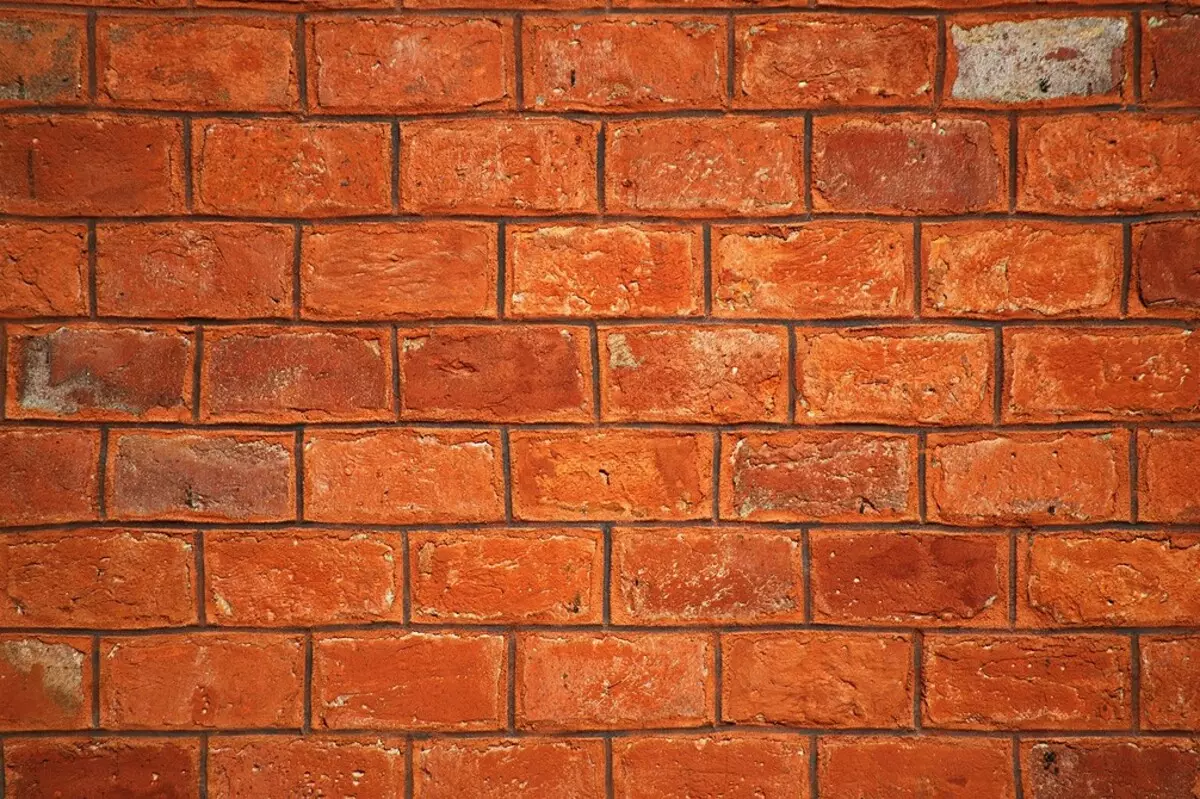

We present a detailed guide on how to independently make brickwork: theory, schemes and advice from practice.

Brick - reliable and universal material for the construction of any buildings, including country buildings. The safety and strength of future walls depends on the choice of the most building materials and its styling. We understand which types of brick masonry exist: from terms to practice.

All you need to know about the varieties of masonry

General principlesThickness

Types and Dressing Features

- chain

- multi-row

- Trier

- reinforced

- Lightweight

Technique of work

Extending

General principles

In working with any building material, accuracy, accuracy and clear observance of the rules are important. Brick is no exception. Before you begin the analysis of ways of display, we suggest to deal with professional terminology.

Important terms

- The two wider planes of the artificial stone (from above and below) are called bed.

- Spoons - vertical long side. It happens face and face.

- Two are the smallest side of the side of the side are called "Stick".

Basic rules of work

- Each element must stand strictly parallel to neighboring, both horizontally and vertically. This is due to the physical characteristics of the material: it easily transfers the load in the form of compression, but does not tolerate the bend. The maximum allowable angle in laying is not more than 17 degrees.

- Spoons and stumps should be connected by longitudinal and transverse seams. Two systems - the key to the strength of the whole design.

- From the previous two rules it follows the third, most importantly: longitudinal seams should be located strictly parallel. The same applies to the transverse. And both systems must be perpendicular to each other.

Thickness

Before determining the type of brick masonry, you need to understand the thickness of the brickwork - this is the width of future walls (taking into account concrete mess). It depends on the type of building and operating purposes.

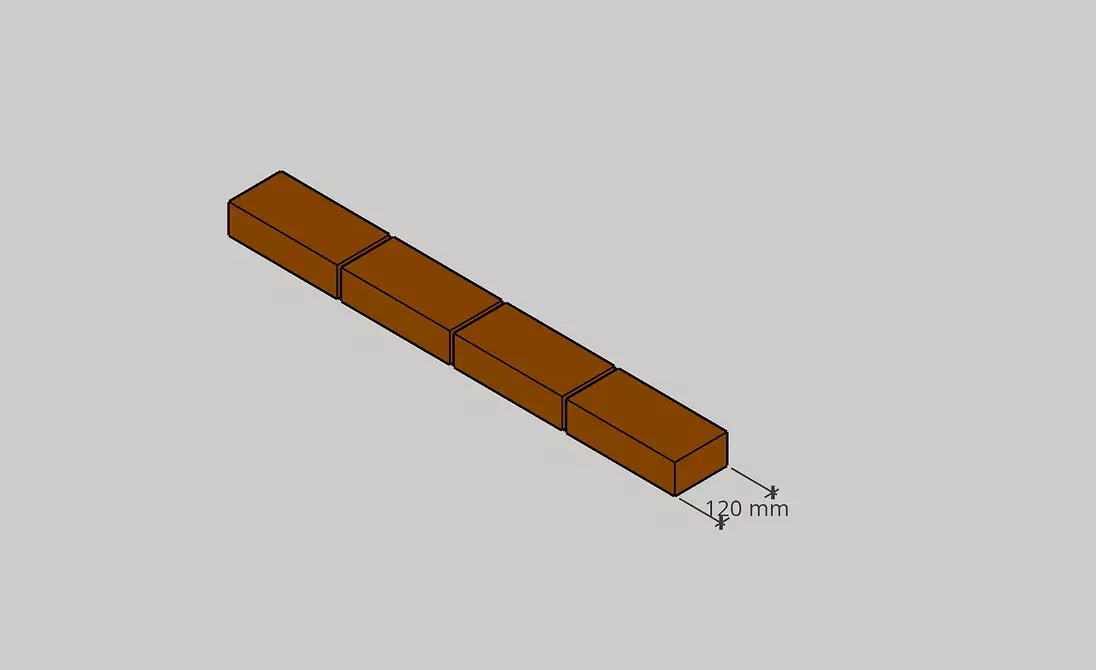

- Half - 120 mm thick. Suitable when erecting partitions, fences and decorative elements of buildings.

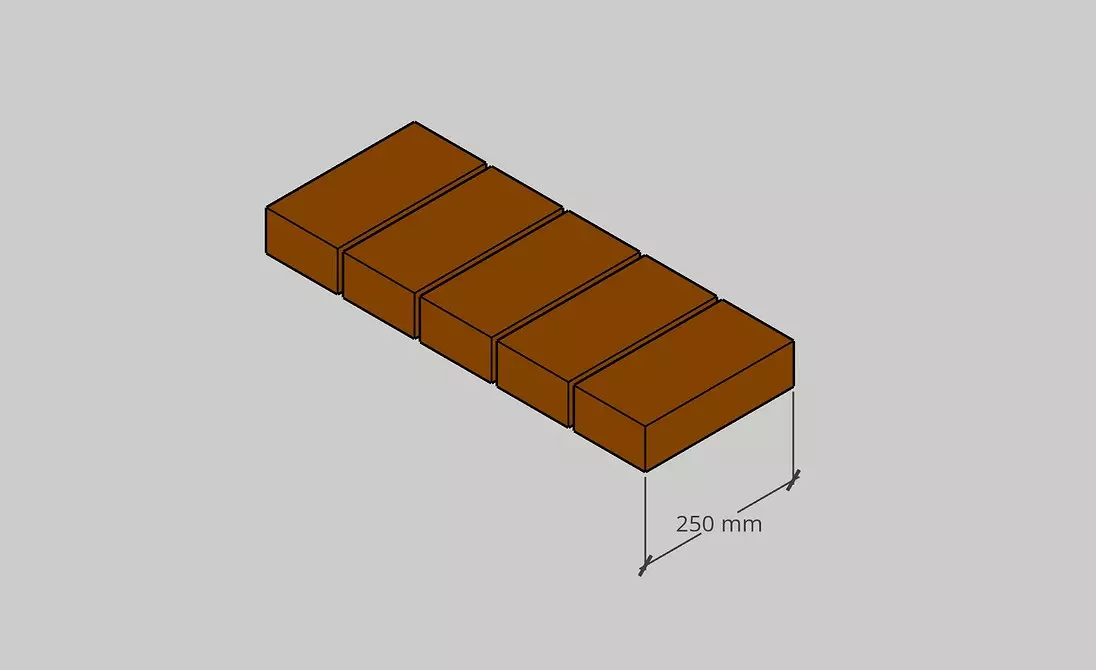

- In one - thickness 250 mm. Mainly applies in the construction of garages, summer kitchens, fences, and so on.

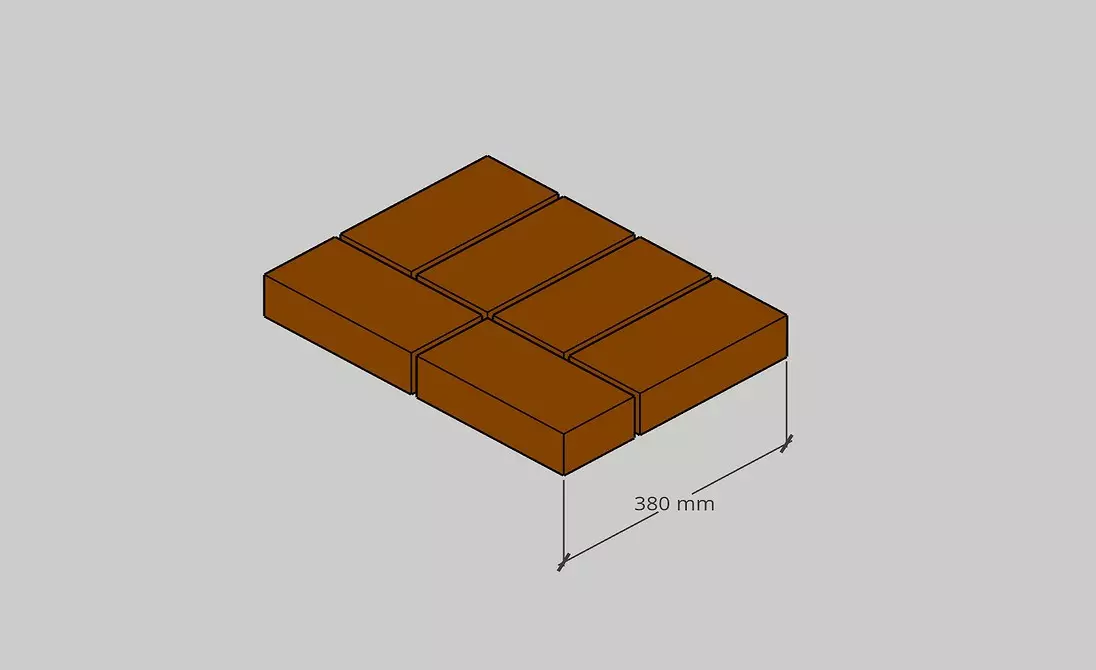

- A half, thickness 380 mm. The most popular appearance is suitable for a small structure in one, the maximum is three floors.

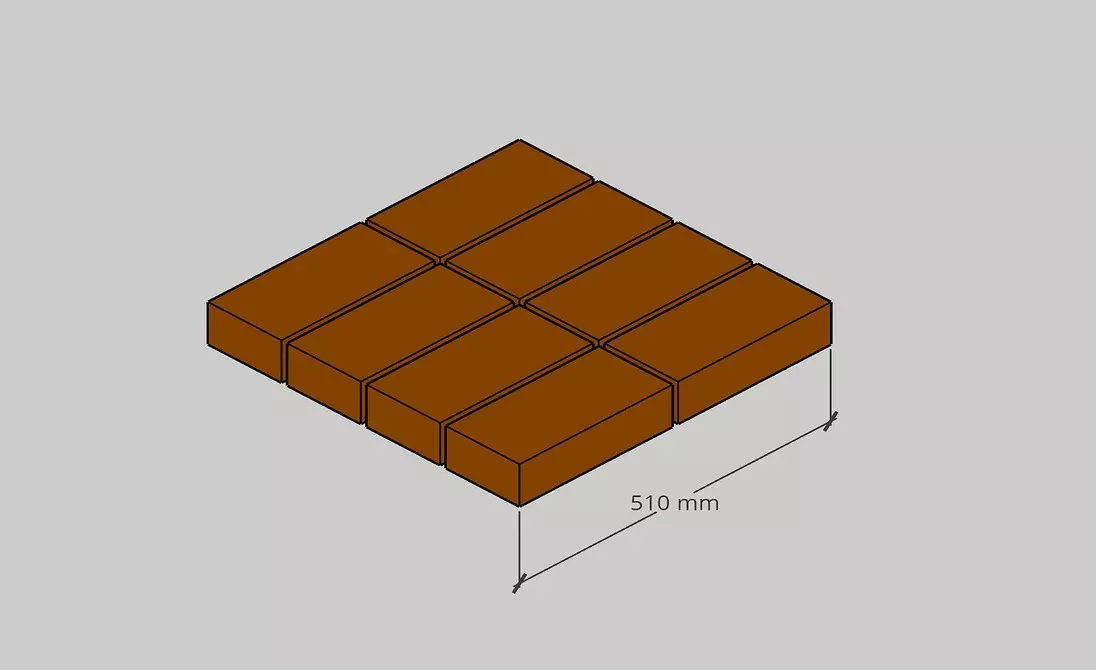

- Two bars, 510 mm. Most often used to create bearing structures, as well as during the construction of multi-storey buildings.

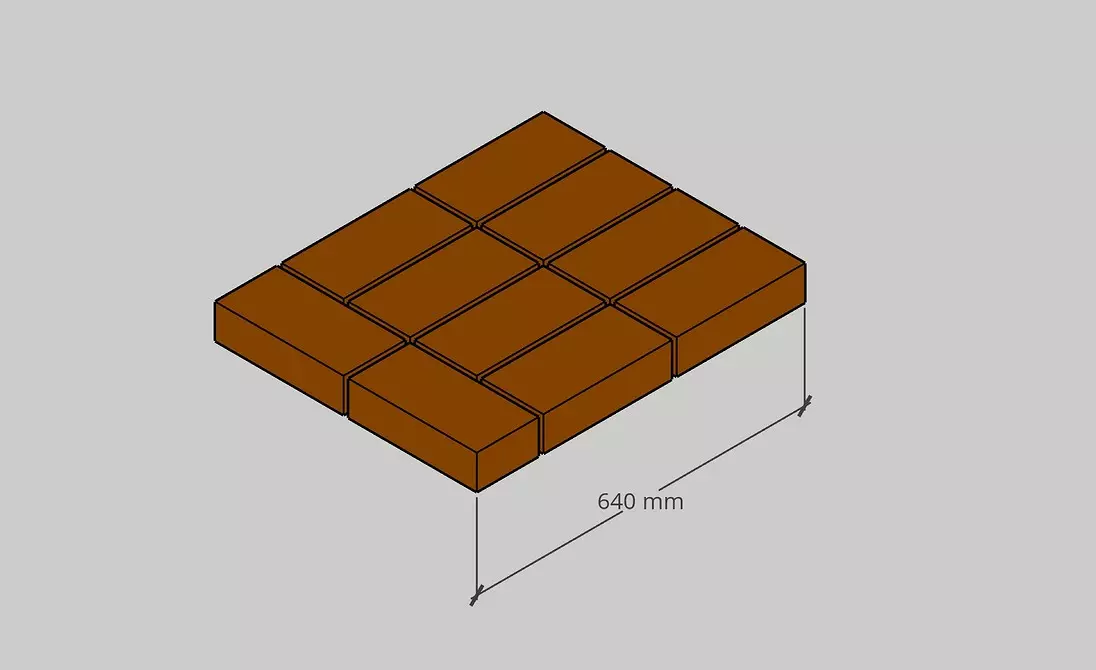

- Finally, the thickness of two and a half - 640 mm. It is also used to erect the bearing walls in high-rise buildings. Such structures must withstand a huge weight, but in construction rarely involved - it is inexpedient.

The size of ordinary bricks in all manufacturers is standardized: single - 250 x 120 x 65 mm, one-and-a-half or modulated - 250 x 120 x 88 mm. However, the reality is that products of different companies may differ for a couple of millimeters, so the elements are combined in this way extremely rare. When buying it is worth paying attention to the evenness of products. Even small chips and uneven faces can lead to an incorrect load distribution, resulting in cracks.

Types of masonry bricks for walls

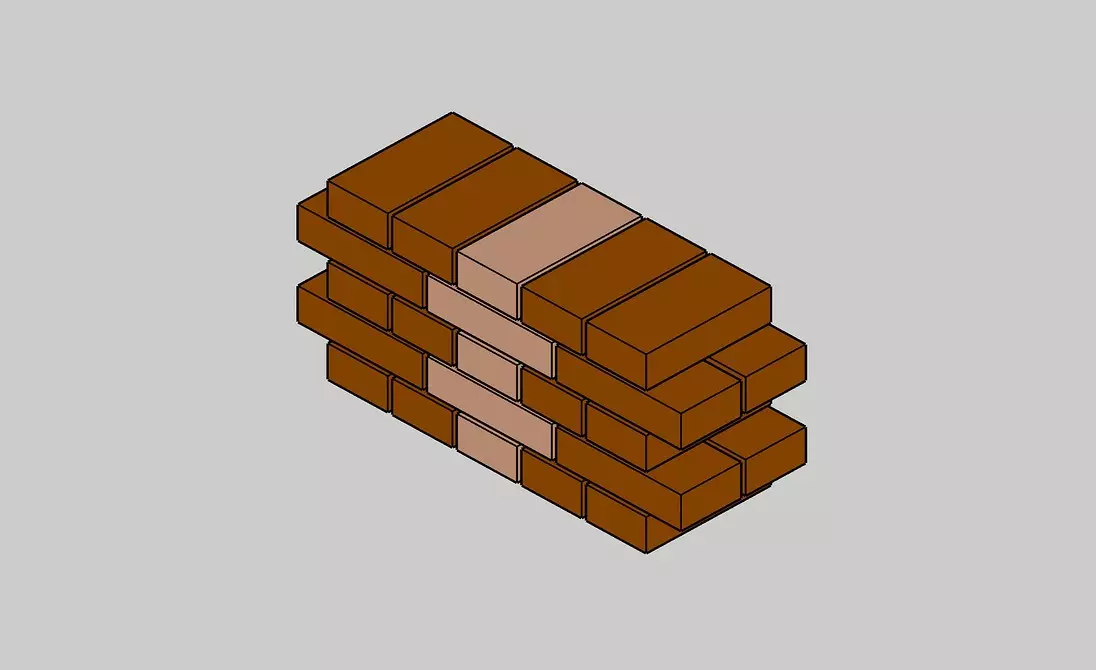

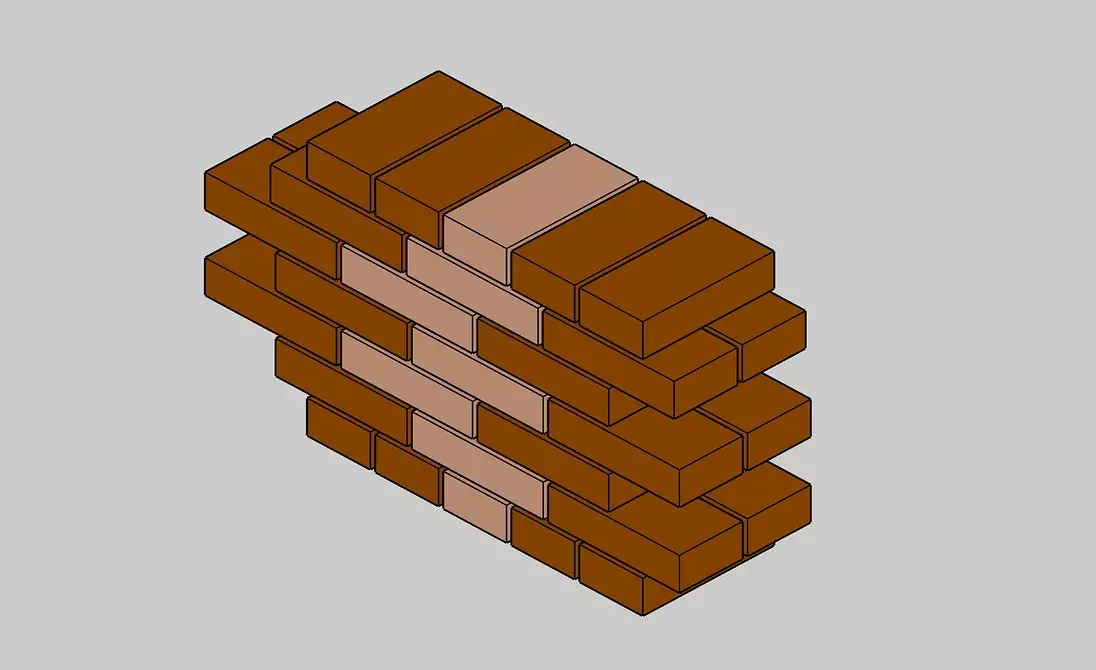

Another professional term used by bricklayers is a bandage. This is the scheme of placement of the material, the order of their laying. Due to it, all elements are binding to a single whole, a monolithic mass of equally distributed load. The bandage is carried out by offsetting half or a quarter of the stone.

- If the elements are located to the outwards, such a number is called Tychkov. Then only the smallest edge of the stone is visible.

- Spoon - a series in which all the elements are turned with a long facet - a spoon.

There are three main variants of sutures. Consider each kind of brickwork with photos and title.

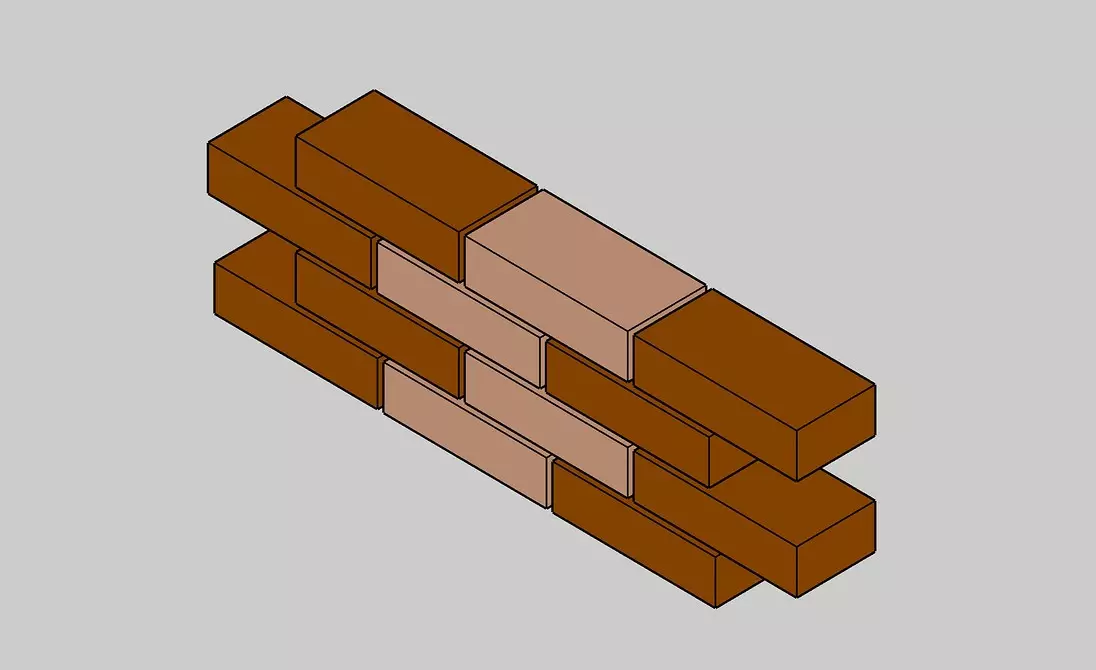

Single row

It is also called chain. The meaning in the sequential alternation of the rows of the tick and spoons. Such a gleaming is used to build draft buildings when there are facing in the future. Suitable for both exterior and inland bearing walls. And such decorative styling is most often found in the interior design.

- The first and last level is necessarily laid by the tilers.

- Longitudinal seams are shifted to the Polkirpich, transverse - on a quarter.

- Vertical seams should not coincide with the upper and lower, the stones overlap them.

Such a gleeness is considered difficult to work, but at the same time and most reliable.

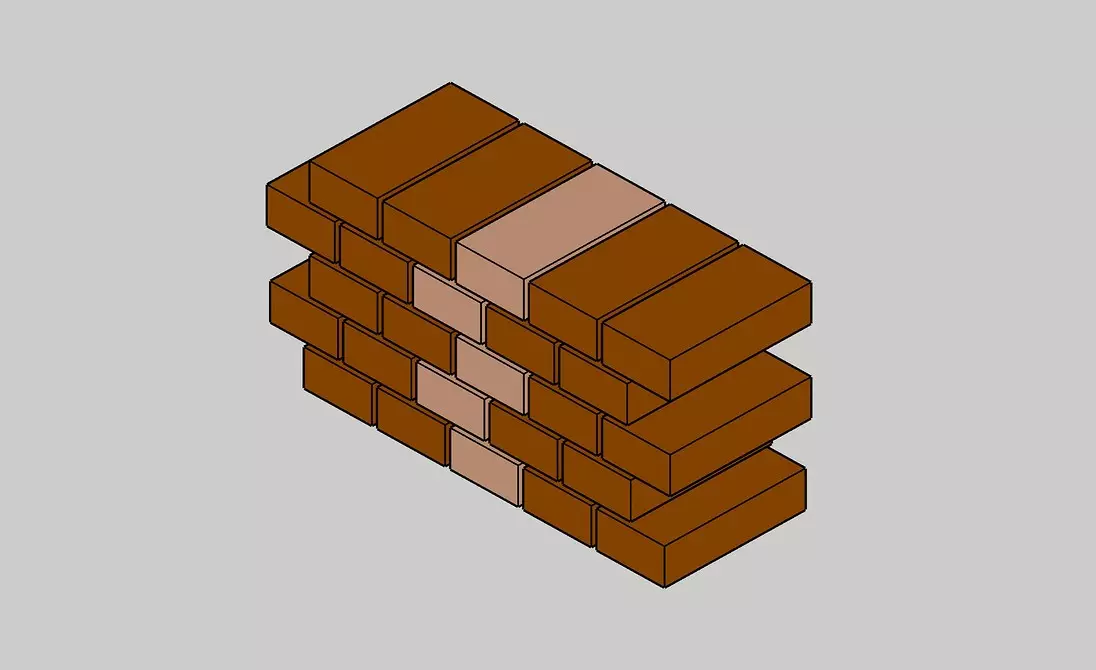

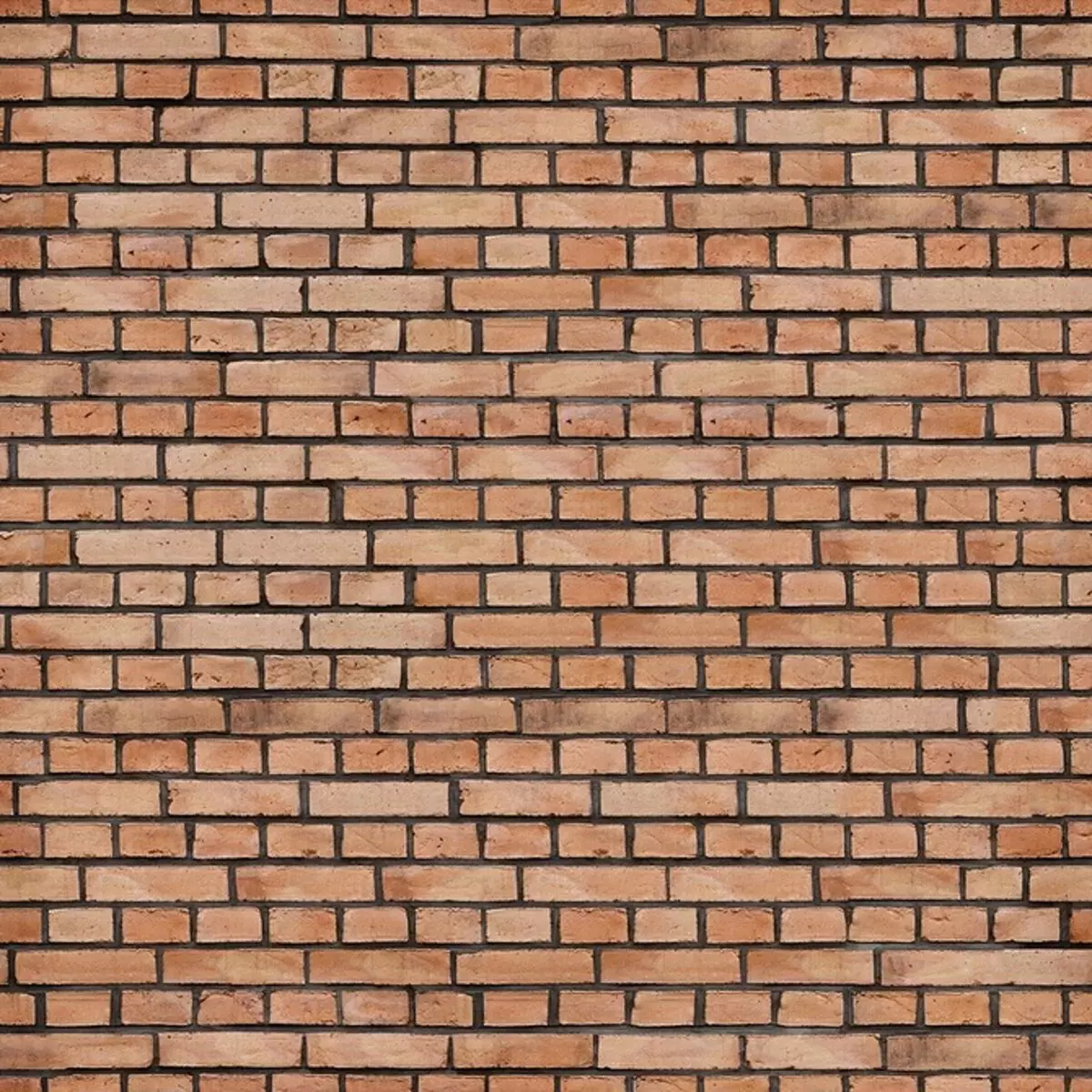

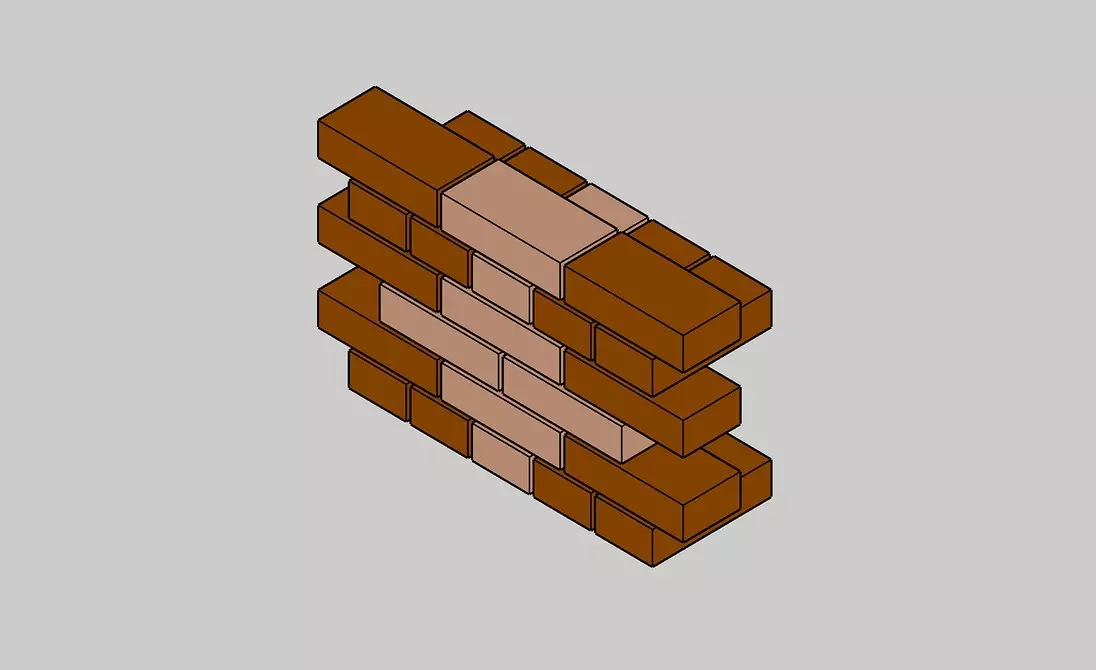

Multi-row

This is a way of erection of outdoor and inland walls. The scheme is this: six rows are bowing (for single bricks), tied by spoonfully nearby. If the stone is modular, the torch rows will be five.

- The first and last row be sure to make Tychkov.

- Spoons tied up with a shear on the Polkirpich, regardless of the thickness of the styling.

- The seventh row to the quarter overlap the spoons of the previous one.

The multi-row dressing system is cheaper than the chain, and the laying itself is also easier. But its strength is counted below. In addition, it is not possible to use it in all works.

Trushene

Typically, fences, simpleness, pillars and other more decorative designs are laid out, in which the load is not provided. With such a scheme, one twitch level alternates with three spoon.

There are a number of more complex types of brick masonry, they are used for facing work. These include, for example, the Bavarian - alternation of stones of different colors, chaotic is the alternation of the spoonful and twitch side in chaotic order or gothic - the same alternation, but ordered. Without experience, such a masonry does not do, it requires technical perfection and skill.

Reinforced

Separately, it is worth mentioning the reinforced display. Such a technique involves enhancing reinforcement. It is placed on the solution between levels. At the same time, the reinforcement itself can be performed both horizontally and vertically (using a mesh or individual rods).

- The number of reinforcement as a result should be at least one tenth of the total laying.

- Grids are laid at least than three levels - for ceramic products, four - for thickened, and five - for ordinary.

- The grid diameter is at least 3 mm.

Lightweight

This option is relevant when insulating inland walls, when you need a durable light design.

- The wall in this case consists of two commoners thick in the Pollipich, fortified by reinforcement. Such a design is rigid.

- There is a cavity in which the insulation is laid, for example, polystyolster or polyurethane foam. The width of the cavity is determined at the initial stage.

- Sleeple should be connected with jumpers from stone bars or reinforcement. At the same time, the points themselves are at a distance of no more than 1 meter from each other.

Technique of work

Important moment in the construction of a brick wall - styling technique. There are two main ways to carry out work. The choice depends on the quality of building materials, plasticity of cement mortar and weather, which affects the time of its frozen.Injecting

This method is suitable when the cement is default, and the reference cone goes into a solution of about 9 cm. The solution is laid out with an indentation from the front side by about an hour and a half centimeter.

- The right hand is Kelma, in the left - brick.

- The solution is applied to bed to bed - a number below.

- Part of the concrete is presented by the edge of the Kelma to the vertical face of a neighboring stone.

- Left hand placed stone bar.

- The element is pressed, closed to shrinkage. The residues of the solution are removed by Celma.

Iniquit

Thus, elements are placed on an elastic cement when the cone is drowning by 14 cm.

- The solution is dismissed by a uniform layer over the entire surface of the masonry.

- Each new element is moving towards previously laid in such a way that when driving it turns out to blow the cement on its face. That is, the solution was on a spoon or arrow - depending on the laying.

- At the same time, both vertical, and horizontal seams are filled.

- Surplus are cleaned by Clavma.

Extending

This is the final stage of calculations when the seams are processed between the formation. Thus, not only take care of the aesthetic component, but concrete concrete. After that, the seams become convex, concave, triangular, single-carved, and so on.

The easiest way to make concave. To do this, it will be needed wire bent loop. These tools are carried out through a layer of concrete, cutting off excess. Convex can also be made of remedies: cut the circle of the desired dimer in the pipe. Put the tube perpendicular to the wall and spend on it.

The formation of the shape of the lines is carried out before the solvent is frozen.

If after it is planned to finish and plaster, it is best to put the composition by 1.5-2 cm from the edge. This method is called inlet - seams remain empty outside.