Thin layer levels, self-leveling mixtures, different types of screeds - we tell about different materials for floor leveling and methods of their installation.

The base of the floor in the apartment is rarely perfectly smooth, because the overlap is usually assembled from individual reinforced concrete slabs, on the joints of which there are levels of levels, and part of the elements can be laid with a slope. The consequences of negligently or improper preparation of the base of the floor may be apparent immediately at the end of the repair: it is difficult not to notice the rich hound or the thresholds on the border of the rooms. But much more often they give themselves to know later when the symptops appear, as well as sweeps and cracks on the site of minor irregularities. How to create a smooth and durable "base" for laying outdoor coverage? Let's talk about flood alignment methods.

Plate for concrete

In many apartments (mainly in new homes), the slabs of the overlaps are laid quite smoothly, and their joints are reliably chosen; As a rule, the cement-sand screed is arranged over. At the same time, defects may remain. The removal method depends on their character, as well as from the type of flooring selected.

Local surplus of the solution on the tie from the developer can be cut down with chisels, and small holes and traces from the rule to withdraw the cement-polymer or polymer putty on concrete and thus get ready-made base for laying tiles, laminate or parquet board. Ruling coatings directly to the rough screed Since they are manifested by the slightest defects (the finish alignment of the bulk mixture is necessary). If a massive board is chosen as a coating, a glueing floorboard or piece parquet, you need to ensure the high strength of the putty on the gap. For this purpose, a two-component epoxy replacement will be perfectly suitable, but it is necessary to carefully prepare the reason - to dedust it, degreased, and sometimes to be rebuilt with the hardening primer.

Polymer and bitumen mastic can be used for floor-insulation. The first are easier to be applied, dry faster and create a more durable waterproof layer

Thin layer levels

If on the tie, made by the developer or the previous owners of the apartment, there is a ledger, a hill or a bias, but the value of the difference does not exceed 20 mm, it is advisable to use bulk solutions from ready-made mixtures, such as Weber.vetonit 4100, "Yunis Horizon", Ceresit CN 68. They are easily applied, that is, in fact, they themselves spread over the surface - you only need to help them with a spatula and drive the air with a needle roller. Such solutions dry very quickly, and after 4-12 hours the base can perceive the hidden load, and after 1-3 weeks (depending on the thickness of the layer), the coating is allowed.

When aligning the floor by thin layer bulk mixtures, first with the help of laser level "beat" the overall level

Set point lights from the calculation one lighthouse for every 3-4 m2 floor

Next prepare a solution, the vitality of which, as a rule, does not exceed the half

Therefore, it is necessary to very quickly distribute the mixture on the basis and remove air needle roller out of it

With a minimum layer thickness, after 4 hours, you can walk on the screed, and after a week - lay the coating

Self-leveling mixes

Self-leveling mixtures are combined with any coatings, but quite expensive and, as a rule, can only be applied with a thin layer - no more than 30 mm. Carefully read the instructions for use of the mixture! Many materials of this type impose specific requirements for the ground, for example, they need to be dedicted, but exclude the application of adhesion primers like concrete contact.

The base for parquet floor should have a low residual moisture (no more than 3%) and high tile strength of the upper layer (from 35 kgf / cm2).

Wet screed

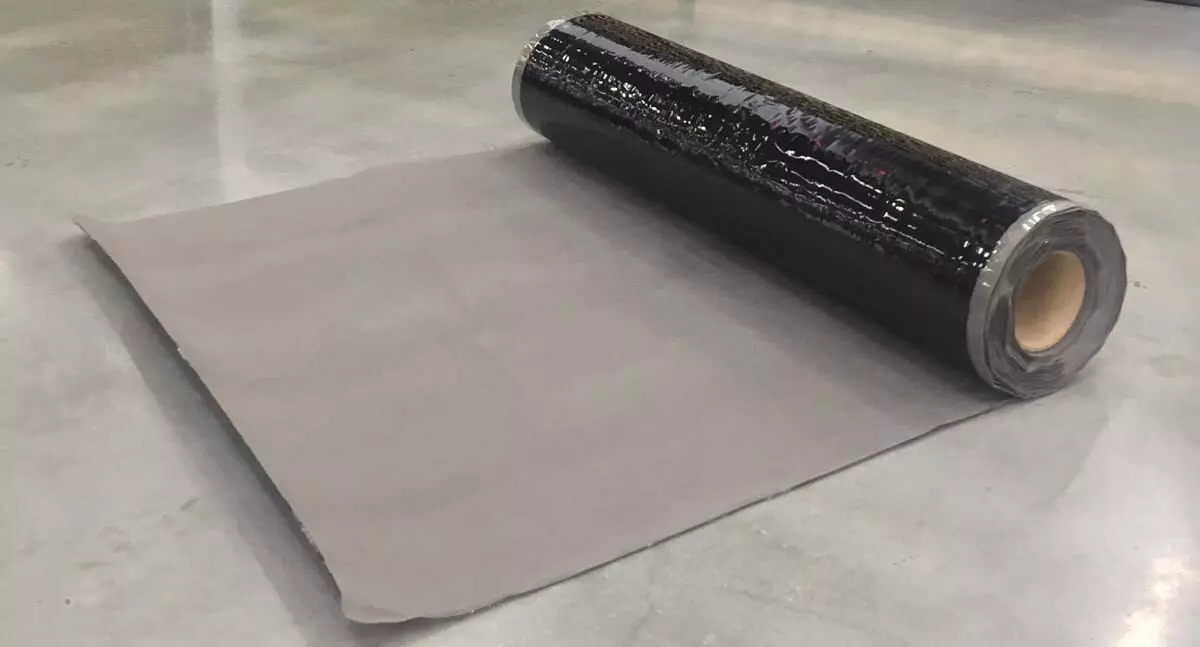

Significant unevenness is usually eliminated by means of a screed, the device in the new building should be carried out according to a typical project, and in secondary housing requires prior approval with the authorities of the housing. constructions (this may cause a closure of wiring within two floors) and in the location below. In addition, when a screed device, it is necessary to ensure insulation of shock and structural noise. Once, both tasks will help rolled materials on a bitumen basis with a thickness of more than 4 mm or special two-layer substrates, such as Antistuk, "Techno Elast Acoustic" or "Shumnet-100". All joints of the strips (plates) of the hydraulic insulation are sampled by mastic or special scotch.

When the device is screed, a thick solution is difficult to know the right to know perfectly (it is especially touched by a semi-dry method of laying)

Cold cars help align the sand layer. Rent of such equipment costs from 800 rubles / day

Cement-sand screed

Its optimal average thickness is 40 mm, the minimum local thickness is 20 mm. The design is preferably reinforced with steel road grid, and concrete is prepared from the factory mix in bags. With the calculated thickness of the screed more than 40 mm, light concrete is used, most often a ceramzite concrete, less often - more expensive concrete with foam glass.

It is important to slightly dry the screed, covering it with a film or periodically moisturizing. Open the window cannot be opened, only ventilation through the vents or inclined flaps is allowed. The average ripening period of the wet screed is a month, but before laying the coating necessarily check the residual moisture content of concrete by electronic moisture meter.

With the help of cement waterproofing for non-prone deformations of concrete bases, you can create a waterproof floor-padded pallet in the bathroom before laying ceramic tiles

The material is easy and quickly applied with a brush or spatula. It is durable, vapor permanent, racks to salts and alkalis

In experienced builders, subject to the use of non-fair mixtures (for example, Veber.vetonit 5000), the screed turns out quite smooth, it is quite possible to lay a laminate and a locking parquet board (on top of the substrate).

However, often the base layer requires the finishing alignment of bulging mortar. It is usually carried out after 7-14 days later, when sandbetone (ceramzite concrete) will drop about 70% of the strength, but some levels are allowed to lay only on a fully dried base.

For rapid alignment of differential differences, a thick-layer bulk floor can be used.

But more often use a cheaper modified cement-sand mixture

Semi-dry tie

It will dry no more than a week and do not threaten leaks in the apartment below (this does not mean that it is possible to do without a hydroximacy of the layer). However, not all workers have experience in applying this technology, which increases the risk of marriage.Theoretically, a special equipment should be applied to a semi-drying tie, a concrete mixer, a pneumatic pharmacker, tamping and throat machines. But in practice, work is often performed by hand, simply trying that the water-cement attitude does not exceed 0.2 (instead of the usual 0.3-0.5). Such a mixture is difficult to lay and align, and the density and strength of concrete without machine trash will be lower than with a traditional recipe. Therefore, the reinforcing polypropylene fibers are mixed to the water (approximately 100 g per 10 l). Alignmenting the layer is still preferably a grouting machine, although the use of bulk levels is possible.

A serious minus of a semi-dry screed is that only its thin top layer is stronger enough, so it is not suitable for some finish coatings, such as parquet and large-format tiles.

Dry team screed

The team screed consists of dry frighting and sheets of flooring, respectively and reliability is inferior to screeds from concrete, but it is possible to collect it very quickly. The flowing screed weighs little, provides additional noise and thermal insulation, and its thickness can be varied within 40-100 mm.

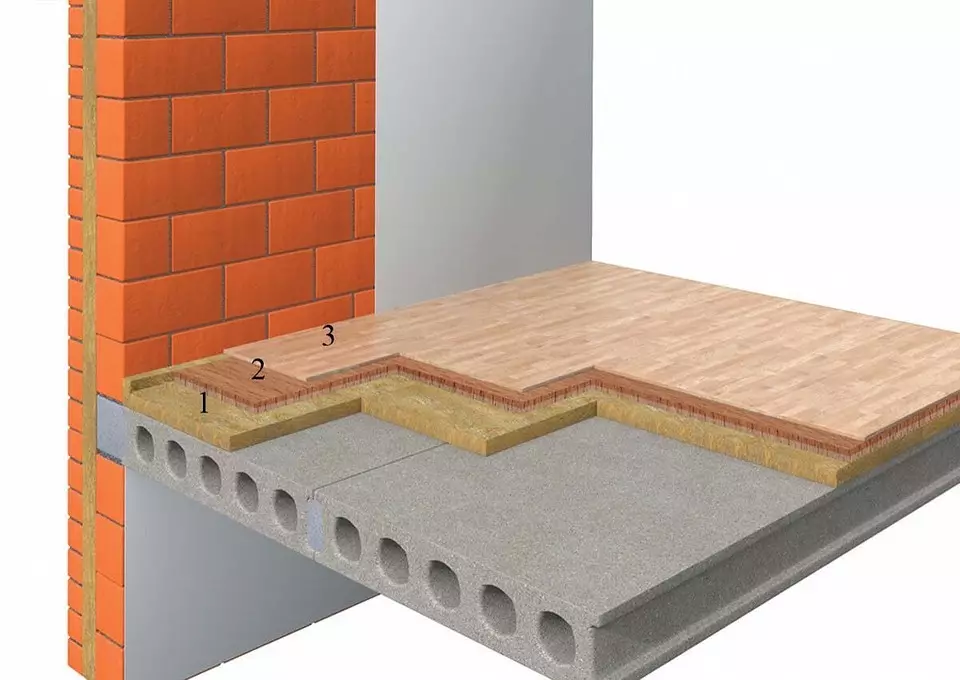

Design version of a dry screed: 1 - High density mineral wool slabs (at least 125 kg / m³); 2 - waterproof plywood (two layers of 8 or 10 mm), 3 - floor covering

For leveling backfill, the ceramzite gravel is best suited for a specially selected fraction (in order to reduce the shrinkage), which is placed on top of the vapor barrier film and smash through the beacons. Next, shelted sheets on a plaster or cement basis (most often GVLV 12.5 mm thick); They are placed in two or three layers and fasten with screws, and then put the joints. It is also possible to use ready-made two-layer elements of the floor with stepped edges.

When installing a dry dumping screed first to the floor, with a plastic film with an overwear of a strip of at least 10 cm. This layer will prevent sweeping moistening with pairs, bringing through the overlap from the bottom apartment

Then isolate the screed from the walls using the polyethylene strip

Fall asleep calibrated clay gravel. The use of ordinary clay is undesirable because it will give a significant shrinkage

The backfill is leveled with beacons and racks with a bubble level, and then two-layer floor elements from GVLV are placed on top.

Almost immediately after that, it is possible to start the flooring of the floor covering, for example laminate

Dry screed screed from mineral wool mats of high density and plywood are much less common. Such a design is more expensive than a falling and cannot be used to align the floor - it only provides additional heat and sound insulation.

Any dry screed is afraid of moisture, so it is not suitable for bathrooms and kitchens, and after the leakage, most likely, it will have to partially dismantle. The compressive strength and the separation of the surface layer is insufficient for the use of coatings from a solid wood array - geepboard and piece parquet. However, this is one of the optimal solutions for old houses with very uneven and also worn and cold overlaps. The dry screed is perfectly combined with a castle parquet board and laminate, and also allows laying of linoleum, carpet and large-format porcelain tiles.

Much improved thermal insulation and repay structural noises allows a slashing slash

With its device you need a vibration-protected border along the walls and durable flooring from plywood

Paul on lagha

When it is necessary to create a reliable base for a wooden coating and, it is impossible to significantly increase the load on the overlap, lags are used or (much less frequently) so-called modular raised floors. These structures allow you to eliminate any irregularities of the overlap, but with a significant additional loss of ceiling height - at least 50 mm (the minimum own thickness of the design).

Lags are easiest to make out of high-grade coniferous bars and align with plastic wedges. Aluminum products on screw adjustable supports will cost several times more expensive.

When assembling the base on lags, the horizontal can be set up using a bubble level.

Lags are attached to the overlap of dowels.

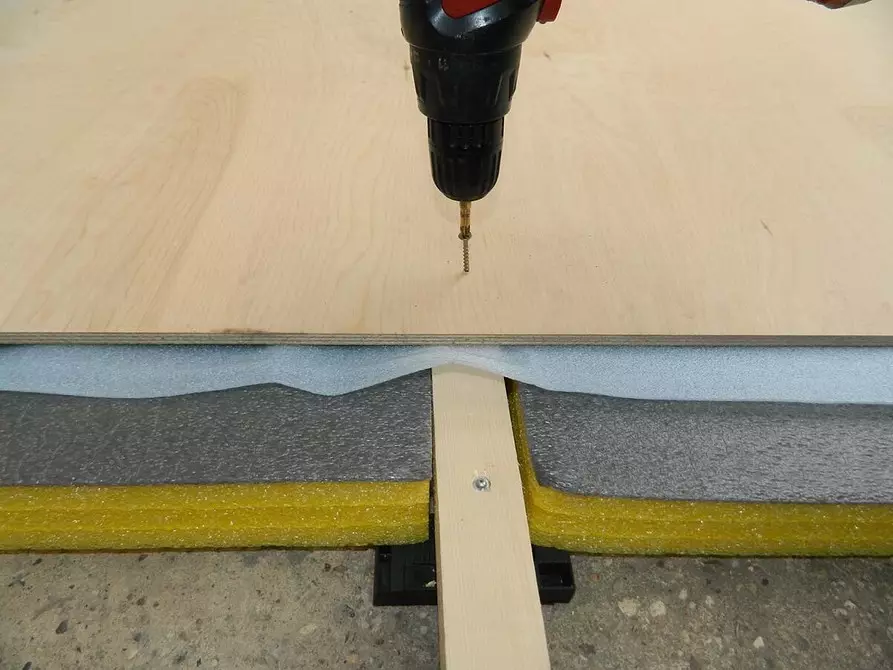

Phaneru to lagas - ordinary self-drawing.

The sexual tipped board is fixed directly to lags (with this design, their cross section should be at least 50 × 50 mm), and parquet and parquet board - to plywood flooring with a thickness of 16 mm. The space between the lags is desirable to fall asleep with clay, fill with mineral wool or soft wood-fibrous plates - it will improve heat and sound insulation.

Modular raised floor

Modular raised floors help to quickly align any overlap level drops and implement non-standard layout solutions. They cost expensive and in apartments are used mainly to solve non-standard tasks, such as devices of considerable height or gasket under the floor of the ventilation and air conditioning channels on the basis of low-power plants.

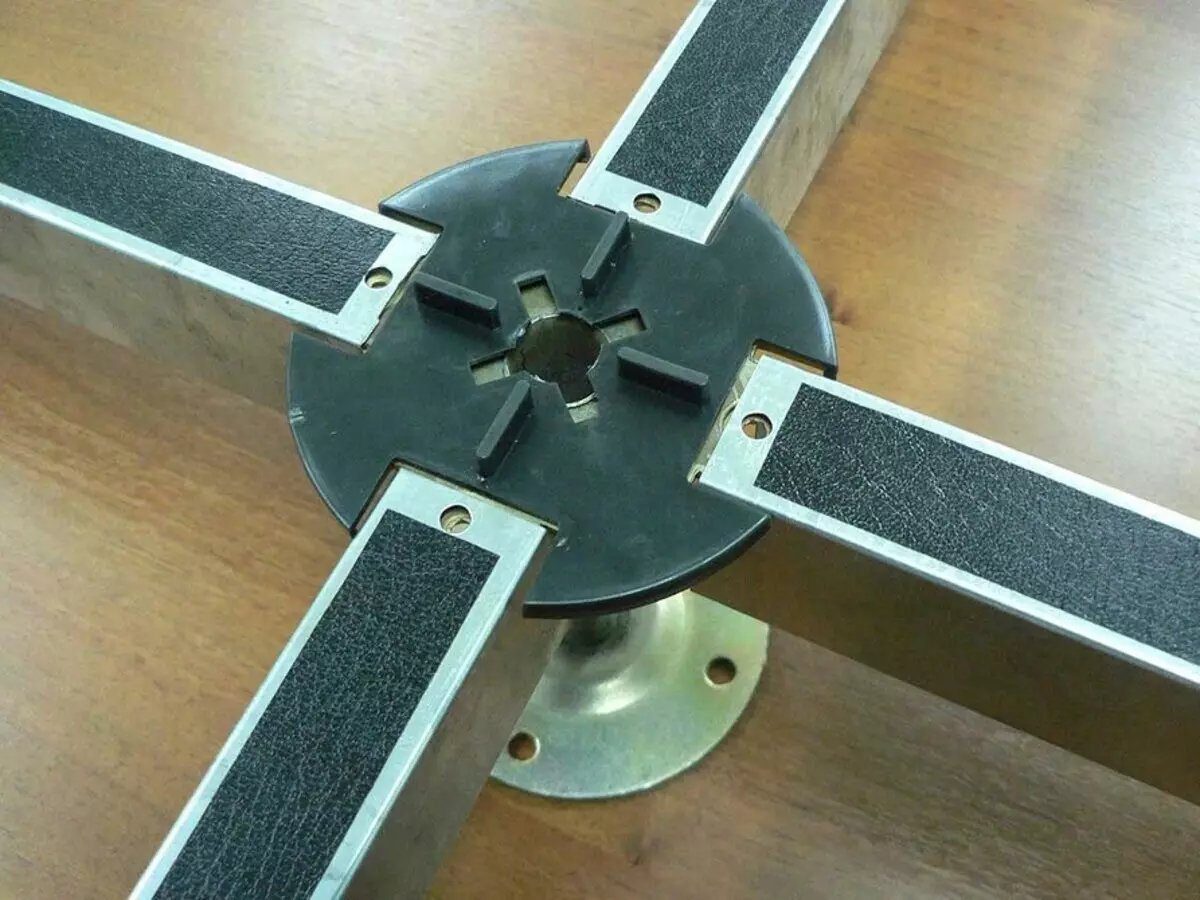

The main parts of the raised floor are support racks, stringers and stoves. The most common slab size is 600 × 600 mm, and the height of the support varies from 50 mm to 1.5 m.

Supports can be made of plastic (solid PVC, polyamide), steel or combinations of these materials. Floor elements are mainly produced from high-density chipboard with a thickness of 38 mm. To prevent the emission of formaldehyde, they are littered along the plane by aluminum foil, and on the edges - PVC tape. The cost of the set of parts starts from 2200 rubles. for 1 m2.

A more environmentally friendly solution - plates of reinforced gypsum (on the sites of firms you can meet the name "calcium sulphate"), reinforced with steel sheet, but they are twice as expensive.

Falsefield support length can be adjusted within 20-100 mm (depending on the system)

As a rule, jumpers stringers with elastic overlays are laid on the supports

When the podium device, the end part is closed with a special threshold profile.

There are stoves with a vibrational coating on sale

Also laminated under the tree

When installing the rawflake simultaneously install supports and plates. Supports are glued to the base with high-strength polyurethane glue or fasten with dowels. The position of each plate is controlled by the level. Modular raised floors create a minor overlap load, quickly mounted and easily disassembled - this quality allows you to easily inspect and repair communications. Falsefields are combined with laminate and parquet board, you can also buy plates with a finished coating.

When installing the national bases, do not do without noise. Recall: in residential buildings (except for new buildings), repair work can be carried out from 9:00 to 19:00, break from 13:00 to 15:00. On Sunday and holidays can not drill.

At what stage to lay communication?

- You can deposit cables, as well as steel and polymer pipes with unsolved compounds and a calculated service life of at least 40 years.

- When the device is dry, the pipe and cables need to be protected from contact with fastest ducts and covers to avoid friction damage during shrinkage.

- It is easy to pave communications allow floors on the lags, as well as modular raised floors. In the process of work, it is important not to reduce the cross section of the lag and do not increase the pitch of the supports.

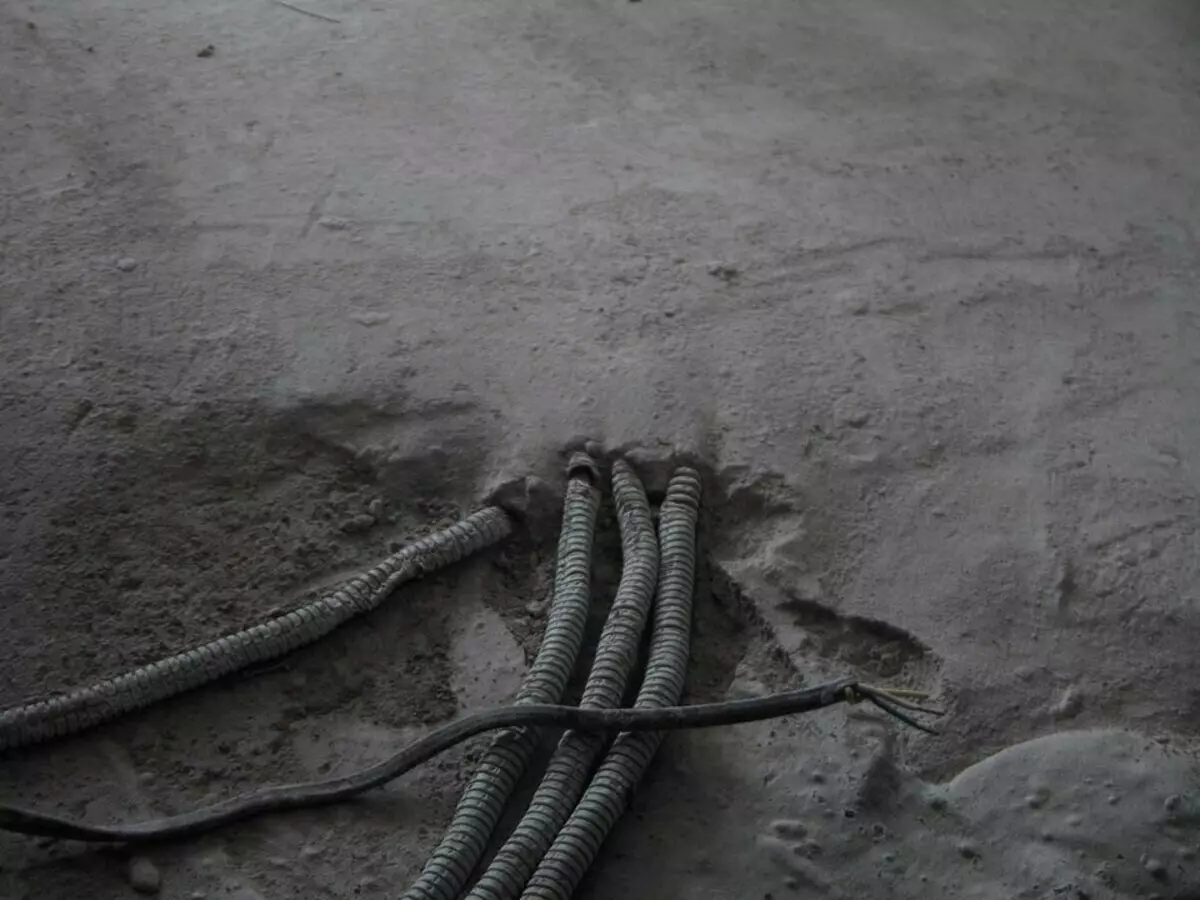

Wires in double insulation is permissible to put in the screed without additional protection, but still it is more correct to put them in plastic corrugation or cable channels

Characteristics of base designs

| Type of construction | MIN / MAX thickness, mm | The average installation time by a brigade of two people, m2 / day | pros | Minuses |

| Wet screed | 20/80 | 15-20; Finish coating can be laid no earlier than 30 days later | Frying, moisture resistant, combined with any coatings, relatively inexpensive | Labor creation creates a significant load on the overlap |

| Semi-dry tie | 30/80 | 15-20; Finishing coating can be laid no earlier than 10 days later | The same as the wet screed, plus not very high requirements for waterproofing | Significant weight, low strength of the main layer, the need to use special equipment |

| Dry team screed | 40/100 | 30-40 | High assembly speed, good heat and soundproofing characteristics, small mass, relatively simple disassembly | Low moisture resistance, risk of deformation of the upper layer under load and shrinkage during operation |

| Paul on lagha | 50/200 | 10-15 | Durability, relatively simple disassembly; The design is perfectly combined with wooden coatings. | Low moisture resistance, with a solid plywood base device - high cost |

| Modular floor | 50/1500 | thirty | Fast installation and disassembly | Very high cost, not suitable for many coatings |