Gypsum plaster allows you to quickly create a smooth surface, ready for finishing finish. We tell what tools will be needed for work, how to make marking, keep laying with lighthouses and without and prepare the surface to the final finish.

Gypsum plaster is not similar to traditional cement-based finish and sand. It is suitable only for a specific microclimate. In a humid environment, it will require additional protection. It is plastic than mineral substances, but not all the mixtures have this property. Wet, not yet grabbed the coating allows you to form a perfectly smooth surface. Its not necessarily put off after frozen, but to achieve high quality, special methods of application and subsequent processing are required. Work can be performed with your own hands without the help of the repair and construction team. For this you do not need professional equipment, the necessary tools are easy to find each construction store. Today we will tell you how to plaster with plaster plaster, with video and detailed description of the process.

Plastering Wall Plaster Stucco

Pros and cons technologyIssues of the compositions

Step-by-step instruction

- Required tools

- Preparation of the foundation

- Volumetric mark

- Stirring process

- Laying in lighthouses

- Work without Mayakov

- Final alignment

- Preparation before finishing

Pros, cons of the material and features of technology

Positive characteristics

- Ease is a property makes it possible to lay layers more than 5 cm. The sand-cement mass weighs much more. With a considerable thickness, it falls off.

- High plasticity allows you to create a perfectly smooth surface that does not require supels. She goes immediately under painting or under the stick of wallpaper. Thanks to the mobility of the mixture, it is easier to ram. Work does not take away a lot of time and strength.

- Lack of shrinkage when drying - a change in the size leads to the formation of cracks and weakening the connection with the base caused by internal shifts. Such deformations are characteristic of cement and solutions where it is used as a binder.

- Parry permeability is an important feature, thanks to which the walls begin to breathe. Indoor with such a finish is more comfortable than in a concrete "box."

- Porous structure creates a barrier for sound waves. Gypsum does not apply to soundproofers, but it allows you to significantly reduce sound permeability.

- Low thermal conductivity - the cold slower penetrates through the structure with a high content of emptiness.

- High grasp - it averages one hour and varies depending on the components. The finish can be made week after shuffling. An ordinary solution without additives is gaining marching strength for the month.

- Mobility - you can work with any base: brick, reinforced concrete and wooden. The wood is characterized by constant temperature and humidity deformations, as a result of which the connection with a fixed coating is lost. The soft mineral base in combination with polymer additives is able to shrink and stretch without cracking.

- Ecology - the material does not emit harmful substances.

- Fireproof - high resistance to open flame exposure, non-hatching.

- The heat resistance - the coating is used in the construction of objects experiencing a constant effect of high temperature. They can be fermented with a stove, a sinking zone and space near the gas stove.

disadvantages

Porosity improves vapor permeability, heat and sound insulation properties. It makes an array easy and movable. However, this quality has other parties.

- High water absorption - in dry rooms it is not critical. In wet coating with such a property it is not recommended to use. He will need an external protective shell, but then the use of a plastic mixture will be meaningless. It is needed to create a flat surface and saving time to the finish finish. For the same reason, the powder is not suitable for the outside of the building.

- High cost of products - it is not profitable to apply them to create a lower layer.

- Fast setting - stacking should be carried out as quickly as possible. It is necessary to breed dry powder in small quantities and put immediately. With a slight delay, it will grab in the pelvis. To use it simply, but this feature has to get used to it. In order for the work to be not stopped, one person prepares the solution, the other puts it with a trowel and smolders. Therefore, before plastering the walls with gypsum plaster with your own hands, you should carefully examine the instructions. It specifies the time of setting.

Types of compositions and their differences

- Powders with a small content of plasticizers and polymer fillers - they are less plastic. They are harder than spatula. Such materials are distinguished by low adhesive ability - they are badly held on the surface. To solve the problem, you need to use special impregnating primers.

- Standard mixtures with plasticizing additives and polymer filler that increases elasticity. They are stronger and moving. When applied to a porous base, for example, aerated concrete or red ceramic brick, impregnation of penetrating primers is required.

- Materials with improved characteristics. With increasing porosity, indicators for sound and thermal insulation are improved. Special additives allow to extend or shorten the grasp. Plasticizers simplify the laying, making the molding mass of the more mobile. It is easier to ram. Polymer fillers give it the ability to withstand mechanical loads under which a stronger, but solid coating breaks down.

- The mass intended for laying with special equipment is characterized by improved operational performance. This method is rarely applied at home. It is convenient when you need to cover a large area and when a team has a brigade of several people at the facility. This method is suitable for private houses and large apartments.

How to keep laying

Required tools

- Construction mixer or electric drill with a nozzle suitable for stamping powder dissolved by water.

- Flat capacity of more than 10 liters. A plastic or enameled pelvis is suitable. There are special construction tases made from secondary plastic.

- Taste - rectangular or pointed at the end.

- The spatula is better to use two at once. One wide, the other is elongated. The first is suitable for smoking and is used as a scoop where the solution is gaining, so as not to bent to the pelvis. The second is easier to process hard-to-reach areas. For corners, a spatula with a blade bent in half at right angles is used.

- Rule is a long rail with an ideal flat side. She eliminates bulges and depressions at the final stage.

- Spring grater. You can pelt the surface with small emery. They wrap a piece of bar, which goes well in the hand.

- Construction level and plumb.

Preparation of the foundation

The old coating is completely removed. The slots are expanded. It is necessary to remove the sprinkled edges, which are no longer possible to strengthen. The base should be durable. Dust and wet pollution remove it. Fat stains are erased with alcohol. Then they are impregnated with primers. They are used on the basis of a large content of pores and cracks. Durable reinforced concrete slabs do not necessarily soak. Sowing coats with penetrating compositions that strengthen them from the inside. There are solutions that improve the grip with the stove.Marking on the walls and ceiling

It denotes the required layer thickness. At a distance of 10-20 cm from the corners, the holes are drilled under the dowel, then screwed screws to the height of the finishing layer. The position of their caps exhibit in terms of and plumb. Between self-stakes stretch the threads. It is easy to find curvature. In the case when the thread concerns the plate, the thickness of the layer is increased.

How to dilute gypsum plaster

The proportions differ greatly depending on the composition and purpose of the powder. Before you knead it in water, you should read the instructions on the packaging. It is necessary to act in a certain order.

- In pure pelvis pour water. Its quantity must comply with the proportions specified in the instructions. It should be good to represent how much material will leave for one kneading. Catching occurs within one hour. During this time, the mixture must be fully developed. Craisted residue cannot be used. It is necessary to calculate the proportion. If the packaging requires x liters of water, and we can only put 1/10 part of its contents, then we will need x / 10 liters. From the first time, it is impossible to find out the optimal amount of dry component. Typically make small tests, allowing you to determine how much material goes per unit of time. Then take as much as you need for a certain period of work.

- Powder falls asleep in the container. At the same time, it is constantly stirring, so that it dispels better and did not merge in lumps.

- The mixer is lowered in the pelvis and mix the mass, evenly distributing the particles and giving it homogeneity.

- After receiving a homogeneous mass, it is maintained for 5 minutes, then re-stirring. During the mixing, the mixture is already starting to be captured. The time that went to this process should be subtracted from the total period of hardening. It will remain about 40 minutes.

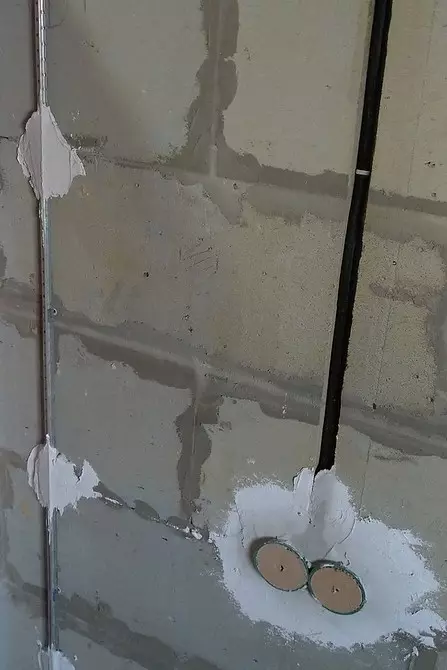

Laying with lighthouses

Lighthouses denote the level to which the solution should be laid. The method is used in the presence of irregularities more than 5 mm. When the layer thickness exceeds 3 cm, the metal reinforcing mesh is fastened. Lighthouses serve metal profiles or thin rails, laid on the bugans from the solution. These elements are aligned in terms of or plundering. They should occupy a strictly vertical or horizontal position. When the bumps are slightly grabbed, proceed to the main work. The plate is wetted with water from the sprayer or wipes with a damp cloth. To wet base, the material is bigger. He is thrown by a trowel, trying to close the surface evenly. Too thick pieces can fall off. In addition, with significant differences it will be difficult to conduct alignment.

It is better to work in small areas, otherwise the mass will not have time to work out and grab into the pelvis. Typically take the space between the rails, without going beyond its limits. Surplus are removed by spending the rules dropped to lighthouses. Then they are spent several times, while performing rapid zigzag movements. They are needed in order for the mixture better than the remaining emptiness.

The stoves of the plates pass by the corner spatula, moving it from the bottom up. It is easier to do this, laying it on the profile or rails, put on perpendicular surfaces. You can lay in several layers, allowing the bottom to grab. At the final stage of the rails and the profile is removed. It is impossible to leave them, as they will begin to collapse, relaxing the finish. The remaining trails close and smash.

Laying without lighthouses

It is used in the presence of irregularities up to 5 mm. With this method, it is impossible to get perfectly smooth walls and ceiling. It makes it possible to save time. Send them easier to learn how to throw a mixture.

Mass are uniformly loaded on a wide spatula with a narrow rectangular blade. Then spend a wide spatula based on the bottom up, trying to create a layer of the same thickness. Move follows from the corner. Hold a wide shovel in hand difficult. It is necessary to calculate the power so that the pressure from both edges is the same. At the slightest distortion, the blade will leave the trail on the newly laid composition. Newcomers are easier to work narrow blade. Wide better to use for rareling. At the final stage, a rule is used.

Final alignment

Not every wizard knows how to break down the gypsum plaster. Meanwhile, this method allows you to quickly get rid of irregularities without putty and long grinding. When grinding, dust is released, penetrating all the corners of the apartment. You need to work in protective glasses and respirator. It is extremely inconvenient to do it. Head is better to hide. Thin-dust dust settles slowly. When it falls, it will have to remove it for a long time from windows, lighting devices, items remaining indoors.

Wet grinding is more simple and effective. After the final setting, the surface is wetted by water from the pulverizer or is wiping into a damp cloth. She is rubbed by the spongy grad. When grilled in drops of water, fine dust is released from the pores. This mass fills up all irregularities, cementing them and making less permeable. It is an analog of putty.

After drying, you can move to the sticking of wallpapers and whiten the ceiling. The coating is ready to apply texture paints. To put ordinary glossy or matte paints, make a glossy. A wide spatula is applied under a sharp corner and cut off the remaining minor irregularities. After this operation, the wall is ready for final finishing. The coating is able to withstand the load from any materials. If necessary, it is lined with a stone or tile, decorative mineral compositions are applied.

Preparation before finishing

These activities are carried out after complete drying and setting the binder. It is gaining marching strength for 5-7 days.

To close the pores from moisture, strengthen the internal structure, improve adhesion, use the impregnating primers. Corners are closed with a perforated profile that protects them from mechanical damage.

In the final, we offer to watch a video that demonstrates how to plaster with plaster plaster.