We tell about the peculiarities of the material and design, technical calculations of the load, the preparation of the site and the installation process.

During repair, sometimes there are enough stepladers or a homemade wooden frame, rigging on an ambulance hand. For large-scale work, a design will be required that will not need to be rearranged from place to place, each time I search for a suitable platform. It will fit several people, the necessary materials and tools. The metal frame of pipes is not only more convenient and safe than flooring from the board. Such a solution allows you to save time, which is usually spent on the rearrangement of the stairs from one point to another, the transportation of materials upwards, vain attempts to optimize the workflow. Building forest assembly can be carried out independently. About this tell in the article.

All about assembling scaffolding

Materials and features of elements- Equipment

- What pipes are made

- Frame device

Installation instructions

- Select model

- Preparation of the site

- Installation Instructions

Installation on facades of complex shape

- Technical specifications

- Instruction

Construction Material and Features

It is more convenient to use the set of finished parts. They are manufactured taking into account technical standards that ensure security at the facility. Before collecting building metal forests, you should check the list in the instructions, whether all the parts are in place.

Equipment

- Vertical racks taking the main load. They are installed on the platform and the other elements are fixed to them.

- The struts arranged horizontally or diagonally. They combine racks together and give the system stability.

- The jumpers on which the flooring is stacked. The width of the flooring on average is 1-3 m. The height of the tier depends on where the work is carried out. As a rule, it is equal to 1.8 -2 m.

- The stops are needed that the design is reliably stood on the ground and did not walk.

- Stairs for which you can climb to the top of the facilities.

- Mounts connecting all elements among themselves.

To insure from falling yourself, tools and materials, from the outside, stretch the front grid. If the hammer falls into the gap between the grid and the horizontal pipe, it will not be able to cause any harm to anyone. Mesh fabric also protects from the sun, wind and rain. It is much more convenient to work with it. The only drawback is that it delays dust in the inner space. When grinding the surface of the facade or working with toxic compositions, it is better to remove it or use the respirator.

Materials of pipes

- Aluminum parts have low strength. They differ in a small mass, so they are most often used when repairing low-rise buildings. Such systems are inexpensive, but with strong impact it can be damaged. Broken and browning elements are not subject to repair. When breakdown, replace them with new ones.

- Steel prefabricated elements are the most durable. They have a significant mass, but assembled as compact as aluminum systems. They cost more, so it is better to rent them. Galvanized steel is more rack to external influences, but in strength no different from the usual.

Design

Systems differ in the method of attaching racks and spacers.

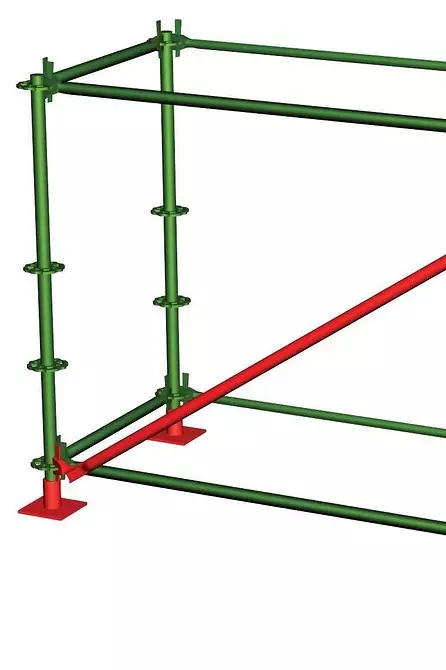

- Frame - consist of welded flat frames connected by horizontal and diagonal jumpers. They form sections that are fixed with flag locks. Vertical top tier racks are inserted into the lower. Such forests are suitable only for smooth facades.

- Pin - Installation is made using holes in horizontal parts and pins - in vertical.

- Wedge - reliable docking provide flanges - planes with bolt holes, and holders. Suitable for any objects, since they are able to change the angle, adjusting to the complex relief of the wall and the uneven platform.

- Clamps - the connection occurs with a wrench twisting clamps. They are blind and swivel.

For low-rise private houses it is better to use frame systems. They are easy to assemble and have the smallest mass. They are used both inside and outside the building.

Installing frame scaffolding

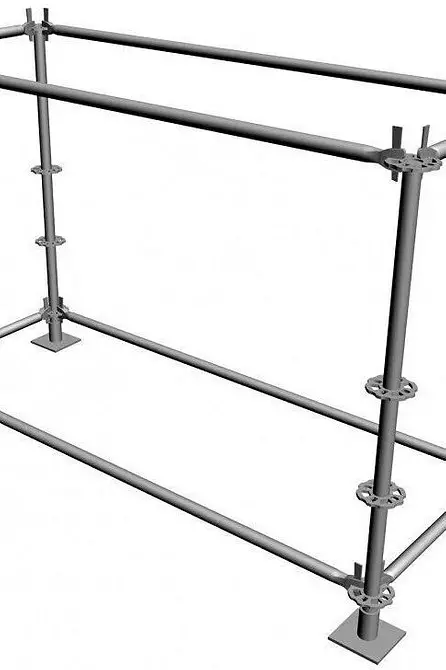

Choosing technical parameters

- The diameter of the pipe is 30 mm.

- Wall thickness - 1.5 mm.

- Limit load - 600 kg.

Domestic models have labeling LRSP-30, LRSP-200, etc. The two-digit number in the end denotes the maximum height in meters, the three-digit - maximum permissible load in kilograms. A model with a LRSP-30 brand is suitable for a low-rise private house. Its maximum height is 30 m. Such a stock should be enough even for the highest cottages.

Sizes of one section

- Height - 2 m.

- Length - from 2 to 3 m.

- Width - 1 m.

Types of support

- Unregulated on the steel groove.

- Adjustable - with a screw mechanism that allows them to raise and omit.

Types of products with labeling LRSP-30

Products with labeling LRSP-30 do not always have the same device. They differ in the following features.- The jumpers between the frames are diagonal and vertical. Diagonal creates the most rigid connection between the elements.

- For mounting to the facade, one-time brackets mounted on the dowels or reusable are used. They are fixed on the anchors that can be removed from the wall.

- The flooring makes from boards or steel perforated parts designed for heavy loads.

Preparation of the site

To ensure that the design is not risen, you need to properly prepare the basis. Soil should be dissolved and tamped. It is advisable to arrange the racks on the solid surface or to put an even base for them. In this case, it will have to take advantage of either to achieve stability, adjusting the position of the legs.

In the wet soil make drainage embankments from broken bricks and other materials through which water will go into the soil. So that the soil is not washed away, they arrange drainage ditches. They should be located away from racks. It is not necessary to strengthen the walls, but it is better to close them with sheets of tin or slate, or flood with rubble.

Mounting work

It is necessary to build scaffolding according to the instructions. Each model has its own characteristics. To spend the work correctly, you need to accurately follow the recommendations and do not try to improve the existing technology.

Installation starts from the corner of the building. The soil is stacked by shoes with a height of 4 cm and stripping from the tree. Their position should be strictly horizontal. Step is strictly regulated by the instruction. To properly set the shoes and gaskets, use the construction level. Supports are located on top. Then adjust the screw mechanisms if they are. The position of the supports should be the same, otherwise the frame will be fused. At an altitude of several meters, even small movements are very noticeable. It is dangerous to work in such conditions.

Flat welded frames are inserted into the shoes. They are located in parallel and are connected by horizontal and diagonal jumpers. The quality of work is checked using a construction level.

When the first tier is ready, it is fixed on the wall anchors or dowels. From above laid rheglels - horizontal parts that perform the role of grounds for overlapping.

Then the staircase leading to the second tier is attached. Flooring on the riglels. The boards are steady, in order to be between them no gaps. The coating should be solid, otherwise the tools will fall into the slot. It should not use steel flooring, because it is needed only with significant loads. With a low thickness, the boards are harvested with the allen and strengthen so that they do not sprawl when walking. To understand how much material is needed, you need to know the length and width of the frame. Some models have on-board fences.

Scraping scaffolding scheme provides for the possibility of creating several tiers. If you plan to create a third floor, you need to install the second staircase and make a hatch in the flooring to climb upstairs. The diagonal jumpers of the upper and lower floors are attached in a checker order, forming a rhombus separated by half the overlap.

Installation of forests for facades of complex shape

For complex facades, pin, clamp and wedge systems are suitable. Pins are too massive for the private site. Installation of clamp takes a lot of time, so it is better to use wedges. Their compounds allow you to change the angle of details, which makes it possible to get even to the hard-to-reach sections of the facade.Technical specifications

- The height of one section is 2 m.

- Length - from 2 to 3 m.

- Width - from 1 to 3 m. For a country house, it is enough to 1 m.

The load varies depending on the model and its modification. The limit load is 500 kg / m2.

Installation process

Preparation of the surface of the base is made by the same principle as with frame forests. The site should be smooth and, if possible solid.

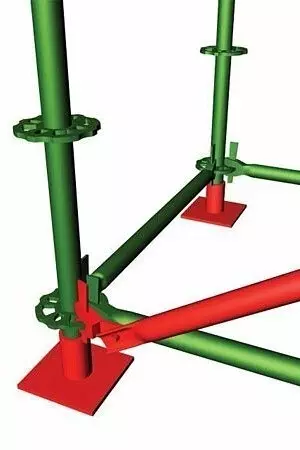

Cross wooden layers are fitted onto the ground under each pair of supports. Foreign heels can be welded or regulated. Vertical frames are inserted into them. Their position is checked by level. It should be strictly vertical.

At the racks on the surface there are flanges - perpendicular to them planes with mounting holes. Longitudinal and transverse jumpers are fixed on flanges using wedge locks - wedge enters the hole and clamped with the locking mechanism.

When the frame is ready, the rigleels are attached from above, the hinged staircase and flooring. Most models include enclosing railings.

Before collecting scaffolding, you need to explore the instructions. The assembly details may differ from different models.