We are talking about the advantages of the acoustic ceiling of drywall and list the design options: an extension ceiling on a wooden shell, suspended design on a metal frame and others.

To ensure good acoustics in the room with musical equipment or in the home theater, as a rule, it is not enough to install wall noise absorbers. Part of the interference is created by waves reflected from the smooth concrete ceiling. Special ceiling structures will help solve the problem.

Benefits of the suspended acoustic ceiling

Almost every manufacturer of components for suspended and stretch ceilings offers acoustic materials. However, they are often either roads (as, for example, wooden panels), or almost do not dissipate the sound wave (tensioning canvas), or they have a specific appearance (foam-rope noise absorbers). Optimal in terms of price and effectiveness today is the suspended acoustic ceiling of drywall - perforated or ordinary. In this case, the design has a relatively small thickness (from 35 mm), fireproof, not dust and does not distinguish harmful substances. Externally, such a ceiling may not be very different from plaster.

At the stage of selection of the ceiling design, it is desirable to conduct an acoustic inspection of the room. Quality quality control should carry out a construction acoustics specialist.

Features

Most often for acoustic structures, special perforated GLCs are used, for example "KNAUF-acoustics", "Soundline acoustics", Gyptone Activ Air Point, and others. Pierced in the holes of the hole can be round or square, their diameter (side length) 8-12 mm , and step 18-25 mm.Perforation makes a leaf permeable for sound and much reduces the intensity of echo (in the language of specialists - increases the reverb coefficient of sound absorption material). The physical essence of the phenomenon is that the sound wave passing through the holes is crushed into parts that face the space behind the ceiling and quench each other. A small additional noise reduction is provided by a subtle synthetic web striking on the back side of the sheets.

The result of unequal at different frequencies. At the same time, it depends on the size, form and mutual position of the holes, as well as on the attitude of their area to the sheet area (perforation coefficient). Standard acoustic GLC thickness - 12.5 mm, dimensions - 1200 × 2000/2500 mm. The nonwoven canvas glued to the back can be black or white. The first makes the holes well noticeable, the second masks them - the choice depends on the designer idea.

The acoustic GLCs should not be confused with sound insulation ("Gyproc Aku-Line", "Knauf Sapphire", etc.), which differ from the usual only increased density.

Designs

On the acoustic characteristics of the ceiling affects not so much the character of perforations as the total structural solution. For example, with an increase in the reciprocal of HCL from the overlap, sound absorption at low frequencies increases sharply, and on high, on the contrary, decreases. If you position in space behind the ceiling layer of mineral wool, sound absorption will increase by 10-15% in the entire hearing range. However, with incorrect assembly, the plasterboard ceiling will not only do not improve acoustics, but also will begin to interfere. So, let's talk about the specific designs and the rules of their installation.

The problem of insulation of sounds from the top apartment, the acoustic ceiling decides only if there is a layer of mineral wool or other noise-absorbing material.

1. Stitching ceiling on a wooden shepherd

Wooden rails are fixed to the slab overlap with steel anchors, for example, a cross section of 22 × 35 mm. The mounting step at the same time should not exceed 600 mm. It is very important that the rails are dry (no more than 8% humidity). It also does not hurt to the other side that contacts the stove, to glue a layer of cork veneer in advance to reduce the transmission of oscillations between the ceiling and overlapping. The plates of GLC are fixed to the rails.

When installing GLCs fasten with screws in 250 mm increments.

Then coopclothes the caps and fill the sheets of sheets with a gypsum replacement to the entire depth. On the finished painted ceiling of the seams are invisible.

The main advantage of such a design is a small thickness (from 35 to 50 mm) and quite simple installation. But its weighted average (in the frequency range from 250 to 4,000 Hz) AW sound absorption coefficient will not exceed 0.35, while the effect will be felt mainly at high frequencies, and on low medium and low, where the most unpleasant interference occurs, it will be minimal . The stevy acoustic ceiling will only slightly improve the sound of speech and dynamics of equipment. It is suitable for a small room, where listening to music, as an addition to the wall noise absorbing panels and corner bass traps.

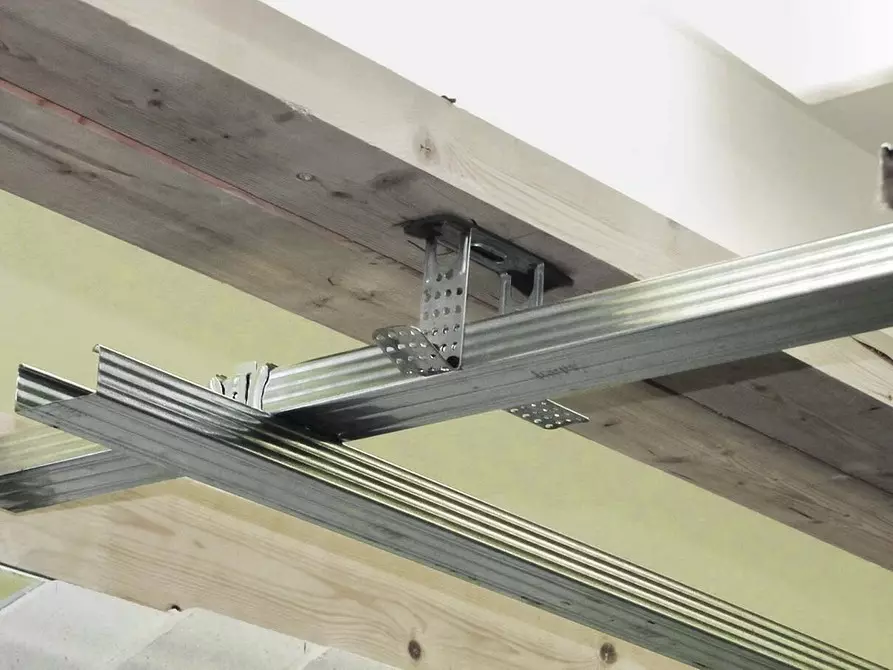

The base of the acoustic plasterboard ceiling is a frame of wooden plates or steel profiles that are attached to the overlap using suspensions.

The joints of the long sides of the GCC should have to the profiles.

When installing can not do without tape for joints.

Soft sealing tape for mounting.

It is advisable to use acoustic suspensions.

2. Suspended ceiling on a metal frame

It can only rely on the walls, but only if the magnitude of the span (width of the room) does not exceed 4.25 m. When mounting, you need to fix the guides on the perimeter and set the beams from dual profiles dual profiles. Between the beams and the slab of the overlap must be left a gap of at least 10 mm, and between the guides and wall lay the soft tape, otherwise the appearance of vibration noise. Next - the casing. The minimum construct thickness is 70 mm, and the sound absorption coefficient is 0.55-0.60. If the width of the room is more than 4.25 m, the frame is fixed to the overlap with simple or adjustable suspensions. They are fixed with metal anchors through elastic gaskets, with a step of no more than 110 mm. Ideally, you need to use special vibration insulating suspensions, but they are 3-6 times more expensive.

For the installation of sound insulation and acoustic ceiling, it will be necessary: noise absorbing material.

Absorbing material.

Frame details.

Special plasterboard sheets.

3. Suspended ceiling with an additional layer of noise absorbing material

The fibrous noise absorbing material installed in the prescription space is particularly effective in constructions, wherein the GLC from the overlap is small (50-100 mm). In addition, this solution will improve the overlap sound insulation by 4-8 dB: the upper neighbors will not definitely hear the sound of your columns, and you will noticeably reduce the volume of the shock noise. In the design of the suspended ceiling, the slab of the noise absorbing material with a thickness of 40-50 mm (technoacoustik, "isover sound", "isolat-l", etc.) usually rely on the frame profiles. In this case, the load on profiles and suspensions increases by about 25%. This must be taken into account when calculating, reducing the step of the fasteners or using the two-level framework (for example, the system of KNAUF P 112 or P 232).

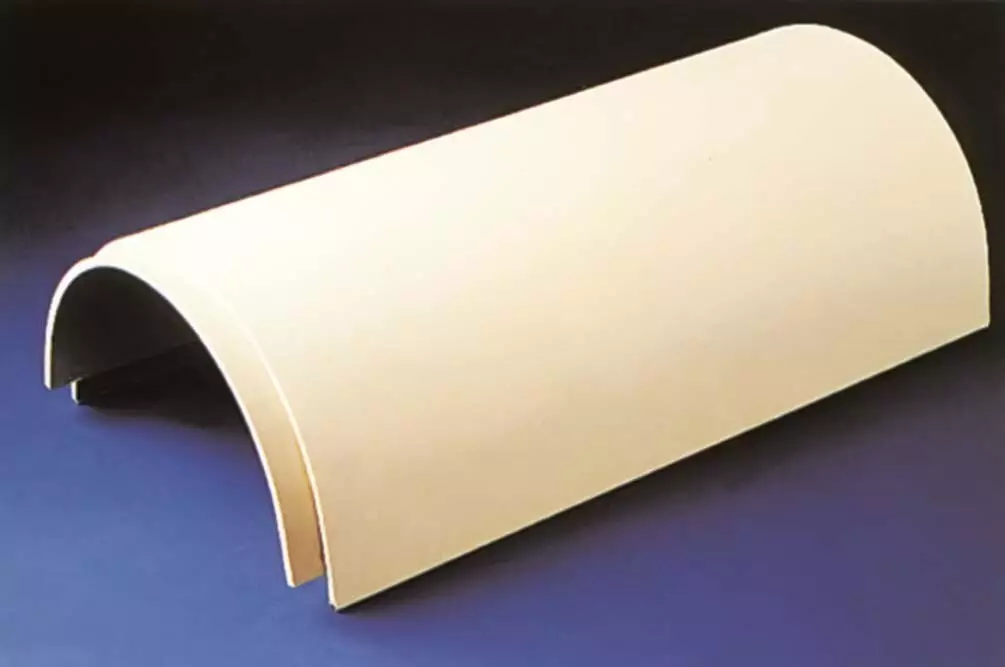

The wavy ceiling is good devouring a low-frequency echo. To assemble such a design, it is necessary to bend GLC.

6.5 mm thick sheets can be bend on radii from 1 m in a dry state, but usually the material is required to moisten.

Another, much more serious problem is associated with the possibility of emission of mineral wool particles to the room. Theoretically solve it is not difficult, laying under the noise-absorbing material polyethylene film. But in practice, this is very difficult to install: through the film you need to skip the numerous suspensions, then seal the holes, the joints of the strips, the adjunctions to the walls. Such work is expensive and requires careful quality control. An alternative is to replace mineral wool soft fiberboard with wax impregnation, firmware synthetic mats, flax-based materials or cotton.

| Type of perforation (Perforation coefficient,%) | The value is taken From overlapping, mm | Sound absorption coefficient in octave stripes *, Hz | ||||

| 125. | 250. | 500. | 1000. | 2000. | ||

| Solid round (15.5) | 60. | 0.15 | 0.30 | 0.70 | 0.80 | 0.50 |

| 200. | 0.45 | 0.70 | 0.80 | 0.55 | 0.45 | |

| Solid Square (23.9) | 60. | 0.15 | 0.25. | 0.65 | 0.85 | 0.60 |

| 200. | 0.45 | 0.75 | 0.85 | 0.60 | 0.50 | |

| Blind round (12.9) | 60. | 0.15 | 0.30 | 0.55 | 0.70 | 0.60 |

| 200. | 0.45 | 0.55. | 0.65 | 0.55. | 0.50 | |

| Block square (16.3) | 60. | 0.15 | 0.35 | 0.55 | 0.65 | 0.55. |

| 200. | 0.45 | 0.60 | 0.65 | 0.55 | 0.50 |

* The value of the coefficient can be from zero (no sound absorption) to one (complete sound absorption).

4. Acoustic waveres

Not only perforated, but also embossed surfaces, in particular, the highlight ceilings are capable of quenching the sound wave. It is not necessary to create complex curvilinear forms with a variety of tiers. In the conditions of the apartment, it is quite enough to arrange a cornice decrease in the level of the walls or a couple of fisbalkas. Optimal acoustics will provide a caissional ceiling - imitation of longitudinal and transverse beams, which can be decorated with polyurethane stucco. But it will require a rather complicated carcass and painstaking plates - due to the many edges and corners.

For the assembly of the multi-level ceiling, the suspensions are needed at least two types, standard guides and carrier ceiling profiles, as well as a thickness of 9.5 mm. When developing drawings, a reference book "Model building structures, products and nodes", which is easy to download from the site Knauf.

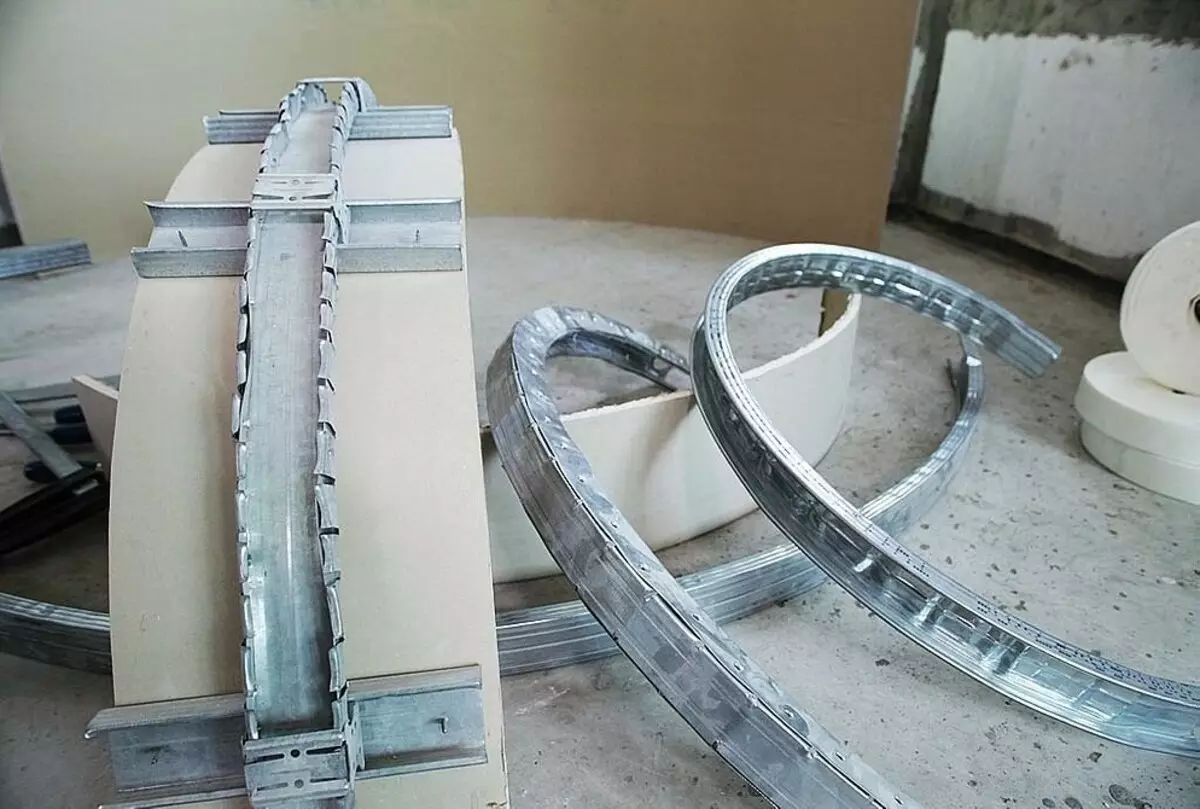

For the framework of dome structures, pre-curved parts are used or made on notch profiles and give them the desired form when assembling.