About a lucky person no wonder he was born in a shirt. If you wear a house in the "shirt", creating a beautiful ventilated facade, it will also be possible for a long time and successfully exploited. What materials should be used for this purpose?

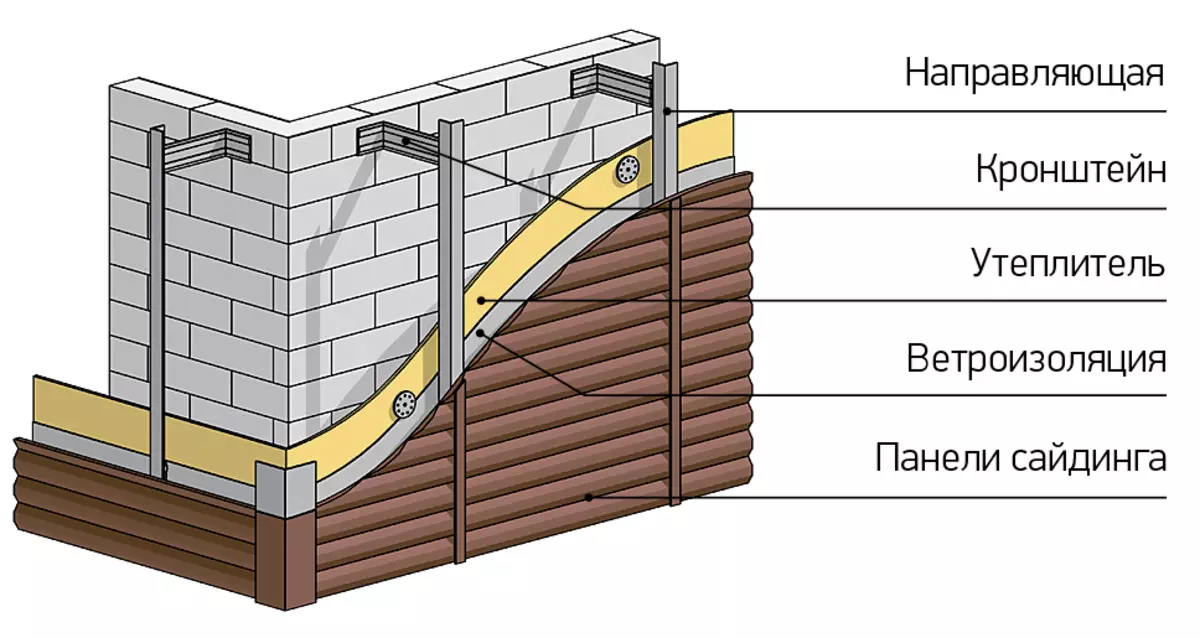

Thanks to the ventilated facade, the developer gets the opportunity to realize almost any architectural intent, giving the building a unique appearance regardless of what kind of design is the walls of the house. The main advantage of the ventilated facade consists in free air circulation in the gap between the wall of the building covered with insulation, and the facing material, which makes it easy to dry the thermal insulation, prevent the development of microorganisms, to ensure a long service life of the structure. For cottages, it is usually enough to be a gap in 40-60 mm - it is provided for installation of a wooden root or metal subsystems from brackets and guide profiles.

Vinyl siding

Plastic siding is made of polyvinyl chloride (PVC), although it is usually called vinyl. The material is produced in the form of separate panels and necessary for the installation of so-called challenges. The market presents siding as domestic firms: "Alta-Profile", "Tern Polymer" (Brand Fineber), Dolomit, TZK Technostka (T-Siding brand), etc., and foreign: Mitten (Canada ), PLY GEM (USA, Brands Variform, Georgia Pacific, Napco, Cellwood, Kroy), Docke (Germany, produced in Russia), LRS (Germany, Brand Holzplast), etc. Thanks to the large selection of colors, forms and textures, as well as This material is probably the most widespread protective coating for insulated walls or frame structures today is a price diversity. All plastic panels can be divided into wall, basement and auxiliary.Vinyl siding. Wall panels

When installing, n-profiles, internal and external angles are used, as well as chamfer, fox, platbands and slopes that attach a harmonious appearance

Thanks to a small mass, vinyl siding can be mounted on a wooden doom, but galvanized steel subsystem is considered more reliable

To interfacitate panels on different planes of the facade, do not use challenges

Wall panels imitating one, two or three boards of clay-American women, are offered in a wide range of colors and textures.

Wall panels. Their surface imitates one, two or three boards, traditionally mounted flashes on each other in the distance from the bottom up. The zigzag arrangement went to the benefit of plastic siding - the bends significantly strengthen the thin (1-2 mm) material. Such siding is produced by extrusion technology - the mixture in liquid state is pulled through a number of devices in which the required form acquires and hardens.

Air gap

The distance between the inner surface of the facing and the heat-insulating layer should be sufficient for complete removal (due to the ventilation) of water vapors entering the diffusion through the enclosure design from the room through the heating period, as well as moisture that penetrates outside through the screen gaps. The size of the gap is calculated depending on the climatic conditions, height and architecture (curvature of the surface, the number of windows, etc.) of the building, as well as on the design of the subsystem for installation (number of brackets, rails, etc.). Why do I need calculation? The width of the air gap largely determines not only the degree of thermal resistance of the enclosing structure as a whole, but also its life. Upon underestimation of this parameter, the rate of flow of ventilated air will decrease, which will contribute to an increase in the temperature of the air layer and the level of its thermal resistance. In the house, of course, it will become warmer, but at the same time the ability of the system to self-sewing will decrease, and moisture will begin to accumulate in the insulation. And then the troubles are not avoiding.For the convenience of mounting at the bottom of each panel, a hook bent is provided, and in the upper - "groove" under the "hook". In the edge of the panel over the "groove" there are perforations for fasteners, elongated along the long side. Installation, in theory, very simple - the lower "hook" of the installed panel is inserted into the upper "groove" of the already mounted (or a special starting profile), and then its upper part is fixed to the nesting nails with a wide hat or screws. Located in the same row of the panels are fitted with each other or through a special profile. Next, the following row is mounted, and all operations are repeated. As a result, a solid moisture refractory coating is formed. The PVC panels are sufficiently long (up to 4 m), so the cover of the house takes at a minimum of time, and due to the low width (10-30 cm) and the mass of the products, the installation is performed manually. The price of domestic products - from 180 rubles. For 1 m², imported - from 450 rubles. For 1 m².

Vinyl siding. Central

High rates of strength and wear resistance determine the popularity and demand of the base siding. Moreover, this material is used not only for direct purpose, but also for the facing of the entire facade, as well as small architectural forms (arbors, fences, etc.)

When finishing the base, siding is better to use a more durable steel subsystem

The surface pattern determines the configuration of locks by which the base panels are connected to each other in length.

Single and double-flop panels, imitating the texture of a wooden dranco, look great in combination with wall siding.

Congue siding. The material is much stronger wall panels, since its thickness is increased to 3 mm and more. It is this parameter that is especially important for the base part of the house, which is more often exposed to mechanical effects (shocks, blows, etc.). The panels are made by injection molding (injection molding), and their surface most often imitates facing brick and natural stone. The size of the base siding is approximately 1 × 0.5 m (two panels close about 1 m² wall). Preparatory work Before the shearing house, the base panels are practically no different from similar events before using wall siding. The installation of products is also similar, but to seal the joints of the panels, it is necessary to be treated with a special cloud composition.

If necessary, the ventilated facade is easy to repair: damaged individual cladding elements are easily removed and replaced by new

The choice of good items is somewhat less than the wall siding: external and internal angles, facing planks, J-profile and starting plank. At the same time, the internal angles of the two types are offered: the whole and collapsible (consist of two parts), and some manufacturers are advised at installation instead of the listed elements use two J-strips. But in this market segment more manufacturers, since all the above-mentioned companies are added to companies specializing in the production of baseline siding: Novik (Canada, Brand Holzplast Wandstein), Nailite (USA), Aelit (Russia), etc. The cost of the base panels is much higher. than walls: domestic - from 400 rubles. For 1 m², imported - from 900 rubles. For 1 m².Monoecastrusion and coextrusion

The wall siding can be made as from one species of the compound (the composition of vinyl powder and technological additives that ensure the required properties) - this process is called mono-extrudes and from two species - coextrusion. In the latter case, the panel consists of two inseparable layers: the lower occupies 80% of the thickness and determines the stability of the size and strength, the upper - 20% and ensures resistance to climatic influences and aesthetics. The main advantage of coextrusion panels is more cheap. However, if a compound is chosen for the lower layer using waste (grey-back-siding) or a composition in which there is less pigment

and additives, the operational properties of the panels deteriorate.

Auxiliary panels. These are primarily among the sofa panels used to cover the frontones, eaves, visors, etc. First, they were acquired as components to vinyl siding, but then they began to be used when the roofing device of all types, regardless of the material of the walls and finishing of the facade. According to the composition, the material of sofites does not differ from the usual vinyl siding, but has greater flexibility. The panels have a standard length - 3 m, and the width varies from 250 cm (two-band) to 350 cm (three-band). The cost of domestic soffits - from 220 rubles. For 1 m², imported - from 400 rubles. For 1 m².

Vinyl siding. Sofita

Perforated panels provide air intake in the ventilation clearance

Sophisticated panels can be solid, and also partially or completely perforated

Metal:

For a long time, metal siding was offered only in the form of single or doubles of several colors, which did not contribute to its widespread use in private construction (used mainly for finishing stalls and small stores). The picture has changed dramatically with the advent of steel galvanized sheets with a polymer colored coating Printech produced by the South Korean plant Dongbu Steel, as well as the Japanese metal siding company IG Kogyo, qualitatively reproducing both natural and artificial materials. Not so long ago, the domestic producers - "metal profile", "Nord House", Grand Line, "Promintech", and other, released panels that mimic wooden building materials are involved in the competitive struggle. Moreover, Russian companies have an advantage over foreign - their products are manufactured under the order and corresponds to the length of the facade, which simplifies the installation and reduces the amount of waste.

Figure: Igor Smirhagin / Burda Media

It is recommended to apply the facade subsystem by which the carrying frame is assembled from brackets and vertical M-shaped profiles

Metal siding manufactured by Russian companies is panels made by cold rolled metal metal with a polymer multilayer protective-decorative coating (the most frequently mentioned Printech is used). Mimiting tree Figure is applied to the surface of the metal using photofaxet technology. Panels are not deformed when the air temperature changes, have a low linear extension coefficient, which allows you to mount and operate the facades at temperatures from -50 to +60 ° C. Material non-combustible, resistant to ultraviolet, atmospheric precipitation and various pollution. The specific mass is from 4.5 kg per 1 m². The estimated service life is at least 20 years. It is possible to divide them on wall, basement and auxiliary.

So that the facade lived long

The reliability of the ventilated facade is due to the quality of not only the panels used and subsystems, but also the installation. That is why when buying a material for a device such a facade, it is necessary to find out if the company-seller has its own assembly brigade or the installation service is offered. Official sellers will not only provide both, but also perform a project (or even a design project) with layout panels and the calculation of the required number of elements of a metal or wooden subsystem, which, as a rule, can be purchased from the same company. Such an approach will save not only from making erroneous decisions, but also from unnecessary costs, which is especially important when buying such expensive materials, such as imported base siding or Japanese panels of the FDP.

Wall panels, in turn, are divided into four types: Blockhaus, Eurobrus, Eurovantia and Shipboard. Panels blockhaus repeat the outlines and log texture (Width Working / Full - 188/211 mm, price - from 615 rubles per 1 m²). Eurobrus panels, imitating profiled timber, are produced not only with a tree pattern, but also in standard color execution according to the RAL catalog (width - 176/198 mm, the price is from 635 rubles. For 1 m²). Euro-making panels reproduce natural lining. They can also be used as basement elements (with vertical installation), to cover the sinks and device of suspended rush ceilings (width - 182/210 mm, the price is from 635 rubles per 1 m²). Type panels Shipboard are similar to vinyl siding configuration.

Photo: Vadim Kovalev / Burda Media

Varieties of Nord House metal siding panels: Blockhaus (a), Eurobrus (b), Eurovantia (B), base siding (g), Sofite panels (e)

Congue siding. In principle, it represents the same Eurovantia panels. The difference is that the metal thickness is 0.45-0.5 m, the drawing imitates the masonry from the wild stone, and the elements are mounted only vertically.

Auxiliary siding is mostly sophisticated panels, for the manufacture of which steel with alumochin coating is used. They can be like without perforation and with longitudinal perforation - sparkling holes.

Note that the listed varieties of metal rings can be made as in the form of single-row panels (that is, each of them mimics one element: a log, a timber, a board of cladding) and in the form of double-flop panels. According to some specialists, one-row execution has some advantages. So, the single-row panel is attached from top, and below. The two-time is fixed in the same way, but it is twice as wide, so the plating from the single-row panels will be about 2 times with a rigorous. In addition, such a covering more reliably reproduces a natural log or bar, since all longitudinal joints are homogeneous. In a two-round panel, the lock between the components of its elements is only simulated that, as a rule, visually noticeably.

Metality. Doborny elements

The facade lined with a metal blockhaus is similar to collected from rounded logs. But, unlike the log, there are no cracks on the surface, it does not need to be tying or regularly handled with antiseptics

The composition of the Nord House metallic siding company includes: H-profile (plank for docking panels in length) (a), an angle of internal (two types) (b), an angle of outer (B), slopes for window finishing and doorways (d), as well as j-profile (universal element), start-up plank and waterproof - window and base

Dobly elements. The manufacturer strongly recommends the use of the above-mentioned types of wall siding during installation, corresponding to the geometry of each material (their composition is listed in one of the dying signatures). Product price ranges from 68 to 165 rubles. For 1 p. m.

Figure: Igor Smirhagin / Burda Media

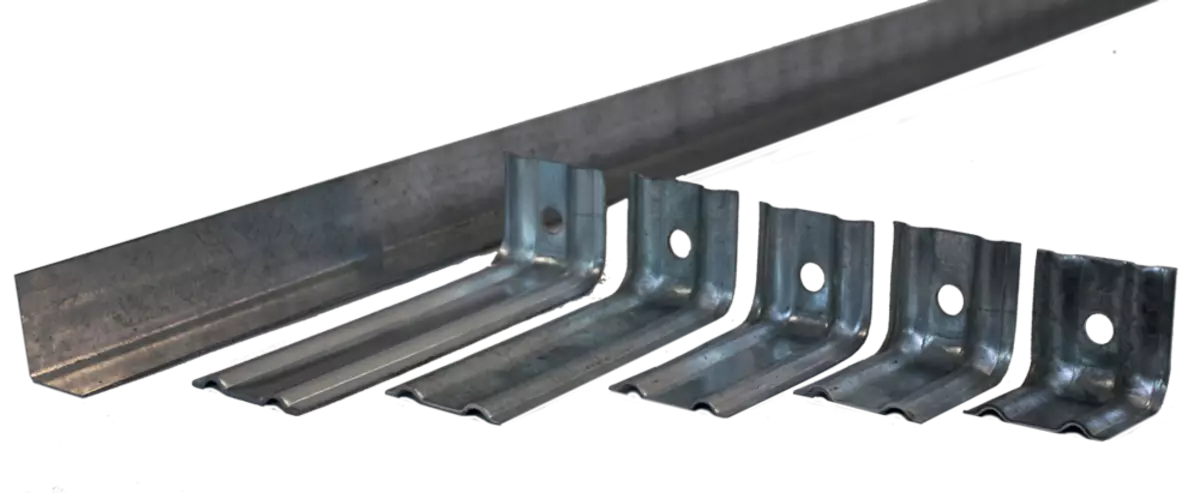

All elements used to mount subsystem have a zinc coating weighing 175 g / m². Bracket thickness - 2 mm, guides - 1.2 mm. Maximum load - 65 kg / m²

Cement-chipboard (CSP)

This environmentally friendly material is made by pressing a mixture consisting of wood chips of coniferous rocks, portland cement (binder), mineral additives and water. In the process of production, a chip-cement carpet is formed from four layers: exterior - from chips of small fractions, internal - from larger. The dialed carpet is pressed.Cement marking plates. Ways finish

When finishing the ventilated facade of CPSP-slabs, you can combine with wooden elements

Can be covered with elastic plaster

You can cover the slit with wooden slats, imitating the half-timber

Can be fed by decorative stone

The resulting plates (density 1250-1400 kg / m³) have a smooth and solid surface. Currently, they are widely used in a frame house-building ("dry installation" technology) - products are attached to a wooden frame with self-tapping screws, give it extra hardness and simultaneously protect against atmospheric influences. The material has a sufficiently high strength (bending strength - not less than 9-12 MPa), weallory (class G1), resist the effects of fungi, tree beetles, rodents, etc. and biostostility is achieved due to the fact that in the curing process Cement is formed by calcium hydroxide - it creates a strong masculous medium that impedes the development of fungi. Another advantage of the material is high frost resistance - the regulatory value of the reduction in bending after 50 cycles does not exceed 10%. In addition, the plates are easily saw and drilled.

Today, the market presents a CSP with a thickness of 8-36 mm exclusively domestic production. Products 8, 10 and 12 mm thick can be used as the elements of the hinged facade. Price - 180-240 rubles. For 1 m².

Holes for self-cutting in CPSP plates should be drilled in advance. Although the installation of CSP and is complicated, but the facade will be strong enough

Therefore, in an economical version of the external finish of the house, the desired color can be given with the help of facade paint.

CSP-slabs must be mounted on a doom made of bars with a minimum cross section of 50 × 50 mm. CPSP-slabs need to be attached to the bruus only with self-draws having a zinc coating.

Holes for self-cutting in CPSP plates should be drilled in advance. Although the installation of CSP and is complicated, but the facade will be strong enough

Significant weight makes it difficult to mount a 3.2 × 1.2 mm panels. It is much easier to work with "Tamak Hobby" plates 1250 × 470 × 10 mm (8 kg)

Fibro cement panels (FDP)

The material consists of a mixture of cement and reinforcing fibers (cellulose fiber), which introduced special polymer additives and plasticizers. Panels are manufactured by autoclave pressing method, so that they acquire such properties as fire resistance, the impairment of corrosion, rotting, the appearance of fungus, resistance to direct exposure to sunlight and aggressive media. The only minus can be considered the weight - the front panels from fibrocement are heavier than other materials. Today, FDPs offer such foreign companies as Nichiha, Kmew, Konoshima, Asahi (all - Japan), Eternit (Belgium), etc. From domestic producers, Lato's domestic manufacturers (Latonite brand), "TD LTM" (brand CEMBOARD ), "FIBRIT-M" (brand "FIBRIT"), Brevitor Construction (Brand "Facade Master"), "Construction Industrial Company" Surozh "(Brand" Rospan "). We will consider in detail the Japanese front panels manufactured by KMEW (part of the Panasonic group).

Photo: Kmew.

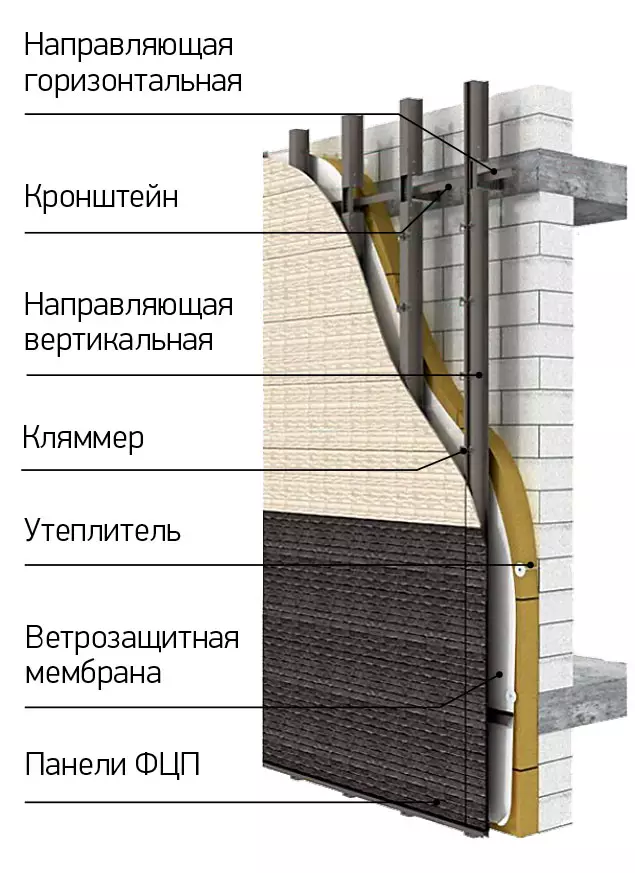

The FCP panels 16 and 18 mm thick should be mounted on the metal subsystem, and the panels of 14 mm thick can be installed on a wooden doom. Relatively low cost of elements and ease of installation of the wooden subsystem provide an economic advantage of more subtle panels.

These products are easier than normal (if the standard fibrotent panel has a specific mass of 20 kg / m², then KMEW - 14-16 kg / m²), withstand strong frosts, besides excellent design and extensive color gamut (presented more than 500 colors and textures: under Natural stone, wood, brick and stone laying, etc.) allow you to implement solutions in any architectural style.

There are several types of outer protective coating: acrylic silicone, hydrophilticone, photoframic and hydrophilic ceramics.

Acrylic silicone coating prevents the destruction of panels under the influence of ultraviolet rays, due to which the products retain the color over the entire 20 years. For ordinary acrylic paint, this period is only 5-7 years. The hydrophiltic acid coating has the ability to self-cleaning - during the rain, dirt and dust are easily washed away, and the color and texture of the surface remain unchanged for a long time.

The photofuric coating not only contributes to the self-cleaning of the facade and color preservation for 30 years, but also purifies the environment - the photocatalysts included in its composition helps to split even nitric and sulfuric acids formed from exhaust gases. You can apply the panels not only on the facades, but also in the interior of the house.

The hydrophilic ceramic coating is self-cleaning during the rain, and also retains the surface of the panels at an initiated form for almost 40 years (which confirm the operating experience and a series of experiments).

In addition to panels (3030 × 455 mm), the price of which, depending on the thickness (14, 16, 18 mm) and finishes range from 1500 to 3600 rubles. For 1 m², the company offers elements for finishing external angles (length - 455 mm, price - from 750 to 1100 rubles. per 1 pc.), as well as all accessories for mounting.

Photo: Kmew.

Both with wooden and under the metal panel subsystem are fixed to the vertical guide of special clamps, which are almost invisible outside. In addition, they allow you to compensate for the changes in the size of the panels under the influence of temperature