Factory concrete Nedloysh, and the delivery of a car is not always possible, therefore, on our construction sites, a homemade concrete is often used on our construction sites and other structures. How to achieve high quality of this material and ready-made designs?

1 Use electrical tights

Mix well components well, of course, it is possible, but it takes a lot of time and effort. Breaks in concrete will increase, and with them - and the number of "cold" seams (or the sacrifice of the speed will be brought thoroughness of mixing, which means the strength of concrete). The cost of renting the electrical concrete mixer with a capacity of up to 1 kW is an average of 500 rubles per day.

The manual method of preparation of concrete is often used with the device of the scene and tracks. Photo: Izba de luxe

2 Watch the sand without clay

For the preparation of concrete, electric winds with gravitational mixing principle are used. Photo: PRORAB.

The clay impurity negatively affects the strength of concrete, so it is advisable to buy a career washed sand (rinse or sissing it yourself in large volumes too hard). Small dust sand for cooking concrete is better not to use.

3 Choose the rubble fraction correctly

Cement is packaged in multilayer bags, but such protection is not able to resist moisture for a long time, so when buying (especially a large batch) requires careful quality control of the material. Photo:

Ideally, the crushed stone of two fractions - shallow (5-20 mm) and medium (20-40 mm) should be used. This will achieve maximum concrete strength with minimal cement flow. The gravel gravel graveyard M800-M1200 is preferred. High strength of granite rubble with low-rise construction remains unclaimed, and pebbles have a relatively low adhesion with a concrete mixture, which negatively affects the strength of concrete.

Crushed stone is usually ordered by private traders - drivers of dump trucks. But far from each of them will bring the material of the desired fraction, so it is better to contact the company or to verified suppliers. Photo: Gorsnabstroy

4 Control the "Freshness" of Cement

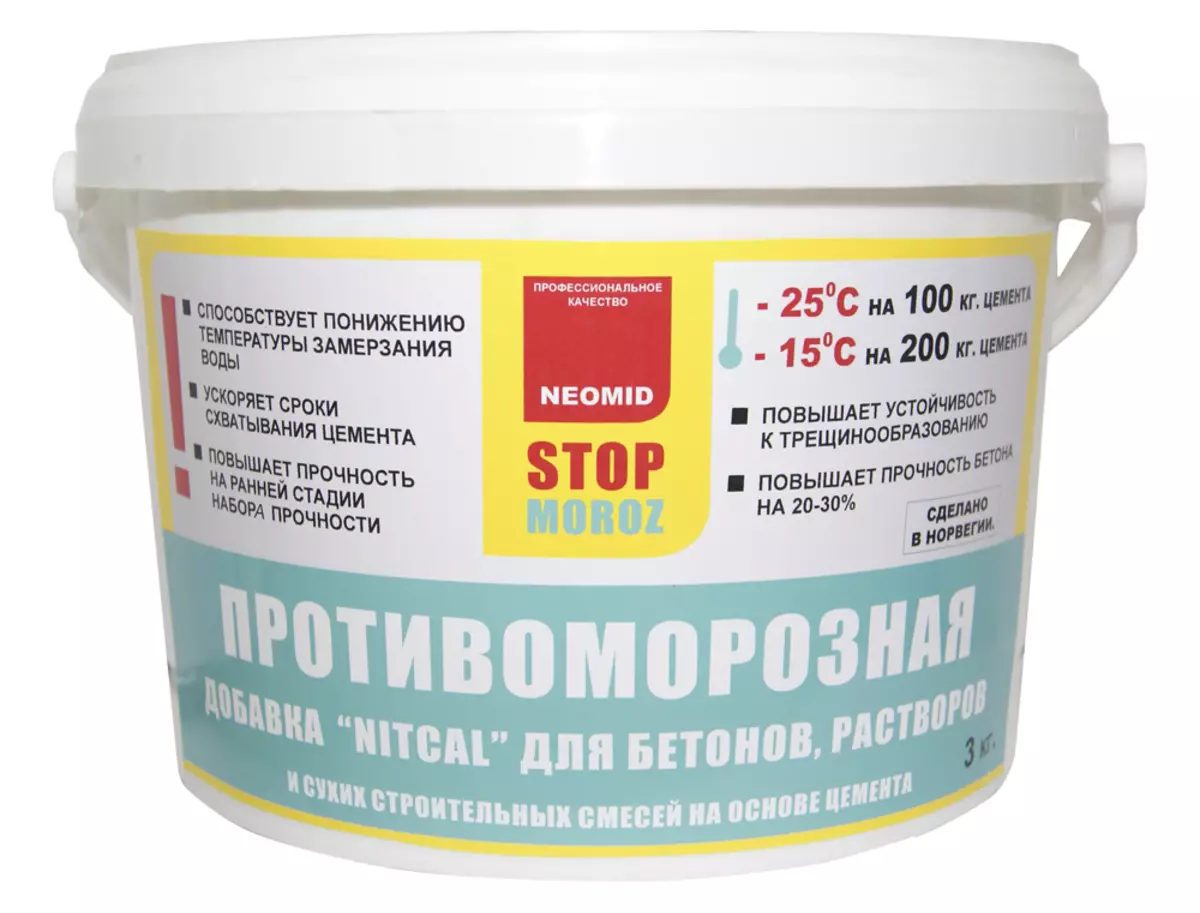

According to manufacturers, antiorrosal additives allow concrete work at temperatures to -25 ° C. And yet in individual construction it is desirable to avoid concreting in such extreme conditions. Photo: neomid.

Cement with anterorable shelf life or stored in conditions of high humidity (it is easy to determine the presence of lumps) cannot be purchased, even with a significant discount. The final characteristics of the concrete product in this case are completely unpredictable, as a rule - unsatisfactory.

5 Follow the proportions

Photo: Bitumast.

The "Classic Recipe" concrete brand 200 is a combination of cement 400 grade, sand, rubble and water in proportion of 1: 3: 5: 0.5. When using cement 300 sand grade add two parts, rubble - four, and the ratio of cement and water remains the same. It should be borne in mind that excess water, increasing the mobility of concrete, significantly reduces its total strength.

Photo: Izba de luxe

6 Do not neglect modifying additives

Hydrophobic supplements are indispensable in the construction of basement and basement floors. Photo: WDM.

In the threat of cooling, anti-massorous additives (hardening accelerators) should be administered into a mixture. Plasticizers will allow an increase in the fluidity of the solution (so that it is easier to ram) while maintaining the optimal water-cement ratio. Corrosion inhibitors will extend the life of reinforcement, hydropobizers will help achieve waterproof design (for example, basement wall).

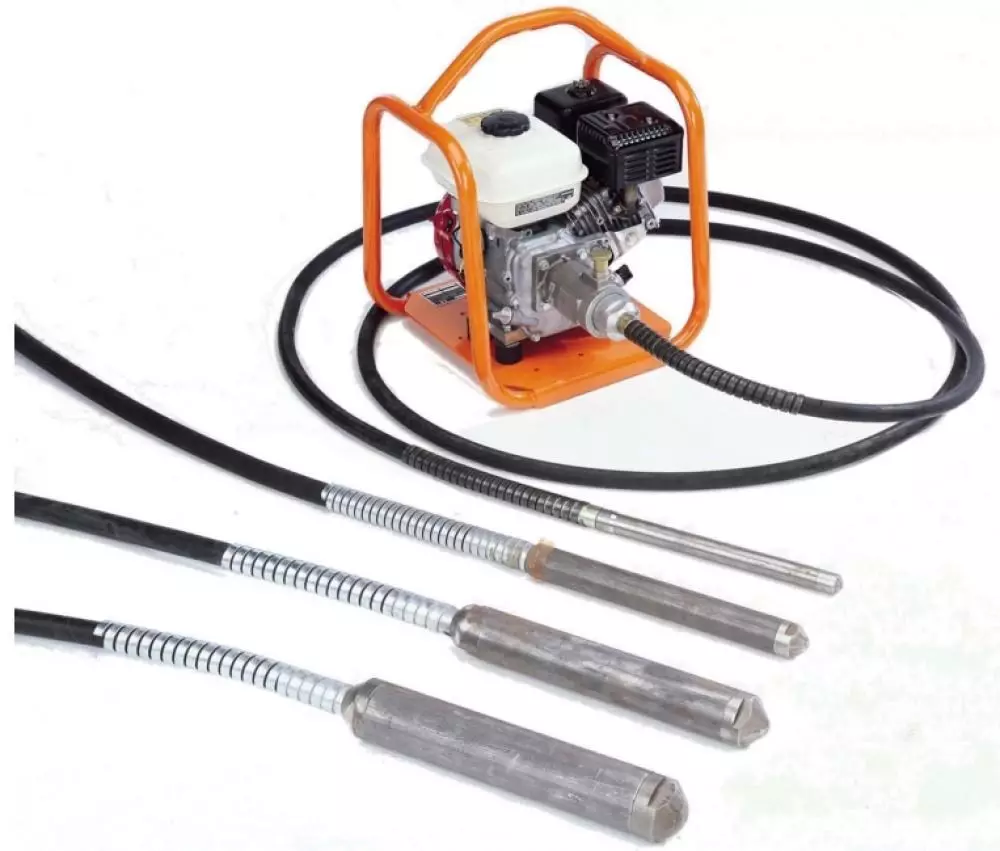

7 When laying a solution will also use the means of small mechanization - surface traammen and submersible vibration devices

Submersible depth vibrator allows high-strength drilling piles and tape foundations. Photo: Belle.

They are well compacted concrete and make it possible to bring homemade reinforced concrete products to be closer to the factory.