Ceramzit is one of the most sought-after building materials. We will tell me how and from what it is manufactured, and where it can be used.

It may seem that almost everything is known about the granules from ceramics. Any domestic wizard will easily tell you what clay is. However, such a popular material has its secrets and features. We will talk about them today and talk.

What is the ceramzite

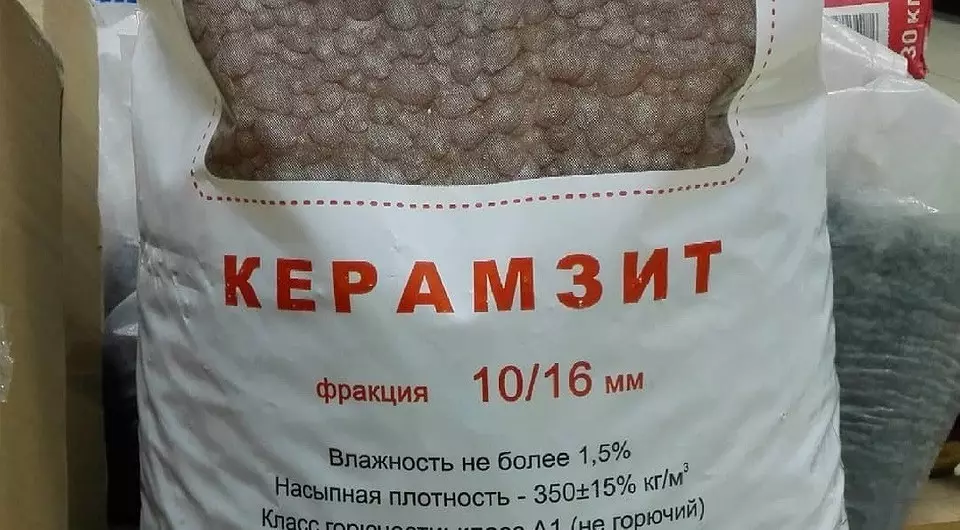

These are light balls from ceramics with a special porous structure. Raw materials for their production become clay shale and various grades of clay, which accelerately burn in special furnaces. As a result, grains are obtained with a crispy, very dense shell. Inside, they are preserved filled with air pores - their presence determines the properties of products.

The form depends on the method of manufacture and can be different. Elements are produced in gradations from almost the right ball to parts similar to the cube. The form does not affect the product characteristics. Different and size. In some cases, a mixture is used from different fractions, which allows, if necessary, lay the elements as tight as possible.

Varieties of ceramic material

The main feature in which the classification is carried out is the grain value. Based on this, three groups distinguish:Ceramzite sand

The size of the granules does not exceed 5 mm. It is manufactured by the grinding of large fragments of ceramic mass or firing of elbows of clay raw materials. The fine fraction is good as a filler in the manufacture of cement solutions, ultralone concrete concrete, etc.

Ceramzite gravel

It is the grains of only a rounded shape with a size of 5 to 40 mm. Produced by swelling billets from clay in the furnaces. Have the highest possible insulating characteristics. Used as insulation of various purposes and in the production of concrete blocks.Ceramzite crusp

These are the largest elements, from 5 to 40 mm. Moreover, the difference in size can be significant. The form meets any, but most often it is angular details. It is manufactured by grinding pieces of ceramic mass. Most often used as a filler in the process of manufacturing light concrete.

How to make ceramzit

Production begins with the selection of raw materials. Clay is sorted, the impurities are maximally removed, if necessary, substances that improve swelling are added. It can be solarium oil, anulit, fuel oil, etc. After that, raw granules are formed, which can consist of different grade clay. They must pass the drying process. After drying, loaded into the drum furnace, where the root occurs.

To accelerate the crushing process, raw balls are constantly mixed. In the firing zone, the temperature of about 1300s is maintained. For the processing of one batch goes about half an hour. Finished products are stored and calibrated, separated by fractions. If necessary, additionally crushed. After that package.

The characteristics of the material directly depend on the quality of raw grains. Produce them with 4 different methods:

- wet;

- dry;

- plastic;

- Powder-plastic.

Each of them gives a good result only provided that in the process use Certain grade clay. Such production is possible at home: for this, mini-installation is purchased. True, the quality of handicrafts is lower, which limits their scope.

Features of granular material

It has good performance characteristics, which makes it possible to use it in different areas of construction. Experts know exactly what the clamzite is needed on the floor, under the roof and in other parts of the design. Its main advantages:

- Low thermal conductivity. Due to the fact that their inner pores are filled with air, the granules are very poorly carried out. But it is well preserved. This makes the material with an effective insulation.

- Durability. Ceramics serves decades without losing its operational characteristics.

- Inertia to most chemical compounds. Acids and alkali do not destroy ceramic balls.

- Fire safety. Ceramics without prejudice to herself withstands high temperatures, does not release toxic substances and does not ignite.

- Good noise absorption. Air filled pores effectively prevent the passage of sound waves.

- Frost resistance. Low temperatures are safe for granules, whose shell is not damaged. If this is not the case, and in the pores got water, during freezing it can destroy ceramics.

- Ecology. Only natural raw materials are used for production, which makes items completely safe for living organisms.

Of the flaws it is worth noting a small hygroscopicity of the clay. Having worst, he will dry for a very long time that it is necessary to take into account when conducting construction work. For this reason, it is advisable to perform vapor and waterproofing when laying a ceramic insulation.

What is a ceramisite in construction

The scope of material is very wide. It includes several directions:Filler for light and ultralight concrete

They are indispensable for pouring draft screeds and the construction of monolithic walls. Especially in cases where an excessive load on the design is invalid or undesirable. The use of ceramic filler can significantly reduce the weight of the systems and does not affect the degree of its strength.

Insulation

Optimally use highly porous varieties. They are distinguished by maximum insulating characteristics. They are falling asleep on overlap, under the floor, in the walls, etc. To get a good result, it is necessary to carry out calculations to accurately determine the height of the insulation layer.

Sweep when arrangement of foundation

Granules are recommended to be used in the construction of the foundation. This allows you to prevent its freezing, as well as reduce the depth of the bookmark almost half, which significantly saves funds.Filler for clay concrete blocks

Elements from cellular concrete are very in demand for low-rise construction. The use of ceramic grains in their manufacture increases the thermal insulation characteristics of the blocks, reduces their weight.

Basis for dry screed

The design is used for fast and efficient floor alignment. The basis of the system becomes ceramic grains. They improve its thermal insulation properties and do not give excessive load on overlap. It turns out a durable and reliable basis for any finishing coating.Drainage

For these purposes, varieties are used with less porosity, since their feature is the minimum hygroscopicity. They are stacked as a drainage in the mound during the construction of roads, with the arrangement of the water-reducing water, etc.

Warming of thermal networks

Granules fall asleep pipes, bringing heat to the houses. This allows you to maintain the desired temperature of the coolant and save funds for heating. Additional plus - the use of ceramic grains greatly simplifies the repair of pipes.

This is not all directions where clamzit can be used. It is very in demand due to its good insulating properties, low weight, strength and durability. In addition, it is very easy to install. Make a sinking or lay the insulation layer is very simple, it does not require special tools or professional knowledge. The video shows one of the easiest ways to fill the screed.

Application of material in agriculture

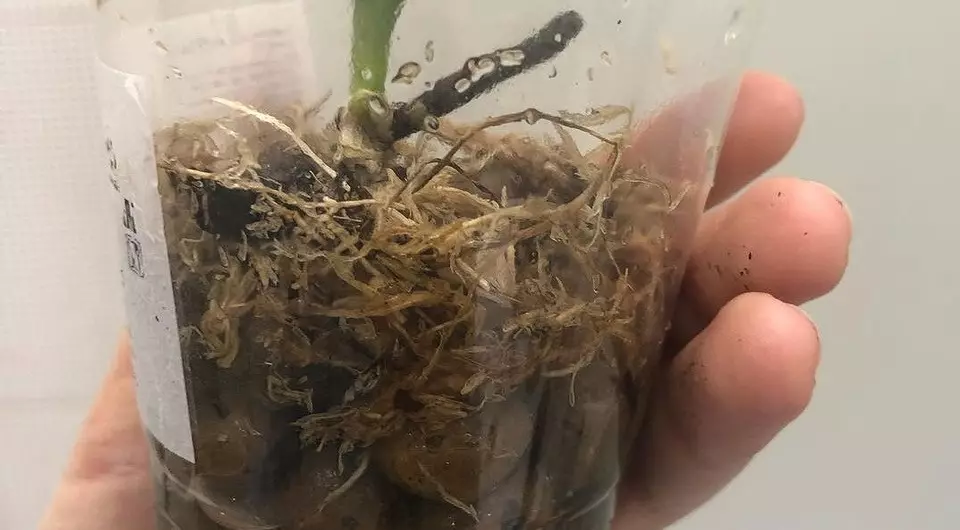

Agrarians successfully use it in the process of growing vegetables. Excellent drainage, it removes excess water from the root system of plants, preventing the development of rot and fungi. The grains optimize the air exchange plants, especially those are planted into dense clay soils. Granules can be added during the arrangement of the beds, the layer of 2-3 cm thick will be sufficient for effective drainage. And it is possible to do it on a home garden.

At home, grain is used when growing potted colors. With such a drainage they look much better. Another promising direction of use of ceramics is hydroponics. Granular material successfully replaces the soil for plants. His porous varieties first absorb the nutritious substrate, and then gradually give it to the roots. There is a peculiar dosing of food, which has a beneficial effect on the development of plants.

We disassembled how to produce clamzit. Due to the good operational characteristics and relative cheapness, the area of its use is very wide. But it would be a mistake to think about the full versatility of the material. There are several types of its varieties that are optimally suitable for different purposes. This must be taken into account when choosing granules.