Glazing of the facade and roofs using translucent structures: Review of specialized systems, extinguishing technology of the facade profile design.

Probably, admiring the magnificence of heaven, the man came to the idea of creating transparent buildings of glass and metal, and in particular glazing the facade and roof using translucent structures.

Since the usual wooden window frames at a large glazing area do not maintain their own weight, abundant precipitation and strong wind, engineers have come up with a new system called "profile". This is a supporting design consisting of a complex configuration profiles. It is used for insulation and glazing facade, balcony, veranda IT.P. Among such structures, the facade systems are most of the structures.

Electrode, a set of drills, a screwdriver, a plunger gun, scissors, as well as a conductor (similar to the composter in the tram, a special device in which there is a necessary number of holes located in the desired manner and serving to direct the drill). The conductor "put on" at the end of the profile and is used as a template when drilling mounting holes in it.

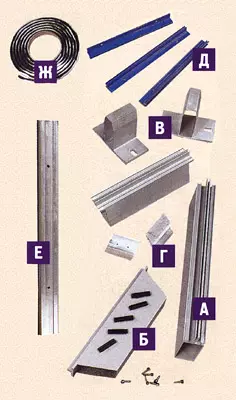

Materials used[BUT] racking profiles [B] transverse profiles (riglia), [IN] Aluminum "shoes" of the D-shaped (mounting nodes, with which the base of the rack profiles is attached to the foundation and walls), [G] Aluminum T-FORBRDERS (segments of aluminum sewller, serving for connecting rheel and rack profiles), [D] Aluminum corners for windows, [E] clamping strips, three glasses with a thickness of 10 mm and a size of 30 40 cm, [F] Roll of self-adhesive butyl tape, screw screws, plastic gaskets for glass, decorative facial planks, sealant cartridge.

Facade systems

A variety of facade profile systems, despite the external differences, have common functions and objectives: protection of facilities from atmospheric influences, facade design, decreased material consumption and acceleration of construction.

[one] Using the "conductor", fixed on the profile of a clamp clamp, drill holes for connecting the rack profile with T-FOREBIDERS and BRIGHELS.

[2] Attaching T-FORBRDER screwing screws at one end of the rack profile, the latter is put on another end on the "shoe".

[3] T-FORBRDER, profile and "shoe" are drilled through and fasten with screw-based screws.

[four] All T-FORBINDERs are installed and fixed on a rapid profile, laid in the grooves sealing rubber and cut off the excess with scissors.

According to functional features, these systems can be divided into two groups: mounted and translucent. The first are divided into ventilated and heat-insulating. One of the varieties of mounted ventilated facades are facades from siding. Plug-insulating structures as insulating materials use polyurethane foam, polystyrene foam, foam or Rockwool plates. We have already written about attached facades in more detail in our journal (see the article "Hinged Ventilated Facades").Glass unit systems for facades and windows

Systems are based on the use of single, two-or multi-chamber profiles from aluminum alloy. The camera is the cavity inside the profile. The separation on the camera is made to increase thermal resistance. Punching zones of the heat flux breaks between the chambers in more complex structures are used insulating jumpers (thermomosts) from plastic, such as fiberglass reinforced polyamide. Thus, the resistance of heat transfer from a three-chamber profile with a thermal survey is not less than 0.36m2C / W. To install glass, various sealing and connecting parts on profiles, grooves and deepening of different shapes are made. At the same time, aluminum structures are superior to the rigidity of the B7, similar articles of wood and B23RAZ - from PVC. To give the room a more noble view from the inside, wood or plastic is used to finish aluminum profiles.

[five] On the brigates, at the place of installation of glass, attach aluminum corners, pre-applying a layer of sealant on their "sole".

[6] On T-FORBERDERS install the riglels.

[7] The top strips of riggers are attached to the rack profile by self-draws, whose caps are hiding under the sealing rubber.

[eight] Collecting the module's flaps, the installation of glasses, using plastic gaskets.

In addition to the strong support for translucent facade systems, special windows are needed. To improve the indicators of sound and thermal insulation, strength and impermeability for ultraviolet rays, most often used double-glazed windows of two or more sheets of glass of one or different species. The space between them is filled with air or gas and sealed.The combinations of various types of glasses make conditions in the house more comfortable. For example, if the windows come out on the south and summer, the room is raised under the scorching rays of the sun, it is advisable to put the glass reflector, which will reflect up to 43% of sun rays. In order to save heat in the room, it makes sense in the inner layer of glass package to make from K-glass. If straw winds blow in your area, the best solution will be the use of reinforced glass. It not only withstands wind pressure by speed up to 60 m / c, but also limits the spread of fire and smoke during the fire, as it does not destroy under the action of high temperatures. Because of the increased crime rate, the factor of housing was important. Therefore, facade glassyuminous systems that are protected from hacking and shelling were developed (using armored glasses). In appearance, their protective elements are no different from ordinary, and they are compatible with the standard components of the base system.

[nine] Having placed self-adhesive tape on the perimeters of the glasses, in special grooves screwed the clamping planks in such a way that their edges overlap the edges of the tape.

[10] In the skate systems, the roofs and visors are used by special skaters, which are attached to the reference profile.

The idea of the diversity and the use of facade systems gives a table in which the characteristics of only four systems of each of the main manufacturers are given.Facade profile designs, like bee honeycombs, consist of separate modules (the module is an autonomous element and can be made separately from others). Standardization of connecting parts makes it easy to combine elements of various systems not only than one manufacturer, but also from different firms. For example, you can combine the systems of warm and cold facades, the system for winter gardens with a system of inclined roofs and create buildings of a wide variety of geometric shapes.

Mounted "Wide" profile

We will illustrate the essence of the construction technology of the front profile design on the example of the assembly of a reduced copy (model) of the module for the Winter Garden. This module and its model have been designed based on the elements of the Schuco FW50S profile system. The module is three sash, located at an angle of 150 each other and framing double-glazed windows. The elements from which the module model is collected are shown in the picture.

[BUT] In the manufacture of double-glazed windows, you can use combinations of various glasses (tinted, reinforced and other).

[B] Wood aluminum structures are collected from multi-chamber profiles. Decorative wooden planks are glued to the surfaces of the profile that will be indoors.

[IN] Single-chamber profiles are used in systems for cold facades and external supplies (Alpha Wall system of the technocket).

[G] The internal cavity of the profile working chamber in the cold facade system is filled with polyurethane to the installation of glass (the system "visible progress" of the Mosmek company).

[D] In the facade systems, warm and cold glazing is used at the same time (the system "seen the progress of SPL-06" of the company "Mosmek").

The location of the sash under the desired angle in relation to each other is ensured by milling the side surfaces of the riggers adjacent to the racks. Under the same angle, T-Forbesters, which will be attached to the riglels. Drilling all the mounting holes and taking all the details, you can go to the assembly. This process begins with the mounting of T-FOREBERS to the side surfaces of the rack profile at the same level on both sides. Each T-FORBINTER turns the corners of the corners of the side into which the rigleel will be deployed, and fastened to the racking profile by four self-pressing. Then the base of the rack profile is put on the thickened part of the "shoe" and is attached to four screws. To create a glass stops, aluminum corners, wrapped with sealant, are screwed onto the inner surfaces of the upper and lower riggers (designated in the photo in blue). On the perimeter of the resulting frame in special grooves on transverse and rack profiles, segments of the sealing cord are laid. Now the preparatory work is completed and you can start the main assembly. Rigels are put on T-FORBRIDERS (already fixed on the rack profiles) and screws are screwed to them and to the top plank of the rack profile, while the screws of the screws screwed into the upper bar are hiding under the sealing rubber. Having absorbed this way the entire module, proceed to the installation of glasses. It is appropriate to note that in real conditions the construction of glass is inserted after fixing the structure, and they were put into place in this module only to demonstrate technology. Glasses are installed using plastic pads that prevent rattling and reduce the load on the glass. In order for water and dust to penetrate the inside of the room, a boutique tape is pasted around the glass perimeter. From above, it presses with straps, which are installed in special grooves in the rack and transverse profiles. From above, these planks are closed with lining, which are produced in different colors. The room shown in the illustration for the winter garden is collected from similar modules, but only large sizes. They inserted tinted double-glazed windows reflecting straight sun rays. People and plants feel comfortable in such a winter garden all year round. Let your home, "dressed" in the lungs, but durable glass mulware structures, will become lighter, spacious and cozy.