The reason for writing this article was the phrase read on one of the construction sites: "Brick houses are constructed through the technology spent centuries, which means that the fatal errors are rather difficult ..."

Photo: Ivan Sorokin, authors of the project Olga Konykin, Ekaterina Ivanova

When you meet with such a "shapporteatory", you remember the remaining brick cottages that have been unfinished, in the walls of which were formed cracks, the basement was floodbated, the laying was collected due to the poor quality of the wall material. But all this is the work of workers, and significant financial losses of customers, and their unrealized dreams of a generic nest. Experts in the field of construction expertise can lead many examples of practices, which indicate how often in brick house-building admires unreassed errors equal to signing a death sentence under construction or ready-made building. In this article, we will not affect the calculation of house design. Our task is to tell about the errors that are committed during construction.

Photo: kadmy / fotolia.com

At the material selection stage

From the choice of bricks depend the reliability and durability of the walls of the house. The cottage construction uses several types of this material: a brick of a private ceramic (full and hollow), silicate, large-format ceramic porous stone. The first is a red-cut bar, without holes, porosity from 8 to 12% and serves as the base of masonry. According to production technology, plastic and semi-dry bricks are distinguished. A second type brick cannot be used to build foundations, basements, fences. The brick of the ordinary hollow is different in that it has through and non-core voids, which are round, slightly, oval or square. Holes make up 13-43% of brick volume. The inner air layer reduces heat exchange between the space of the house and the street, so the walls from the hollow material are warmer than from the full-scale. In addition, the hollow brick is 25-40% more easily, which reduces the load on the foundation. Walls from ordinary ceramic bricks (and full, and hollow) need mandatory subsequent plastered or facing.

It is much less likely to use a silicate brick that is produced from a mixture of lime and quartz sand. For strength and sound insulation characteristics, it exceeds ceramic brick, however, due to high water absorption, the area of its application is limited. Recently, instead of traditional bricks, a ceramic stone is increasingly used (picked block). Large-format products simplify all technological processes: a smaller amount of solution is required, the construction time is reduced. But the main advantage of the block is the low thermal conductivity coefficient equal to 0.29 W / m ● ° C (in a simple brick 0.39-0.42 W / m ● ° C. Thus, it is possible to lay walls with a thickness of 64 cm without using insulation: Peredished stone plus facade trim facing bricks.

To protect brick facades, hydrophobic silicone impregnations are used from moisture. If the processing has not been carried out on time and appeared, they can be removed, they can be removed by surface-active substances and acid cleaners. Photo: "Krako"

In the production of both traditional bricks and a pated stone, the technology of manufacturing material can be broken, and it becomes unsuitable for construction.

For example, a case is known when a ceramic pricked stone, from which the cottage settlement was erected into the pendulum of Kovye, after some time began to "shoot" (chips appeared on it). In the course of a complex and long-term trial, the developer on the basis of laboratory research was managed to prove violation technology of production. Of course, this example does not in any way detract from the merits of building materials. Hospital - choose to choose it.

The easiest way to determine the quality of the brick is visual. If you see that the core has a more rich color than the external surfaces, and when the brick is hit, the ringing is distributed, then in its quality you can be sure. When the sound is deaf, and the color mustard or on the surface there are stains, it means that the brick is inexpensive. Such products are distinguished by low frost resistance and are more susceptible to the negative impact of moisture.

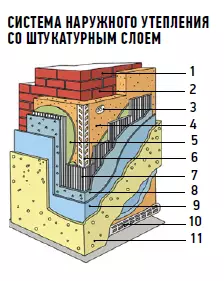

1 - brickwork; 2 - penetrating primer; 3 - Dowel; 4 - thermal insulation; 5 - glue; 6 - corner profile; 7 - a tiled fiberboard; 8 - solution; 9 - primer; 10 - base profile; 11 - layer of plaster. Visualization: Igor Smirhagin / Burda Media

Checked brick will have black, melted edges, fuzzy face. Such material is also considered defective (it is significantly deformed, and its dimensions do not fit into the laid tolerance, besides, the brick will crumble) and is not suitable for construction. If we talk about the technical criteria for choosing a material, then its strength is important, which is indicated by the letter M in combination with a digit reflecting the maximum permissible load in kg / cm2. Maximum brick strength - 300 kg / cm2. However, for the construction of a cottage with a height of two or three floors, the M100 brand is enough. Another important image of the brick is frost resistance (material ability to withstand alternate freezing and thawing in a water-saturated state). It is denoted by the letter F. For construction in the middle line of Russia, experts recommend using a brick with frost resistance not lower than F35, and better - F50.

Photo: Vadim Kovalev / Burda Media

How to prevent the appearance of water in the basement

Build a house with a basement or basement floor on a plot where the level of groundwater is less than 2 m from the surface, and hope only for waterproofing the foundation wall (without drainage system) - a rock error. What consequences it can lead, the author of these lines recently saw on one of the objects in the Moscow region. Fresh brick house, beautifully separated by a clinker facade, and in the basement in the spring and autumn there is water. When representatives of the construction expertise arrived at the place began to understand, it turned out that the house was erected without a seriously developed project, and led by the work of the foreman made a number of errors. For example, the base was protected from moisture with a thin layer of coating waterproofing, and the holes from the dowels that kept the formwork remained open. The foreman convinced the owner that if we glue the sheets of thermal insulation on top, then she closes the holes and water will not penetrate the basement. The gullible customer fell on a very convincing argument: "Always built, and everything was fine."Perhaps everything would be fine if the drainage was correctly performed correctly. But a brigade was made without any project, adherence to the slope, etc. As a result, the accumulative well completely flooded, and the water went to the basement. Exodus fatal. And the sentence of construction expertise sounds like this: to disassemble the pie cake to waterproofing, to make it high quality and arrange a new drainage system with a large number of viewing wells and forced pumping from the accumulative tank. But on the mastered area, it will be possible to put drainage pipes without everywhere, so, as we see, not all the miscalculations can be corrected.

What can not save on

In brick house-building, as practice shows, quite often one error attracts the other, and to correct the situation, you have to get to "sources". And the "sources" are considered to be geological surveys, which must be carried out at the site of future construction even before the development of the project. Exquisitions help determine the characteristics of the soil and the level of groundwater, and also serve as the basis for choosing the type of foundation and calculating the depth of its embedding. Here is an example from the practice of experts showing how Russian may be brought to what consequences.

On the land plot, a brick house was built without any geological surveys. It was not possible to not only enter it, but even start finishing: in the basement, even in the summer there is water, and the walls are covered with cracks. What is the reason? In the wrong choice of the type of foundation. Perhaps the site is not just a high level of groundwater, and in this place the underground river flows. With confidence, it is difficult to call the exact reason, however, the deplorable result is obvious. And this is the most real fatal error - the house will have to fully disassemble and build anew, now already having experience, which is known, "the son of difficult mistakes".

Photo: Atelier Iron Studio

At the stage of the foundation and base

Let's talk about the next portion of errors. The mass of 1 m2 of the brick wall is 1200-2000 kg, which requires a device of foundations, the sole of which is lower than the depth of the primer of the soil (for the Moscow region - below 1.5 m). If the basement is planned or the basement operated, then the deep-cutting and pour the monolithic foundation. At this stage make a variety of mistakes, including fatal. Even if the foundation is designed competently, but the builders did not stand the design time of the strength of them (SP of 70.13330.2012) and began to load it seven - ten days after the pouring (stacking overlaps, erect walls), cracks may appear in the foundation.

Violations of the requirements of SNiP to the stone masonry: the brick from which the base was laid out already began to collapse; The thickness of the seams was not respected, which reduced the heat efficiency and strength of the walls of the house; A typical example of "steaming" walls of the house. Photo: "Independent expertise quality of construction"

The next important stage is the waterproofing of the foundation (and basement) and the device of the drainage system. If you do not protect the concrete from the impact of moisture, then, having absorbed in its pores, during freezing the water will expand, which will lead to the formation of microcracks through which moisture will be seized in the foundation. That is why it is necessary to perform its vertical and horizontal waterproofing. Errors at this stage are associated with the use of unsuitable materials or violation of the technology of their laying. For example, hydrokhotkloxylazol rolls must be supplemented in no less than a day in a room with a temperature of 20 ° C. Often builders ignore this requirement, and as a result, the laying is performed with violations. Another example of a construction marriage. All surfaces of the foundation before performing waterproofing should be dried (permissible humidity not more than 5%) and primer are primarily pricked. In practice, due to weather conditions or negligence, workers are often waterproofing glued to a rejected basis. It is very difficult to achieve its reliable fixation in this case. And then - "Water hole will always find" and the basement will fill at home. In addition to the vertical, it is necessary to perform horizontal (the so-called cut-off) hydro isolation, which is necessary to protect the walls of the basement and the house from the soil moisture penetrating the base of the foundation. It is sometimes mounted with violations, either generally forget to put. According to construction regulations, in unwhawable buildings, the cut-off waterproofing should be performed in the base unit (as a rule, 20 cm above the level of the scene). In houses with cellars, it is suitable in two places - at the base of the floor of the basement and in the base part of the building, above the level of the scene.

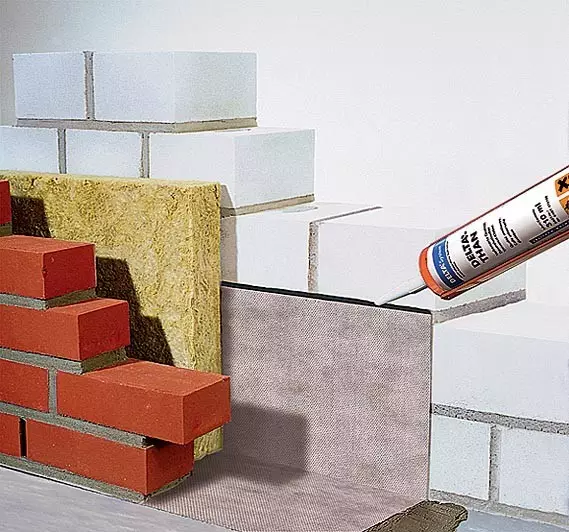

Today, quite often in the construction of a brick house use three-layer masonry. It can be guided both simultaneously in three layers and separately, that is, first fold the inner carrier wall, and then it will be insulated and putting the facing. But the most important thing is not to forget to lay mortgage details (flexible connections). They preferably make from steel galvanized wire, installing with a step of 60 cm horizontally and 60 cm vertically. They bind among themselves the bearing wall with a facing layer of brickwork with a thickness of 120 mm. Sometimes the builders are "forgetting" to ensure the vapor permeability of the structure. Often used low density thermal insulation - 25-35 kg / m3. Over time, it settles, and the wall loses the heat and protective properties. We recommend using the insulation of the density of 80 kg / m3. Between it and the outer wall need to leave 5 cm's ventsor, as well as in the base and under the cornice to make ventilation holes in the outer layer of the masonry.

Alexander Shukhatovich

Leading expert ASK "Advocate of Quality"

At the laying stage of walls

At this stage, such mistakes such as distortion of the geometry of walls, non-compliance with diagonals are most frequent. As a result, the walls begin to "fall". The sooner the masonry defect is seen, the easier it will be to fix it. Another violation, allowed during the masonry work, is poor-quality execution of seams. Sometimes workers believe that if the laying is rough, then you can not try, because then the walls are separated by facial bricks. However, this approach is fundamentally incorrect. Here are the basic requirements that must be observed when building walls.Walls begin to erect from corners. The correctness of the building corners of the building are tested by the coal. The horizontal of each row of masonry is at least twice the rule and level. If the deviation does not exceed the established limit, it is eliminated during the masonry process of the following series. Otherwise, it will be necessary to disassemble the "defective" series (ranks). With any version of the laying at the corners of Circular, piches should cross, forming the lock. Therefore, first stood up the first row of one wall and attach to it the first row of the second wall. The following row is put in the opposite direction: first - a number of the second wall and only then the second row of the first wall is attached to it. Another indispensable technological process is the reinforcement of masonry to increase strength. For this purpose, steel reinforcement (welded grid) is interinted into the solution in the seams between bricks at least after five rows of masonry when using traditional bricks. As for the large-format ceramic stone, the requirements for the reinforcement of the walls of the walls are contained in the recommendations of manufacturers of this product.

Types of seams

- Seam between bricks are performed in several ways:

- In a waste-show - the solution does not retake to the outer face of the brick, and the slot remains. This method is used when the wall is planned to be placed. The plastering mixture is covered in the gap, it will be better to stay on the wall.

- In the sublica, the solution fills the gap flush with a brick face. The seam of this type is made when laying chimneys and fireplace pipes, and also used as decorative.

- Went or convex seamless "scenery". In the manufacture of the first apply a small cut of a tube or a round stick. To obtain a convex seam, a portion of the surface is cut at the tube.

Be sure to check the thickness of the seams, focusing on the average indicator of the five-six rows of masonry: the height of the masonry is divided into the number of rows and from the result obtained, the brick thickness is deducted. The average thickness of horizontal seams within the height of the floor should be 12 mm, and the vertical is 10 mm. Any negligence in this matter may lead to the fact that the variable seam thickness in different parts of the wall will create increased voltages in the masonry. After completion of the laying, the seams need to be immediately filled with a solution and align (partition). Bad stuffed seams is a serious building error, leading to a decrease in the strength of the masonry and heat-shield properties of the building of the building.

The main reason for the appearance of cracks in the walls is errors in the construction of the foundation. To determine how much one or another crack is and is it possible to save the house, it is worth contacting the experts. They will conduct a thorough examination of the building, they will establish the causes of cracks and will give the necessary recommendations. Usually, thin cracks are purified from residual solutions and dust, and then filled with liquid cement mortar using a mortar pump. Wide cracks are repaired in this way: parts of the damaged masonry are disassembled, and then sequentially close the crack for the entire thickness of the wall with separate sections as brick locks. In some cases, the wall is reinforced with metal lining.

At the finish stage

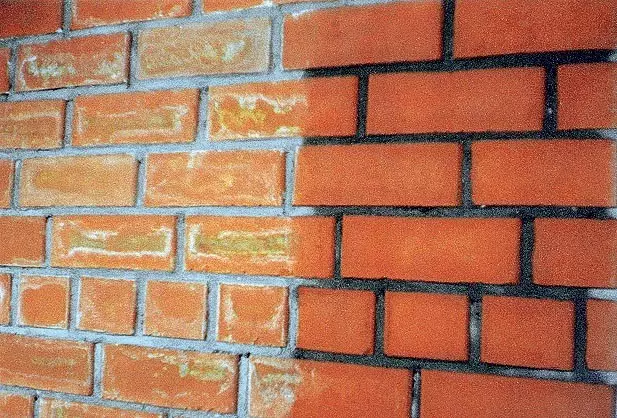

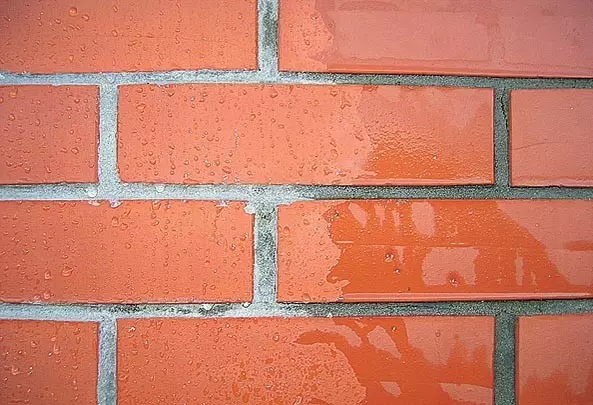

Quite often, during the finish of the outer walls, the builders admit errors that later lead to the appearance of white spots - saws. Of course, you won't call them fatal. Rather, a comparison with chronic disease requiring periodic treatment is suggested. Salted at the facade of salt - not only not aesthetic, but not a harmless phenomenon. The growth of salt crystals in the pores of the material is accompanied by the destruction of the brick. The seals on the facades are formed due to the exit on the surface and crystallization of the salts contained in the building materials (in water, which is added to the solution in the solution itself, in the brick). As in the case of any disease, it is easier to make prevention, rather than treatment.First, for a masonry solution, it is necessary to use cement with low salts and without additives (though, if the construction is carried out in the cold season, without additives can not do). Secondly, make sure that the solution does not fall on the front part of the bricks (otherwise it is necessary to remove it with a dry brush). Thirdly, during the rain you can not work, and the walls need to be covered with a film. Fourth, laid out sections of the walls (as they grow) it is necessary to constantly process the hydrophobizer (water-repellent impregnation). After such procedures, the brick facade becomes more resistant to the looping cycles, the moisture does not fall even into cracks with a width of 1 mm. Water is not absorbed into the surface, and flows from it.

How to defeat the invisires

If the heights could not be avoided, they should be "treated". In the chemical composition, the zip is heterogeneous: they are soluble and insoluble. The universal way to remove those and others does not exist. But before performing against the "White Enemy," it is necessary to find out the reason for its appearance. Effective combat with discovery is carried out in two stages. The first is to clean the facade with a chemical method using special washes, which include acids and surfactants dissolving the supremes. The method of applying all the compositions is almost the same: the drug (pre-divided by water, if it is indicated in the instruction), they are put on the wall with a brush, a brush or roller, withstand for 20-30 minutes, and then the residues of the solution are flushed with water. The second stage (hydrophobization) is to protect the masonry from the penetration of moisture that contributes to the removal of the salts from the thickness of the wall. For this purpose, silicone (silicone) compounds that give the perempics of water-repellent properties are used.

Solutions on the walls are talking about violation of the construction of a brick house. Photo: Tatyana Karakulova / Burda Media

As the wall is erected, you need to immediately cover the hydrophobizers. During precipitation, masonry work cannot be carried out. Photo: Tatyana Karakulova / Burda Media

Laying of the walls is made with large violations. The thickness of the seams is 2-3 times higher than the regulatory requirements. Photo: "Independent expertise quality of construction"

Laying of the walls is made with large violations. The thickness of the seams is 2-3 times higher than the regulatory requirements. Photo: "Independent expertise quality of construction"

Laying of the walls is made with large violations. The thickness of the seams is 2-3 times higher than the regulatory requirements. Photo: Tatyana Karakulova / Burda Media

The masonry lead from the corner of beacons with mandatory dressing of seams. Photo: Tatyana Karakulova / Burda Media

The high resistance of heat transfer of ceramic invoked blocks allows you to build a house without insulation, which significantly reduces the cost of construction. Photo: Tatyana Karakulova / Burda Media

The surface of the wall before coating with a wash (left) and after it (right). Photo: "Celers"

Preparation of base for finishing. In the masonry drill holes. Photo: Saint-Gobain

In the holes are injected into waterproofing. Photo: Saint-Gobain

After injection of waterproofing, the surface is treated with cement mortar. Photo: Saint-Gobain

Brick masonry after treatment with hydrophobizer. Penetrating bricks, the composition blocks the capillary effect. Photo: "Celeva"

Brick masonry after treatment with hydrophobizer. Penetrating bricks, the composition blocks the capillary effect. Photo: "Celeva"

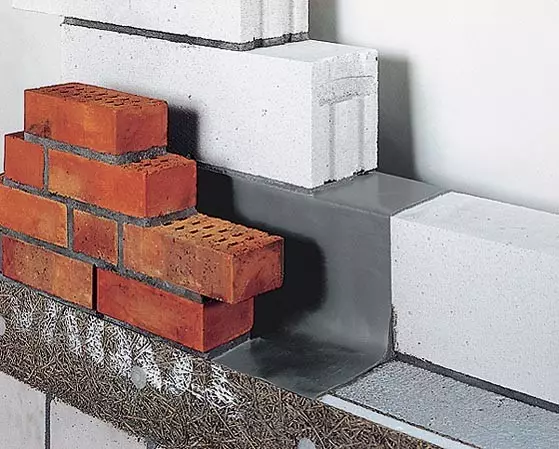

Horizontal cut-off waterproofing prevents the capillary moisture lift from the concrete foundation to the walls. Z-shaped molding of shut-off waterproofing. Photo: Dörken.

L-shaped module for mounting shut-off waterproofing. Photo: Dörken.

On a swampy area, the drainage system allows you to lower the level of groundwater below the basement sole and eliminate the hydrostatic pressure on the underground building building. Photo: wavin.

The main elements of the system: pipe drain, observation and accumulative wells. The technology implies observance of the rally, the device of pillows under drains, as well as a reliable docking of parts. Photo: "Studio L-Design"

The crack in the wall of the basement is possible to close only if the foundation has stabilized and is no longer pronounced deformations. Photo: Penetron-Russia

Arc-shaped cracks, going through window openings, most often arise as a result of the bend of the nestonic beam. Photo: Tatyana Karakulova / Burda Media

Vertical are a consequence of errors when building a foundation. Photo: "Independent expertise quality of construction"

In the basement of the built brick house costs water. Causes - disorders of waterproofing technology and lack of drainage system. Photo: Tatyana Karakulova / Burda Media

This is what the fatal errors lead: the wall pie is disassembled to waterproofing that it is necessary to perform again. Photo: Tatyana Karakulova / Burda Media

Layered masonry necessarily implies a device of the ventilation gap between the insulation and the facing wall. Photo: "Jetstroy"