We are talking about the design features of the flooring of the floor: the properties of overlapping, laying technologies, soundproofing materials.

The floor should be beautiful, wear-resistant, warm, durable, sonorous, inexpensive. How to achieve this when reorganizing apartments? In the full cost of redevelopment work, the proportion of the device of a black screed of the floor is 8-17%. Therefore, often the customer neglects it. And in vain: Squeaky parquet, rubbed spots on linoleum - all this is often the consequences of what the black floor device has been performed.

What is a draft floor and how to make it

From what is the floorReliability of different supports

Wet and dry black floors

Soundproofing for different noise

Features of different floors

From what is the floor

The list of requirements The owner of the apartment is easy: not slippery, easy to clean, eco-friendly. Perform all this is not easy. The main reasons for this:

- Layout design. What is associated with the concept of "floor" is actually a finite coating. It can satisfy only parts of general requirements. But most of them are ensured by the properties of what is below the coating.

- Tightening requirements for heat and reconstruct enhancement structures, an abundance of new, not proven long-term practices, materials.

- Confusion in terminology. There are floors in the building and there are floors. Between the floors, they exist together. The problem is in dividing the components what to attribute to.

SNiP 2.03.13-88 does not solve the problem, there is no interpretation of the term "floor", but the last five concepts for the constituent structures are completely not described. In the builder's environment, other concepts are used: base, "black" floor, base, cauldron, concrete preparation, rolling, heat and soundproofing layers.

Therefore, you need to specify the scope of work at the repair brigade. Whether they will be reduced only by the pure layer or lay all the layers and put the carrier elements.

Mainports on the construction of draft floor at home range from 50 to 95% of the total labor intensity. For example, it is easier to make a concrete base for ceramic cladding, but much more difficult - floors on metal beams and lags.

To simplify the understanding of the essence, remember that the floor is a design consisting of "clean" and "black" levels. It lies on the bearing foundation that takes the load. Between the floors, such bases are bearing elements.

The structure of the "black" level depends on the general requirements, the type of "pure" coating, base design.

Before agreeing with the builders, decide:

- What are the requirements for the functional zones of the apartment;

- As far as the room is removed from the elevator shaft;

- Do you have noisy neighbors;

- Are heavy items: large aquariums, hot tub, piano, fireplace.

Then make a project to reorganize the apartment. The more difficult your plans, the more carefully it should be worked out.

Reliability of different supports

Overlap are divided into beam, slab and monolithic. The design depends on their properties.Beam

In the beam overlaps, carrying elements are durable beams: wooden, metal, reinforced concrete.

Wooden beams

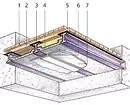

Wooden beams are found in old low-rise buildings. The gaps between the beams are closed with wooden rolled. The "black" layer is performed on the lags, which are stacked across the beams. From the bottom on the beams, the ceiling below the apartment is located. Unfortunately, the repair of wooden beams without disrupting the ceiling of the lower neighbors is impossible.Metal and reinforced concrete beams

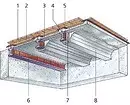

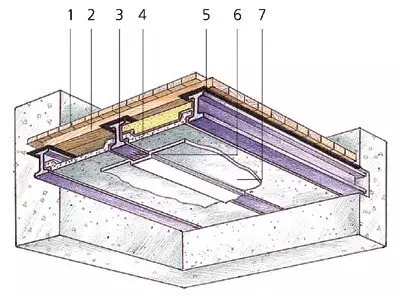

Metallic and reinforced concrete beams of the brand or foreign section were used in the homes of the Soviet buildings to the seventies of the twentieth century. The lower shelves of the beam could be placed in the form of solid plaster or hollow concrete liners, or precast concrete plates. "Black" Paul in this case can be done on the shapper or on the screed. And since when repairing, it is not always possible to purchase prefabricated plates, they are replaced with a monolithic reinforced concrete slab onto the entire room, cast on the spot over the beams. As formwork and reinforcement, it is sometimes used high-profiled steel sheet.

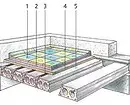

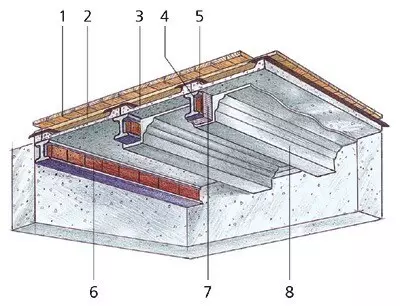

In the houses of the construction of the seventies-eighty, well-known series II-29, P-3, P-44, P-46, P-55 with their modifications, coil reinforced concrete floors are used. They can have a width of 1.2 to 3.6 m, a nominal length from 2.4 to 6.6 mm. They can create "black" floors on the lags or on the screed. Less often meet multi-console plates with a thickness of 220 mm. They are in the old series, for example, II-68, and in new: and-155. Provide better sound insulation than solid plates.

Overlapping on wooden beams: 1 - "Clean" floor; 2 - lag; 3 - Failure; 4 - waterproofing; 5 - beam; 6 - clay coating; 7 - duncar; 8 - plaster; 9 - cranial timber; 10 - shield panel

Overlapping for metal beams with prefabricated railway plates at the bottom of the beams: 1 - "Clean" floor; 2 - boardwalk; 3 - beam; 4 - team railway plate; 5 - waterproofing; 6 - plaster grid; 7 - Plaster

Overlapping on metal beams with prefabricated railway plates on beams:  1 - "Clean" floor; 2 - boardwalk; 3 - team railway plate; 4 - beam; 5 - waterproofing; 6 - brick; 7 - plaster grid; 8 - Plaster

Overlapping from railway plates with round voids: 1 - floor tiles; 2 - glue; 3 - pouring with a solution; 4 - screed; 5 - R / B Overlapping Plate

Wet and dry black floors

"Black" layers according to the peculiarities of manufacture are divided into wet and dry. When laying the first, materials are used to be licked by the liquid component: water or polymer suspensions. They require a drying time, hardening.To wet floors include:

- dissolved by water, such as concrete, cement-sandy, slag- and gypsum concrete, foam concrete;

- Bulk, using polymer resins as a binder component (polyurethane, epoxy, polyester).

The main function of the screeds is the correction of defects: failures, steps, distortions, level drops. Using a screed, you can create a specific slope of the surface or a step at the boundary of the sections with different coating. It is closed with pipes and wires passing under the coating.

Chatting tight, fire-resistant, but you can only lay them on the slab base. The main plus - on them you can drain all types of coatings.

Dry floors include:

- coating on the shelter;

- team with dry tie;

- Adjustable.

Soundproofing for different noise

Noise is transmitted not only to neighbors from below, but also in all rooms of the apartment. And if the noise in the apartment below will be more permissible, a neighbor can cause you to remake all repairs through the court.Noise are divided into two types: air (speech, music, murmur of water) and drums (steps, furniture movement, bumps, knocks in household appliances). Fight with them in many ways.

Air noise

Air noise delay base elements. Mass is important here. Sound waves cannot dig massive items. If the mass of more than 350 kg / m2 (the indicator of solid slabs with a thickness of at least 160 mm), the air noise is extended successfully. Otherwise, in the design of the "black" level, it is necessary to include a layer of soundproofer from an elastic porous material.

Shock noise

With impact noise, it is more difficult to deal with. The large mass of the designs here is also useful, but more efficient isolating interlayers from the materials of a fibrous structure with thin air channels and a small modulus of elasticity. Here, the energy of the sound wave is spent on air fluctuations and the walls of millions of microchannels.

Typical structures used in the houses of the construction of the eighties, new standards of sound insulation do not provide. Therefore, with redevelopments, old systems do not repeat, but create new ones. Materials are important, place of their location, new coating designs. For example, it is more expedient to place a soundproofing interlayer, but under it.

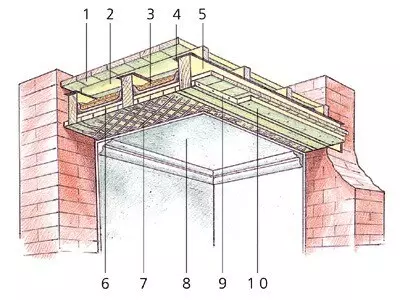

With the help of steel studs, lags can be lifted over a base of 150-200 mm, placing a checker order if necessary

In this way, it is possible to create an empty space for laying any communications - from electrocabels to pipes and air ducts of the ventilation system

In addition, the design helps to improve the thermal insulation characteristics of the overlapping, as well as provide additional insulation of air and (to a lesser extent) of shock noise - with this purpose, mineral wool is laid between lags

New sound insulators:

- "Floating";

- Suspended ceilings with noise insulator;

- Of the two separate bearing plates.

How to choose the material of the insulator:

- Under lags, the mats of glass gambler who lie on the beams work well, and the walls are growing up to the plinth level. Out of the sheets of chipboard or tongue boards are stuffed, tightly pressing the glass gods to the wall;

- Under the concrete screed, dense mats from basalt wool or polyethylene slabs, and on the walls - strips are glass gambles with a thickness of 20 - 30 mm. On top of the mats are covered with polyethylene film, wrapping it at the walls up, and then pouring a solution for a screed;

- In the case of ceramics, a basalt thin-fiber canvas layer 20 - 30 mm and a cement-sand tie with a thickness of 50 mm.

Sound insulation indicators on aligned reinforced concrete overlap with a thickness of 140 mm:

| Components (from top to bottom) | Option design | |||||

|---|---|---|---|---|---|---|

| one | 2. | 3. | four | five | 6. | |

| Parquet board (18mm) on HM * | +. | +. | ||||

| Parquet board (28mm) on HM. | +. | |||||

| Parquet piece (17mm) on HM. | +. | +. | ||||

| Linoleum PVC with fabric base (3mm) on HM. | +. | |||||

| Fiberboard plate solid (4mm) on HM | +. | +. | +. | |||

| Plate Fiberboard solid (4mm) on g. ** | +. | |||||

| Plate Fiberboard soft M1 (212mm) on HM | +. | +. | +. | +. | ||

| Flooring board (25mm) | +. | |||||

| Laga wooden 8040mm, step 400mm | +. | +. | ||||

| Gasket from DVP-M1 (12mm) | +. | +. | ||||

| Ruberoid, 1 layer on G.M. (3mm) | +. | +. | ||||

| Total thickness to base, mm | 49. | 52. | 42. | 45. | 77. | 70. |

| Surface Mass of Design, kg / m2 | 39. | 47. | thirty | 38. | 34. | 32. |

| Air Noise Insulation Index Columns RW, DB | 52. | 52. | 53. | 53. | 53. | 51. |

| Index of the shown shock noise under the foundation of LNW, dB | 65. | 65. | 65. | 65. | 65. | 66. |

| Notes: * H.M. - Cold mastic; ** G.M.- Hot mastic |

Features of different floors

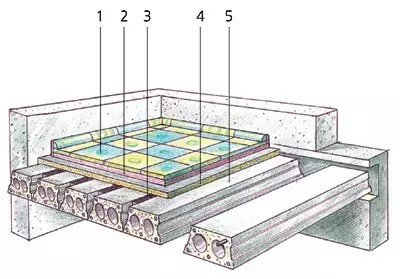

On lags

Pros:- The device of the draft floor on the lags is used if you need to store a piece parquet or board in the rooms. The base from bars and plywood responds to a change in temperature and humidity in the same way as a wooden coating, which reduces the stresses in the design, minimizes the risk of swelling, the separation of boards and planks;

- The design allows, without a significant increase in the load on the basis and with minimal consumption of materials, level the values of the level of up to 10 cm;

- Such a base can be arranged faster than the wet screed, and it is allowed to immediately lay the coating.

Minuses:

- The minimum base thickness is 50 mm, and in the apartment with ceilings 250-65 mm, the loss of the height of the premises will not justify itself;

- The design is afraid of water, and in the case of a flood, it is most likely to be disassembled, dried and changed part of the details;

- The lag base is considered less reliable than, for example, concrete, even though it is easier to repair.

Choose a chamber drying lugs: perfectly straight, without tracking traces and dimensional deviations. Defects on such bars are usually a bit, and yet the knots and cracks sometimes meet. If the installers will not pay attention to them and reject some products, the likelihood is greater that over time the floor will begin to creak. Sometimes the material turns out to be deficient and starts slightly barred during the installation process. It is impossible to exclude the possibility of warping and later - for example, after switching on heating.

Reliability also depends on the installation technology. For the alignment and attachment of the lag to the plates use nodes of different types.

Lining and dowels are suitable if the lags need to be lifted over a plate of a maximum of 40 mm. At the same time, the most practical lining is the textolite plates of different thickness or double plastic wedges: they are durable and with their help you can easily and quickly set lags on the same level. The trimming of waterproof plywood is suitable, but it is less convenient to work with them.

But wooden chips, cutting of fiberboard or drywall for lining will not fit - they can crack and move off, flatten under load.

Rules for the coating device on the lags:

- Before starting work, the gaps between the plates need to carefully close the fibro-cement putty. When it dries, the base surface is extremely desirable to be pinned with penetrating polymer primer to reduce the likelihood of wet air penetration from the lower room.

- Lags and elements used to align them must be securely fixed. However, the size and number of mounting holes are desirable to minimize.

- Lagging deflection under load 150 kgf on the site between supports should not exceed 2 mm. That is, with an increase in the step of the supports (in practice it is usually from 80 to 120 cm), it is necessary to increase and the section of the lag.

- Mounting and alignment nodes must be no less durable than the lags themselves.

- Overnight at the joints of the plywood sheets should be aligned with grinders.

Cork ribbons attached to lagas

Perform the function of elastic interlayers and the transfer of vibrations from plywood base to overlapping

Optimal material for a solid base of lags - waterproof plywood

Most Economical - OSP

Lags must be dry and antisept. Humidity is not more than 12%, otherwise they twist. They are not brought to the walls by 20-30 mm, the clearance is filled with mineral wool. On the slab the root should be based on the entire bottom surface. Therefore, they are put by a soft chipboard strips, which also serve as a soundproofer.

All heat and sound insulating dry backfills must be calculated to burn organic inclusions. Between the filling and wooden trim, there should be free space with a height of at least 20 mm to ventilate a tree. This space should not be connected to air cavities in the walls. In the corners of the rooms it is useful to do the outstands, closing them with a grid.

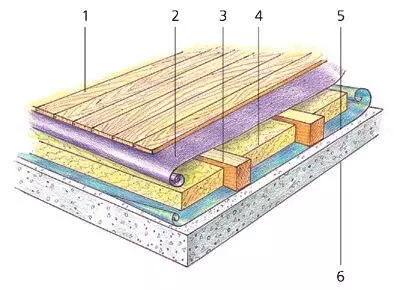

Paul by lags on the screed:  1 - "clean" sex fest board; 2 - vaporizolation; 3 - lag; 4 - heat and sound insulation; 5 - waterproofing; 6 - Concrete screed

Floors on screeds

It is unacceptable to align the concrete slab base or an old screed, pouring cement mortar. Two materials have a different shrinkage, so the gravy is peeling and cracking. Rovic follows with polymer cement mortar. But the fresh screed is aligned with cement mortar, but it is necessary to do it no later than 6 hours after creating a screed. If it is planned to obtain an almost perfectly smooth surface with a polymer concrete, applied on top of a screed, for the latter it is necessary to use a durable concrete of class 15 and higher, or cement-sandy solution M 250.Floors with heat and waterproofing

With thermal insulation, it usually does not occur problems, because in the glorified flavored apartments heat, and the soundproofing materials used are quite well kept temperature. Waterproofing is needed only in wet areas: in the kitchen, in the bathrooms, in the laundry room. Therefore, expanding the bathroom or kitchen, do not forget to arrange reinforced waterproofing. Errors are more common when using bitumenting materials. They are cheaper, but bitumen is inclined to destruction over time. Therefore, in places of high humidity, the inlet bitumen isolation should be applied in two layers. The waterproofing layer should be on the walls to a height of up to 300 mm. Before laying on the canvas of a concrete or cement-sand screed, you need to miss their hot mastic and press the coarse sand to ensure reliable contact of screed and waterproofing or use loose materials on latex base.

Building new walls and floor instead of destroyed during redevelopment or in homes, surrendered without finishing, do not forget about sound insulation and inlets. The coating must be done "floating". New partitions should be based only on overlap, adjacent to them, as well as to other lateral enclosing structures and ceiling, through elastic gaskets.

Qualitative arrangement of the foundation is due to the status of hundreds of parameters and technology nuances. Everything that is thought out in advance and recorded on paper will save you money, time and nervous energy.