We tell me what an alkyd enamel, which features her features and how to apply it on the surface.

If from all paints and varnishes to allocate the most resistant and universal, the choice is definitely falling on the alkyd varnish coating. Find out everything about alkyd enamel: what it is, its features and where it is applied.

All about alkyd enamel and ways to use it

What it isFeatures

Mode of application

What is alkyd enamel

The current range of finishing materials in the markets is huge. Each type is suitable for a specific type of work. However, if you choose a universal agent that is suitable for inner and outer decoration, it is an alkyd enamel.

It is based on pentaphthalic or glyphthale varnish, solvents and coloring pigments. Sometimes the coatings include substances that protect surfaces from corrosion, fungus and insects.

-->Differences are licking in varnish.

Pentafthalian - based on resin. It moves well mechanical effects, temperature differences and chemical cleaning.

Gliphala - dries quickly. So within 6-24 hours you can get a fully dry coating.

Enamel classification

In the manufacture of the composition, a special marking is used, which helps buyers to navigate in products. For example, the PF-120 number is the composition of the matte coating, where PF - Pentafthalian, 1 - designation for the use of external work, and 20 - number in the directory. The Marking of GF is used to designate the glyphthale solution.

-->Division on the first digit in marking

- 0 - alkyd primer

- 1 - Ability to use for outdoor decoration

- 2 - use only for internal works

- 3 - coating suitable for conservation work

- 4 - waterproof material

- 5 - Solution for certain materials (wood, metal and other)

- 6 - Oclochnaz resistant

- 7 - Standing tolerates the impact of chemicals

- 8 - composition carrying low and high temperatures

- 9 - electrical insulating and electrically conductive solution

In composition and method of application

- GF-230. The base consists of glyphthalic components, so such a substance is used for internal repair. In stores you can find a large palette of materials, easy to use and apply.

- PF-115. It is usually used for the color of the facades of brick and wooden buildings, as well as metal surfaces.

- PF-223. This species is used for painting heating devices. However, very few colors are available on sale.

In quality characteristics

- Quick-drying. If the repair is very limited in time, it is important how much an alkid enamel is dry. In such cases, this solution will become indispensable. Thanks to special solvents included in the drying, it does not take much time. This species is well suited for repair indoors.

- Melaminoalkide. It is characterized by a good clutch with the surface, so it is most often used for painting metal.

- Alkudo-uretteo enamel. Differs high strength and speed of drying. Despite the fact that it is rarely on sale, it enjoys wide demand.

Advantages and disadvantages

This coverage has many advantages, but there are disadvantages. Therefore, each of them Consider separately.pros

- If compared, which is better - alkyd or acrylic enamel, the advantage remains for the first, since it perceives the mechanical effects more persistently, and also better preserves the view.

- It does not fade in the sun and does not lose the color years after applying, does not yellow.

- Quickly dries.

Minuses

- Material has a sharp poisonous smell, which is weathering for a long time. Therefore, with interior decorations, provide good room ventilability, as well as wear a respirator.

- It has a low degree of fire hazard.

How to apply enamel

Before starting work with a substance, read the instructions on the package. You also need to prepare a mask, protective clothing and gloves. In its pure form, the composition is rarely applied, it is more often diluted before applying.

-->Than dilute alkyd enamel

- White Spirit. Oil liquid with a sharp smell of gasoline. Such a solvent is suitable even for the thick mixtures.

- Turpentine. Previously, he was the most popular solvent. It has the same characteristics as White-alcohol.

- Xylene. Almost transparent or yellowish solvent. It can also be used as a degreasing mixture for surfaces.

- Solvent. Colorless liquid, which not only breeds the tool, but can also clean and degrease.

- Solvent 646. This species is most often used to dilute varnishes and paints. It gives the coating a special glossy effect, helps the solution to form a dense and high-quality film on the surface, thereby very simplifying work.

How to calculate flow

To understand how much the amount of the mixture you go to the decoration, we must take into account several details. Please take attention to the thickness of the original solution. The thick mixture, the more solvent it will be necessary for it.

The amount of layers applied will be completely dependent on the quality of the surface. If you cover metal, then the consumption of the solution may increase. Consider that after applying each layer, he needs to give drying within 24 hours.

-->Consumption depends on the type of work. So for the interior trim, the consumption is always greater than for repairing outside.

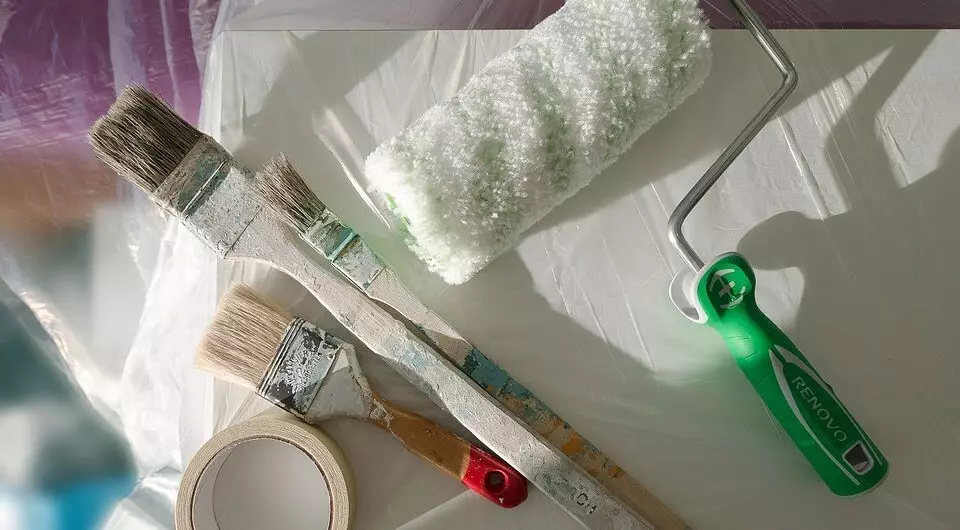

Application tools

You can apply a mixture with different tools. Each of them has its own characteristics:

- Brush. Thanks to this option, you will get a dense coating, but thereby you will significantly increase the consumption of substance.

- Roller It reduces consumption, however, with this tool will be difficult to cross the corners and joints.

- Spray. It makes the paint best, however, here for accurate application need special skills, so that high-quality and accurate work as a result.

The tool is applied in several layers, giving dry each previous one.

We advise you to start processing the surface from the most hard-to-reach places. Treat them with a brush, and then proceed to paint using a roller.