Choice of equipment for boiler room: main components; Types of boilers, boilers, burners; New approach to the strapping.

From the interaction of the boiler and the distribution system, heat and comfort in the house are directly dependent. Therefore, it is necessary to reckon with the fact that the modern boiler-complex unit saturated with the elements of automation.

Talk about choosing equipment for boiler room

Basic components for boiler room

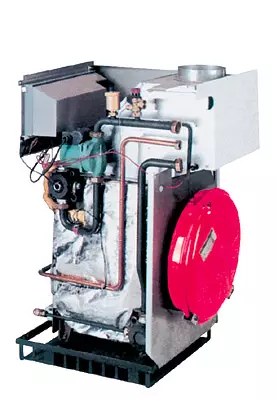

Despite the fact that the boilers of famous Western firms are able to work uninterrupted within 25-30 years, their dealers in Russia do not guarantee more than 1-2 years. This indicates that we have some problems with the competent choice of boiler and its further exploitation.The boiler and other household equipment for water heating (that is, the "nutrition of the hot water supply system, DHW") is called boiler equipment. The agencies where it is located (in the boiler room) you can highlight four main elements: boiler, burner, automation and strapping. In this case, under the strapping, it should be understood as a set of connecting pipelines together with a shut-off, control, control and additional reinforcement and units connecting all equipment into one system.

The strapping should create normal conditions for the operation of the boiler, and if it is mounted unsuccessfully, then trouble with heating is not avoided. Watering cases of strapping are sold together with the boiler, in others, they need to be purchased separately and mounted on the spot. As it should be reflected in the project. Consider, different firms complete the boilers are completely different. Do not "buy" to the small price of the boiler. When buying, be sure to specify what exactly is included in the package of equipment.

Boilers

The choice of a particular type of boiler is determined primarily by the predominant fuel type in a given area and your financial capabilities.

Electric boilers. When they are installed, the main problem is to achieve permission to supply the desired power supply power (a very difficult case with more than 15 kW) and pave an electrical cable for this. The most appropriate use of electricity for heating cottages is the use of the "Scandinavian package", when electric heaters (Tenni) are used as an auxiliary heat source at night, for example, with the help of Cottles of ESAV (Sweden), ZAO "Stanav-M" and others. and pay at the night rate (which must be documenting).

The cost of the boiler is 40-70% of the cost of the entire boiler room, which, in turn, is 30-50% of the cost of the entire heating system and ranges from $ 15 to $ 30 € 1m2 of the total area (kinmera, in addition.)

For reference (according to the leading specialist of the company "New Russian House" S. Sokolov): 20 years of operation The total costs associated with the heating of the house with an area of 150m2 will be (focused on January 1999) when using the boiler: electric- $ 23 thousand, diesel $ 14.6 thousand. and gas- $ 8,6 thousand.

Gas boilers. First of all, you will have to "collect" a lot of documents: permission to a supply to the house of the gas pipeline, permission (separathnadzor) on the use of this boiler with a given burner or with other models of burners from a certain list, the act on the delimitation of powers between the buyer, a gas management trust and service Service and a few more different papers. Gasket gas pipe will cost you about $ 50 per stranded meter. The main source of problems when installing the gas boiler of the gas pressure (especially in winter) to 6-8 mbar (60-80mm water. Art.). At the same time, many import burners cease to work normally, because Designed for European pressure standards (from15 to 20MBar). You have to look for a boiler with more reliable burners.

Liquid fuel boilers (often they are called diesel). Remove there is no paper red tape, but there are other difficulties. So, due to the increased sulfur content in the domestic fuel, the products of its combustion are very aggressive and further enhance the corrosion of the equipment. In addition, additional troubles arise due to the need for filtering it. Listening to this type of fuel boiler for the season requires quite a lot (7-10 tons). For its storage and freezing protection, special tanks are needed (worth at least $ 2000) and a separate room. It is also necessary to ensure the possibility of entry of the tanker and take care of the periodic cleaning of the tanks.

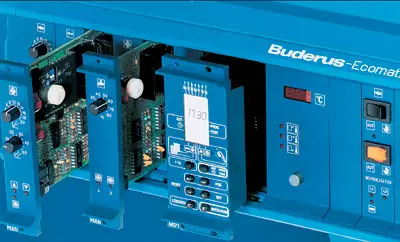

Now in the market of boiler equipment you can select three categories of prices. High quality prices have products of such firms with global reputation as de Dietrich (France), Wiessmann, Buderus, Vaillant (Germany), CTCAB (Sweden). At average prices and with high-quality support of basic functional and consumer properties, boilers of the company Bosch (Germany), Teledyne Laars (USA), Roca (Spain), etc. Cheap and at the same time good boilers are offered by ACV (Belgium), Protherm (Slovakia ), Soulic (Greece), "ZIO" (Podolsk) and others. Note that this price comparison is somewhat conditional due to different configuration of the boilers.

Knowing some subtleties will help make your choice justified. Therefore, we pay attention to the general signs of the designs of boilers, with which one way or another have to face the consumer. This is the material "shirt" (heat exchanger), the number of contours, the volume of "shirts", the dimensions and weight of the boiler. The heat exchangers are made of cast iron, corrosion-resistant steel and copper. The material greatly affects the design of the boiler, its layout, size and repair technology.

Choosing a boiler, watch the natural gas pressure necessary for the atmospheric burner does not exceed the 13 mebar (the less, the better).

The choice of the type of boiler is determined primarily by the predominant fuel type in this area and your financial capabilities. Good atmospheric burners should be stable at a gas pressure of 6-7 mbar.

Cast iron heat exchangers Make sectional, so easier to produce them and repair. Their main advantage is high resistance to corrosion. Cast iron boilers are usually more expensive than steel. They are more winned for liquid fuel and low-temperature boilers in systems with low water temperature, i.e. Where is the likelihood of condensate formation. But due to insufficient plasticity of cast iron, such heat exchangers are sensitive to mechanical and thermal shocks. Therefore, to feed cast iron boilers with cold water follows after their cooling or very slow (up to 6h). Such boilers are more demanding of the tune in the burner. Good, plastic cast iron uses De Dietrich, Buderus, Protherm.

Steel heat exchangers Can be performed in the form of various combinations of coils, cylinders and pipes. They are not so capricious to the terms of service, as cast iron, but inferior to them in resistance to corrosion. Therefore, in relation to them, various schemes of the boiler and water circulation are used so that harmful condensates do not stand out.

Copper heat exchangers In the form of coils and pipes are usually used for boilers of low power, wall performance. They require special attention, because When water leakage from the system immediately go. For the floor boilers "shirt" in the form of a single-row grid of short copper pipes applies TELEDYNE LAARS. It is easy to remove, clean or replace.

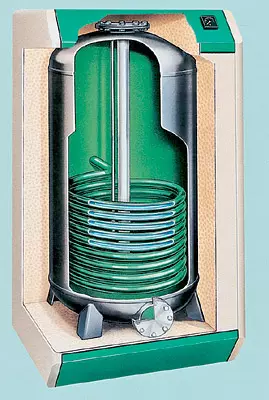

Boilers are single and two-kindy. Forward, one heat exchanger for powering the heating system. In the second case, the second heat exchanger for powering the DHW system was introduced into the design of the boiler. It can be a flow or capacitive (accumulative) type. The latter is usually called a boiler and apply more than flowing. As a rule, the volume of the built-in boiler makes small (up to 130l), so as not to increase the dimensions and weight of the boiler. This is quite enough for a family of 2-3 people. Single-mounted boilers are cheaper than double-circuit, but to have hot water in the house, to the first one must acquire a boiler. But the latter can be selected and placed on your own.

Boilers

The cumulative boiler of large volume (more than 200l) is sufficient that a family of 4-6 people can enjoy hot water in the usual mode. It is convenient to heat the water in it overnight up to 60s, and then only slightly warm. So economically, safer and scale is formed once a six less than with constant heating up to80c. But, in the warm, congestive water of the boiler can multiply harmful bacteria. It is useful to follow the following rule: water consumption install so that no more than 0.1 billboards pour out for 1 minute, then cold water-enclosed into the boiler will have time to warm. In addition, periodically water must be heated to 75-80s and withstand 10-20 minutes for disinfection. If the boiler power is greater than it is required to heat the water in the duct mode, the so-called may occur in its operation. "Tact", i.e. Fast and frequent short-term power on the burner. Naturally, it reduces the life of the boiler. Therefore, a powerful boiler simply needs a good automation that can solve this problem. Including heat exchangers Cold water is heated as under pressure under the heat transfer elements heated with water from the boiler. The main plus of such systems is always ready for the supply of a sufficient amount of hot water, but at the same time require greater power than capacitive boilers.

Regarding the volume of the heat exchanger of the boiler, specialists have different opinions. It is worth considering the consumer only two circumstances: the system with a low-pressure boiler can be easier and fill or merged faster; It reacts faster to the automation teams and therefore it provides a comfortable temperature in the house.

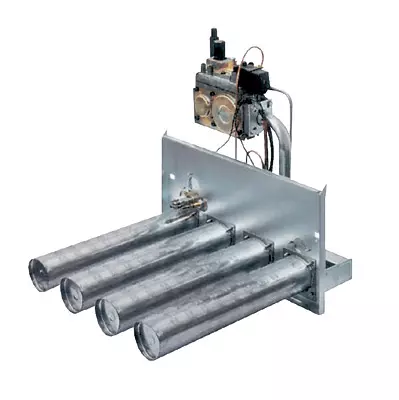

Burners

Gas burners are of two types: atmospheric (injection) and fan (blowing). Liquid fuel burners are made only by fan (or "capture"). So they are distinguished by the method of formation of combustible fuel-air mixture. Both types of burners, by and large, "squeeze" from fuel almost all possible. Next, already in the designs of some boilers, it is possible to carry out additional burning of fuel combustion products (so-called chimic hurry) and thereby increase it by k.p.d. (efficiency) and reduce the release of harmful oxides into the atmosphere. If kpd. The boiler you choose is 92-95%, do not look for the best, and consider other indicators. Do not try to buy a boiler with KPD. 100%, according to advertising. The figure of 100 is some trick of the calculation technique. Plots really can be obtained by adding heat, condensing water vapors resulting from gas combustion. The trouble is only that from 2-5 l / h of caustic condensate should be easily delivered. The easiest way to move into the sewer is destroyed at home treatment facilities. The civilized decision is to be processed in special recyclauses, unprofitable at our gas prices. Solid side, do not turn away from the boilers of American and Canadian producers, seeing the meaning of them k.p.d., equal to 80-82%. It is simply calculated differently than is accepted in Europe, and its value is 11% less than that of similar European heating boilers.

To reduce the fuel consumption, the burner can be two- and three-speed or smoothly changing power (modulating), for example, as in Bentone products (Sweden), Vaillant, Hansa (Germany), etc. All steps are included by the automation team only when The heat requires a lot, for example, if on the street it is cold or in a "bath" day. Usually one step works, and that on reduced power. This significantly prolongs the life of the boiler.

Atmospheric burners are cheaper than fan, work quietly and shipped with the boiler. Their main disadvantage-unstable burning at low gas pressure on the network, which is why the flame is approaching or "sits" on the burner, causing its burning.

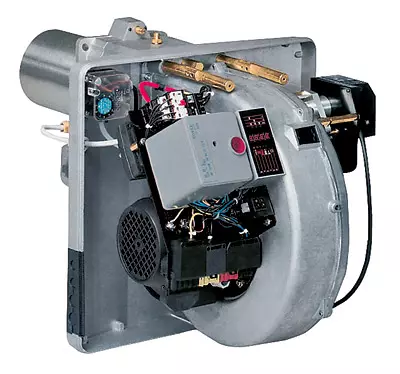

IN Fan burners The built-in fan creates an air flow that pulls out (ejected) gas from the nozzle. Therefore, such burners are not afraid of a gas pressure drop to 5-6 mbar. A good burner of this type is approximately as much as a single-circuit boiler of the average cost. Its main disadvantage of fan operation (up to 40-60 dB, like a vacuum cleaner). Therefore, the boiler with such a burner has to be put in a separate room.

Liquid fan burners Have a built-in pump for pumping fuel from the tank. They are noticeably cheaper than gas due to simplicity of fuel management scheme.

Fan burners can be placed on different boilers, the list of which is determined by the Gosgortkhnadzor. The battery of reliable practice models includes products of Giersch, Riello, Hansa (Germany), Bentone (Sweden), ELCO (Switzerland).

Automation

Automation is responsible for the safety of the boiler and takes the daily management of the system. It should also provide control functions: the presence of flame, the minimum and maximum gas pressure, the presence of diesel fuel, gas leaks, the presence of thrust in the chimney, the minimum and maximum temperature of the coolant and its circulation. Choosing a boiler, ask which of these functions are made by the supplied devices.

Regulation of water parameters (or other coolant used for heating) can be performed in several different ways.

In the simplest case, the value of room temperature and the room thermostat commands (costs about $ 40). When the temperature reaches the specified level, the burner is turned off and again turned on if the room has cooled. The method is not proteomic and small complex, because The boiler constantly issues water as much as possible, while in the rooms without a thermostat can be cool. Installing thermostats on radiators and a temperature sensor on a feed pipe or a thermostat built into the boiler allows you to reduce fuel consumption and raise climatic comfort in the house. Well, if you install an automatic heating regulator (from $ 500 to $ 1500), then adjustment in accordance with weather conditions and more a lot of amenities will be provided, but only if foreign automation will withstand the domestic level of power supply: voltage jumps, frequency and breaks in nutrition . Without the help of a voltage stabilizer, a network filter and a block of emergency power supply of reliable operation of a boiler room, as a rule, it cannot be achieved.

Bottle block

To fully use all the features of the selected boiler, it must be properly installed in place and connect with the distribution network of heating and the DHW system to the general system, i.e. it is necessary to make a strapping boiler room. In the event, a new approach has emerged in this area. Increasingly, the developers began to install in the boiler room instead of one boiler - two, but half-power each. In this case, one of the boilers can even be combined or calculated on the natural circulation of the coolant. Wet have its own sharms. First, the low probability of the failure of both boilers is immediately guaranteed that the house without heat will not remain. Secondly, the efficiency and comfort of the system increase. After all, the necessary power of heating is considered to be the temperature of the coldest days, and there are only about 15% of them during the heating season. When the boilers are two, the second is turned on if the demand for heat actually increases. Further. Each of them works with a longer working cycle, i.e. With a smaller number of turning on the burner, which increases its durability. Well, minus additional costs for the second boiler. True, a reasonable choice of boilers and other equipment of the boiler room, this lack can be loosen. For example, to create multilateral household boiler houses, Teledyne Laars has developed a new concept of a boiler room and a number of small-sized boilers with a capacity of DC24 D54kW for its implementation. At the same time, a two-cell boiler room at 240 = 80kW with a 200 liter boiler costs about $ 8,500 and mounted for 3-4 days. Agree that only one boiler can be bought for such money in some firms.

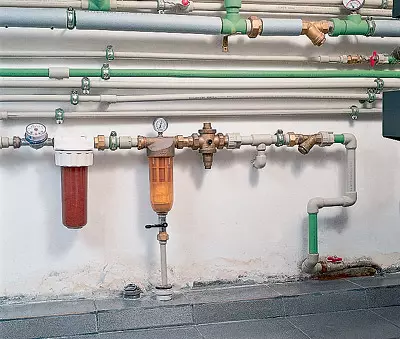

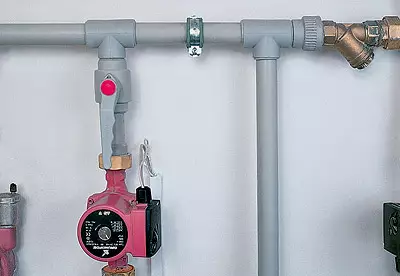

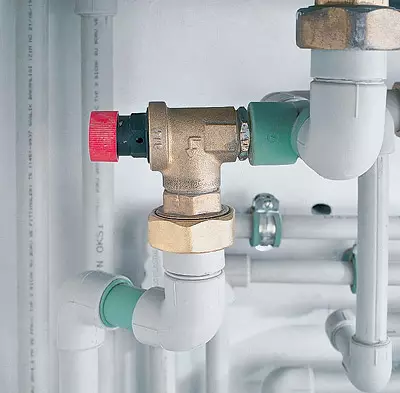

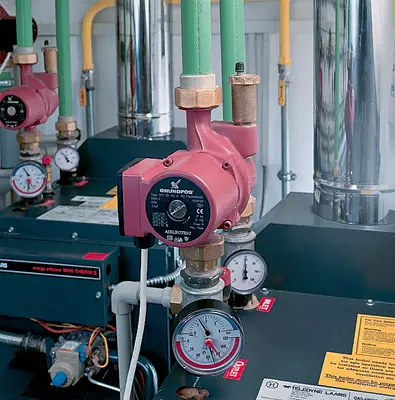

The essence of the new approach is as follows. Boiler or boilers feed the pump coolant into a short closed chain-primary ring. We make taps for feeding branches with heat consumers: floor branches with radiators, warm floors, and the like. - These are secondary rings. The boiler pump is pumped by the heat carrier only on the primary ring. Each secondary ring is equipped with its pump and "draws" from the primary ring so much warm as he needs. To coordinate the operation of the pumps of the primary and secondary rings, the selection of water selection and its return should be located nearby, not further 300mm from each other. If this common section of two rings is short, then it serves as a peculiar expansion tank for the secondary ring, which takes heat from it, without disturbing the work of the first ring. Such a scheme allows you to manage the minimum of pipes and shut-off valves. We will tell about such a strapping photo report.

Installation of the strapping of the boiler room begin after entering the gas pipe and install the gas meter, performing electrical wiring, the installation of sewage taps and the flow of cold water. The boiler must be installed on the floor with a non-splashing coating so that access to its inspection and maintenance is provided, and in front and for sufficient air access. Ventilation holes should be made with limited space. When feeding air from the street, the inlet should be of the size at the rate of 600mm2 on 1kW of the boiler power. The outlet chimney of the boiler is connected by a removable chimney with an opening in the wall of the room, which goes into the exhaust pipe of the building - chimney.

The chimney is the most important link of the system, providing traction, and such what is suitable for the burner of the boiler. Excessively long or large sections chimneys can lead to the supercooling of flue gases, and consequently, the deterioration of the thrust and the formation of a caustic condensate, which destroys the chimney, up to the failure in order for 5-7 years of its operation. Therefore, chimneys should be gas-tight, for example, carefully plastered inside, have optimal sizes and cleaning holes. Lord there are good chimensing stainless steel pipes (single and two-layer).

The obligatory element of the strapping is an expansion tank that serves to compensate for leaks and a thermal increase in the volume of coolant. Its volume is chosen by calculation, but it is approximately 10% of the water volume in the system. With a low volume of the tank, it is possible to reset hot water through a safety valve, and then the system will have to be replenished (fow) with tap water. Although such a feeding device is always included in the strapping, the frequent "podium" of water leads to the formation of scale inside the system and to corrosion of aluminum radiators. Installation of pipelines start after fixing the boiler and expansion tank. Plongs are mounted pumps, air and dirt discharges. Safety and drain cranes are installed on the boiler and the boiler. Pipelines are fixed on suspension holders so that the weight of the pipes, in particular the gas pipe, has not been transmitted to the boiler. Then the pressure gauges, thermometers, thermostats and temperature sensors are installed.

Electrical installation is performed, grounding is connected. Then there are various tests and thorough preparation for the trial launch of the finished boiler room, but the conversation should be separate about all this.

The editors thanks the director of the Moscow firm "RSK-Hydromontazh" S.V. Govoritsky for helping the organization of photographing and preparation of material.