The owners of cottages and houses outside the city have to think through how to deliver water to the house. So how to choose materials for water supply right? Let's try to figure it out

So, you have a water source. A wells can act as a well, a well with drinking water or a technical well on the street in which a communal tube passes and the connection of your (insert) is supposed. In any case, the street pipeline for year-round use should be blunting below the level of primer of the soil so that water in it does not freeze even in the strongest and long-lasting frosts.

What pipes will be?

Twenty years ago, everything was simple and clear with the pipes: metal pipes were used - steel galvanized, rarely iron. Now the range of pipes for water supply has expanded significantly.

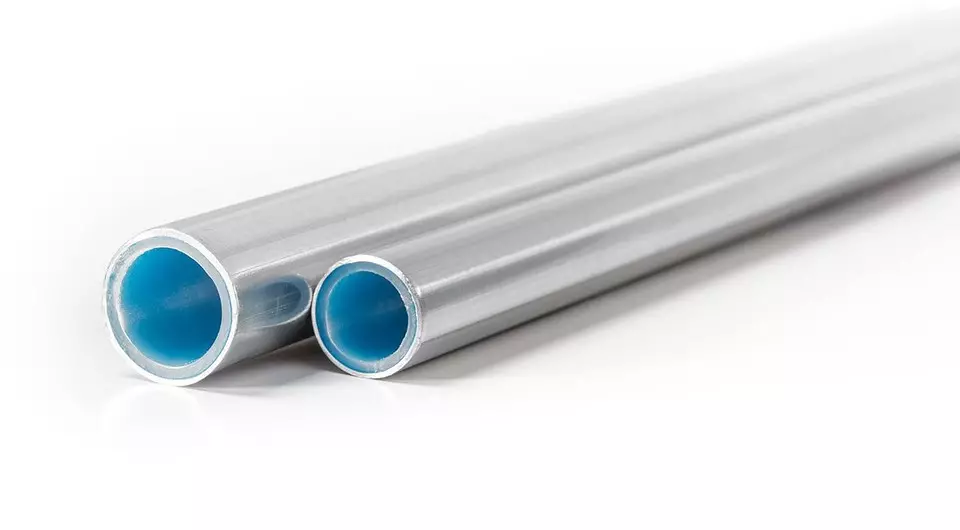

Viega Pipes, Smartpress Series (Stainless Steel Fittings)

Pipes for cottage water pipes are chosen based on their technical characteristics, service life, ease of installation and, of course, cost. Pipes made from polymers (PE polyethylene, polypropylene PP, PVC polyvinyl chloride, etc.) and composite materials were obtained the greatest propagation. The latter includes metal-polymer pipes and polymer pipes reinforced with fiberglass.

Viega pipes, PROFIPRESS series (copper)

We choose the material

Polypropylene (PP)

Polypropylene pipes are distinguished by low price. Let's say 1 pose M unarmed PP pipe with a diameter of 20 mm can be purchased for 25-30 rubles. Polypropylene is quite rigid, the pipes are well holding the form, but they can not bend. The connection of PP pipes and fittings is made using welding. This requires a special tool that, however, can be purchased approximately 1 thousand rubles. The main disadvantage of PP pipes is a large temperature deformation when heated. Some models of such pipes cannot be used to pump fluids with a temperature above 60 ° C. For example, these are pipes made of propylene random copolymer (denoted by PP-R). Now manufacturers switch to thermostabilized polypropylene (PP-RCT), which is designed for fluid to 85 ° C with the condition that temperature compensators will be arranged in the pipes. In their roles, there are separate curved areas of the pipe or P-shaped inserts.| Diameter Pipes, see | Pipe Horizontal, cm | Pipe PP horizontal, see | PNDT PND vertical, cm | Pipe PP vertical, cm |

|---|---|---|---|---|

| twenty | 35-40 | 45-50 | 50-55 | 60-65 |

| 25. | 40-45 | 60-65 | 70-75 | 75-80 |

| 32. | 45-55 | 70-75 | 90-100 | 100-110 |

| 40. | 50-65 | 90-95 | 110-120 | 130-140. |

* The step depends on the brand of pipes and water temperature (the table shows the values for water with a temperature of 20 ° C, with an increase in temperature, the step decreases).

Low Pressure Polyethylene (PND)

Refers to one of the cheapest types of pipes. Bay pipe with a diameter of 20 mm and 25 m long can be purchased for 400-500 rubles. PND pipes well tolerate temperatures below zero and are often used to mount the street plotting, but they, as a rule, are not suitable for water with a temperature above 40 ° C.

Low pressure polyethylene tubes and fittings (PND) are widely used when laying outdoor water supply

| Type of pipe | Polypropylene | Polyethylene Low pressure | Metalplastic | Stitched polyethylene | Steel | Copper |

| Features | Hard trumpet, economically one of the cheapest, is going on an uncalapted connection, poorly tolerates high temperatures | Economically one of the cheapest, not afraid of ultraviolet | Flexible tube, easy mounted, impenetrable for oxygen, not afraid of high water temperature | Flexible pipe, assembled on an inadvertent compound, poorly tolerates the effects of sunlight | Hard trumpet, threaded, welding or crimping fittings | Chemical resistance flexibility, good appearance, high price |

| Application | Cold water supply, PP-RCT type and hot water supply, domestic wiring | Street network of water pipes | Heating, Water Supply, Outdoor Wiring | Outdoor heating networks (warm floor) and water supply | Universal type used everywhere | Heating, Water Supply Luxury Networks (including Decorative Elements) |

Metal Plastics (MP)

These are multilayer pipes in which the outer and inner layers of the pipe wall are made of polymeric materials, and between them is a layer of aluminum. The MP pipes are intended primarily for heating, since their design eliminates the diffusion of oxygen through their walls. But they are also used for the domestic wiring due to a number of constructive advantages: they are flexible, while well hold the form and do not give noticeable temperature deformations. In addition, they are enough to simply mount with the help of crimping removable fittings. Such advantages led to the widespread spread of MP pipes, despite their comparative high cost (the price of them is approximately 1.5-2 times higher than that of PP, fittings are also about twice as expensive). It should, however, remember that removable fittings are not the most reliable installation mechanism. The condition of such compounds must be monitored and inspecting every six months a year. If the connection weakened, it must be tightened. Removable crimping fittings can not be mounted in a concrete screed or in some other way that excludes the possibility of access and inspection.

Uponor pipes are manufactured using seamless aluminum composite pipes manufacturing

Stitched polyethylene

Stitched called polyethylene, treated with a special way (for example, a chemical way or UV irradiation), so that the chains of its molecules are connected to each other. Such material is obtained quite strong, chemically very resistant and durable. Pipes from it are about 80-120 rubles. For 1 p. m, they can be used for cold, and for hot water supply. They are used with unknown crimp fittings and are generally among the most reliable options. The elasticity of the walls protects them from damage during bends and squeezing. The only limitation is stitched polyethylene to be exposed to direct sunlight.

Universal pipe RAUTIITAN FLEX (REHAU) for heating and water supply; Material - Stitched PE-XA polyethylene

Technical symbols on pipes

All the necessary information is usually indicated on the pipe. This is, first, the type of pipe and the material from which it is made. The diameter and nominal working pressure may also be indicated (PN marking is not currently mandatory, but is often used to designate the allowable working pressure at a fluid temperature of 20 ° C). For example, PP-R DN32 PN10 is a polypropylene tube having a diameter of 32 mm and designed for pressure of 10 bar. Or, for example, PP-R / PP-R GF / PP-RCT (SDR11). It looks frightened, but in fact it is a three-layer tube, an average layer - reinforced with fiberglass polypropylene, designed for pressure 20 bar. A SDR is a parameter indicated according to European standards, instead of an outdated PN. The dimensionless value denotes the ratio of the external diameter of the pipe to the thickness of the polymer wall. The smaller the value, the higher the pressure that the pipe can withstand. SDR6 means that the pipe will withstand the pressure of 25 atm, SDR11 - 12 atm, SDR26 - 4 atm.

Manufacturers often use color labeling: pipes with a red line are designed for hot water, with blue - for cold. In general, with some skill it is quite possible to learn to understand all these designations.

What's new on the pipe and fixtures?

From the novelties, first of all, a variety of fittings modifications that become more reliable and more convenient every year. Not so long ago appeared, for example, fittings made of cross-linked PE-XA polyethylene with the RAUTIITAN gilbe (Rehau), without sealing rings and other elements subject to wear. Or, for example, Viega's innovative press fittings, thanks to which the installation of stainless steel pipelines (Sanpress Inox), galvanized steel (Prestabo) or copper (PROFIPRESS) does not require welding, soldering or cutting threads, saves time and is fireproof.

The flexibility of polymer pipes gives an additional advantage when installing

Note the appearance of pipes made of new generation materials. This is most often combined materials, such as stitched polyethylene products with an additional inner layer that prevents the diffusion of oxygen, as in the Copex HT (OVENTROP) line. Or polymer pipes with an outer layer protecting from the effects of ultraviolet. The Uponor has a novelty Metallic Pipe Plus, a multi-layer tube with an outer seamless aluminum layer covered with varnish. This design retains all the advantages of metal-polymer pipes, but in addition and looks much better.

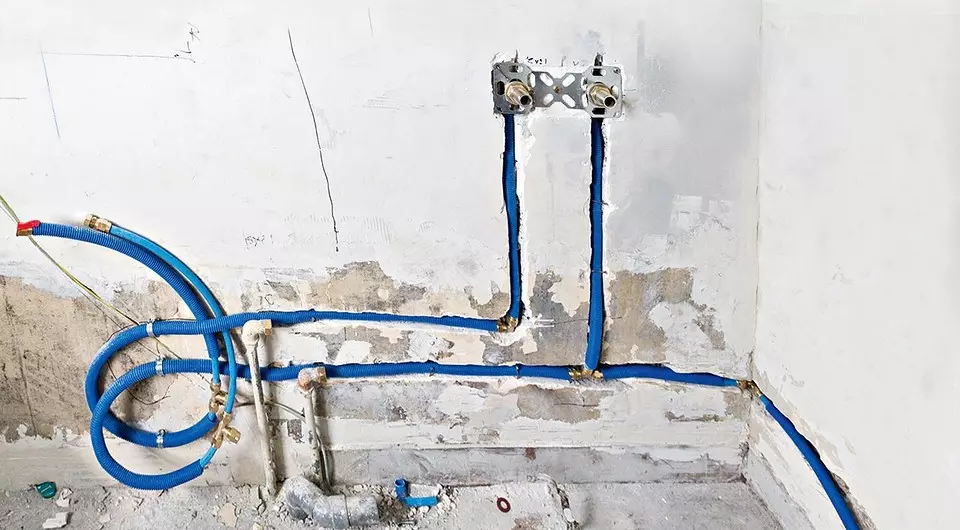

Installation of water supply system using metal-plastic pipes (a).

There are other constructive innovations. So, reinforcement by basalt or fiberglass allows you to increase the strength of the pipe several times and three times reduce the coefficient of temperature expansion. More exotic looks like pipes with antibacterial additives, such as HP PPR Nano AG (HP Trend) series. The content of silver compounds and substances inhibiting the vital activity of bacteria can be important in the conditions of irregular exploitation of the pipeline.

To install inside the walls and in the concrete screed, only tubes with unknown fittings are used, which do not require regular maintenance. If the installation of such fittings requires a special tool, you can rent it

Sergey Bulkin, Head of Technical Support Group Direction of Rehau Engineering Systems in Eastern Europe

All compound technologies can be divided into two classes - discerned and indefinitive. The first includes threaded, threaded and flange connections. The general disadvantage of all disconnect compounds is their weakening over time and, as a result, violation of strength and tightness. Such connections must be periodically tightened. Therefore, according to the construction standards, it is prohibited for the construction of the pipes with the connector elements in a hidden way. Local connections do not require regular maintenance and allow hidden pipe gasket with them. A compound by axial pressing with the help of supervised sleeves is considered one of the most versatile and provides a fully sealed connection.

The editorial board thanks Viega, Rehau, Leroy Merlin, Uponor for help preparing the material.