Ukubuka konke kweziteshi zokupompa ezenzakalelayo zama-cottages: Izinhlobo zamaphampu, abavikeli be-re-ter-term inclusions, izimiso zokufakwa.

Photoxpress.ru.

Ingalo 100/25 ngesisekelo sepompo ozimele nge-ejector eyihlane iphakamisa amanzi kusuka ekujuleni kuya ku-35m

Redcover.com.

Ukucindezela kwamanzi okubuthakathaka? Usebenzisa isiteshi sokupompa, qinisekisa ingcindezi edingekayo ekuhlinzekeni kwamanzi

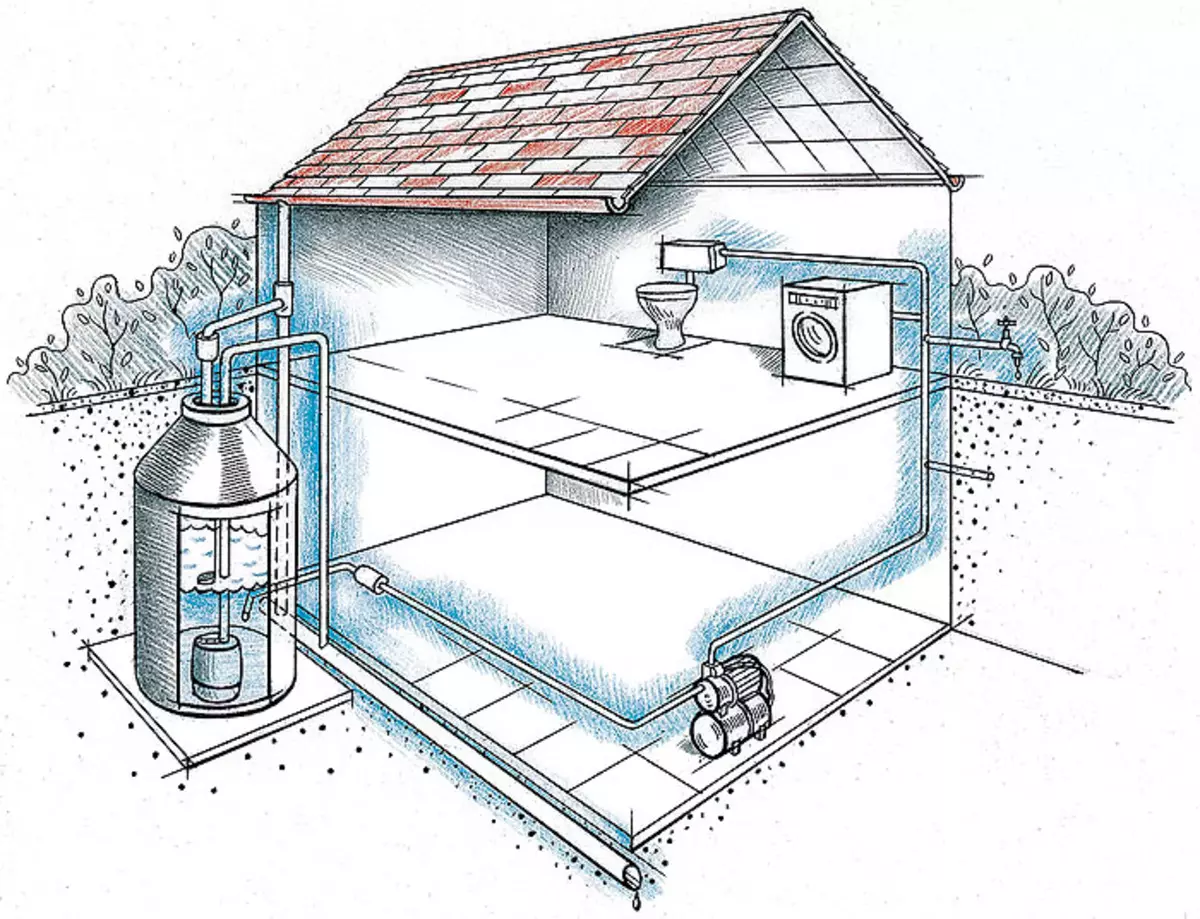

Uhlelo lokwelashwa lwamanzi ekhishini linokumelana ne-hydraulic ephezulu, ukunqoba iziteshi zokuposela okuzenzakalelayo zivame ukufakwa emnyango

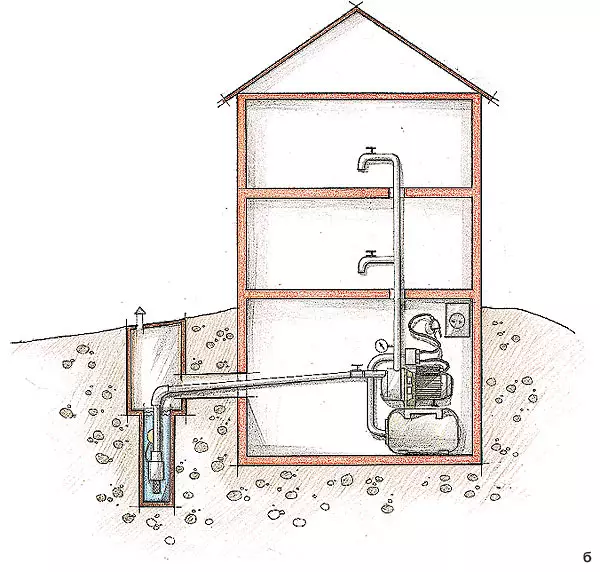

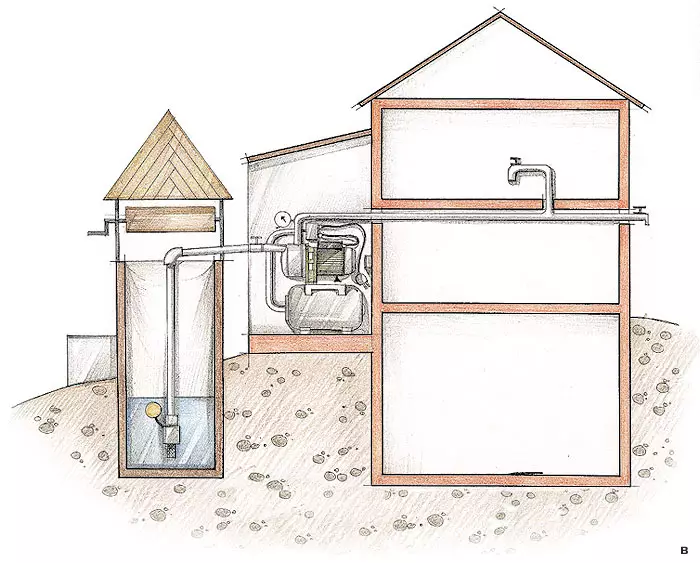

Uhlelo lokuhlinzekwa kwamanzi olususelwa esiteshini sokupompa esizenzakalelayo kanye nethangi elihlanganisiwe

Ulwelwesi olubunjiwe lwe-Pear lwe-hydroaccumulator

Ukuhlunga kwamakhilogredi ngezinto zokuhlunga ezingenazipheni (amakhoyili asetshenziswa kakhulu "amakhoyili" avela ku-polypropylene filament) afakiwe kwipayipi yengcindezelo

Isiteshi se-SOER esine-Hydraulicular and sel-Priming Steel Flow Pump

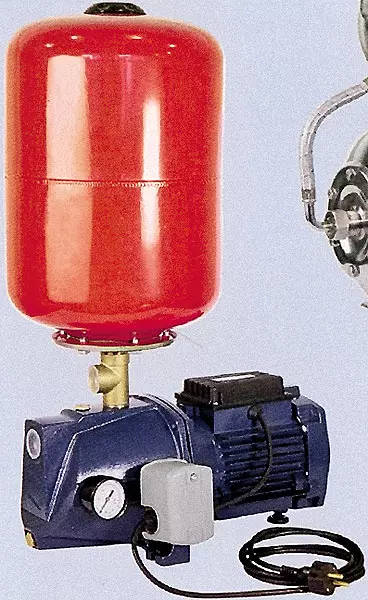

Iziteshi zokupompa ezenzakalelayo eziqukethe ipompo elingaphezulu ngemoto kagesi, ithangi eliqongelelwa nge-hydro elinamanani afinyelela ku-60 amalitha, ukushintshwa kwengcindezi, kanye ne-hose yokuxhuma nekhebula kagesi, Amadivaysi anjalo angathathwa ngokuthengiswa kunoma yisiphi isitolo esikhethekile ekuthengisweni kwezimpahla zengadi kanye nengadi), okulungile kufanelekile ukuthola amanzi asekhaya endlu yezwe. Umnikazi wesiteshi angaba yinto evamile ngenani elincane - kusuka kuma-ruble ayizinkulungwane ezingama-3-4. Ukuze uthole imodeli eyenziwe eChina, "eyanele" yonyaka owodwa noma ezimbili, kuya kuma-ruble ayizinkulungwane eziyi-10-17. Ngedivayisi yoMhlangano WaseDenmark, waseJalimane noma wase-Italy, impilo yenkonzo yayo engaba yiminyaka eyi-3-10 nangaphezulu.

Nje futhi kuyatholakalaIziteshi zokupompa ezenzakalelayo zinganikela emanzini avela emithonjeni, emithonjeni, emithonjeni evulekile yokudla kwamanzi. I-Wriegions ngesimo sezulu esishisayo abazifaka ebhulini lamapayipi amanzi okuphuza amanzi avela emathangini; Ngombhalo wabo wokusiza ukuhlelela ukunisela ingadi. Iziteshi zivunyelwe ukungasebenzi ezweni kuphela, kodwa futhi nasendaweni yokuhlala yedolobha, uma ingcindezi yamanzi ekuhlinzekeni kwamanzi ayisanele futhi kuyadingeka ukwandisa ingcindezi ohlelweni lokuhlinzekwa kwamanzi. Into esemqoka ukuthi emswakama ophonyisiwe bekungekho izinhlayiya ezinzima (isihlabathi, njll.) Nezinhlanganisela ezinde ze-fiber - zonke izinhlobo zezinduku, ama-blade anosayizi oqondile ngaphezulu kwe-2mm. Inani eliphelele lokungcola kwemishini akufanele lidlule i-100G / M3. "Abamele" abasebenza emndenini "abanamandla kakhulu banikezwe indlu kanye nesakhiwo sendlu saya ku-3.5-8m3 umswakama ngehora, ukugcina ukweqisa ku-2-3bar kunethiwekhi yokuhlinzekwa kwamanzi, futhi kwesinye isikhathi kuphakeme. Ngenxa yalokhu, ngaphezu kwamaphoyinti endabuko ekwelashweni kwamanzi, njenge-cranes ekhishini, egumbini lokugezela kanye nama-plams egumbini lokugezela, ama-heather arrigation nezinhlelo zokugeza kanye nezinhlelo zokunisela ezixhunyiwe kunethiwekhi.

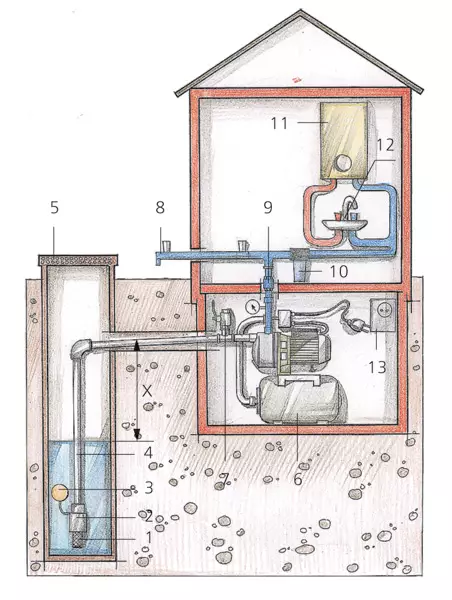

Isikimu sohlelo lokuhlinzekwa kwamanzi oluyindilinga oluyindilinga elizungeze i-cottage kusuka emnandi (x - ukujula kokumunca):

Isihlungi se-1- Mesh;

2-Bheka i-valve;

Ukushintsha okungu-3-ukuntanta;

4- Ukudonsa ngamapayipi;

Isivalo esifudumele;

Isiteshi sokupompa;

7 - ukugcwalisa crane;

8- crane yokunisela;

I-9-Bheka i-valve epayipini yengcindezi;

Isihlungi se-10%;

11- Amanzi kagesi we-heater kagesi;

I-12th Mixer;

I-13- Stabilizer for 220V

Isiteshi sokupompa sibekwe endlini noma phesheya, into esemqoka ukuze amandla wokumunca, ingcindezi kanye nokusebenza kwepompo yawo kwanele ukuhlinzeka ngezindlu ngamanzi. Uma uzosebenzisa idivaysi kuphela ngesikhathi esifudumele, ngokwesibonelo, ukunikeza amanzi e-crane eyodwa ekhishini bese ugcwalisa ichibi elincane, faka imishini elula- ingavuswa ngo-1 wesibili. Kwanele ukuphakamisa i-hose yamanzi ekhethekile ukusuka emthonjeni esiteshini (kulesi sigaba, amanzi kufanele asukume okungenani ngaphansi komthambeka we-1, ngenkathi ama-tubes avundlile nawo angamukeleki). Okulandelayo, udinga ukuxhuma iphampu yokuphakelayo epayipi lokuhlinzekwa kwamanzi, xhuma esiteshini kunethiwekhi kagesi bese wenza eminye imihlahlandlela engeyona eye-Slip yomenzi yokwethulwa kwemishini.

Ukufakwa kwesiteshi sokupompa, esilungiselelwe unyaka wonke, kungenzeka ukuthi sibambezelwa izinsuku eziningana. Ingafakwa endaweni evuthayo ye-cottage noma e-caisson efudumele eduze komthombo, kanye nomgwaqo omkhulu ovela emthonjeni noma kahle endlini ukuze ifakwe emhlabathini ngaphansi kweqhwa (okungenani 1.5- 1.8m). Umthombo kufanele uvalwe ngesembozo esifudumele. Lapho ukhetha indawo yokufaka isiteshi sokupompa, kubalulekile ukukhumbula ukuthi njengoba kususa emthonjeni noma kahle, ibanga elivumelekile libheke esibukweni samanzi sepayipi selincishisiwe: Uma isiteshi siye emthonjeni kungu-5m- 5%, 10m- ngo-10-35% wamanani wepasipoti wokujula kokukhulisa okuphezulu, kuya ngomabanzi we-hose yokumunca, impahla yayo, inani lokujika (elishiwo yi-Turns). Uma phakathi komthombo kanye nendlu kungaphezu kwe-10-15M noma ngaphambi kwamanzi emthonjeni, ngaphezu kwamanzi, esiteshini kungcono ukubeka eceleni kwaso, nasendlini ukwelula ipayipi kusuka epayipi layo .

Iziteshi zokupompa ezenzakalelayo ziyasebenza ngokuzimela, indaba yesikhathi, ngaphandle kokubamba iqhaza komuntu; Into esemqoka ukuthi amanzi asemthonjeni anawo wonke futhi ugesi akazange acishiwe. Inethiwekhi yamapayipi esiteshini esizenzakalelayo esixhunyiwe kuyo, ingaphansi kwengcindezi ekhiqizwe yi-hydroaccumulator (membrane pressure hydrobacom). Uma uvula i-crane ekhishini, amanzi aphuma kuwo ngejethi ejabule, kanti i-hydroaccumulator izoqala ukungabi nalutho, futhi ingcindezi ohlelweni iyancipha kancane. Lapho iwela ngaphansi kobuncane obusethiwe (imvamisa cishe ngo-2-2,2bar), ukushintshwa kwengcindezi kuzovula ngokuzenzakalelayo iphampu, futhi kunxephezela ukusetshenziswa kwamanzi. Ngemuva kokuvala i-crane, impompo izosebenza isikhashana. Kuzogcwalisa i-hydroaccumulalator kuze kube yilapho ingcindezi ohlelweni ayikhuphuki kuze kube okuqala (cishe i-3Bar), ngemuva kwalokho, ngenxa yokuvunyelwa okuzenzakalelayo lapho kuzoba nokuvalwa kwephampu okuzenzakalelayo. Ukushintshwa kwengcindezi ephezulu nangaphansi kwengcindezi yokucindezela kufakwa efektri, kepha uma kunesidingo (ngokwesibonelo, ukwandisa ingcindezi ohlelweni), kungashintshwa.

Isilinganiso sokusetshenziswa kwamanzi kwansuku zonke| Uhlobo Lohlelo Lokunikezwa Kwamanzi | Okujwayelekile kokusetshenziswa kwamanzi kwansuku zonke komuntu ngamunye, l / usuku |

|---|---|

| Indlu enokusetshenziswa kwamanzi kwamakholomu okulashwa kwamanzi emgwaqweni nemithombo | 30-50 |

| Indlu nokuhlinzekwa kwamanzi kwangaphakathi nokukhucululwa kwendle ngaphandle kokugeza | I-125-160 |

| Amabhati afanayo + nama-heater amanzi endawo | 160-230. |

Ikhanda nokugeleza

Ngaphambi kokuthenga isiteshi, kuyadingeka ukuthola ukuthi ingcindezi eyakhiwe yi-IT futhi ukusetshenziswa kwanele ukufeza izidingo "zamanzi" zekhaya lakho nendawo. Ngokuphambene nalokho, ukuthengwa okubizayo, kepha akukwazi ukubhekana nezibopho zalo eziqondile zedivayisi yezobuchwepheshe kungenzeka. Izindleko ezinkulu zesiteshi ngokufanele kufanele zilingane nenani lezindleko zakho konke kufakwe amaphuzu akhomba endlini. Ukususwa kwesiteshi okudingekayo ukuqinisekisa ukusetshenziswa kuwo wonke amaphuzu asuselwa emanzini, aqukethe izakhi ezintathu. Okokuqala, kuyadingeka ukwazi ukuthi mangaki amamitha adingayo ukuveza amanzi kwisibuko samanzi omthombo ukuya endaweni ephezulu kakhulu yepayipi lamanzi. Lapho-ke kuyadingeka ukubheka ingcindezi esebenzayo kupayipi elilingana okungenani ne-2Bar (ehambelana nengcindezi engu-20m), - Kudingeka ingcindezi evamile yokusebenza okujwayelekile kwemishini yasendlini. Ingxenye yesithathu yengcindezi kulo lonke ubude bepayipi lamanzi, ezingxenyeni zokumunca nokunikeza izigaba.

Ukuze uchwepheshe ukunika izincomo ezinekhono, ungavilapha ukuchitha izilinganiso ezithile esizeni sakho. Nquma ibanga ukusuka endaweni yokufaka yesiteshi kuya komthombo, ibanga langempela ukusuka embuthweni wamanzi ukuze uthole isibuko samanzi emthonjeni noma umfutho othe xaxa kwamapayipi amanzi. Kuyinto efiselekayo futhi ukuba nohlelo lwendlu nendawo yamaphoyinti asuselwa emanzini. Akufanele uchithe isikhathi ufuna imininingwane edingekayo yereferensi kubulukhuni bamapayipi, ukumelana kwe-hydraulic kwezinto ezenziwe nge-IT.d.- kunoma iyiphi inkampani ehlonishwayo, imininingwane enjalo izothola umeluleki wemenenja noma umklami. Kuzobala ukusebenza okudingekayo, kanye nokusetshenziswa kwamanzi futhi kuzokhetha isiteshi ngecala lakho elithile, futhi futhi kuncoma ukufaka okufakiwe okungase kufakwe ngokushesha nangendlela efanele.

Into eholayoIsiteshi siwukuthenga okunenzuzo kakhulu uma kuphela ngoba bayifaka efektri. Isethi yezinsizakusebenza ihlolwe ngokuphelele ngumenzi, okusho ukuthi izinkinga ezihambisana nomhlangano wekhwalithi engeyinhle yokufakwa angesabi. Uma isiteshi sehluleka, singalungiswa kwi-Waranti Workshop noma esikhundleni esisha. Kodwa-ke, ukukhetha okuqondile kwemodeli ethile akunakwenzeka ukudelela izingxenye zalo eziyisisekelo.

Iziteshi zokupompa ezenzakalelayo zihlome ngamaphampu ngeplastiki, ziphonsa izindlu zensimbi nezinsimbi; Imoto kagesi ibaholela kubo. Amaphampu ngokuvalelwa kwepulasitiki eshibhile, kusuka ku-cast iron nensimbi engenasici - okwengeziwe nokuhlala isikhathi eside. Kodwa-ke, ukwahlulela impilo yangempela yenkonzo yamaphampu nezinjini ekwakhiweni kweziteshi ezizenzakalelayo kunzima. Idatha ekuhlolweni kwezinsizakusebenza, izibalo zokuhluleka kanye neminye imininingwane ethokozisayo mayelana necebo elenziwe abenzile Akekho kubakhiqizi, alashe, amane akhangise. Ngolwazi olwethuliwe lapho ukhetha isiteshi sokupompa, imininingwane esuhlobo lwepompo ingaba mkhulu kumsebenzisi, kuya ngokuthi yikuphi ukujula kwesiteshi okuzokwazi kanjani 'ukuqinisa' amanzi endlini, kuzokwenza kube lula kanjani ukusebenza. P.

Imvamisa, iziteshi zokupompa ezenzakalelayo zenziwa ngesisekelo samaphampu we-inkjet-centrifugal wokuzikhandla ane-ejectors eyakhelwe ngaphakathi. Banethuba elihle kakhulu ngaphezulu kwamaphampu wezinye izinhlobo ngenxa yengcindezi ephezulu (kusuka ku-40m) kanye nokujula kokumunca (ngokunembile ukuphakama) kuya ku-7-8m, ukuzwela okuphansi komoya ohlelweni. Lokhu kusho ukuthi lapho impompo isiqalile, kwanele ukugcwalisa ngamanzi kuphela izindlu zayo, okudingeka ukuthi ukhiphe ipulaki umgodi wophethiloli, uthele amanzi epumpeni kuze kube yilapho unamathela emaphethelweni, bese ujikeleza ipulaki . Ipayipi lokumunca kusuka ephampu liye emanzini kahle alikwazi ukugcwaliswa. Iphampu, okokuqala ukupompa umoya, izoqala ukondla amanzi endlini (umoya owengeziwe ovela emgaqweni omkhulu uthululwa usebenzisa i-valve ezindlini zepompo noma ukuvula noma iyiphi i-crane). Lesi sici sepompo esizimele nge-ejector eyakhelwe ngaphakathi silusizo ikakhulukazi uma umthombo wokuhlinzekwa kwamanzi yi-soinal tube, ushaye phansi emhlabathini. Kepha kunoma yikuphi, hhayi ukuzwa ukungaphatheki kahle lapho usebenzisa isiteshi, ku-Pipe e-Suction, kunconywa ukufaka i-valve ye-Check ngesihlungi se-mesh, uma kungenjalo kungenzeki ukuthi ngaphambi kokuqala kwempompo ngayinye kuzofanela kulinde isikhathi eside Isikhathi (imizuzu engu-3-10, futhi kwesinye isikhathi isikhathi eside) ngenkathi amanzi enyuka engena ephampu kusuka emthonjeni.

Phakathi kweziteshi ezahlukahlukene, sizobona "Jambo" ("Djelex", eRussia), i-Ukraine kanye ne-MQ (i-Grundfos, iDenmark), iWilo-Jet HWJ (WILO, Germany), I-PKM (PEDRORO), i-Inox Waterpress (Nocchi), i-Aquiset INOX (DAB), i-Self (Marina) (i-Marina) (YONKE I-Italy).

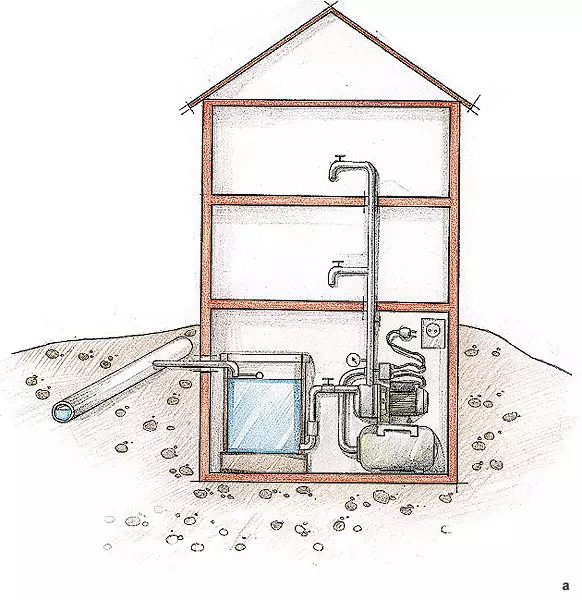

Olunye uhlobo lweziteshi luhlanganisa futhi ngamaphampu we-inkjet-centrifugal, kepha anawo ama-ejectors akude. Zisetshenziselwa ukupompela amanzi kusuka ekujuleni (kuze kube ngu-20-45m) Wells nemithombo. Isiteshi esinjalo sibekwe ebusweni, futhi i-ejector (ibhlokhi elincane) linamathiselwe kumapayipi amabili lehliselwa emthonjeni. Elinye lamapayipi lisetshenziselwa ukuhambisa amanzi phansi, i-ejector, futhi kwakha i-Jet yokumunca lapho, kanti okwesibili kungukuphakamisa amanzi abuyele ku-ejector, futhi aqondiswe kancane epayipi lamanzi endlu. Iziteshi zomculo zalolu hlobo kufanele zibizelwe iqiniso lokuthi zizwela emoyeni, esihlabathini, zinokusebenza kahle. Ngasikhathi sinye, isiteshi esinjalo singabekwa endaweni evuthayo ye-cottage endaweni, uma umthombo utholakala kude nasekhaya (kuze kube ngu-20- 40m). Izisetshenziswa zemishini - Ingalo100 / 25 (Marina).

Kwesinye isikhathi ungathola iziteshi zokupompa ezenzakalelayo ezinomqondo owodwa, isikhathi esisodwa kanye ne-multistage evame ukuncela amaphampu we-wilo-multipress Zisebenzise ikakhulukazi ukukhulisa ingcindezi, kepha ezinye zingaphakamisa amanzi ekujuleni kuka-3-5m, kwesinye isikhathi ngaphezulu. Kodwa-ke, ngaphambi kokuqala ukusebenza, kuyadingeka ukugcwalisa nge-hose yamanzi amanzi kanye nengxenye yokusebenza yepompo. Uma lokhu kungenziwa, owokugcina wehluleka. Ukuze wandise ingcindezi, iziteshi ezizenzakalelayo ezisuselwa kumaphampu we-vortex ziyasetshenziswa, zizwela kakhulu ukuba khona kokungcola emanzini (isihlabathi), kepha "ukunganaki" kumathrafikhi asolwandle. Lapho usebenza, iphampu yeVortex ngumsindo obonakalayo. Kanye nokuhlanganiswa kwedivayisi. Isibonelo sobuciko besitatimende sesibonelo (Calpeda, Italy).

|

|

|

Iziteshi zokupompa ezenzakalelayo zinganikezwa emanzini avela emithonjeni, ngokwesibonelo, kusuka kumsindo wokugcina, lapho umswakama uqhamuka khona epayipini lamanzi (a), noma ngokuqondile kusuka emthonjeni okhethwe kahle (b). Ehlobo, isiteshi kwesinye isikhathi sifakwa ngaphansi kombhede omncane eduze kwendlu (b).

Ivolumu ewusizoUkusebenza (ukusetshenziswa) kwephampu yesiteshi sokupompa ezenzakalelayo kuvame ukwedlula izidingo zendlu yezwe emanzini, ngenxa yokuthi iphampu lingasebenza njalo / likhubaze / ama-disc. Amanye amaphampu angaphezulu eziteshi ezizenzakalelayo avumela imvamisa esheshayo yokwethulwa kunezikhathi ezingaphansi (kuze kube yizikhathi ezingama-30-100 ngehora). Kepha kunoma yikuphi, kuvame ukuqala futhi kuyeke ukunciphisa ngokuqinile impilo yenkonzo yemoto kagesi kanye nama-Launcher. Kungakho abakhiqizi beziteshi zokumpompa bafuna ukuqinisekisa ukuvikelwa kwabo ekuthuthukisweni ngaphambi kwesikhathi komthombo wezakhi ngenxa yokusetshenziswa njalo.

I-limiter eyinhloko yenombolo yokuthambisa okufushane kwephampu ngempompo ngokwelashwa okuncane kwamanzi noma ukuvuza ohlelweni kuyindlela ye-hydroaccumulator. Imvamisa isitsha sensimbi esingenalutho esinomthamo we-8, 20, 24, 25, 50 noma i-60l, ngaphakathi kwawo ulwelwesi lokunwebeka. Ivame ukwenziwa ngerabha yemvelo noma i-butyl (lapho uthenga isiteshi kuyinto efiselekayo ukuhlola isitifiketi sokuhlanzeka) futhi unesimo seflask. Intamo kalwelwesi ivalwe ngo-hermetically ngomphimbo wethangi ngokuxhumeka kwe-flange. I-Flange inokufikelwa yintambo efanelekile ukuxhuma ohlelweni lokuhlinzekwa kwamanzi. Isikhala phakathi kwe-membrane kanye nomgodi wangaphakathi womkhumbi ugcwele umoya ngaphansi kwengcindezi, engashintshwa ngengono yemoto, ngokwedlula (ingcindezi ethangini kufanele ihlolwe ngezikhathi ezithile, ngokwesibonelo, usebenzisa ibhasi Ingcindezi ye-Gauge, uma kunesidingo, mpompa kuze kube yi-1,5thm) edingekayo. Kusukela othintana naye bamanzi kuphela nolwelwesi, amathuba okugqwala komhlaba wangaphakathi wethangi akhishwe ngaphandle. Kwesinye isikhathi esikhundleni se-membrane efana neparele, ithangi elisefulethini, liyasetshenziswa izingxenye ezimbili - kuma-hydroaccumularators anjalo, ingaphakathi linokuhlobisa okuvikelayo. Ukusuka kumswakama wasemkhathini, ithangi lensimbi ephansi le-carbon livikela ukuhlanganiswa koqweqwe lwawo (kepha kusengcono emgwaqweni ngamathangi ensimbi engagqwali).

Ama-hydroaccumulalators anomthamo we-20-24L ajwayele ukusetshenziswa ngokubambisana namaphampu angelona aphezulu afinyelela ku-1.2kw, namaphampu afinyelela ku-2 kw, ama-hydrobars anconyelwa ngo-50-60l. Ngokweqiniso, ngokwezindlela zakudala zokukhethwa, le ncwadi yama-hydroaccumulalators ngokusobala akwanele ukuvikela ngokuthembekile amaphampu ekuqalisweni njalo (udinga okungenani i-80-1550l). Kodwa-ke, ukuzijwayeza kukhombisa ukuthi akunjalo. Iziteshi eziningi ezinamathangi angama-24-litre, ezifakwe ezweni lezindlu eminyakeni engama-5-7 edlule, yize zisebenzisa nsuku zonke, zisebenza ngokuthembekile nokunye. I-Avota ngokwanda kwevolumu ye-hydroaccumularator ku-100-200l futhi ngaphezulu kuholela ekwehliseni okunethezeka kokusebenzisa amanzi. Ukuvula i-crane noma ukujika eshawini, umuntu uphoqelelwa imizuzu embalwa ukuthi abeke ukuncishiswa okubushelelezi ohlelweni ohlelweni, kuze kube yilapho impompo kanye ne-jet kusuka empompini ayitholi amandla anele.

I-hydroaccumularator enkulu iyasiza ekugcinweni kokuhlinzekwa kwamanzi endlini ngaphansi kwengcindezi esimweni sokuphazamiseka kwesikhashana esifushane ekunikezelweni kwamandla. Izohlinzeka ngamashumi amalitha amaningana ama-points okulahla amanzi ngisho nephampu engasebenzi. Uma kunesidingo, ungahlala uxhuma i-hydroaccumularator eyengeziwe ekuhambeni komgwaqo omkhulu wanoma yimuphi umthamo owudingayo.

Ngaphezu kwe-hyddrobook, ukuvikelwa kokufakwa kabusha kwesikhashana esifushane kunikeza ezenzakalelayo zesimanje zeziteshi zokupompa. Amaphampu amaningi ahlome ngokudluliselwa okuvikelayo okuvikelayo, ngakho-ke imodi yesikhathi esifushane ngokuvamile ayiholeli ekubhujisweni kwayo, kepha inciphisa kuphela insiza. Ukushintshwa kwengcindezi yemishini okuzenzakalelayo ukusebenza kwephampu kagesi, kufaka phakathi lapho ingcindezi ohlelweni lokuhlinzekwa kwamanzi iphansi ngaphansi komkhawulo osethiwe bese icishwa lapho kufinyelelwa khona umkhawulo we-elekthronikhi. Isibonelo, eW. P. Superinox 1500 P E (Flotec, Italy) kungenye yemisebenzi yesikhathi sesikhathi se-elekthronikhi, ukufakwa okukhulu kwe-Time Isikhathi, kukhulisa ukuqina kwephampu ngokukhawula inani lokuqalisa kwalo ngehora.

Empeleni akesabi kaningi ukuqala iziteshi zokupompa ezenzakalelayo ezinezinjini ezipholile amanzi, njenge-MQ (Grundfos). Ukufakwa kuwuhlelo oluphelele, kufaka phakathi ipompo, imoto kagesi, inzwa yokucindezela kanye ne-flow sensor, i-valve yokuhlola kanye nethangi lokucindezela u-membrane elinomthamo we-0.18l. Uhlelo luqala ngokuzenzakalelayo iphampu ekuqaleni kwamanzi asuselwa emanzini futhi ayeke ngokuzenzakalelayo lapho ukusetshenziswa kwamanzi kumiswa. I-automation icisha ipompo uma kwenzeka kunhlamvu elomile noma ukucwilisa ngokweqile okubangelwa, ngokwesibonelo, ukugcwala ngokweqile, ngaleyo ndlela kuvinjelwe ukuvela komoya kagesi. Ithangi le-miniature lokucindezela elifakwe esiteshini samaphampu linciphisa inani lemijikelezo ye-rege-term inclusions emcimbini wokuvuza ohlelweni lokuhlinzekwa kwamanzi, futhi luvikele nepayipi lamanzi kusuka ama-hydrowalders.

Amaphampu asebenza kanjani?

Centrifugal. Umgomo wokusebenza kwephampu ye-centrifugal ye-centrifugal umi ngalendlela elandelayo: umnyuziki wokujikeleza emgodini we-drive ubhekene ngqo nepayipi lokumunca elibekwe ezindlini zepompo. Idizayini ye-Impoller ihlinzeka ngokulahleka okuncane kwe-hydraulic ukunyakaza kwamanzi okuvela enkabeni kuya ePeriphery, lapho ama-radial blade ngaphakathi esiteshini se-impeller edlulisela amandla engcindezi futhi andise ukugeleza isilinganiso. Esikhathini esitolo se-impeller, amanzi agijimela ekulingweni, ngenxa yalokho, kanye ne-conic diffuser, ingxenye yamandla we-kinetic aguqulwa abe amandla okucindezela.

Inkjet-centrifugal. Enye yezinhlobo zamaphampu we-centrifugal. Umphumela wokuzihlola kubona kuvame ukufaka isandla ku-Ejector (ekhethekile ye-nozzle) efakwe ngaphakathi kwecala. Uketshezi oluthengiwe luphondliwa ngokwengxenye kuphela ku-nozzle. Ingxenye esele yokuvuselela kabusha ngenxa ye-ejector exhunywe egumbini lokuvalwa, ngenxa yalokho kudala ukukhipha okudingekayo ekutholeni kwamanzi. Kwesinye isikhathi umphumela wokuzibonakalisa kumaphampu we-inkjet-centrifugal unikeza i-ejector negumbi lokumunca, elehliswe emthonjeni bese liyehliswa ngomzimba wephampu ngamapayipi amabili.

Vortex. Lawa mapompo asebenza kanjena: Emgqeni we-impeller wazo, iqoqo lama-radial blades lidlulisela amandla wamanzi adumile. Iphrofayili ekhethekile yama-blades ihlinzeka nge-radial recycling yoketshezi olugeleza lingena empompini phakathi kwama-blades we-impeller kanye nesiteshi esiphindwe kabili atholakala emaphathini ayo womabili. Njengoba i-blades ngayinye ibandakanyeka ekudluliseleni amandla, ukucindezela kwamanzi kancane kancane kukhuphuka ngesikhathi sokuphuma kusuka ekunciphiseni kokukhishwa, ngale ndlela, ngokufana okutholakalayo, ukufana okuphezulu kokuphuma .

Ungayibeka kanjani futhi uyibambeUkufaka isiteshi sokupompa kuyadingeka ngokuhambisana nencwajana yemiyalo. Njengomthetho, kubhalwe ngokuningiliziwe ngokuningiliziwe inqubo yokufaka - ukuphambuka kugcwele ukuphathwa kwangaphambi kwesikhathi kwemishini noma izingozi. Kungcono, vele, ukumema ukufaka ochwepheshe benkampani abanolwazi lapho uzothenga khona esiteshini. Kepha ngamakhono athile, ungathembela emandleni akho.

Ipayipi lapho isiteshi sokumpompa sizoxhunywa khona, kunenzuzo endlini yezwe nge-wiring ephansi. Ngasikhathi sinye, ipulazi layo eliyinhloko elixhunywe ngqo esiteshini sokuhlinzekwa kwamanzi esizimele libekwe egumbini elingaphansi noma ngaphansi komhlaba (phakathi kwepiston kanye nezitezi ezinzima), ngethambeka lika-0.002-0.005 endaweni yephampu. I-Riser, ikhulisa amanzi phansi, isondele ezindaweni zokufakwa kwamapayipi okuqinisa amanzi kusuka ku-riser kumadivayisi we-plumbing kumele abe ubude obuncane. Ukugwema ama-headliws, i-ture apply yasolwandle kufanele ifakwe ngaphandle kokugoba okubukhali futhi ijika. Amakhompiyutha amapayipi kumele abekwe uphawu ngokuphelele, luzogwema ukulahleka kokuvuza nokucindezela.

Uma igridi yamandla kanye nesokhethi, lapho ipompo izoxhunywa khona, yiba nedivaysi evumelekile enesisekelo, khona-ke i-Eind Loomst, bese kuba khona umaphampu wesiteshi othomathikhi kufanele yenziwe ngoxhumana nabo ku-plup yentambo yayo nasendaweni ephumayo. Ngokuphambene, izindlu zepompo zizimele.

Yonke imishini enikelwe evela kwamanye amazwe ihambelana ikakhulukazi namazinga wezimboni womkhiqizi. Ngakho-ke, eziteshini zokupompa ezenzakalelayo zokukhiqizwa kweJalimane, ukuphambuka okuvumelekile kwamandla kagesi kunethiwekhi kagesi kusuka ku-omatinal kungu-6-10%. Naphezu kwezinhlelo zokuvikelwa okushumekiwe, "ama-drawdors" kanye ne-voltage jumps athinte kabi insiza yemoto kagesi. Ngakho-ke, ngaphezu kwesiteshi, i-stabilizer ye-voltage enamandla kufanele ithengwe.

|

|

|

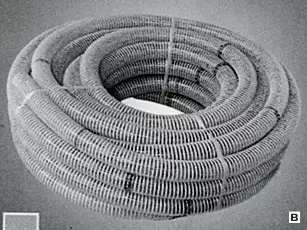

Isihlungi se-Mesh (a) kanye ne-valve ye-Check (B) zifakwe ekugcineni kwengcindezi-vacuum hose ku-rigd spiral braid (b)

Ibhodi lokuhlela ngiyabonga uGrundfos, Wilo, "Avan" kanye ne- "Heatimport" ukuze basize lapho kulungiswa i-athikili kanye nezinto zokwakha zezithombe.