We are talking about the construction of open terraces, the choice of materials and constructive solutions.

The open terrace is invariably associated with the southern flavor and the Mediterranean architectural style. She can adjoin the house, combining it with a garden, or be a separate barbecue pad, or serve as a dacha pool (such a podium not only adorns the courtyard, but also improves the ergonomics of bathing water). Arrange cozy garden chairs and sun loungers on the terrace, decorate it with plants in vases, ensure the shading - and get an ideal place for relaxation, air and sunbathing.

Base

The main elements of the wooden terrace are the base (as a rule, from point supports), carrying beam-lag construction and flooring. In addition, with a significant project height of the flooring, the steps and balustrades may be additionally required.

If the terrace is attached to the house, two approaches are possible: it is possible to build a completely independent base for it or to bind one end of the beams of the flooring to the building, and the second is to be opened on piles. With a large area of the terrace, it is more correct to choose the first option, otherwise the mutual bases of the base (the result of the exposure to the lateral forces of frosty powder on the piles or the precipitation of the main foundation under the load of the walls) will cause the deformation of the flooring, which will be very difficult to correct. The second method justifies itself if the length of the beams (the width of the terrace) does not exceed 3 m and you can do with one side of the piles. Only piles instead of ordinary flanges need to be equipped with screw compensators that will allow you to slightly lower or raise the terrace edge from the house.

From coniferous logs

And today the terrace is often built on the basis of the segments of coniferous brushing (bars) with burnt or dehydrated lower ends. On top, the beams from the bar are either not too thick protein logs, which are nasive from the coniferous board-forty.Alas, even on a dry plot and, subject to the preliminary antiseptation of wood, the service life of such a terrace almost never exceeds 10 years. Rain and melt water over time penetrates wood deep into; Poles, beams and flooring boards are starting to rotten intensively, fuse and break.

From concrete blocks

Significantly more reliable design with the base of concrete blocks or brick columns on the sandbreaker subfolder with powerful beams from a sequence of 100 × 150, laid on the poles on top of the waterproofing layer. Theoretically, it can serve for many years, but only on an even plot with a low level of groundwater and if they have a linear surface drainage along the terrace perimeter. In practice, small-breeding pillars are often harvested and seated under the influence of flood waters and seasonal grounds of the soil, and the beams are blocked and rot.

The described options justify themselves only as a planning and designer experiment. A few years later, such a terrace can be reconstructed taking into account the identified deficiencies. Nevertheless, it is profitable to develop a landscaped project in advance, consider ergonomics and the appearance of the terrace and immediately build a durable design.

In this case, the modular house, and the terrace is based on steel screw piles in combination with wooden beams.

On piles

Drilling piles from metal or asbestos-cement pipes will preserve at least 40-60 years. This is a reliable base for the terrace on bubbly soils, it is performed from relatively inexpensive materials, but quite laborious. If you work alone and only a manual tool, then no more than three piles will be able to install no more than three piles. The mechanized car and the concrete mixer will accelerate the process several times.

Usually for the pile-drilling foundation of the terrace, cropping pipes of the circular cross section with a diameter of 70 = 100 mm are used. The depth of such pile should be 10-20 cm exceeding the depth of the ground freezing (on the latitude of Moscow - about 1.5 m). The pitch depends on the material and section of the beams of the flooring, but is usually 1.5-2 m. The minimum wall thickness of the steel pipe is 3 mm, the metal should be protected by anti-corrosion paint or bitumen varnish. After installation, the pipe must be filled with heavy concrete, and then welcome the supporting pad (flange) to fasten the beam. In the case of an asbestos-cement pipe, concrete filling is required to be reinforced with three corrugated rods with a diameter of 8-10 mm and equip the headband with a mortgage bolt.

It is much easier to build the base of the terrace from the multi-shield screw piles (the speed of installation by the forces of two people is one or two piles per hour). Perhaps the only drawback their rather than high price: from 2 thousand rubles. With a length of 2 m (excluding screwing and concreting).

Sometimes for large terraces pour drill piles.

Then it is suitable for reinforced concrete scarlet, on which the beams are stacked.

On plastic supports

This design consisting of reinforced concrete slabs, adjustable supports and almost eternal aluminum lags, are classified to the premium class. It is often covered with a decidant of valuable tropical wood (Ipe, Kumaru, Merbau, Tick, etc.).

When the terrace foundation is first aligned with the platform and pour a sanding cushion with a thickness of at least 20 cm. It is thoroughly trambed, then they make a formwork, assemble the reinforcement frame or laid two rows of road grid on remote holders and poured a plate of heavy concrete, the thickness of which depends on the terrace area But it is usually 10-12 cm. With the correct technology, the plate is made with a slope or flashed from the center to the edges.

Adjustable plastic supports "Buzon" (from the name of the Belgian company Buzon, the first to offer them in the market) allow you to very quickly install lags exactly horizontally and isolate them and flooring from water that flows on the stove. The design is very quickly mounted and quite reliable, but the price of each plastic "Buzon" (which needed a lot, as they have in a step of 40-70 cm) - from 350 rubles, aluminum lags with a length of 4 m - from 1,200 rubles.

Screw plastic supports can be used in combination with both lags and boards and a garden parquet and even outdoor porcelain tiles. Each support must be attached to the base of the dowels (with the help of a building pistol) or water-resistant adhesive composition.

Flooring

With a pile foundation, the carrier design of the flooring, in principle, may consist only of antiseptic wooden beams. Piala issues are scolded by label made by laser or water levels, thanks to which the beams "automatically" are located at one level (although if there are sawing defects, they have to sharpen along the top plates). The minus is that the beam step (and therefore the pile rows) should not exceed 1 m, otherwise the flooring will be fed under load. Reduce the number of piles helps the structure in which the labels are placed on top of the beams - a cross section of 50 × 100 mm or more, put on the edge at a distance of 50-70 cm. A very durable and durable terrace can be constructed, combining with pile of metal-rolled beams (for example, an arcade and larch boards.

In order for the finished flooring does not vibrate when walking (not inhibited), there is a durable baking lag design.

The maximum allowable deflection of beams and lags between the supports under the load of 100 kgf is 1 mm

Open boardings in the rain often become slippery due to the thin layer of mold living on the surface. Antisepticing, coating with high-quality terraced oil and washing the water jet under pressure will help.

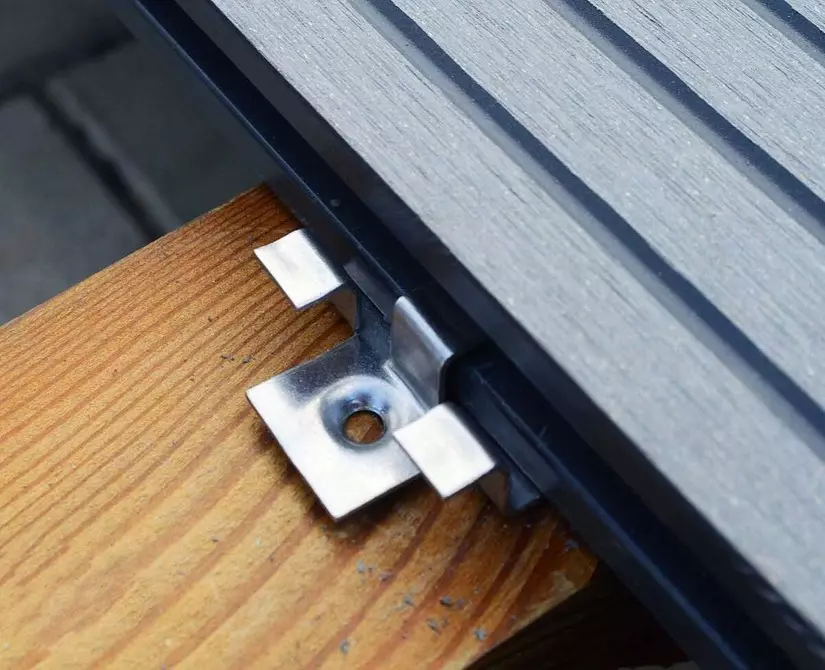

Capital flooring should be covered with decoprian rotting (corrugated board) from larch or wood-polymer composite. The boards are attached to beams or lags with hidden beams, necessarily with gaps of 3-5 mm for water drain, and are treated with terraced oil (special colorless and tinting compositions under the brands Remmers, Black Fox, etc.) are manufactured for DPDs.

T-shaped plastic coughs are designed mainly for the installation of composite decoping, while steel galvanized fasteners are considered universal. The mounted bitmers not only reliably fix the board, but also set the clearance value for water drain.

Before installation, the flooring is desirable to cover (not wondering) carrying beams and lags with rows of rubberoid, and better - vapor-permeable waterproofing material. So you can extend the service life for several years.

Shed

The simplest way to provide a shadow on the terrace is to install a folding garden umbrella or awning. These products are sold in any construction supermarket and stand from 2 thousand rubles. If the terrace is attached to the house and is used as a summer dining room, it is more correctly mounted on the wall of the building a roller-lever marquis, which, by the way, is able to protect the terrace not only from the sun, but also from the rain. Alas, Marquises are made in Russia mainly on request and are notable - from 30 thousand rubles. for a model area of about 3 m2; And if you want to equip the design of the electric drive, you will have to pay about 8 thousand rubles. At the platform for a barbecue, located on a distance from the house, a garden tent is appropriate on the frame of thin metal pipes, which is going and understands everything half an hour and costs from 1 200 rubles.

Stairs

The terrace, towering over the ground level by more than 20 cm, is usually equipped with a staircase. It is done on the assets or cosos, under the ends of which it is necessary to provide individual supports (piles, piles). The optimal height of the steps is about 15 cm, the depth is about 30 cm, the march width must be at least 90 cm. With a height of the terrace 40 cm, it is not necessary to do without a railing - they make the entire platform - and handrails on the stairs. Balasins, railing, steps and risers are easy to purchase ready-made in the construction supermarket - before installing them, they are only required to polish and apply a protective and decorative coating (painted the collected design is more complicated).Terraces without reason

If there is no need to significantly lift the terrace over the ground level, and the main task is to create a smooth, simple for cleaning the platform with a non-slip atmospheric and wear-resistant coating, it makes sense to act just like during the construction of garden alleys.

Large-format pavement tile, sawn natural slazie thickness from 40 mm and the garden parquet is allowed, removing the firing, put 10-15 cm thick on a sandy pillow, but in this case, through the joints of the coating elements, most likely, the grass will be powder, which will have to mow or destroy herbicides .

It is better to climb geotextile platform, limit the border, pour a pillow from Pescogramia (from 20 cm), and then lay the tile on a six-perhatemeter sand layer with the addition of about ten volumes of cement.

Tile coil is convenient in laying and rarely cracks. Sandstone is less durable, but it fits better in the Land Garden Landscape.

One of the ways to lay a stone - on a sandy pillow, a strengthened road grid and geotextile.