In Germany and Scandinavia countries, single-quality houses and townhouses from lungs from light-format panels are very popular, which are a whole wall or a large fragment of the wall, overlap, roofs. This construction technology is available in Russia. We are talking about the specifics of its use, advantages and disadvantages of rapid displacement buildings.

Constructively, the prefabricated house refers to the framework, and according to the degree of factory readiness approaches the volume-modular one: the construction is brought into fact essentially finished fencing and bearing structures, often with finishing, windows and doors, with channels for wiring and other communications, sometimes - Mounted engineering equipment.

Elements of the national team

The main elements of the national team are the panels of exterior walls, partitions and overlaps, as well as roofing shields. Also usually require individual frontal parts and cornose. The dimensions of the panels are limited only by the considerations of logistics, that is, the length of each can reach 12 m, and the height is 4 m (but is usually equal to one floor and does not exceed 3.2 m). The panel should have sufficient strength and rigidity so that it can be installed in the project position by the truck crane. The accuracy of manufacture is very important, without which the house simply may turn out to be kept. On the side edges of each panel, connecting elements are provided (for example, bolt holes) and P-shaped grooves or quarters for the insulation.

Most often, the panel house is a platform-type skeleton. That is, the walls of each floor are based on overlap, the panels of which have a reinforcement.

The porch (terrace) relies on a common foundation with the house and is built by classical frame or glass factor technology. Fronton panels are installed before mounting the roof.

The main assembly stage ends when roofing shields are put in place and the roof coating is laid. It remains to mount engineering networks and connect the house to communications.

Panel Device

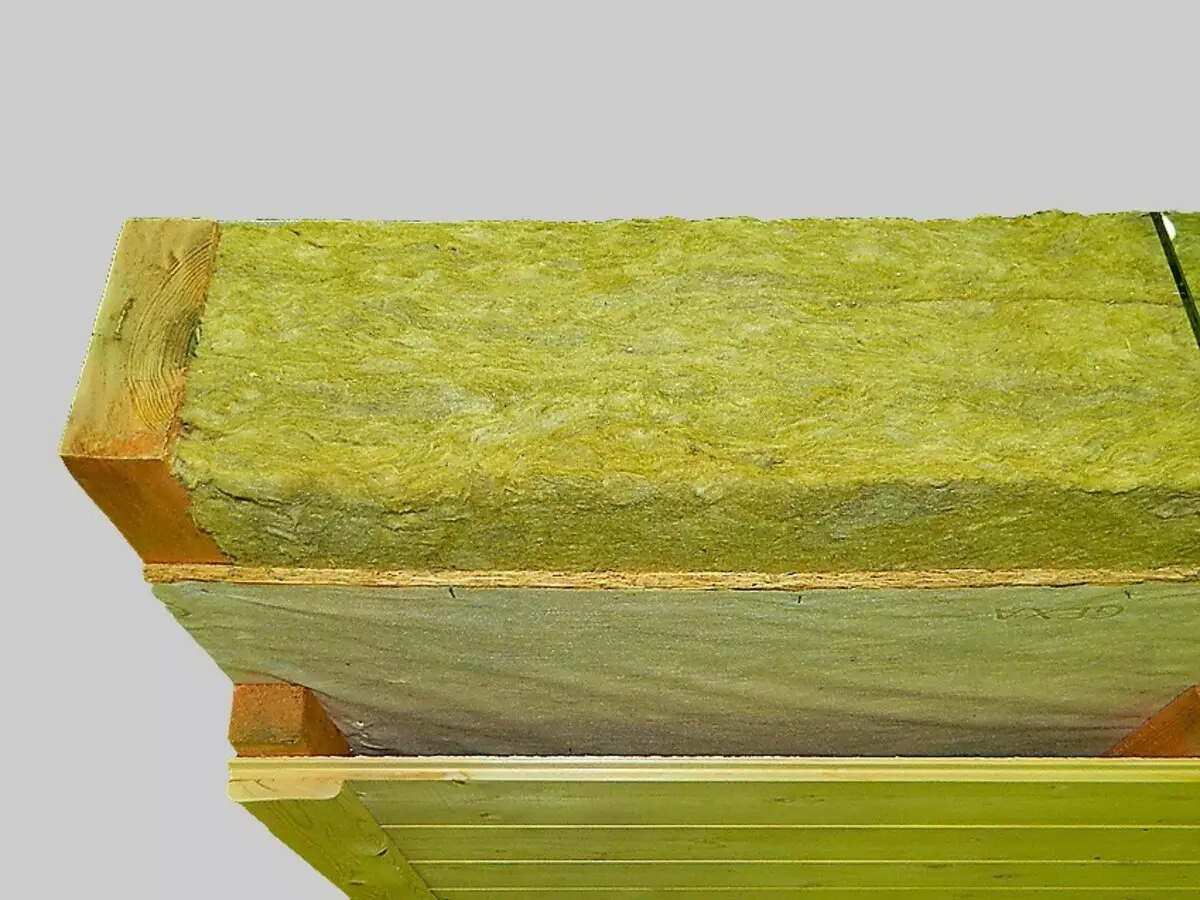

According to the design (number and material of the layer of sandwich), the panel is quite diverse, but always include elements of rigidity, cladding and thermal insulation.Stiffening rib

Ribra ribbon, as a rule, is performed from dry high-grade wood and only if necessary, the LVL-timber or composite stones are used, if necessary, overlapping. The step of the rigidness in the walls and the roof should be no more than 600 mm, in the floors - 300 mm.

Sheaving

The trim most often serve oriented chipboard. In this case, it is necessary that the material has certificates of compliance of GOST 10632-2014 (the inner plate must be a formaldehyde emission class E 0.5, the outer can be class E 1). More durable and besides the fireproof cover from the CSP, applied by Tamak.

Panel with two-layer insulation (stone wool + windproof DVP) and a painted board finish.

Panel with single-layer insulation of mineral wool, insulating with PCP and finishing with regular lining.

A panel with a two-layer insulation of mineral wool, without plating, but with a trim from a thick circular board (timing of timber).

Insulating layer

The main insulating layer is thermal insulation. In the middle strip, the wall panels are usually insulated with a layer of mineral wool with a thickness of about 150 mm (optionally 200 mm), a roof and base overlap - a layer of 200 mm (optionally 250 mm). A sound insulation of a thickness of at least 100 mm should be provided in the interolation panels of a thickness of at least 100 mm plus a vibrational layer of soft fiberboard, technical cork or other similar to the material properties.

From the side of the houses, regardless of the material of the casing, mineral wool must be protected from water vapor formed by the breath of people, cooking food, etc. From atmospheric moisture, the insulation is covered with trim and finishing or hydraulic recovery membrane and trim. At the same time, if the finishing or casing has high resistance to vapor permeation (plastic or cement panels), a ventilation gap should be provided under it.

Another popular insulation is a prestickable polystyrene foam. It is not afraid of moisture and, moreover, allows you to collect the panels with a reliable and fast glue method (in the panels with mineral wool, the trim is nailed to the robbers with nails or screwed with screws). Rights, sometimes use soft fiberboard (with mandatory vapor barrier and outer protection against moisture). This is a classic German technology that has been tested by time and in our conditions.

House in the style of Barn House with two-layer insulation, built according to the modular frame technology.

Internal partitions with a thickness of about 10 cm filled with soft wood-fiber stove, provide an insulation of air noise of about 32 dB. This is quite enough for a comfortable stay.

House-building firms, prices and timing

For the manufacture of large-format panels in Europe, powerful technological lines are used, designed to produce several thousand homes per year. Such an approach provides the low cost of the household complex, but automated equipment pays off only with mass low-rise construction within the framework of state programs. In Russia, the lines set about 5 years ago at enterprises in Tambov and Penza were loaded less than 10%. As a result, our firms went along the path of piece production, making a bet not on the mass, but at a higher than in conventional construction, the quality of houses, their energy efficiency, modern architectural and engineering solutions.

Firms making national teams (Bako, Tamak, Holmstaad, etc.), as a rule, offer clients to choose one of the typical projects developed on the basis of standard panels and nodes. The main mass of typical houses has an area of 70-130 m2. If necessary, the project can be finalized (usually for an additional fee) - "Curler", provide additional bathroom or increase the terrace. The smaller the standardization in production, the greater the number of projects offers a company, but the price of 1 m2 housing is also increasing.

In Russia, the price of 1 m2 of panel housing is approaching 20 thousand rubles. The usual carcass of the Finnish type, as a rule, costs 20-30% cheaper.

Some companies, such as Martin House, can make and collect a home complex even by an individual project: the architect must prepare the manufacturer's recommendations and technical descriptions of possible designs, and at the price of the house comes with construction from the glue bar.

When ordering panels without doors, windows and finishes, construction time is increasing, but it increases the choice of facades design options, and sometimes this way can be saved to significantly.

When a question with the project is decided, the company starts making panels. At the same time, the foundation may be arranged, most often slab or boilers. These works occupy an average of 2 months. However, a set of a small house (up to 70 m2) some firms are able to prepare for the assembly in just a couple of weeks. If the construction should be urgently put into operation and on concrete work there is no time, cuts out the pile-screw foundation. When the panel assembly is installed onto the strapping and are tightened with stainless steel bolts, sealing joints with polyurethane foam, tubular polyethylene or other gaskets.

House assembly is carried out by a brigade of three-five people. The base overlap panels unload the truck and attach to the strapping from a bar based on piles.

Then proceed to the installation of wall elements.

Another way to quickly erect low-rise buildings is based on the use of a unified modular frame. This technology is represented in our market of the company "INSI", "KARCAS +", OKMODUL, and others. The essence is that not the wall panels are collected in the workshop, but rather large (although not in the whole wall) elements of a metal or wooden frame From which the skeleton of a typical house is then erected. At the same time, the total construction time of construction is often even less than with a large-passenger method, especially if the supply of modules is always stored in stock. Their delivery and unloading do not cause any problems, and the assembly, insulation and the trim take no more than a week (at the area of the house to 100 m2). Another 2 weeks will require finishing, installation of windows, doors and "engineering".

How to control the quality of work

Purchase of a large-passage house is little similar to the construction in the traditional way: many hidden work here are carried out in production, and the assembly on the site is made so rapidly that even an experienced expert sometimes cannot follow all operations. And yet you need to watch and control!

It is extremely desirable to negotiate with the company on a visit to production and make sure that the design of the panel fully complies with the drawings. What are those materials that are designated in the project are applied and that they are good quality: there are no cracks on wooden parts, the sheets are not resolve, steam barrier and hydraulic protection are not confused.

Taking ready-made construction, carefully inspect the finish, check all the windows, doors and equipment. If the house surrenders in winter, good service will serve a household thermal imager, with which you can independently detect many defects of enclosing structures.

The factory panels rarely have large defects, much more often marriage is allowed during installation work, so the assembly stage needs to be carefully monitored.

Despite the attentive control, there is a risk that you will not notice the marriage made in the manufacture and assembly of the house. If the integrity of vaporizolation is broken, or the sheets of roofing material are casually docked, or the barn of dooms will blocked the roofing ventilation clearance, it will be detected only after weeks, and sometimes months - depending on the time of year and specific weather conditions. Therefore, it is very important to trace the service conditions of the house after the construction. The optimal option is a five-year warranty period of structures and installation work and 2 years warranty on engineering systems.

Despite the rather large area of glazing, panel houses correspond to modern requirements for thermal insulation, and energy costs for heating in winter do not exceed 50 W / sq. M.