The heating floor of the infrared film is a good way to heating the room. We tell how to properly put it under the laminate.

Features of the heating system

Competent laying of film warm floor under laminate assumes that it will be completed with all nuances of combining two designs. In its work, heating equipment uses IR waves. Inside the thin multi-layer panels, radiators emitting the waves of the infrared range are sealed. They move upwards where massive objects are delayed. In this case, flooring. It accumulates heat in itself, gradually giving it to air.

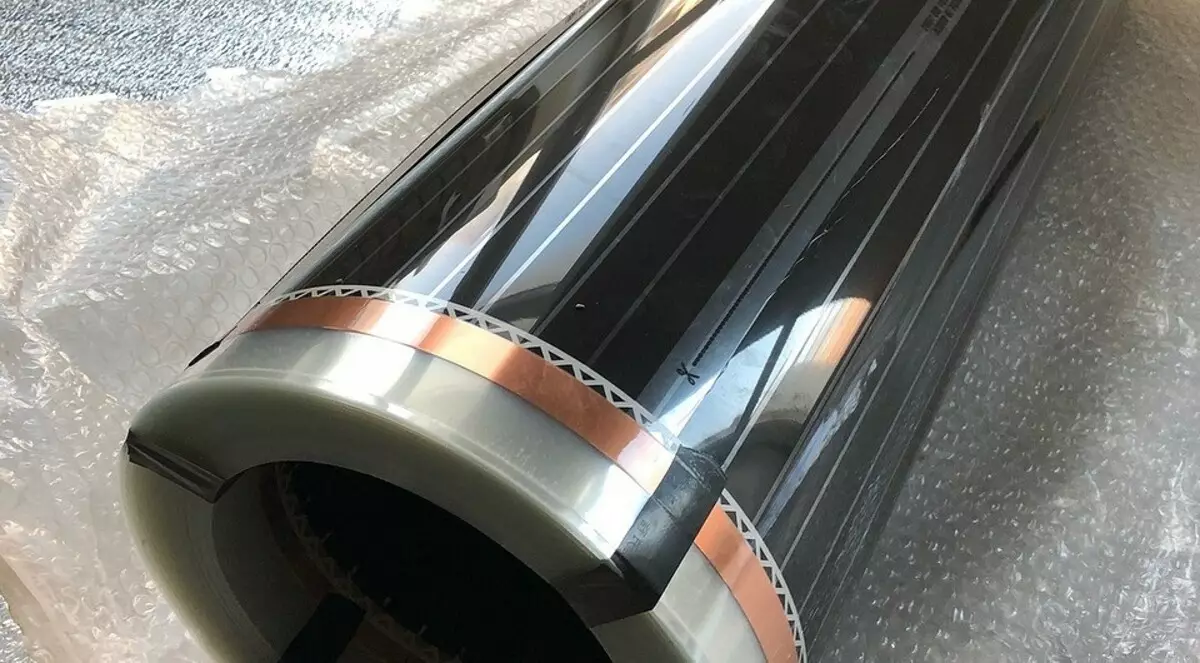

The radiation generates carboxyous emitters collected into several bands. In more powerful systems, the canvas solid. In any case, through its edge there are conductive tires from bimetal, which are responsible for the transmission of electricity to the heater. The power capacity varies from 120 to 230 W. Different sizes and thickness of the cloth.

The last indicator does not exceed 2 mm, which allows you to install the material without any problems under any coating. The width of the standard film can be 100, 80, 60 and 50 cm. For ease of use, linen is divided into segments, between which it can be cut. The average length of such a fragment is 20 cm. Thus, if necessary, you can mount the heating floor of any, even very complex shape.

Film floor under laminate: what to consider when choosing a coating

Standard lamellas can not be mounted on heaters. There are several reasons for this:

- Panels have low thermal conductivity, which will prevent the heating of the room.

- Under the influence of high temperatures, the geometry of the plates may vary, as a result, the surface can be swallowed.

- When heated, an artificial coating can be released toxic substances.

All this is quite serious reasons to abandon its use. However, there are special models of material intended for laying on the heater. For them, a special marking is designed, which is necessarily applied to the packaging. Another important point: the mandatory presence of locks on the lamella. They must be laid only on floating floor technology, that is, without communication with the basis. Laminate laminate is impossible.

Rules for the placement of heating canvas

Heating of this type can be both the main and optional. In the first case, it is necessary to put a film by 70% of the area, in the second it all depends on the number and capacity of the main sources of heat. However, in any embodiment, important recommendations should be taken into account.

- On the floor covering over the film is prohibited from placing heat insulating items. Such as large furniture without legs, dense carpets, etc. The system in such sites overheats and may fail.

- Heavy items, such as overall household appliances and furniture, should not stand above the IR cannon. Lamels under them may suffer, which will lead to excessive pressure on the heater. In such conditions, it breaks quickly.

- If combined heating is assumed, it is impossible to allow the laminate coating to get used from two heat sources at the same time.

- It should be borne in mind that the zone of the heating of the film material comes out for its physical boundaries. For this reason, it is not recommended to be placed close to walls, large furniture, etc. The indent must be about 3-10 cm. It depends on the power of the equipment.

It is optimally putting a warm cloth at a distance of 0.5-0.6 m from each wall. This will allow in the future to make a rearrangement of furniture, if necessary.

Infrared film warm floor under laminate: competent laying technology

The heating system is a peculiar puff pie, which is important to put correctly. Consider step by step how to do it.Step 1. We draw a base

It should be dry, smooth and solid. Laminate can only be laid on the aligned basis. Therefore, if the height differences exceed 2 mm on the trafficphone meter, you will have to carry out additional work. To align the concrete screed, optimally pour its leveled mixture and wait for complete drying. The wooden surface is easiest to align plywood.

Step 2. Put thermal insulation

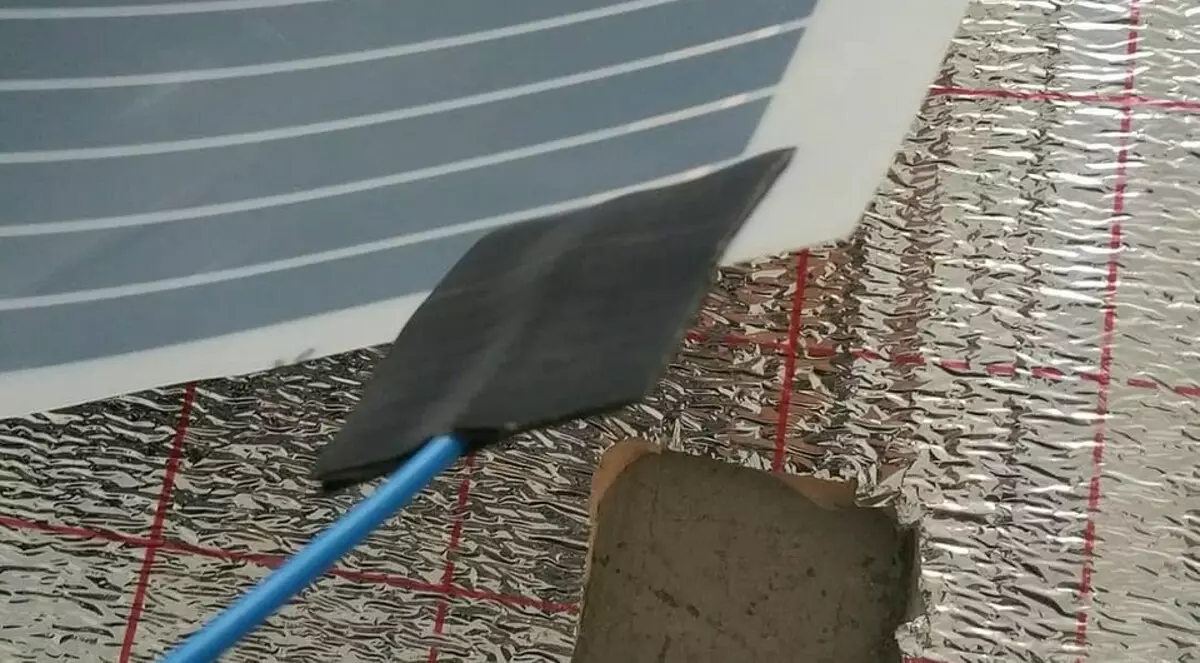

For the normal functioning of the system, it is necessary to equip the heat transfer layer. The standard aluminum foil is not suitable in such cases. This is explained by the fact that the heater is electrical, therefore, the substrate should not be conducted. Otherwise, accidents are possible. The insulator is chosen polyethylene or a tube with a reflective layer applied to it.

Before laying material, we carefully clean the base from garbage and dust. The use of a vacuum cleaner must. On the pure surface of the strip of the insulator. We close the entire area of the room, even if the IR film will not be laid everywhere. The panels are stacked one to another with a slight occasion on the walls. In order to avoid the excuses of the insulator, fix it with a tape or fix it straight to the basis of the stapler.

Step 3: Unlock Film

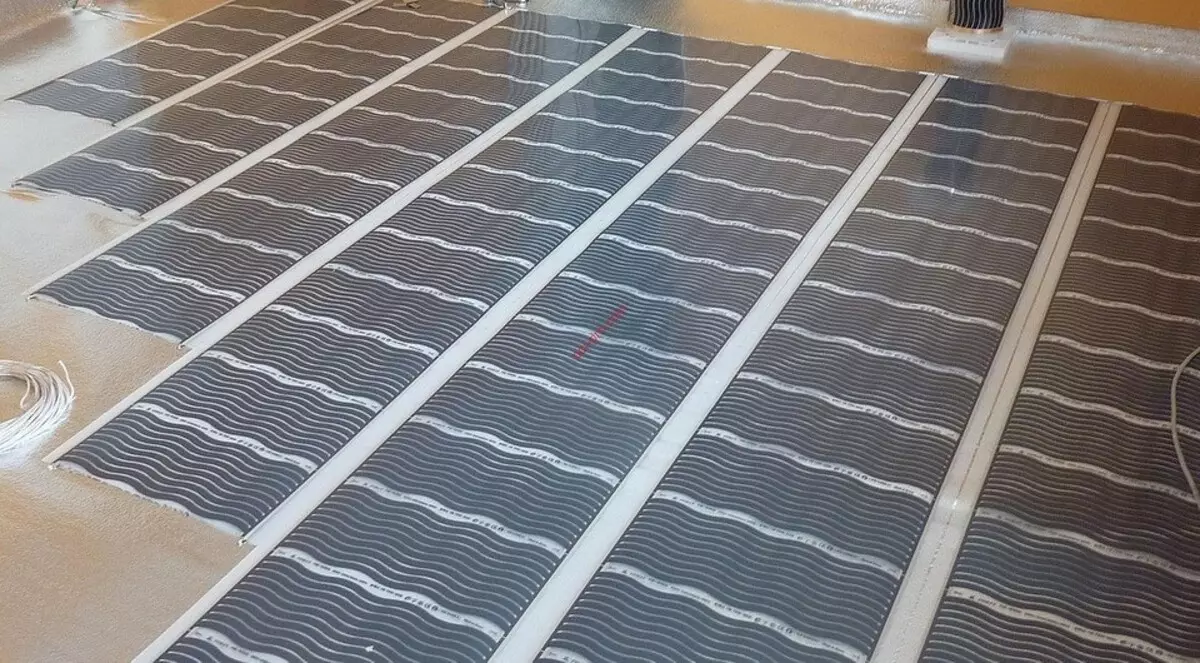

Rolling the stripes, orient them along the longest sides of the room. Thus, it will be possible to minimize the number of contact connections. If necessary, cut off the canvas, but only on special sites that are marked with labeling. In the process of laying, watches the integrity of the elements is not broken. The canvas should be kept so that the adhesive was turned out.

Copper tower tires when laying must lie down the shiny side. This is necessary for further contact connecting. The panels are necessarily fixed to the substrate using a tape.

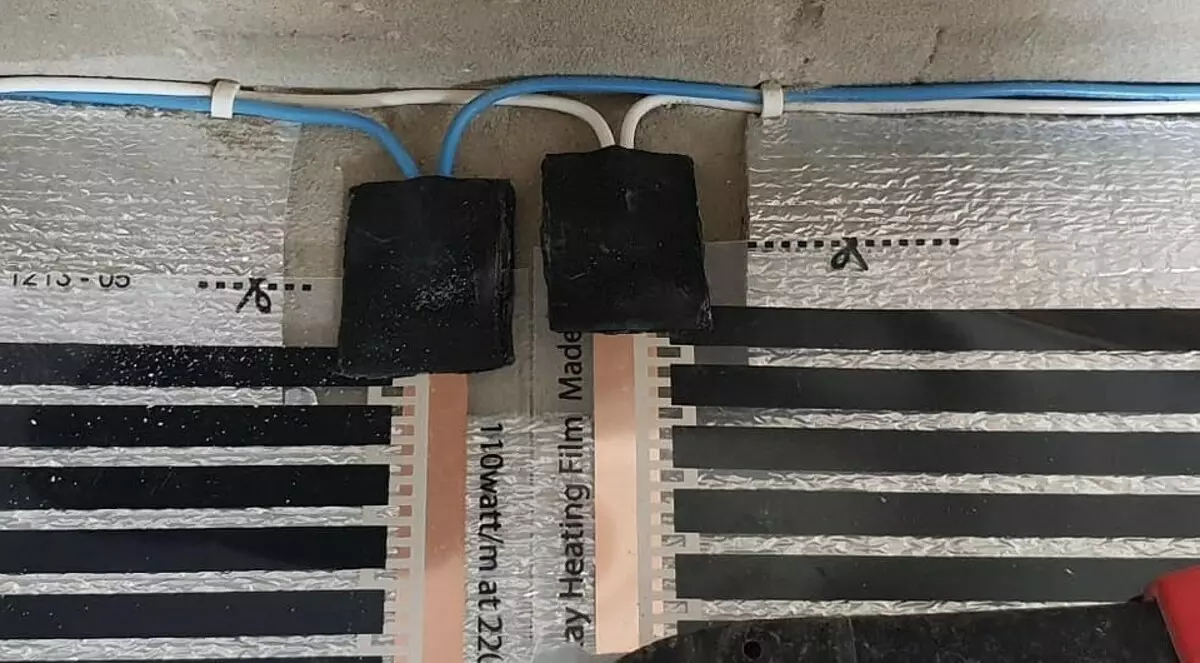

After all heaters are decomposed, we determine which tires will be connected to the cable. All dysfreviated plots are immediately isolated in switching. To do this, close them with a bitumen ribbon, which should be included in the equipment kit.

Step 4: put the thermal sensor

For the correct operation of the system, the element is placed in the coldest point of the room. Moreover, it must be in the middle of the strip width, so that the distance from its edges is the same. You can not put the sensor close to the wall. Between them should be at least 500 mm. Another important point. If the device's standard cable is not enough to put it in the selected place, you should pick up another. It is prohibited to increase the wire.

Cut in the substrate the groove under the sensor body and the channel for mounting its cable. We put the element in place so that it is located on the carbon heater. Fix the device with a bitumen ribbon, stretch the cable from it to the thermostat. Film decompress and fix to the substrate.

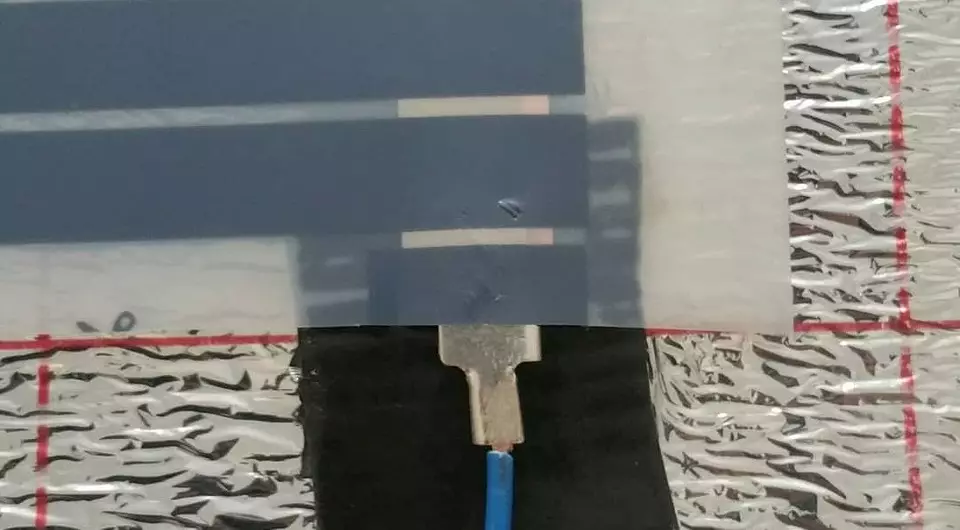

Step 5. Install terminals

In areas where the radiating equipment will be connected to the chain, you need to put special clips-terminals. Most often they have a clips. In this case, the upper petal of the element is inserted into the pin incision of the film, and the lower revealed under it. Then we take pliers and tightly, but gently crimp the terminal, providing her reliable contact with the copper tire. Sometimes there are other types of compounds, their assembly rules need to be viewed in the instructions for equipment.

Step 6. Connect the cable

We stretch the wire by placing it near the plots of connection. Usually cables are displayed on one side of the system: it is so convenient to connect them to the heaters. Although it is also possible to withdraw the zero and phase wire on the opposite sides of the room. In this case, you need to particularly carefully connect the connection so as not to select one conductive bus to switch both contacts.

The ends of the laid cables are cleaned with an insulation of approximately 1 cm and insert into the contact terminal. Crush the resulting compound pliers. We are securely insulated with a bitumen tape. We stick strips on top and bottom of contact, gently crimp. As a result, a waterproof capsule should be obtained, protecting the connection from possible to enter water.

Step 7. Connect the thermostat

Heating floor laying technology assumes that all cables must come together at one point. Where they are suitable for the thermostat. It can serve several sections of the system at once, in this case it is extremely important to correctly choose accessories to connect. It should be only certified terminal nodes, homemade twists are not allowed.

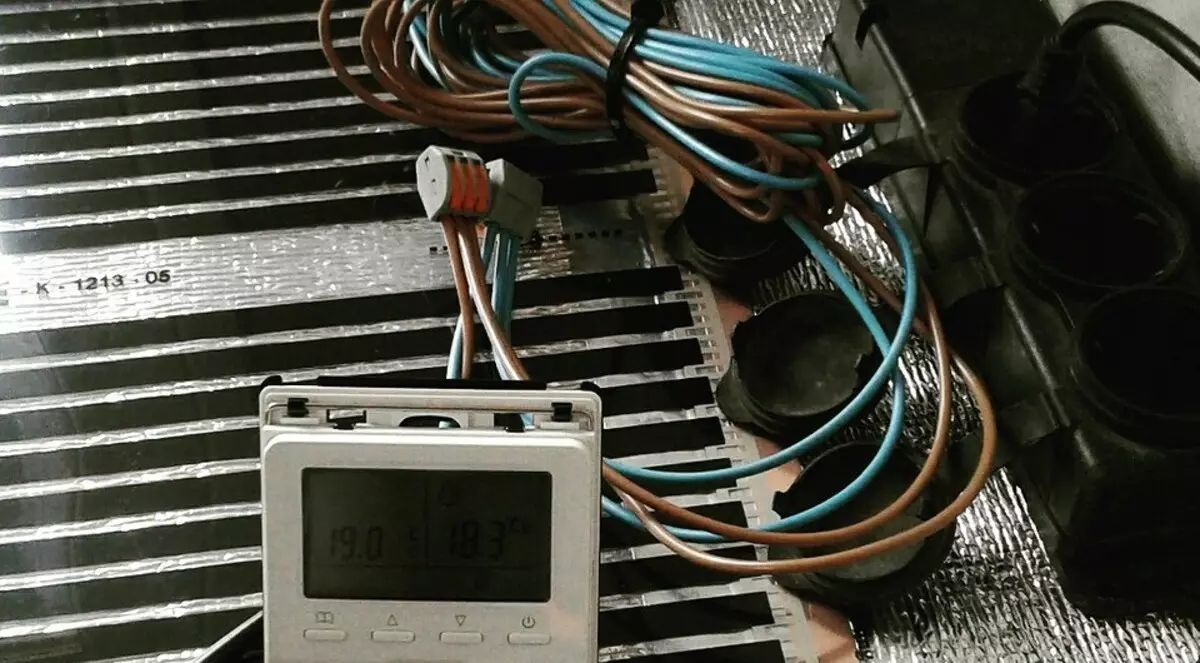

The thermostat control unit is equipped with special connectors to which the wires are attached. To prevent errors, the pictograms indicate the ground switching, load and supply voltage sections. After the connection, each cable is placed in a special channel and fix the thermostat into place.

Step 8. Trial system trial

We check the integrity and correctness of all compounds performed and carry out the launch of the heating floor. If everything is done correctly, it should work normally. When identifying any problems, it is necessary to correct all the shortcomings and re-run the equipment. For clarity, we offer video installation of film warm floor under the laminate.Step 9. We put the coating

Heaters do not tolerate the effect of water, so it is necessary to put on the web isolation. It will be enough that will be a plastic film in 200 microns, which will protect against moisture and will not delay IR radiation. Material cut on the bands of the desired length and lay out over the heating structure with a small adhesive. Be sure to give them to scotch.

Now you can start mounting the coating. How to lay the selected laminate model, you need to look at the package. The manufacturer necessarily gives recommendations to obtain a better result. When working, some caution should be observed in order to accidentally do not spoil the film heater.

Reviews of film warm floor under laminate are good. The coating, despite the fact that is a good heat insulator, with the correct selection of materials and competent installation actively accumulates IR radiation and quickly heats the room. And his attractive look and pleasant texture make the heating floor not only functional, but also beautiful.