We disassemble the pros and cons of the monolithic and cellular polycarbonate and tell how to build a roof with your own hands.

In the summer I want to be in the fresh air as long as possible, but it often arises the need for a space, protected from wind and rain. One of the solutions is the roof of polycarbonate for the veranda and the terrace.

We build a roof of polycarbonate

We choose the material- Monolithic

- Cellular

- Criterias of choice

We carry out installation work

- Put the supports and mount the crate

- We make the trim

We choose the type of coating

With the help of polycarbonate, you can build not only the roof, but also the walls. It has high strength, while perfectly skips sunlight. Regardless of the color, the preferential elements can be transparent and translucent. They are produced from polymers, which allows them to give them any form. The more intense, the more blackout. In appearance, this design seems fragile, but in strength it does not even give way to shockproof plastic. Inside there is no sensation of the closed space, as in the usual room.

The surface may be straight, broken or have bends. She can give the shape of the arch or set a more complex configuration. To attach horizontal elements, a tree or metal profile is used, which performs the role of the baguette. One side relies on the bearing wall of the building, the other - on metal or wooden vertical beams. With a large weight frame, a brick and reinforced concrete pillars are made. In this case, it will take a foundation with a sandy pillow, bulk from rubble and waterproofing. If necessary, additional intermediate supports are made. All work can be performed with your own hands.

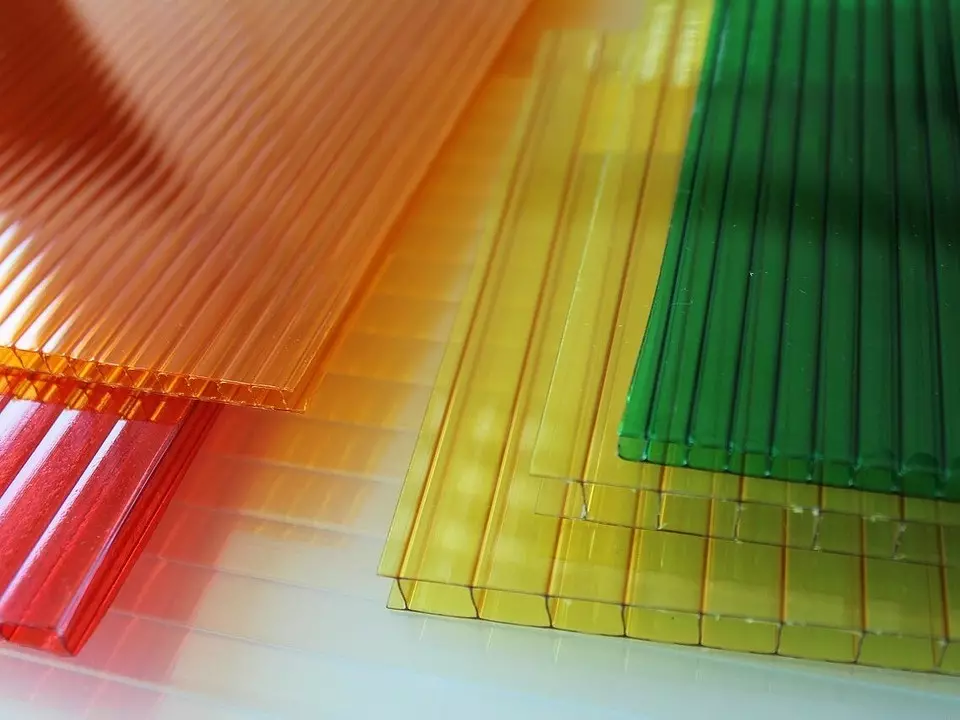

What polycarbonate for the roof of the terrace to choose? Products are produced two types:

- Monolithic - have a solid structure without voids and inclusions;

- Cellic or cellular - they consist of two external beans and inland jumpers forming a cellular structure.

Monolithic

Monolithic panels have the greatest strength of all polymeric products used in construction.pros

- They are able to withstand heavy loads at any temperature.

- The surface does not melt in the heat and does not crack in the frost.

- A few dozen times the hardest plexiglass, while the light skips no worse than the usual glass.

- The coating dissipates the sun rays, which makes the lighting softer and uniform.

- It does not burn and does not allocate harmful substances when heated.

- Constructive elements are well bent. This makes it possible to use them to build arches.

Minuses

- If the details of a complex shape are needed, they will not be done with their own hands. They will have to be ordered at the factory.

Cellular

Cell panels have a number of differences from monolithic. In general, they are inferior to them in their technical characteristics, but during the construction, preference is given to them.pros

- A small mass makes it possible to use light support, which leads to a significant savings and reduces the time of work. For installation can be made on an aluminum profile.

- The bearing capacity allows the use of products for the construction of a roof. They are able to withstand a meter layer of snow and ice formed in winter. By strength, they are noticeably inferior to monolithic polycarbonate, but they exceed some widespread roofing materials.

- Good flexibility opens a wide scope for creativity. Products can be bent or compressed if they are not suitable for the skeleton cells. It is not necessary to heat them for this.

- Svetopropuskitality is lower than that of a monolithic plate by 10%. This is a rather high indicator. Finding into a cellular structure, sunbeams dissipate, creating uniform comfortable lighting.

- Panels do not burn in fire and do not distinguish harmful toxins when contacting open flame.

- Perfectly withstand cold and heat without deformations and loss of strength.

- Air emptiness retain the temperature indoors, providing reliable roof thermal insulation.

Minuses:

- Low resistance to ultraviolet, destroying an external cloth.

- The surface is easy to scratch, so it should not use metal brushes and scrapers when cleaning.

- External membranes are destroyed under the influence of detergents containing aggressive chemicals;

- If the coating got damage, garbage from cells is quite difficult. The problem would be less significant if it did not spoil the appearance of a transparent design.

What's better

After analyzing the features of cellular and monolithic panels, it can be concluded that those and others are equally well suited for the construction of a roof. Usually, high strength is not required for a device veranda or gazebo, but if it is located under a tree with massive branches, it is better to use a more reliable coating. It will cost several times more expensive, but will provide the necessary protection. In addition, it does not have to be changed, if a heavy bitch falls from above.

Thickness affects mainly for mass, as well as on heat engineering and acoustic characteristics. Thin products are easier. The lighting ability of the size almost does not depend. The difference is the tenths of the percent.

To find out what the minimum thickness of the polycarbonate on the roof of the terrace should be necessary to determine its structural features. If good thermal insulation is needed, it is better to use the cellular panels of the maximum thickness. If a reliable coating is required, not fearing loads, and the room temperature does not matter, then it is better to use monolithic sheets. It makes no sense to lay the most massive, because even with a small thickness, they will provide reliable protection.

The thickness of the monolithic slabs varies from 2 to 12 cm, cellular - from 4 to 16 cm. The weight of 1 m2 in the first case is in the range of from 2.4 to 14.4 kg, in the second - from 0.8 to 2.8 kg.

The material should be selected not only by its technical parameters, but also on its decorative qualities. Products can be transparent or painted in different colors. Color surface, even if it is painted muffled tones, looks pretty bright, and this is one of the stylistic features. Such glazing will be difficult to enter into a classic style - there are more completely transparent constructions.

Make a roof of polycarbonate for the veranda do it yourself

To insure itself from errors, first of all it is necessary to think over all the technical nuances and make a detailed action plan. Calculate without visualizing the object is quite difficult. It will be necessary to make a drawing or draw a scheme, and specify all the sizes on it, paying particular attention to the places of fasteners. The purchase of materials makes sense to move only after the plan will be ready.

Even a flat roof must have a minimum of 5 degrees. By configuration, it can be single-sided, duplex and arched. There are other options. You can specify the details of the complex form only in production conditions. If you make them to order, it will lead to a significant increase in the cost of the project.

For work, you do not need to have special skills. Special equipment will not need. For cutting of cellular panels, you will need a well-hot knife. With monolithic, it is more convenient to operate with a circular saw or an electroll. We need a screwdriver or screwdriver, roulette, level and staircase. For drilling, drills for metal are suitable.

Put the supports and mount the crate

First you need to install supports and build a frame. It can be mounted on an old base if it is in good condition and reliably.

For heavy designs, massive steel beams are used, brick, reinforced concrete or wooden poles with a ribbon foundation, for lighter - steel supports or aluminum profile. The last option is suitable for southern regions where little snow falls in the winter. To fix the profile, it must be concreted.

To make a durable belt base, a trench of approximately 40 per 40 cm is digging around the perimeter of the future veranda. Its bottom falls asleep with rubble or broken bricks. The formwork from the boards is suitable on top. From the inside it is covered with a polyethylene film or rubberoid. Then the reinforcement frame is made from steel rods in the form of a parallelepiped. To fit the fittings to outside, plastic racks are used for it. In the locations of the supports are installed vertical rods. They must perform above the frame half. The formwork is poured concrete. The solution is gaining strength for four weeks, after which you can proceed to further work.

The next step is the creation of a brick base. The masonry is made in two rows with a dressing. The protruding rods are better to close the concrete base, which should be combined with supports in size. Depending on which the design is, corners, channels, or other mortgage elements should be concreted into the formwork.

If we want to put wooden poles, they will need to do holes for rods and process them with antiseptics. The joints of the joints are pre-labeled by waterproofing mastic. If the moisture is seamless inside, the tree will start rotting. From above to the columns are attached beams to which the frame is mounted. It can be a truck system from BRUSEV, a construction of metal profiles or parts that are included with the coating.

The rafters are erected in a step equal to the width of the polycarbonate panel. The distance between the elements should be taken 1-2 cm less to avoid the appearance of gaps. The main burden falls on inclined beams directed from home. Between them are fixed horizontal, giving structures stiffness. Metal corners and roofing screws are used for compounds. To the wall of the house, the rafter system is mounted on anchors.

Details of steel or aluminum frame are bolted. To make the arch, they must be bent. For this, cuts are made from the inside every 10-15 cm. In order for the pebble to be easy, it is better to use polycarbonate profiles that are included with the coating. Consider the sheat technology with their application.

We make the trim

The length and width of the roof is rarely multiple panel sizes. To lay the extreme rows, they are usually triggered. The part is fixed on a smooth clean surface and draw markup. Cut better on line, blackboard or bruus. In order not to leave scratches, the lower packaging film is removed only when installed, and the upper after the end of all works.

The elements are located along the slope so that the condensate inside the honeycomb can flock down. When installing, the protective film on the edges is rebuilt by 10 cm, the self-adhesive tape is fixed from the sides. The connecting profile is installed on the self-tapping screw, which is included with the main set, and the shelter is inserted into it. From the back side to the sheet glued the perforated ribbon and close it with an end profile. The bottom is mounted on the self-tapping screw and pressed the snap-on lid. After that, the protective film is deleted.

Baguette can be made independently of wood, plastic or metal. Its components must have a groove in a depth of about 2 cm.

First attach guides, then jumpers between them. The layout is made on them and holes are drilled. The grooves are filled with a seal or sealant, after which they are inserted with holes with holes drilled when laying. The coating is fixed with screws.