We tell about the varieties of mineral wool for the outer and inner insulation of the walls. And also on how to choose the material and install it correctly.

Minvata for thermal insulation at home:

General characteristics of materialDifferences of Minvati

- Glasswater

- Shagkovat

- Stone

Cons and pluses of such thermal insulation

What to pay attention to when buying

- Two more selection criteria

Instructions for proper insulation

- Basic Mounting Errors

- How to insulate the house from within

- Video on warming framework

Mineral wool for the insulation of the walls consists of intertwined fibers. There are several of her species: stone, glass, slag. The best option is the first. It is used in homes where the long life of the design and other qualities are important. Let's talk more about the features of the material and how good it is for thermal insulation of buildings.

General characteristics

The goods are sold in two forms: plates and rolls. The dimensions of the sheets are installed by gostami. In the twisted version, the length of the mat can reach 10 meters, width - from 1 to 1.5 meters. Plate parameters: 1250 * 610 mm. Thickness varies from 2 to 15 cm. The density is another important indicator, which denotes the number of fibers per 1 m³. On the package is denoted by the letter P. To work with walls, values are valued from 35-150. The greater the value, the greater the load on the base.

Differences of Minvati

As we have said, there are three types of mineral wool insulation. Each of them is made from different raw materials and has its own properties.Glasswater

Material consisting of molten glass combat, dolomite, sand, soda or limestone.

Benefits:

- Air permeability.

- Fire resistance.

- Elasticity, resistance to vibrations.

- Withstand low temperatures.

- Lower than other Minvat, cost.

Minuses:

- A small shelf life is 5-10 years.

- Shrinking 80%.

- He strongly absorbs moisture.

- When entering the skin causes itching or even an allergic reaction.

Shagkovat

It is made from metallurgical waste. I am inferior in characteristics to other varieties of insulation.

- Does not provide due to noise insulation.

- It does not withstand strong heating. It does not burn, but sinters and loses its thermal insulation qualities.

- Does not tolerate temperature differences.

- Also required protective clothing and a respirator for mounting.

- It is impossible to warm raw rooms with metal fasteners, as under the influence of wet air, slags will contribute to corrosion.

- High hygroscopicity.

Plus - such a layer in the wall does not attract rodents and insects. Most often used on dry surfaces of temporary buildings or non-residential buildings.

Stone

The most expensive material. It is usually it is usually chosen for outdoor work in private, including frame wooden houses. Production uses rocks. Due to this, the final product has a lot of advantages:- High density, and therefore durability.

- Fire resistance. Not flammable at no temperature.

- Minimum shrinkage (5%).

- Long service life (up to 50 years).

- Provides excellent sound insulation.

- It is almost not broken in the process of work, which happens to other varieties of products.

- Parry permeability. Fibers repel moisture.

Minus - high cost. Despite all the advantages, it is not always rational to insulate these plates.

Advantages and disadvantages of mineral wool for insulation of walls

Let's summarize. The advantages of almost all types of Minvat include several qualities:

- Non-hatching.

- Easy processing. Plates and rolls cut with a knife or saw.

- Good noise and thermal insulation.

- Simple installation.

- Long service life (from 5 to 50 years, with the exception of slag material).

Disadvantages:

- The need to work in protective clothing and respirator.

- For fiberglass, additional vaporizolation may be required.

There is also an opinion that when heated, the insulation allocates harmful pairs for health. Manufacturers argue that this is a myth. In addition, after mounting, the thermal insulation layer is closed with plasterboard, boards or other finishes.

The particles falling into the air can be harmful when cutting products. To do this, it is recommended to close the respiratory tract, and if the fibers fall on the skin - wash them off only with cool or cold water. It is necessary so that the pores do not expand and the cutting dust did not get into them.

In general, it is a modern, easy-to-use, effective material for protecting the house from high and low temperatures.

How to choose mineral wool products

First you need to pay attention to several characteristics:- Minvati thickness for wall insulation. The thicker the insulation layer, the higher its fire safety, sound insulation and durability. For domestic partitions and frame structures, matte 5 cm are suitable for facades - from 5 to 10 cm.

- Density (P). We wrote about her above. It depends on the stiffness of the structure and its ability to withstand loads. For facades, the indicator must be within 100-125 kg / m³. If plaster is chosen as finishing, then 150 kg / m³. For interior partitions - 75-90 kg / m³.

- Thermal conductivity. What she is less, the better. In this regard, basalt and fiberglass products have proven itself well.

- Parry permeability. The coefficient suitable for private buildings is a stone wool. Denotes MU1. Than it is more, the better the products.

- Fire resistance. Fire resistance level of fiberglass - 600 ° C, Materials made of mountain alloys - 1000º C.

What else to pay attention

If you are planning work outside the building - choose basalt plates. When you need to perform insulation from the inside - fiberglass coating is suitable. When buying, look at the storage conditions.

- If the product is at least a little wet - it does not make sense to acquire it. Check that the package does not have knob.

- Blocks and rolls must be under a canopy, not outdoors.

The most famous manufacturers of mineral insulation are Isover, Ursa, Rockwool, Knauf. Their products have certificates and passed quality tests.

How to warm the walls of mineral wool

Let's talk first that all your hard work can let gomark.Mineral wool mount errors

- Lack of surface preparation. It should be smooth, clean and processed by an antiseptic (if it is a tree).

- Working during precipitation or leaving the finished work without rain protection.

- Insufficient application of glue. That's right when it is distributed over the entire surface, including around the perimeter. The most suitable adhesive is polyurethane foam or dry mix. With the first products easier and faster work, but it is a bit more expensive. Both products are resistant to the exposure to the external environment and guarantee a good clutch.

- Unlumped seams between the details of the insulation. They can only be closed by inserts from the same material. Maximum gap - 2 mm.

- Crossing plates in window and door corners. In these places there should be no junction.

- Lack of mechanical fasteners. Anchors and dowels are used as additional compounds for heavy sheets. The optimal amount is 3-4 pieces per piece (two in the corners, 1 or 2 in the center).

- Smooth minting, butt into the joint. The masters advise to install elements in a checker order - it is easier to avoid cracks in the design.

These are the main mistakes that people allow, making thermal insulation at home on their own.

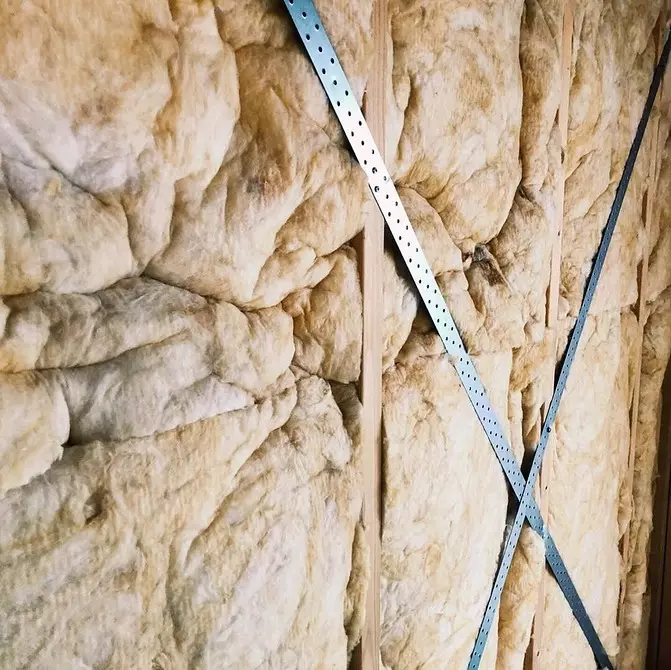

Instructions for the insulation of walls at home mineral wool outside

You will need a metal profile or a bar for creating a crate, related tools for building a frame, a knife or saw, fastening elements and a membrane film for vapor barrier. There are two methods. Consider one of them. Work is carried out in several stages.

- Preparation of the surface. With it you need to remove all the old layers of plaster and other finishes, extortify dirt and mold, carry out processing and remove all the irregularities of the primer.

- Installing a frame. After the primer is dry, assemble the guides at a short distance from the facade - about 10-15 cm in a step of 60-100 cm, 1-2 cm is less than the width of the block or roll.

- Under the first layer, the film is placed - a smooth side to the plate and steam-absorbing inside. It is attached with a bilateral scotch or stapler.

- The first wool layer is fixed on top. Usually choose softer so that it hides recesses or bulges if they remained after alignment. The plates are laid downward, and rolls are topped down.

- Further mount more rigid items. For reliability, they can be consolidated by a construction staple or fungi dowels.

- On top there are another layer of vapor barrier (the film does not stretch), the crate and cladding.

In the case of mounting under the frame, it is important to know in advance the size of the insulation of mineral wool for the walls to correctly calculate the distance between the profiles.

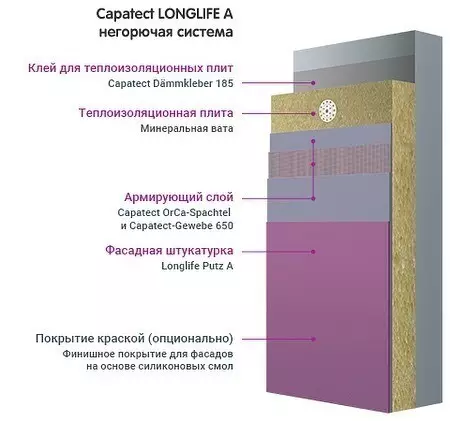

The second method is called wet.

- On the back side of the tiles glue: blots around the perimeter and the entire surface.

- Printed the first layer to the cleaned and primed facade. The location of the tiles should resemble brickwork. Do not forget the rule of window and door corners - you can not poison slices of insulation next to them.

- Additionally strengthen the design of the dowels.

- From above, it is covered with glue with a spatula and apply a reinforcing grid, pressing it to the surface. Align the material is conveniently using Colevma. Then they apply another adhesive layer.

- The next stage is the final decorative finish.

Minvati laying scheme

The installation of the reinforcing grid is mandatory. It helps to secure the mineral wool, avoid cracks and dents on the facade.

Instruction on insulation home from within

Builders are not recommended to insulate the building inside, since there is a danger of condensate and mold with him. In addition, wet heat insulation will lose its properties and will become useless. Another minus - the useful area is significantly lost. But often without such thermal insulation can not do. In this case, it remains only to do everything possible for vapor barrier. For the installation of the design you will need all the same as in front of the facade. Start work is better in warm and dry weather.

- First, surface preparation is carried out: removal of old coating, pollution, fungus. The removal of the previous finish simplifies the heating with a construction hairdryer, moisturizing wallpaper, electric machines for cleaning partitions.

- Strong protrusions need to be knocked down, and dust and other contaminants are removed from cracks.

- The next stage is the coating of antiseptic primer. It is applied with a roller, and the gaps are treated with a brush. It must be done even if the mold is not detected.

- After absorbing and drying the soil, dents must be sharpened and align the surface. You can use the usual cement.

- When the patchwork is dried, two more priming make.

At this preparatory stage ends and it is time to start marking on the installation of profiles.

- Mark the vertical lines at a distance of 40-60 cm from each other.

- On the floor and the ceiling, make markup under the frame of the sheets of GLC. The distance from it to the wall should be more insulation thickness.

- At the vertical lines on the dowel, attach direct suspensions and bend them into the P-shape.

- At the bottom install a guide profile for vertical crate.

Direct suspension

The next stage is the installation of wool.

- On the back of the tile with a layer of 10 mm glue.

- Immediately after that, it is punished on the suspensions and tightly pressed to the base.

- Surplus glue, speaking around the edges, you need to remove. Additional fasteners will not be required.

- When all the details of the design are glued, they are pressed with vertical racks on the self-tapping screw. The protruding parts of the suspensions are rejected to the sides.

The final stage is the attachment of the membrane or film to create vapor barrier. It is important to firmly fix the canvas of the mustache, without the gaps of the windows, gender and doors. For this use two-way tape or stapler. After mounting moisture-resistant plasterboard and make a decorative finish. Besleless installation is also possible. First, the framework is fully made and pieces of insulation felt in it. But this option is less reliable in terms of thermal insulation.

Foil vapor insulation can also be used

After completing the work immediately make cleaning from the residues of the fibers. During installation, it is impossible to leave near open food, in order to place animals and children.

Option of insulation with wooden frame.

Warming of the walls of the skeleton house of mineral wool: video

In frame structures, a construction is usually used with additional film protection on both sides. A timber or metal guides will also need to secure material. In the video - detailed instructions with tips.