The next stage of the evolution of furniture panels is laminates. Materials and technologies for the manufacture of laminated countertops and panels for lining wall.

How humanity persists itself, that natural tree is better, anyway, someone seeks to come up with something like a universal one, with which it is easier to work with less. Laminates from the area of "Power". In the last issue, the magazine talked about laminated floors, now it will be about tabletops and panels for wall cladding

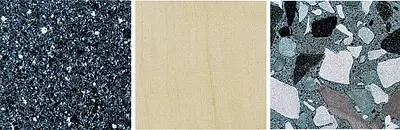

Laminates are another stage of the evolution of furniture panels after plywood, joinery shields, wood-shaped (chipboard) and wood-fibrous (Fiberboard) plates. Most of the word "laminate" is associated with a method of thermal packaging of documents between two sheets of transparent plastic. It must be said that Laminate is literally translated from English how to "split into thin layers." In essence, laminates are multilayer panels from chipboard, fiberboard, MDFs, or other wood bases, in certainly molded, on one or both plates (large surfaces) and the edges of which plastic is applied at high temperature and under considerable pressure. The domestic market of building materials is currently filled with relatively inexpensive laminates, among them there are wall interior panels, post-forming and laminated parquet.

Materials and technologies

Apparently, a big future expects wood-fibrous plates manufactured by a dry way. This material is commonly referred to as MDF, which is a MIDDLE DENSITY Fiber MDF MDF transliteration - wood-fibrous medium density stove. In the manufacture of these plates, additives of harmful phenolofehyde resins are reduced to a minimum, or refuse them at all (in the latter in the latter case it turns out to be a lignin contained in the wood). Due to this, according to its ecological indicators, MDF can be compared with natural wood. This material has twice the larger mechanical strength than the chipboard, and the nails and screws are kept stronger. The plates are produced with a thickness of 2.5 to 10 mm, and they can be glued under pressure, the resulting plates with a thickness of 12, 16, 19, 22, and even 28 mm. Finally, the MDF material does not have such flaws of wood, as the detail of properties, depending on the direction of fibers and the inclination towards cracking when the temperature and humidity is changed.

Wall panels

The basis of the set wall panels can be chipboard or MDF. The thickness of the type panels is 10-12 mm. It is usually produced in the form of a clapboard, that is, the boards width 125-200 mm and a length of 2400-3700 mm with docking grooves along the long edges. Unlike leafy, type panels are not necessarily fixed to the wall. Of these, for example, you can create a partition in the room. Docking panels without additional details, "board to the board", or using an intermediate insert. In both cases, the panels are not strengthened too tightly to each other so that they do not occur in the expansion or compression of the material. Wall-skinned walls, ceiling is similar to clapboard, only instead of nails use special brackets. However, those who decide to design the interior with similar materials should be kept in mind some "national characteristics". In our houses, the walls and floors are far from always perfectly smooth. This means that mount panels directly on the walls can not, the irregularities of the latter have to be compensated by using the crate, selecting the rails of various thicknesses, and part of the panels must be written in accordance with the ceiling height. At the same time, it should be borne in mind that, firstly, the lattice "steals" is completely useful one or two square meters of the area, and, secondly, the cavities between the wall and panels can give the shelter not only dust, but also to home parasites.

Wall panels

| Distributor | Manufacturer | The foundation | Dimensions, mm. | The number of colors | Price for 1 m2, $ |

|---|---|---|---|---|---|

| "Altais" | "Alta- profile", Russia | MDF. | 2600 x 148 x 8 | - | 3.9 |

| Kronospan, Poland. | MDF. | 2600 x 148 x 8 | fifteen | 4,2 | |

| 2730 x 200 x 8 | fifteen | 4.5 | |||

| "Inteko" | "Inteko", Russia | Chipboard | 2600 x 167 (202) x 11.5 | 13 | from 10. |

| DVP | 2600 x 145 (150) x 10 (12) | 13 | from 12. | ||

| "OMS" | WestProfil- Blancopan, Germany | Chipboard and mdf | 2500 x 148 x 8 | 27. | 6.5 |

| 2600 x 150 (160,195) x 9 | 24. | from 7. | |||

| Petropropal | Petropropal, Russia | MDF. | 2600 x 168 x 8 | 17. | from 6. |

| 2600 x 192 x 8 | 17. | from 6.4. | |||

| "Profileline" | "Profileline", Russia | MDF. | 2600 x 148 x 7 | eleven | 3.9 |

| "Resource-Import" | Kronospan, Poland. | MDF. | 2730 x 200 x (8 and 10) | 12 | from 6.2. |

| 2600 x 148 x 8 | 12 | from 5.9 | |||

| SP "ETM" | Classen, Germany | MDF. | 2600 x 160 x 8 | - | 8.5 |

| "TUCH" | Hornitex, Germany Osmo, Germany | Chipboard | 2620 x 2070 x (8-28) | - | 6.9 |

| Chipboard (MDF) | - | - | eight | ||

| "MORNING" | Georgia- Pacific, USA | MDF. | 2440 x 1220, Thickness 3.2 and 4.3 | four | from 15.4. |

| Kronospan, Poland. | MDF. | 2600 x 148 x 8 | - | 5.9 | |

| 2730 x 200 x 10 | - | 6.8. | |||

| Xm. | HDM, Germany | Chipboard | 2600 x 168 x 10 | nine | 12 |

| 2600 x 168 x 12 | fourteen | 12 | |||

| 2600 x 180 x 12 | 22. | 16.5 | |||

| 900 x 300 x 12 | five | nineteen | |||

| MDF. | 2600 x 168 x 8 | 6. | fifteen | ||

| 2600 x 180 x 12 | fifteen | 23. |

Postforming

Postforming is a technology for the production of laminated tabletops, windowsill and similar plates. However, the name was fixed and for the products itself. Postforming, in fact, represents the same laminate as the wall plate, but its lower surface is covered with plastic without pattern. Another difference in postforming from the wall panels is that there are no grooves for pillars at its end, but the front edge is molded in a certain way. It is rounded or has a complex profile. On the stove for kitchen countertops is similarly decorated only the front edge, and the plates for the manufacture of shelves and window sills have three rounded edges.Use postforming mainly for the manufacture of kitchen and office furniture.

Postforming

| Distributor | Manufacturer | Name | The foundation | Dimensions, mm. | Variety | Price for 1 pc., $ |

|---|---|---|---|---|---|---|

| "Altais" | Kronospan, Poland. | Countertops | - | - | - | 45. |

| Window sills | Chipboard | 3060 x 300 (400) | 3. | From 36.6. | ||

| "OMS" | Alpex-Karlin, Poland | Countertops and window sills | Chipboard | 3050 x (300-800) | 12 | From 43 to 125 |

| 2440 x (300-800) | 12 | From 35 to 100 | ||||

| "Resource Import" | Kronospan, Poland. | Countertops | Chipboard | 3660 x 600 x 28 | - | From 50. |

| Window sills | Chipboard | 3050 x 600 x 28 | - | From 50. | ||

| "SCYTHIAN" | Skiff, Russia | Countertops and window sills | Chipboard | 3000 x 600 x 28 | More than 35. | 45. |

| 3000 x 600 x 40 | More than 35. | 61. | ||||

| "Sothery" | Alpex-Karlin, Poland | Countertops and window sills | Chipboard | 3050 x (300-800) | 12 | From 43 to 125 |

| 2440 x (300-800) | 12 | From 35 to 100 | ||||

| "STROYINVEST-2000" | Kronospan, Poland. | Countertops and window sills | Chipboard | (2800-4050) x (300-1200) | 32. | From 45 to 65 |

| "TUCH" | Westag amp; Getalit, Germany | Window sills | Chipboard | Length - 4100. | - | From 48. |

| Countertops | Chipboard | 4100 x 600 x 29 | - | 85. | ||

| Also | Chipboard | 4100 x 600 x 39 | - | 95. | ||

| "MORNING" | Kronospan, Poland. | Countertops | - | 3660 x 600 x 28 | - | 48.6 |

| 3050 x 600 x 28 | - | 48.6 | ||||

| Xm. | HDM, Germany | Countertops | Chipboard | 2800 x 600 x 28 | thirty | 41. |

| 2800 x 600 x 38 | thirty | 48. | ||||

| 3720 x 600 x 38 | thirty | 63.5 | ||||

| Window sills | Chipboard | 2750 x 200 x 38 | four | From 38.5 | ||

| 3000 x 300 x 22 | 3. | From 28. |

Edge stickers (edges) and accessories

All of the above plates, except for two large surfaces (or plastics), have, as well as the edges (ends). When the edges are not covered with plastic, all layers of laminate can be seen on the cut. They decorated with special stickers based on the melamine resin, which has a high heat resistance. These are either self-adhesive tapes or tapes without adhesive base.It is necessary to add that in stores selling those or other decorative laminate slabs, usually there are a variety of profile details: cartlers, plinths, eaves and others that are manufactured by the same technology as laminates.

Accessories

| Distributor | Manufacturer | Name | Dimensions, mm. | Variety | Price |

|---|---|---|---|---|---|

| Petro Profile | Petropropal, Russia | Plinth | 2600 x 50 x 8 | 17. | $ 3.4 per 1 m2 |

| "OMS" | Alpex-Karlino, Poland | Edge stickers | 31 and 40. | 12 | $ 2.5 per 1 p / m |

| Profile elements | 300 and 600. | 12 | From $ 4 for 1 p / m | ||

| "SCYTHIAN" | Skiff, Russia | Edge stickers | 3000 x 35. | More than 35. | $ 3.5 per 1 pc. |

| "Sothery" | Alpex-Karlino, Poland | Edge stickers | 31 and 40. | 12 | $ 2.5 per 1 p / m |

| Profile elements | 300 and 600. | 12 | From $ 4 for 1 p / m | ||

| Skhodnenskaya Factory | Skhodnensk Factory, Russia | Profile elements | - | - | From 6 to 30 rubles. For 1 p / m |

| "TUCH" | Westag amp; Getalit, Germany | Edge stickers | 4100 x 45 x 60 | - | $ 4.2 for 1 pack |

| Plastic plinth | 4100 x 33 x 33 | - | $ 18 for 1 pc. | ||

| "MORNING" | Gossen, USA | Profile details | - | - | From $ 10 per 1 pc. |

| Xm. | HDM, Germany | Edge stickers | 32 and 43. | thirty | From $ 0.5 per 1 p / m |