New Generation Hoses: Classification, Opportunities, Manufacturer Firms, Prices.

Another ten years ago, the hose in everyday life, construction and industry was often considered as a surrogate of a solid metal pipeline and was a sort of "ugly dunchon". Times have changed. It is now difficult to find the sphere of life, wherever the new generation hoses apply.

Hoses are found everywhere: in a professional hairdryer for drying hair, washing machine, domestic pump or air compressor for the car. The wise hoses are used in water purification systems, jacuzzi and swimming pool water supply, in local sewage systems for draining liquid waste into accumulative capacity and pumping into a special sanitary machine - in the laundry and garage. Special hoses laid in concrete perform the role of channels through which fiber optic cables, electric pipes, radio and telecabels are stretched. The glorified hoses are styled under the concrete tie of the floor heating pipe. The same hoses reinforces the compounds of compounds of plastic pipes with cranes and mixers, sections of pipes are protected subject to hazardous damage. The hose buildings are used not only for the traditional oiling of lawns, but also drainage of the manor site, sewage laying, water supply, heating mains, water intake devices from wells are used in various pumping systems. A solution to a height of several floors is supplied to the height of several floors, water from the pit is pumped out of the hoses. Modern fire hoses are also hoses made of polyester tissue with polyurethane impregnation. Air ducts in high-tech ventilation systems are very often made from plastic, plastic reinforced and metal hoses.

What are the fields of application of hoses? Here is some of them:

use on household plots (watering);

water supply (water intake or reservoir);

heating and hot water supply (flexible liner to radiators and mixers);

sewage, storm and drainage systems;

power supply;

Ventilation and air conditioning;

Transportation of bulk materials and gases.

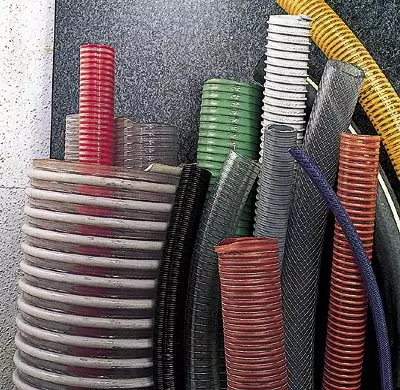

It is possible to distinguish the hoses for technical specifications: incomplete (T3ATM) and high-pressure (up to 135thm); According to the material from which they are made (elastomers, thermoplastics, special fabrics); by service life (from 15 years of up to 15 years); According to sizes (12.5 to 600 mm).

What are the advantages of hoses in front of plastic pipes? First, in the technological basis when installing. Hoses even large diameters have exceptional flexibility and elasticity. It is convenient to transport them in compact bays and mount directly at the facility. Secondly, the hoses have high strength comparable to plastic pipes. They are also inherent in the quality of pipes from polymer materials - wear resistance and high resistance to mechanical damage. The design of the hoses ensures, in addition, the preservation of a smooth inner surface, diameter and performance with complex bends. Thirdly, the hoses are easily dismantled and can be used repeatedly. A variety of fittings and hose nozzles make it possible without any effort to change the system configuration. Modern reusable compounds ensure reliable operation of hoses for transporting liquids and bulk substances at temperatures from -25 to + 65C and operating pressure from3 to 15thm.

BUT - for heating system;

B. - For air conditioning systems and gases, smoke, vapors;

IN - Extremely durable and wear-resistant, suitable for the removal of small and large organic and inorganic particles;

G. - Durable, but lightweight with spiral of spring steel.

The warranty service life of a modern high-quality plastic hose intended for transporting liquids during year-round operation is from 7 to 15 years. The inner surface of such a hose is completely smooth, by virtue of which its bandwidth is significantly higher than that of the rubber diameter. Wrecked conditions (at a construction site, in industry), when the inner and outer surface of the hose is subjected to enhanced mechanical loads, its service life, of course, less. Most of the plastic hoses are made from polyvinyl chloride (PVC), hoses for special purposes are also made from polyurethane. In this case, the durability of the inner surface to abrasion under the influence of mechanical particles in plastic hoses and pipes is the same. The design of most plastic hoses implies the possibility of their deformation, and they do not break even under the wheels of the car. A hose reinforced by a frame or made of polymeric material with molecular memory quickly restores the form and returns to the working state. There are several varieties of such frames. Most often, they are spirals from PVC or metal. Another common design of the hose is a three-layer composition, the central reinforcing layer of which is made in the form of a grid of polyestera. This design makes the hose much more resistant to pressure surges and external mechanical effects. Finally, there are three-channel tape-type hoses, water in which flows over three parallel semi-cylinder channels, monolithically reinforced on a flat plastic basis. These hoses are designed for economical fine-flowered water spraying during watering. The inner surface of the hoses for the transportation of drinking water is made of food plastics that prevents the development of algae. High-quality (professional) hoses that will be used outdoors are protected from destructive ultraviolet radiation.

All types of plastic hoses are easy enough to bay or wound on special drums. Nevertheless, each gardener knows which nodes have to unravel after working with a long hose on the plot. It turns out, solved and this problem. The so-called NotorSionSystem allows you to avoid many inconveniences. A special longitudinal rigid thread included in the design of the reinforced hose does not allow it to be engaged, twisted and prevents the occurrence of nodes. To straighten such a hose, it is vigorously shake it enough.

Russian gardeners make a common mistake, buying corrugated or polyethylene special purpose hoses and using them for watering plots. They are most often designed for laying wires and cables in a concrete screed and protection against damage to pipes from polymeric materials. When the inner surface is corrugated, the water resistance in them is higher than the permissible limit, by virtue of which such hoses will quickly overstate the organic sediments and are subjected to pitting- appear microscopic holes through which water leak occurs.

The question of whether there is a clear line between the hose and the pipe from the polymer material is not solved even at the level of specialists who consider the coefficient of mechanical flexibility as in sufficient criterion.

High culture of landscape work and phytodizain, as well as new technologies for waterproofing foundations involve the use of flexible plastic drainage pipes. They are corrugated hoses with a smooth inner surface and a system of drainage slots, which must be turned up when laying the hoses in the ground. For sandy soil, they are produced in a geotextile filter, for clay - with a surface filter from coconut fiber, which rotates, forming an air layer between the clay and the tube.

According to the logic of things, the hoses should play pipes from polymeric materials in the way they are connected to each other. Of course, the classic clamp by which the hose is fixed in the transitional fitting, the connection is less reliable than the weld or obtained by crimping. However, a professionally installed clamp withstands the nominal pressure of 8-10 atm. In addition, there are special detachable adapters, adapters, tees, fittings and nozzles that allow connecting hoses with each other and connect them to equipment, as well as a lot of special accessories that ensure reliable operation of flexible mobile systems. An interesting know-how belongs to the Moscow Firm "Center Ard-Plus". These are brass fittings that allow connecting hoses with the same degree of reliability with which metal-polymer and re-pipes are connected.

All hoses to visit ...

Unfortunately, domestic producers still continue to treat hoses as the product of secondary meaning. So, even by the producing good products of the Moscow firm "Plastic" at exhibition stands, corrugated polyethylene hoses are presented with dust-dim color and the technical characteristics of the hose for the shower and mixers are not indicated.

IN - Various compounds for foreign and domestic hoses. This import imports are exhibited in all its glory. The eye of the color range of hoses of the English, Italian, Greek, Finnish, German and Turkish production is the decoration of the showcases of specialized stores and firms that are bullshop by this move. More than 400th pvc hoses and other polymeric materials produced by the British firm Flexible Ducting Limited, the Greek company Plexacos.a. The leading firms from Europe offers "Center Ard Plus". A high assessment of consumers was obtained by watering hoses of the Italian firm Fitt. Not the first year, the Russian buyer has been offered a very wide selection of plastic pipes and hoses used in all areas of construction and industry, the German company Unicor RochSystemEgmbh. Mastering the market and other German firm-friatec, producing pipes and hoses from polymeric materials, as well as equipment for their welding and installation. Hoses for electrical purposes are supplied to Russia and the Italian company RecordVinils.p.a. Danish Concern Vavin sells its drainage pipes and corrugated hoses for laying cable networks in Russia and CIS to lay cable networks inside the building. Turkish manufacturers and suppliers are active, the cause of the competitiveness of which is not that their products in quality exceed European, and at low prices. For its class, Turkish products are not at all bad, especially with regard to the price. However, it should be known that they are calculated for pressure 3ATM, the maximum temperature load is 65C and do not take negative temperatures. The product is supplied by the products of Turkish firms Desenplastic, Firat and other companies. At the exhibition of South Korean goods in Moscow, Sejinco proposed a variety of fire hoses from polyestera and polyurethane for quite reasonable prices. These products go to replace their native tarp sleeve, rotating often faster than another fire happens.

Not only finished products comes to Russia. One of the first Bavarian firm Drossbach began to offer for sale and lease equipment for the production of flexible pipes and hoses, which caused great interest among Russian entrepreneurs. Obviously, our country will put out its own production of the main types of hoses and flexible pipes, using both foreign and domestic technologies already in the new millennium. This is how things are in the field of domestic and world "hose-building" and the use of hoses.

How much hoses cost?

Let's say directly: twice-three more than the polymer pipes of a similar diameter. The benefit of the use of hoses is determined, however, not at the cost, but their capabilities. The price of 1p / m of a watering hose, depending on the size of the size, from $ 0.5 to 3, the hose for water supply is from $ 3 and 47, for heating - from $ 3 to 22, for sewage, storm and drainage systems - from $ 3.5 to 45, for power supply - from $ 0.5 to 3.5, for ventilation - from $ 1 and 45, for transporting bulk materials - from $ 3.5 to 218.