at a temperature of 650c, which is achieved approximately for 7 minutes with a conventional indoor fire, melted and sintered into a glass ball. Now, the mineral wool on basalt basis is not melted and does not lose shape even at a temperature of 1000c.

Glass and basalt insulating materials are safe for production and use subject to the recommended work technology

Rockwool Concern is the world leader in the production of construction and technical isolation based on the "stone".

One of the most effective types of thermal insulation - gas-filled polymers. The most common and widely used of them is Polyfoam (polystyrene foam) . The reduced heat resistance and the flammability of foams are not a hindrance when using them in layered structures together with concrete or brick.

The polystyrene foam is made by the prestickable method (traditional for Russia), or the extrusion method developed more than 30 years ago BASF concern (Germany).

The coefficient of thermal conductivity, which is the main indicator of the thermal insulation properties of the material, significantly depends on the content of moisture in it, each percentage of which reduces this coefficient by 4%. In addition, in winter, present in moisture polystyrene foam plates, freezing and turning into ice, gradually separates the material on individual granules, which sharply reduces the durability of the prestickable polystyrene.

Technical parameters of some heat-insulating materials

| Type of insulation | Coefficient of thermal conductivity, W / (MK) |

|---|---|

| Facade panel Polyalpan. | 0.02. |

| Air | 0,022 |

| Polyurene Foolder | 0,025 |

| Styrisol (expanded polystyrene) | 0,027 |

| LOW-E (Fenofolgic Heater) | 0,027 |

| Raroc (basalt wool) | 0.035 |

| Rockwool (basalt wool) | 0.035 |

| Polyeneetylene PPE-R 3010 | 0.035 |

| Insulating rolls Linoterm | 0.036 |

| IsOver (Flag) | 0.038 |

| Nobasil (basalt wool) | 0.039 |

| "Penosole" (foam) | 0.04. |

| Corkboard corkboard | 0.042. |

| URSA (Flood) | 0.044. |

| Equata (Paper) Makron | 0,046. |

| Dekwall (cork insulation) | 0.047. |

| Ceramics | 0.07 |

| Peat-free blocks "Geokar" | 0.07 |

| Bituminous asphalt | 0.1. |

| Heat insulating cellular concrete | 0.12. |

| Solid wood | 0.25. |

| Dry sand | 0,3. |

| Neasavoclave foam concrete | 0.45 |

| Fibrocement | 0.55 |

| Funny brick | 0,7 |

These shortcomings are devised Extrusion polystyrene foam . Having a very low water absorption (less than0.3%) due to the closed structure of cells and high mechanical strength, the panels of extrusion polystyrene foam can be used for external heat insulation, for thermal insulation of underground parts of buildings, foundations, basement walls, where the use of many other insulation is impossible for capillary lifting of groundwater. In the Russian market, extrusion polystyrene was represented by the BASF concern (Germany) under the brand stirodur (Kompl. = 0.027-0.033 W / (MK).

But the polymer thermal insulation material is not limited to the polystyrene fiber. It has long been well known material, which allows you to simultaneously solve the problems of thermo-, sound and waterproofing. it Extruded polyethylene foam (PPE) . It is produced in Russia for more than 10 years (TU 6-55-26-89E) and the framework of builders under the brands of PPE-P and PPT-RL and the "hairpiece". A wide range allows you to choose exactly what is needed. PPE produces various thicknesses: from thin sheets to thick flooring (from2 to 15 mm) and supplied in rolls with a width of from0.5 to 1.5 m and up to 200m. This material is absolutely safe for health and, importantly, biologically racks. Since the PPE has a closed structure, it has practically no moisture absorption and when using it, an additional vapor insulation layer is not required. On the Russian market now there are similar products of foreign firms, however, it is much more expensive.

An important dignity is the simplicity of installation of such a thermal material: it is attached to the walls using a construction stapler. As a disadvantage, it is worth noting that this insulation is absolutely vapor and gas-reading, i.e. The room ceases to "breathe" and, if it is not to ventilate, you can encounter the effect of the thermos or greenhouse.

The heat-insulating materials with a thermal conductivity coefficient of less than 0.06 W / (MK) pay off in 5-7 years of operation due to energy savings.

Another very interesting group Thermal insulation made from natural materials and products of their processing . Increased insulation materials manufactured from paper waste with sawdust, perlite and other binders and fillers. Impregnated with substances to reduce moisture absorption, antipirens to give the material of non-combustible and antiseptics, such materials have good heat insulating properties (grade = 0.078 W / (MK) and can be used to insulate out outer and inland walls, ceilings. Materials are issued as an eco-water or in The form of panels.

The original thermal insulation material is designed in the city of Khezhetsky Tver region. Peat-free blocks "Geocar" . Located in the outer wall, blocks (0.510,250,88m) are capable of withstanding a load of 8-12 tons of us2, and the thermal insulation properties of the wall of such a material with a thickness of 0.5m correspond to a brickwork with a thickness of 2.2 m (graft. = 0.078 W / (MK) . And the unconditional dignity of this material is its ecological purity.

Quite new heat insulator are Plates and rolls from pressed cork . The material is made from the outer layer of the cortex of the Mediterranean cork oak. Products made of extruded tube have an attractive appearance, they are environmentally friendly and are used for the internal insulation of residential premises, mainly walls, while performing a decorative trim function. Cork is often used for insulation of floors. Corkboard thermal insulation shields can also be used for insulation of facades and exterior walls.

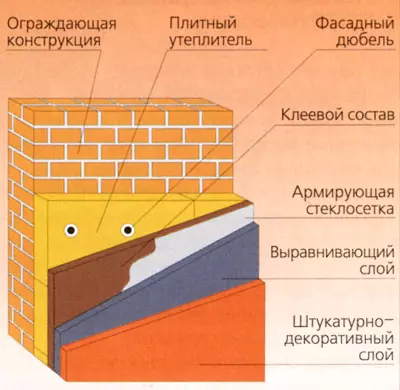

Need to mention O. Special Building Heat Insulation Systems , such as the "warm house", "Fassolite", Ispoterm Wall, about heat-insulating facade sandwich panels (Polyalpan, Isoterm, Pflaum, etc.) and on the systems of the intimidated formwork ("isode 2,000" and "thermomour").

So, having started the insulation of your home, you have an excellent opportunity to choose and use those heat-insulating materials that are best suited to solve problems facing you.

Technical parameters of some glass and mineral wool insulation

| Firm Manufacturer | Material | Brand / View | Coefficient of thermal conductivity, W / (MK) | Price, $ / m2 |

|---|---|---|---|---|

| Isover (Finland) | Glasswater | KT-11 / Roll | 0.041-0.036 | From 2. |

| CT / roll | 0.041-0.036 | |||

| KL / stove | 0.041-0.033 | |||

| KL-A / Plate | 0.041-0.033 | |||

| URSA (Russia-Germany) | Glasswater | M-11; M-15; | From 3. | |

| M-17 / Roll | 0.046-0.044 | |||

| P-15; P-17 / Plate | 0.046-0.044 | |||

| Paroc (Finland) | Basalt Vata. | IL / stove | 0,0365 | From 6. |

| A-IL / Plate | 0,0335 | |||

| IM / roll | 0,0365 | |||

| Rockwool (Denmark) | Basalt Vata. | Flexix Batts / Plate | 0.035 | From 5. |

| Batts-42, -40, -48 / Plate | 0.035-0.033 | |||

| -80; -100; -160 / stove | 0.035-0.033 | |||

| Rollbats / Roll | 0.036 |