If you want to celebrate the country housewarming as soon as possible, and the funds for the construction of the house are not so much, it is worth using frame technology. It will reduce labor costs and consumption of expensive materials, as well as achieve the high heat insulating abilities of the walls

Photo: "Terem-pro"

Any construction, walls of which are a combination of strong bearing elements (racks and strapping) and lightweight materials with good thermal insulating properties can be attributed to the category of frame. There are also foam blocks with reinforced concrete columns, and half-timbered, and from ready-made SIP panels. However, it is most often so called Canadian type houses - with a wooden frame, whose cells are filled with insulation in the construction process, and then closed with sheet skin. About the walls of such a design and will be discussed in the article.

Photo: Legion-Media

Advantages of modern technology

Frame technology has many advantages. It allows you to do without powerful technique and a large number of workers: a brigade of two people, it is quite possible for the season to bring under the roof and prepare a house of 150-200 m2 for the decoration. An important advantage over the use of bricks and ceramzite-concrete blocks is a small weight of the walls: it is possible to save on the foundation by choosing, for example, a design from screw piles and steel randbalkas. If you compare the classic Canadian house with the collected from the factory panels, the first will cost significantly cheaper (1 m2 walls from SIP panels with a thickness of 200 mm, taking into account installation costs 2600-2900 rubles, and frame - 1800-2200 rubles). However, in practice, everything is not so unequivocal.

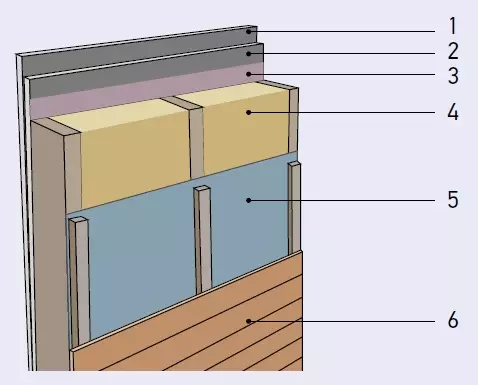

Frame wall design: 1, 2 - drywall sheets; 3 - vapor barrier film; 4 - mineral wool; 5 - windproof membrane; 6 - imitation of a bar or block mobile

It is well known that in the shield dacha houses, built 20-30 years ago, to overhaul even in May, and it is simply impossible to live in them in winter. In addition, in a short time, most of these structures strongly dilated and glanced. Of course, the case is not in the shortcomings of the frame structure as such, but in the extremely negligence of the then builders, unsatisfactory quality and ridiculous amount of materials used. Shields with a thickness of no more than 100 mm at best were filled with a rolled glass gamble, and in the worst - fragments of foam. The elements of the walls somehow were shot down by nails, not paying attention to the gap, because the finish will close them. Well, when the device, windproofs and vaporizolation fell entirely on short-lived parchment.

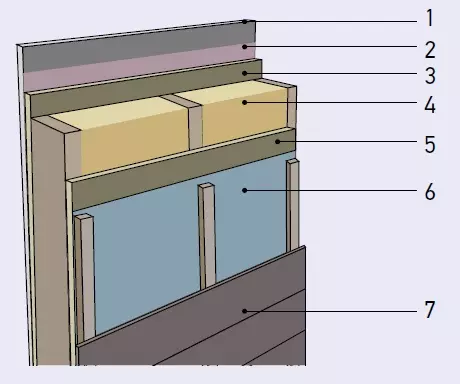

Frame wall design: 1 - plasterboard sheet; 2 - vaporizolation; 3, 5 - osp; 4 - mineral wool; 6 - windproof membrane; 7 - Vinyl siding

Since then, the level of construction culture in our country has noticeably increased, a detailed set of rules of the joint venture 31-105-2002, developed on the basis of Canadian experience, became available materials with improved properties. And yet ... in standards and instructions there are many contradictions and dark places that each designer interprets in its own way. In addition, the customers, seeking to save, make their own adjustments to the adopted technology - and contract firms without objections are incarnate incorrect solutions. Avoid mistakes will help understand the overall principle of "work" of the frame wall and the nuances of its construction. Or you can go Another way.

In the insulation of frame walls, first of all pay attention to the thermal insulation properties of the material and the convenience of installation. We recommend using the innovative material "Light Batts Scandik". One edge of the plates sprouts, so that their installation is simplified in the design, work is accelerated, and the amount of waste decreases - the stove with light pressing is inserted between the racks and fits tightly to them. With this installation, the qualification of the builder is not important, so work can be done on your own. As for the thickness of the heat insulating layer, it depends on the climatic conditions and structural material of the walls. Calculate this parameter for each specific case will help an online calculator developed by the Rockwool Design Center specialists and submitted on the company's website.

Natalia Pakhomov

Rockwool Design Engineer Design

Pile and tape (c) Foundations of deep downlies will serve at least 50 years, and the wooden overlap may require repair far earlier.

Pile foundation. Photo: Vladimir Grigoriev / Burda Media

Ribbon foundation. Photo: Vladimir Grigoriev / Burda Media

Wooden overlap. Photo: Vladimir Grigoriev / Burda Media

Stages of construction of a box of a frame house

Consider the main stages from the point of view of construction theory and practice.Assembly of the carcass

Classical technology provides the so-called platform frame with floor racks. It is assumed that first on the plate, tape or frame of the foundation is erected by the beam overlap of the first floor with draft floors. Next, on this site, the frames of the walls of the first floor are harvested in a horizontal position, which are then raised and fastened to the upper strapping. After comes the queue of the interhesive overlap, and then the rafter design of the attic. The cross section and step of the frame elements are chosen, based on the calculated load and the thickness of the insulation. Usually used boards 40 × 150 mm and 50 × 200 mm bars.

In practice, the order and principle of assembly can be different. Let's say if there is not enough working hands and there are no devices to raise vertically and fix the finished carcasses of the stretched walls, the design is made up of fragments of 2-4 m long temporary tightness ties.

There is no "crime" and to mount the frame in a vertical position, the rack behind the counter, on the lower strapping attached by anchors to the foundation. True, the accuracy of the assembly will decrease (deviations in the sizes of cells will be at least 10 mm), and time costs will increase.

A rough mistake should be considered the construction of a frame of natural moisture wood and without amplifying with horizontal jumpers ("Bridges"). Big troubles threaten the maximum permissible step of the racks (60 cm), as well as the wrong choice of fasteners, such as the use of non-scattered plates and screws.

Installation of windscreen

Prevent the wall blowing and the destruction of the insulation of air flows formed in the thickness of the design, helps rolled windproof materials. They are located on the outdoor side of the frame, pressing 25-40 × 40 mm with a cross section of a cross section of 25-40 × 40 mm, which subsequently fasten the leaf trim. The bands are assembled horizontally, starting at the bottom, with a turnover of at least 10 cm. With such a design, sufficiently reliable protection against wind and atmospheric moisture is ensured, as well as the ventilation of the insulation (thanks to the gap under the trim).

If the wall is collected from the panels already covered with PCP, windproofs are placed on top of the plates. In this case, it is necessary to envisage the venge of the facade. Materials with vapor permeability coefficient less than 0.05 mg / (m ● ● ● PA) should not be used for windscreens. Such films interfere with water vapors leave the enclosing structure, and the insulation reuses.

For external framework of the frame, moisture-resistant oriented chips, which are much cheaper than plywood. Photo: Legion-Media

As a rule, the walls or their fragments are collected in a horizontal position on the overlap platform, and then raise vertically. This method is much simplified by the installation of the frame. Photo: Green Building

Sometimes in order to save items, customers refuse to leave the leaf outdoor, limited to the trim. This solution is permissible, however, the frame will be required to strengthen the pink. Photo: Vladimir Grigoriev / Burda Media

The frame assembly will be easily used to use modern fasteners - special ties and plates. Significantly accelerates the operation of the power tool, for example, a novelty pistol. Photo: "Canadian Izba"

To protect the fibrous insulation from moisture, it is tightened with a windband membrane outside, and from the inside - a vapor barrier film. Photo: Dörken.

Fibro cement facade panels are much longer than wooden lining and even vinyl siding. Such a finish of the non-combustible, is able to imitate the tree, brick and stone, but its installation is quite laborious. Photo: ENTERIT.

Often the project provides for the same design of outdoor and inner walls, although it is better to use OSP for partitions, but drywall. Photo: Vladimir Grigoriev / Burda Media

PVC siding allows you to have a neat appearance without high costs. The average service life of the material is 25-35 years. Photo: Mitten.

Tailing house outside

Instead of an OSP, it is possible to use windproof panels made of Paraffin impregnation and polymer coating (in this case, the diffusion membrane is not needed) or cement-based plates, which will increase the strength and fire resistance of the fence. Insulation. According to traditional technology, the skeleton cells are filled with soft plates from natural or synthetic fibers. Today, out competition insulation from mineral wool. It is important that with time the material does not give a shrinkage in time, so when choosing it is worth asking whether the manufacturer conducted the appropriate tests. And pay attention to the parry permeability ratio - it must be at least 0.3 mg (m ● h ● PA).

In the middle lane of Russia, the required thickness of mineral wool slabs is 200 mm, and the "skeleton" of the houses are often collected from the 40 × 150 mm boards, since the bars of 50 × 200 mm are supplied only to order and in terms of cubic meters cost more than standard lumber. In this case, they are resorted to two-layer insulation, that is, they are mounted on the outdoor side of the frame (of course, after the value of a value of at least 25 mm) an additional layer of extruded expanded polystyrene foam.

The thermal conductivity of polystyrene foam is lower than mineral wool, and some customers insist on the use of this material as the main insulation. The result always turns out to be negative: foam sheets are extremely difficult to cut so that the fragments obtained firmly stood between the frame elements. The design will remain emptiness that will become cold conductors.

As for the eco-friendly, taking into account the mechanized application services (only a humid-adhesive method approaches) it will cost 20-25% more expensive than mineral wool slabs and limits the work of the work on warmth time of the year.

For the outer decoration of the frame house, you can use a wide range of modern facade materials, but it is worth choosing a particular option, taking into account the specifics of the installation of finishing and features of the wall design. For example, siding is advisable to fix the leveling inches, and not directly to OSP plants, so as not to damage the membranes that protect the insulation from moisture and ensure the irrepressibility of the wall. Silent, for example, fibro-cement, decorative panels can not be mounted on a wooden doom - it is necessary to apply special metal profiles and the fastener provided by the manufacturer. For the plaster facade, silicate and acrylic compositions should be used, which are applied to PCP or EPPS with a polymer grid reinforced on them.

Timofey Tenne

Head of the Design and Technological Department of the company "Terem-Pro"

Installation of vaporizolation

The best insulating films are made of two layers of polyethylene or polypropylene and reinforced with synthetic fiber; They are durable and elastic, so they are difficult to damage when installed. The stripes of the film are perpendicular to the frame racks, starting from the upper portion of the walls and providing an inlet strips of about 10 cm. The joints are necessarily sampled by mastic, and the places pierced with the brackets are delayed by self-adhesive tape.

Osserving from the inside

Internal objects It is advisable to perform two layers of moisture-resistant drywall, handling the gap and vapor insulation the clearance of at least 30 mm, which is necessary for laying cables and mounting sockets and switches.

Main Enemy Frame Wall

It is hardly the main enemy is moisture, and not atmospheric, but contained in indoor air. In winter, a diffusion flow directed towards the street can be formed in winter inside the fence. At the same time, the pair of the room penetrate into the insulation, as the wall approaches the outer surface is cooled and turn into water. As a result, the insulation reuses, its thermal conductivity increases, which means that heating costs increase. The moisture inside the walls threatens and more serious troubles - the deterioration of the microclimate in the house, the destruction of the frame and the trim. Failing with condensate helps vapor barrier, the main requirement to which is the integrity and continuity of the layer. But even a competently completed parobararier does not give warranty from the wetting of the insulation: during rains with wind, water is capable of "filming" under the outer windproof. Therefore, you need to give the material the opportunity to dry, handling the ventilation gap under the outer skin or wall trim.Typical errors in the construction of frame walls

- Assembling frame of natural moisture wood and using fasteners unstable to corrosion.

- Wrong selection of section and steps of frame elements, an insufficient number of connections between them.

- Use as the main insulation of polystyrene foam plates. They cannot be accurately adjusted for the size of the skeleton cells, which is why cold bridges are formed.

- Refusal to the outer ventilation gap. As a result, the insulation does not dry, the wall loses insulating properties and is destroyed faster.

- Laying communications in the thickness of the outer walls. As a result, the integrity of the parobac was violated and the likelihood of wall reservation increases.

3 Features of a skeleton house microclimate

The ability to quickly warm up

The likelihood of sudden room air temperature jumps

Alas, the medals have a reverse side: to maintain a comfortable temperature in the rooms very difficult. Since the walls do not have a heat-accumulating ability (thermal inertia), it is necessary to closely monitor heating equipment and weather or to acquire expensive automated techniques.

The complexity of the air exchange organization

In a frame house, it is difficult to fight with an increase in air humidity and content of carbon dioxide. The fact is that when carrying out through the open windows, the room is getting out the same quickly, and so far the street air is heated with a radiator (for which it takes from 15 to 45 minutes), in the Zyabko room and uncomfortable. Ventilation problem solved in different ways. The best choice is the installation of a modern channel system with heat recovery. If this option is impossible, air heating, water warm floor, as well as window supply valves will help to increase the comfort of dwelling.