Decorative stucco plaster, variosystems and textured paints: what it is, the scope of application, technology of work, prices.

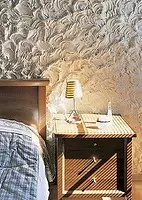

Photo: Zinur Outdins

Photo: Zinur Outdins

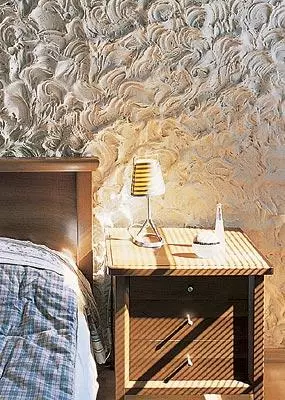

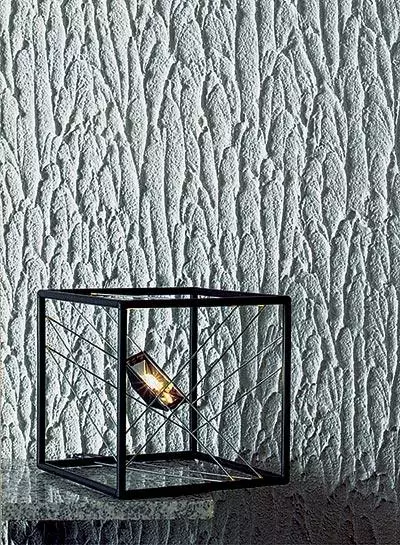

Photo: Evgeny Luchin

Photo: Evgeny Luchin

Over the past 6-7 years, many new finishing materials appeared on the Russian market of building materials, among which decorative coatings forming special interests, forming a variety of monochromatic or multicolor embossed surfaces. Consider them more closely.

In order for the surface painted or woven the surface well, it must be carefully aligned: because even small tubercles or roughness will be visible. People understood it for a long time and decided to create a special finishing material for the last layer; He had to possess, on the one hand, high decorative properties, and on the other, it would hide small cracks, surface defects and minor irregularities of the walls. The first attempts of its production were taken another 50 years ago. But only in 1994, the Russian market has fallen and rather quickly received the distribution of the Finishing Material of the Turkish company Bayramlar Grubu - Bayramix, which is a mixture of an acrylic binder with colored marble crumb. After him, a huge number of similar finishing materials appeared on sale, which were combined under one common name - decorative plaster, although many of them are not "real" plaster. As soon as we call them: both "plasterings", and a variety of "bertures", and even the intricate word "Stukko".

In order to figure out what it really means, it will have to look into the German, Anglo- and Italian-Russian dictionaries. The result speaks for himself: Putz (Him.), Plaster (English) and Stucco (Ial.) - This is three languages the same word and concept, namely - plaster. The appearance of various writing of these words in foreign firms in the prospectuses (for example, Pleister in the Dutch version or "Plaster" in Russian) is only unsuccessful and fairly meaningless borrowing. Even in Prospects, companies can be found the following phrases: "Structural, textured and textural decorative coatings". Differences that want to emphasize in this way are very conditional. Look in the intelligent dictionaries. The structure means the structure, the internal device, from the lat. Structura - location, structure. The texture is the structure (solid, wood, rock, for example, wood texture is a natural pattern of wood in context), from lat. Textura - textile, connection, connection. The texture is a peculiar quality of the material being processed, its surface (for example, wood texture, marble texture), from it. Faktura and Lat. Factura - doing.

So there are difficult distinctive signs of coatings based on these concepts, find it difficult. But since foreigners, manufacturers for their materials, some defining words are used, and translators are somehow interpreted, then sellers of decorative plasters are forced to look for their own summarizing explanations. Often they say this: "The textured plaster is easy to fix by adding a dye or just paint, while it is impossible to do it with structural plasters." Another version of interpretations: "When using structural plasters, the surface relief is formed as a result of special operations, and the texture is formed immediately after applying." But the term "textural coatings" has recently disappeared from use.

Of all these not very distinct interpretations and Sumbur with terms, one practical conclusion can be made: they can not succumb to the magic of foreign words - they wear, rather, advertising. To understand the peculiarities of a specific type of decorative plaster, it makes sense to more carefully treat those definitions that the word "coating" or "plaster" in the titles are preceded: for example, "relief", "mosaic", "under a fur coat", "roller", " Rust ". They, as a rule, speak not only about the appearance of the surface resulting, but also about the method of applying or leveling the material. Taking into account the foregoing, we turn to the review of specific materials. But at first a little refinement: In the future, we will only consider the decorative plasters that are more often called "relief" - with their help on the surface of the surface, a visually noticeable relief is formed (in contrast to say, from completely smooth Venetian plaster). According to the properties, they (though, only very approximately) can be divided into "actually decorative embossed plasters" - materials forming a fairly thick (1-6 mm) finishing layer, "textured paints" - it is much finest coatings (1-1.5 mm), and "variosystems".

So what is "decorative embossed plaster"?

It includes: a) something binder - most often it is a synthetic resin (which can be in the form of a dispersion or solution); b) filler; c) A variety of additives are such as solvent, thickener, preservatives, hydrophobic (water-repellent) substances, antiseptics and biocidal substances. By type of binder element, decorative plaster can be divided into two large groups: materials on aquatic and non-aqueous basis. And besides, they differ in the filler material, the method of applying and forming the surface pattern. But first things first.The basis of decorative embossed plaster . Most materials on the non-aqueous basis have epoxy resins and polyurethanes as binding elements. Their advantages include high wear resistance of coatings, resistance to aggressive media, strength and good adhesion to the base. Decorative plasters on an epoxy basis are used only for internal works, but polyurethane compositions can be fried surface and inside and outside the premises. After applying and drying, decorative plaster on the polyurethane and epoxy body bases are not supported. However, it should be remembered that when heated above 140s, the resin, which makes the basis of the material, begin to decompose with the release of toxic substances (decorative plaster based on epoxy resins, isolated compounds with chlorine, and polyurethane - cyanides).

In this regard, decorative water-based plasters are much more safe: polymers included in them, decomposing, do not emit poisonous substances. However, these plasters have its drawbacks: first of all - lower temperature resistance, that is, they cannot be applied to highly heated surfaces (more than 65-90 ° C), for example, water heating radiators. The most common binding elements of water-based plasters are acrylic, styrene acrylic, polyvinyl acetate (PVA) and butadiene-styrene dispersions. Coatings based on acrylic dispersions of the rack to ultraviolet rays and temperatures up to 90c; They are characterized by good vapor permeability and adhesion to the surface; They have excellent moisture resistance, although in this parameter are inferior to butadiene-styrene and styrene acrylic coatings. Styrene-acrylic coatings have even better water resistance, decent vapor permeability and considerable resistance to ultravioleti, but at a temperature of more than 65C begin to shrust. Butadiene-styrene dispersions have the highest moisture resistance, turn yellow, also at a temperature of more than 65C and do not possess vapor permeability. Well, and coatings based on polyvinyl acetate dispersions have limited moisture resistance, good vapor permeability, resistant to bright sunlight and temperatures up to 90c.

Fillers . With mineral fillers of decorative embossed plasters, the situation is much easier - they are three main species. This is a marble, granite and quartz crumb or mixtures thereof. The size of crumb grains may vary in fairly wide range: from 0.5 to 4-5 mm. In this case, the same material can be produced in several embodiments with a variety of crumbs. It is natural that its size affects not only the appearance and degree of surface relief, but also significantly affects the consumption of the material: the more, the higher the flow rate. It is worth noting that decorative plaster with large filler granules is preferable to use for the outer finish, as they look at such surfaces. Massed: so that the surface structure is noticeable, it should have a rather large relief. On the contrary, materials with a small fraction of crumbs are suitable for finishing inner premises - the surface will be less successful.

Now it is worth saying the features of each of the fillers.

Quartz crumb has an average adhesion with a polymer binder, a smooth surface, an abrasion stand and scratches.

The marble crumb has a good cloudy with a polymer, however, its resistance to abrasion and scratches are low. The grains of marble crumbs have a rough surface.

Granite baby also has a rough surface, medium grip with polymeric binders, good resistance to abrasion and scratches.

In addition to mineral fillers, polymeric granules can also be used in decorative plasters (Corail coating company SOFRAMAP), cellulose (DecoCril coating company SomeFor) or silk fibers (coating Oriental Coat FUDZIVARA CHEMICAL CO LTD).

Areas of applying decorative embossed plasters

| Basis of material | Floors inside buildings | Walls and ceilings indoors: | Facades of buildings | Casoccols of buildings | Maximum heating, with | |

|---|---|---|---|---|---|---|

| in raw | in dry | |||||

| Epoxy | +. | +. | +. | Up to 140. | ||

| Polyurethan | +. | +. | +. | +. | Up to 140. | |

| Acrylic | - | +. | +. | Until 90. | ||

| Styrene acrylic | - | +. | +. | +. | +. | Up to 65. |

| Butadiene-rigid | - | +. | +. | +. | Up to 65. | |

| Polyvinila acetate | - | - | +. | - | - | Until 90. |

Application : "+" recommended, "" allowed, "-" Not used.

How do embossed surfaces create?

By the method of forming a picture on the surfaces, decorative plasters can be divided into three large groups. The first includes plasters, the drawing on the surface of which is applied by the "method of display", for example, a relief roller, a slight knife, special brushes, brushes, broom or just with fingers.As an example of materials, the Kevyt-Rae Decorative Places of Kevyt-Rae company Tikkurila (Finland), KH-RollPutz TEX-COLOR (Germany), SPS-RollPutz Firm SPS (Netherlands) and them are similar.

The second large group is plaster containing a small amount of coarse granules of mineral filler and the forming surface according to the "method of combination". After applying to the wall, the mass is spattered with a spatula or ironing. At the same time, a drawing appears on the wall due to the corresponding movement of the filler grains: a) in the form of grooves and grooves - if the filler granules have a rounded shape; b) scratches or "beard" - if the grains of the filler are rough and have an irregular shape. These are imported plaster KH-RILLENPUTZ of the company TEX-Color, SPS-SPS-SPS-SpachTelPutz firms SPS, Bolix-RM firms of Bolix (Poland), DeKor + Firms of KaleteraSit (Turkey) and domestic Svyatozar-7-Decor of StroyKompleks (Russia), Plastone Tone Firm "Plastone" (Russia). Well, there is another very extensive group of decorative plasters (above them called "textured"), which are applied with a simple spatula, roller or spraying without any subsequent processing, and can be sprinkling with a smoother. At the same time, the surface, depending on the material used, becomes a monophonic or multicolor. One of the ways of applying such coatings is spraying with professional pneumatic equipment. It is quite expensive, and they usually use professionals. Sometimes it seems that such a method of coating is very simple, however, there are its subtleties here: for example, the skillful use of various nozzles to the pneumatic equipment with a hole diameter depending on the size of the filler particles; Regulation of spraying pressure and air flow, which together provide the optimal application mode and consumption of material. These parameters manufacturers usually lead on packaging products.

Decorative variosystems

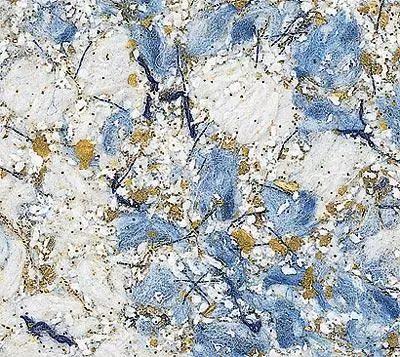

Decorative finishing materials, which have received the name of the "variosystems" from manufacturers, deserve separate consideration. Their main difference from decorative plasters is that they consist of several components that are consistently applied to the surface being processed. For example, the delivery of the Capaflock Vario System's decorative variosthem (Germany) consists of 3 packs: this is a Capaflock Call glue container, a box with multicolor particles Capaflock-chips and containers with transparent Capaflock-Finish lacquer. Recently, many similar materials have appeared on sale. This, for example, Jobi's JobiFloc chips system (Germany), Multicolor Spektra Domflok Spektra Domflok, Multicolor Decorative Coatings Luminence II and Luminence Grain Fin FIN FIRMAP (France), Mosaik Lack Firm Tikkurila (Finland) and many others.

Working with them is usually carried out in three stages. First, the glue composition is applied with a brush, roller or spraying, then on it, without waiting for drying, spray (with a special pneumatic pistol) chips or flakes - so that they completely closed the surface. For better clutch, as drying, flakes are rolled with a rubber roller. After the glue dries, a roller or spraying is applied to the final lacquer coating, which gives the material with high wear resistance and the ability to wash it. Perhaps the only disadvantage of such decorative coatings is that after applying the varnish, the treated surfaces cease to "breathe".

Some decorative variosystems

| Firm | Mark. | onecomponent | 2. component | 3. component | Note |

|---|---|---|---|---|---|

| Building complex | "Svyatozer-colorophil" | Glue | Multicolored flakes | Acrylic lacquer | Components are applied succession |

| Caparol | Capaflock Vario System | Capaflock Call | Capaflock-chips. | Capaflock-Finish | « |

| Job | Jobiflooc. | Jobiffloc-grundschieht. | Jobiffloc-chips. | Jobiffloc-finish | « |

| Soframap | Luminence II. | LUMINENCE-BASE. | Luminence-Flakes. | Luminence Vernis. | « |

| Helios. | Spektra Domoflok. | Domoflok Base | Domoflok-leaved | Domoflok-varnish | 2nd and 3rd components are mixed |

Decorative texture paints

Well, and to complete the overview of the decorative finishing coatings under consideration, it is necessary to at least briefly characterize another group of materials that called "decorative textural paints". They differ from ordinary paints high density and viscosity. The texture paint is applied with a brush, roller or spraying with a thick (1-1.5 mm) layer, and then with the help of special rollers with a ribbed surface, the desired drawing is given.

Here, let's say more than one novelty: granite, marble and quartz fillers, which are sold separately and can be used with the most different types of binders (in particular, they are proposed to be mixed with conventional colors). And there are systems in which the binding element and filler are supplied in different packages, and before use they need to be mixed, selecting the proportion to their own taste. As an example, a Catteau ADMS system can be cited, consisting of a container with a binder from styrene resins and marble crumb packaging.

Surface preparation

The surface should be durable, dry and clean, without traces of chalk, oil and silicones, not have significant irregularities and defects (more than 2-4 mm). Almost all firms in the description of the surface preparation operations with a mandatory requirement is the preliminary impregnation of the surfaces of the surfaces with special primers, which, on the one hand, are strengthened, and on the other, create conditions for a much better adhesion of decorative plaster with the wall.How much is "fur coat" for the wall?

Locusing prices for finishing decorative materials is very significant, but stacked in the range of approximately $ 1.2 to $ 8-10 per kilogram. It should be noted that different materials flow ranges from 1 to 6 kg per square meter - accordingly, the price of the decoration of the square meter will increase. The lowest consumption of material in variolations: for example, for the "holyting-coloroflock" the flow rate of the varnish and flakes is about 0.2 kg / m2, and varnish - 0.15 kg / m2 (as a result, the cost of finishing the square meter will be approximately $ 2, 8-3); CapAflock Vario System coating will cost about $ 8 per m2. Several more consumption of material in the case of decorative texture paints: 0.9-1.5 kg / m2. Their cost can range from $ 3 to $ 8-9 per m2. Well, of course, the highest flow rate (1.5-5 kg / m2) in decorative embossed plasters; It must be borne in mind that in the case of the use of plaster with mineral filler, its consumption directly depends on the size of the filler's granules - the larger the grain, respectively, the flow rate ($ 3-15 per m2).

Some of the domestic and imported ornamental coatings

| Firm | Mark. | The foundation | Fill Tel | View of the coating. Application area | Consumption of mother Ala | Dry *, a / b, h |

|---|---|---|---|---|---|---|

| Petrmix, Russia | Mosaic, plaster | Acrylic | Marble or quartz crumb | Mosaic and textured plaster for finishing facades and interiors for any surfaces, except silicone and plastic. | 1.5-3.5 | 4-5 / 24. |

| Plastone, Russia | Plastone-tone | Acrylic | Marble or quartz crumb | Decorative finishing plaster for indoor and outdoor use on concrete, metal, etc. | 2.0-4.0 | 2/24 |

| Construction Plex, Russia | Svyatozar-7 decor | Acrylic | Quartz crumb | For decorative protective coating of facades and walls indoors. | 0.5 | 1-2 / 24. |

| Akzo Nobel Sadolin Firm, Finland | Sadolin Sandokryl-G | Acrylic | Not | Structural paint. For internal and external works on concrete (including light), shutkatu- Fire surfaces. | 1-1,2 | 1/24 |

| Bayra- MLAR GRUBU, Turkey | Bayramix Mineral. | Acrylic | Granite and marble crumb | Decorative coating for finishing facades and interiors indoors on concrete, chipboard, wood. | 1.5-3.5 | 12/24 |

| Bolix, Poland. | Bolix Tu. | Acrylic | Quartz crumb | Universal plaster mass. For external and internal works. | 3.5 | 2-4 / 24. |

| Kalete- Rasit, Turkey | Dekor +. | Acrylic | Marble chips | For external and internal works. | 3.3-3.5 | 2/24 |

| Litex, USA | Corev-Stone | Acrylic | Marble and granite crumb | Decorative coating. For facade works on the decoration of walls and base, on any surfaces. | 1.2-1.6 | 3-4 / 24. |

| RM Distribu- Sion, France | Crepi Decor. | Vinyl copolymers | Quartz crumb | Relief coating. With external work for finishing facades and indoors | 1.5-2.5 | 0.5 / - |

| Soframap, France | Corail | Acrylic | Polymer granules | Multicolor coating. Indoors for wall decoration. | 0.45 | 8/8 days |

| SomeFor, France | DecoCril | Acrylic | Cellulosic fiber | Decorative structural plaster. For interior finishing works. | 1.3-2.0 | 3-4 / 24. |

| S.P.S. BV, Netherlands | Minigrani. | Synthetic resins | Granite crumb | Rough material with large quartz grains. For internal work. | 2.5 | 6/3-5 days |

| Tex-Color, Germany | KH-RollPutz. | Synthetic resins | Not | Decorative plaster for internal and external work on mineral bases, DVP, chipboard, plywood, etc. | 2-4 | 24 / - |

| Tikkurila, Finland | Kevyt-Rae. | Acrylic | Not | For walls and ceilings indoors, concrete, plaster, fiberboard, chipboard, GVL. | 1-1.5 | 1-5 / 24. |

| Viero, Italy | Graniplast | Acrylic | Marble chips | Decorative plaster for finishing facades and internal works. | 3.5-4.5 | 2-4 / 24. |

* Drying time: and - to "turning", b - full.