We tell about the methods of cutting acrylic glass with a grinder, hacksaw, cutter and other devices.

A homemade master has to deal with different materials. Well, when there are special tools for processing each. But it does not always happen, the universal set is more often used. We'll figure it out how and how to cut the plexiglas at home to get accurate cut and not spoil the workpiece.

All about self-cutting plexiglas

Features of the materialRules cutting

Tools for cutting material

- Hoven

- Cutter

- Electrolovik

- Electrophezer

- Bulgarian

- Nichrome wire

Features of the material

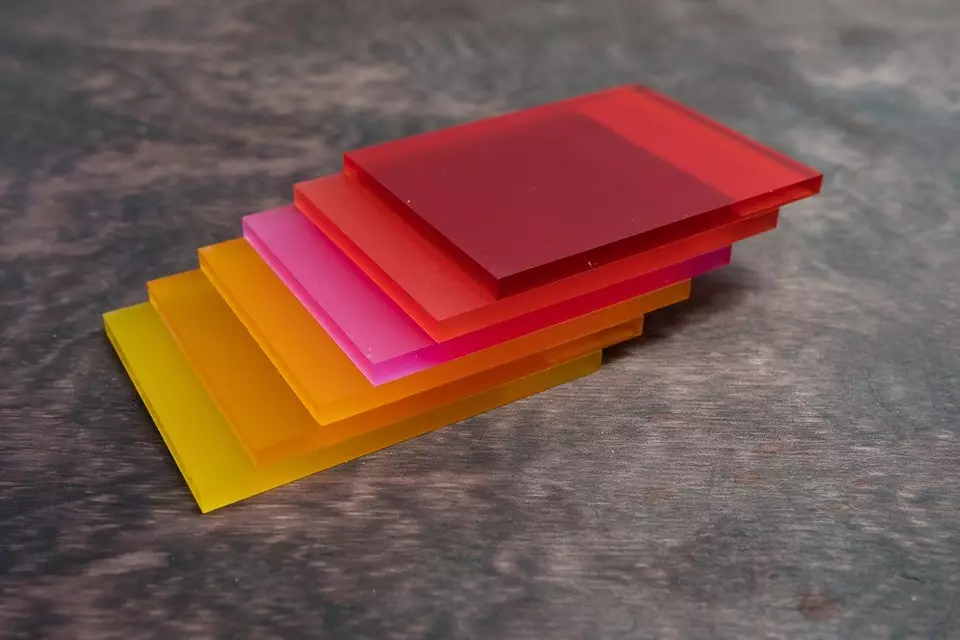

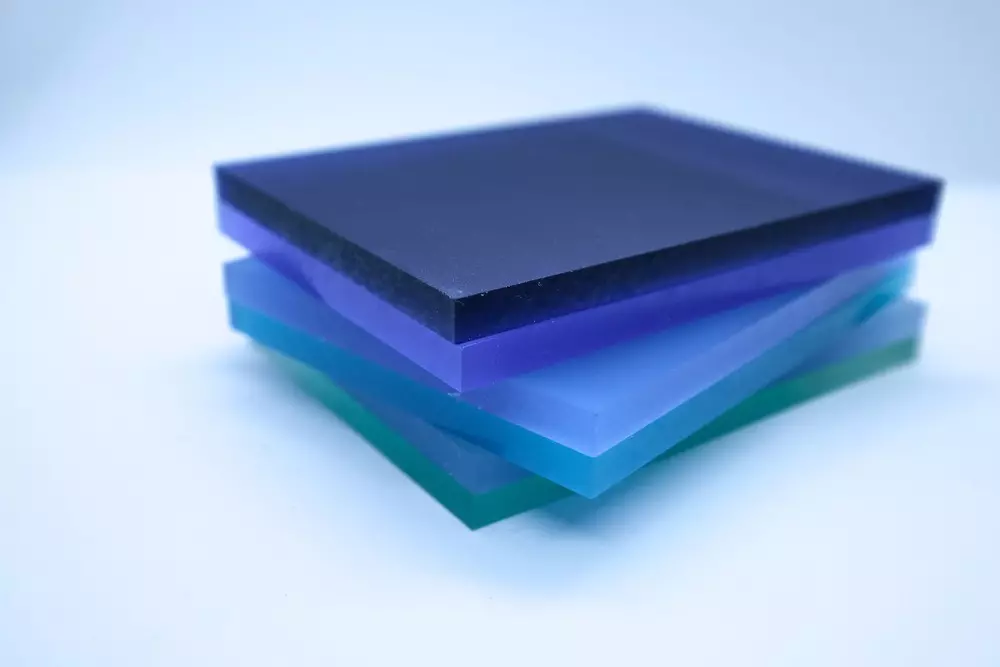

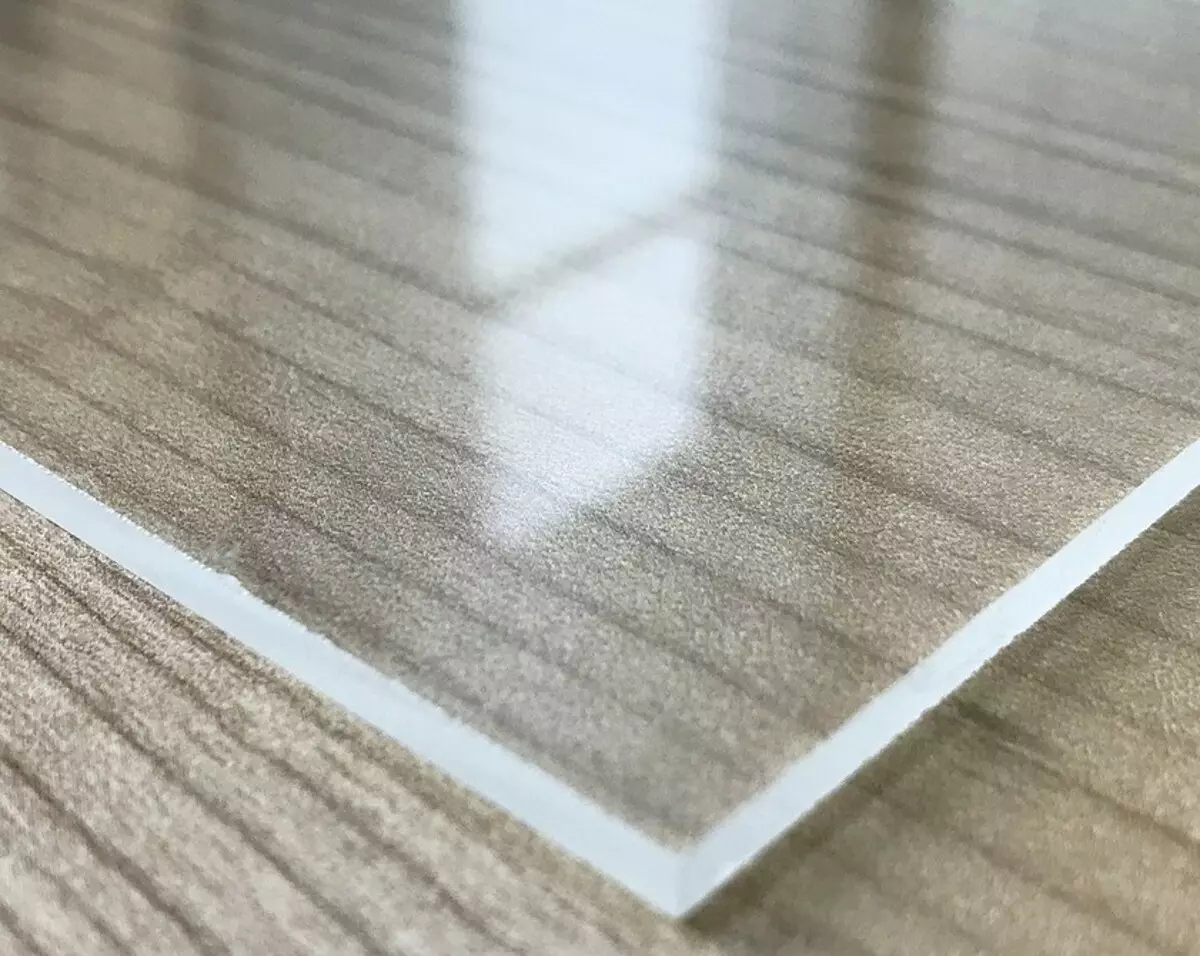

Acrylic glass is called plastic. It is obtained by mixing methylacrylic acid with the essential components and subsequent polymerization. Known under the names acrylic, plexiglass, plexiglass. Not inferior to glass in transparency, but it has a smaller weight. When heated to 90-100 ° C, the material becomes plastic. It can be bent, to give the right shape. This property must be taken into account when processing. When heated it is easy to deform the workpiece.

Melting acrylic begins at 160 ° C. The blade of the power tool during the cutting process is heated and heats up the workpiece. The temperature rather quickly passes the melting point. The plexiglass melts, its particles stick to the cutting knot, which makes it difficult to work. Therefore, it is desirable to use cooling. So, in production is carried out by blowing a jet of cold air or water is supplied. The last method is usually used in the home workshop.

Rules cutting

To quickly and accurately cut the workpiece, you need to execute several rules. They "work" for most synthetic materials: organic glass, polycarbonate and others. We list the basic rules how to cut at home Plexiglas 4 mm and other sizes.

- Direct or curvilinear cut is much easier if the detail of the breakdown. For this, before processing, it is heated a little. A construction hairdryer is used as a heat source or gas burner. Important moment. In order not to bounce acrylic, it is kept at a distance from heating tool.

- To work, it is best to choose a cloth with marking MP.s. This is tempered high strength steel.

- Cut in any power tool only on low revs. Otherwise, acrylic glass will be heated from the blade and melt. Speed for each fixture is selected individually.

- Cutting material without eye protection is impossible. We must wear a mask or special glasses. When working, many very sharp small fragments are formed, which are scattered from under the cutting node.

Suitable tools

Options than cutting at home Plexiglas 2 mm and thicker, a lot. In detail we analyze the most efficient and easily accessible.1. Hoven

The hardness and complexity of processing the plexiglass is comparable to the beech. It is enough to simply cut the hacksaw or if the scope of work is small, a homemade cutter made of cutting canvas. For processing, the blade with frequent small teeth is chosen. First, the workpiece is placed, the cut slicer is carried out on it. Most often it is straight. Cut the curvilinear detail of the hacksaw is very difficult. Markup is good to perform a felt-tip pen or a marker. He leaves a clear mark. You can do otherwise. Scratch the line with a sharp nail or knife. You need to cut slowly, not allowing strong heating of the part. To prevent the blade sticking, it is recommended to periodically water the cutting section with cold water. The cut from the hacksaw is uneven, requires grinding.

2. Cutter

It is convenient for them to use with small amounts of work, when the sheet thickness does not exceed 2-3 mm. Building stores selling a cutting device. With it, straight cuts are performed, curvilinear is difficult to do. Before cutting, the workpiece is placed. Then tightly pressed the metal line to the intended line. With effort carried out a cutter on the sheet. Do it several times so that it turned out the depth of approximately half the plate. Then they put it on the edge of the table or workrix and the exact movement climbs the edge.

The slice turns uneven, it is grinding. In some cases, the homemade cutter from the metal blade is used. Take the canvas, sometimes even used, on a sharpening circle, they make a sharp "spout" to make it convenient to cut. The opposite edge will be a handle. It is wrapped with a tape. Homemade cutter ready. They work as well as hacksaw.

3. Electrolovik

For work, only a padzik with an adjustable number of revolutions is chosen. It is best to take the pinks of the metal, if it is impossible, the blades for the tree are also suitable. At the same time, they should be with small and frequent teeth. It is possible to perform not only a straight cut, but also curvilinear. True, it will not be easy to do. In any case begin with marking.

The pylon put on the cut line, include the tool. Choose the smallest turnover and minimum speed. They try to move slowly so that the saw does not warm. With the appearance of signs of melting material, the work stops, pouring cold water into the cut. It is easy to notice melting. Plastic in the area of the section becomes milky white, smoke and characteristic smell appear.

4. Electrophezer

Using the cutter, you can make high-quality smooth cut, but the cutting unit is quickly triggered. For cutting, you choose a mill thickness with a thickness of no more than a millimeter. Another minus is a strong smoke when working, since acrylic is heated. Without cooling, it can not only melt, but also foam. Therefore, it is necessary to bring water to cool the cutting section. The easiest way to serve a cooling liquid from a plastic bottle, in the tube of which is inserted with a small diameter tube. In such a simple way, you can achieve a transparent and even cut.5. Is it possible to cut plexiglas with a grinder

Experts recommend that it only if the sheet is fat enough. Its thickness should exceed 5 mm. Almost straight cuts are performed by a grinder, curvilinear is impossible. The tool cuts quickly, acrylic glass does not have time to overheat and melt. It does not stick to the cutting knot.

To work, choose a disc on which three large teeth are located. It is intended for wood processing, but copes well with the plexiglass.

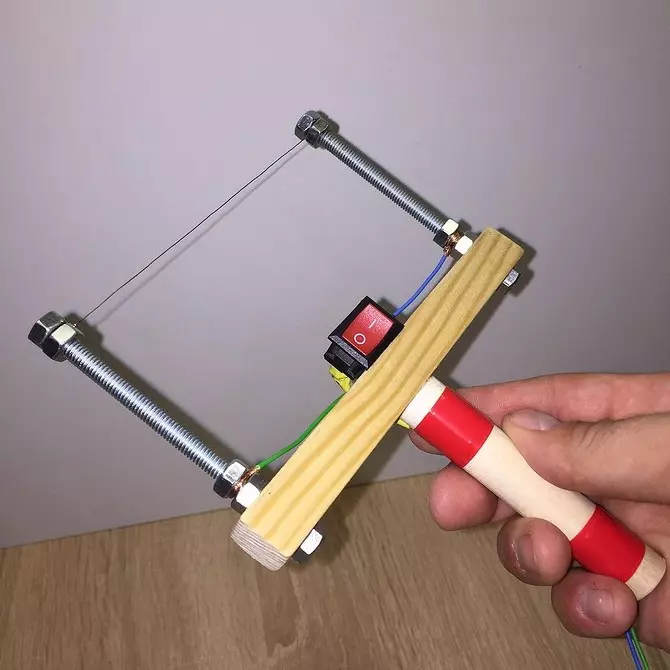

6. Nichrome wire

With it, it is performed by curvilinear vertical and straight horizontal cuts. To do this, you need to assemble a homemade device. The nichrome thread connects to the current source, voltage - 24 V. It is advisable to use the retainer so that heating can be adjusted. Wire fixed on both sides to make it possible to cut the cutter. Sometimes to the top end attach the handle to the bottom - the weight. Such a device is convenient to perform curvilinear vertical cuts, cut complex figures.

These are not all options than cutting a plexiglass 5 mm (or thicker). You can use glass cutter. The technology does not differ from the one that is used for glass. Marking is applied onto the sheet, the glass cutter is income, then the edge is barely. Unfortunately, it is not always possible to cut the item without chips. So that they were not, instead of glass-cutter take a slotted screwdriver, heated by its soldering iron. Climb to the leaf until it starts to melt. Then the screwdriver moves on the markup. Plugged about the middle of the thickness sheet is laid out and cleaned.