The surfaces of the walls adjacent to the window are striking and therefore should look at least neatly. Meanwhile, they are often yellow and covered by cracks. How to avoid similar troubles?

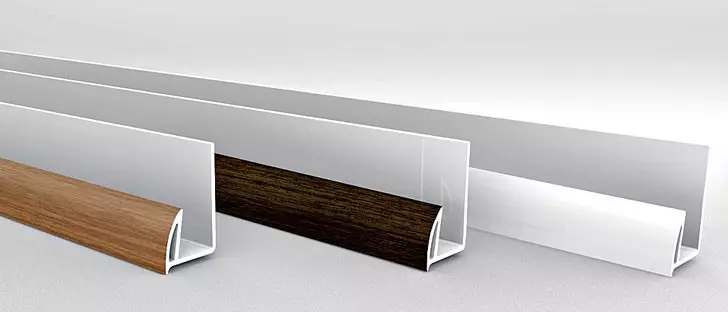

Photo: "PROFIN RUS"

The finish of internal and external slopes can be entrusted by the team of installers from the window company or construction workers. Let's talk about the advantages and minuses of the most popular materials and technologies.

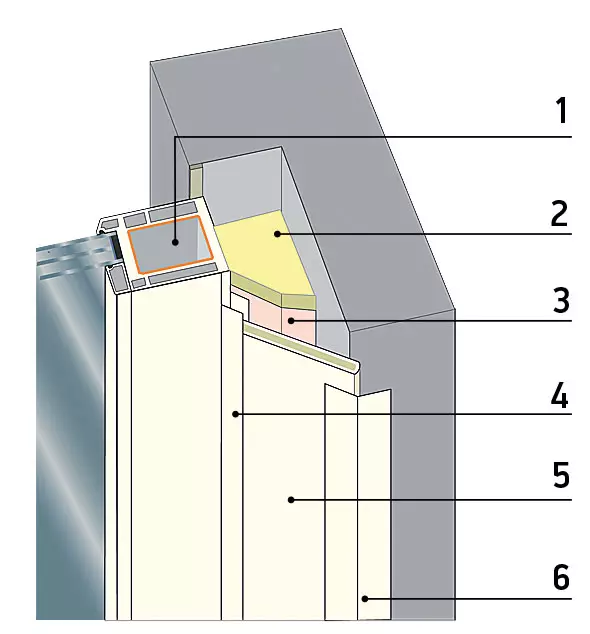

Figure: Vladimir Grigoriev / Burda Media

Silence system from PVC: 1 - window frame; 2 - insulation (polyurethane foam); 3 - vaporizolation; 4 - starting profile; 5 - Silent Plank; 6 - Calicar

Walking takes a lot of time and requires a professional approach. If the width of the mounting seam exceeds 10 mm, the solution has to be applied in two or three layers with an intermediate drying, and then smooth the shtlock. Plaster slings are up to 15 years, but only when using high-quality mixtures and compliance with the technology of preparation and applying a solution. Cement or cement-lime-based compounds - Litoplan (Litokol), Ttt (Weber-vetonit), Sevener (Knauf), Flyvel ("Best"), etc. They are somewhat more complicated in work than gypsum, but Provide high strength and moisture resistance of surfaces. For exterior slopes, facade mixtures and tile glue are used.

With a layer thickness, more than 20 mM plaster must be reinforced with a grid. If the window frames are made of plastic, the location of the box of the box to the slope should be closed with a special self-adhesive profile-ignition with a flexible petal: as a result of the thermal expansion / compression of PVC, the crack is inevitably formed inevitably.

Photo: "TBM"

The order of the finish of the carriage can be different, and yet more often, first shut off the slopes, and then mount the windowsill. To achieve minimal gaps between the details, the latter need to be accurately tightened with stusl

Outdoor plaster slings should be covered with facade paint, internal - washing interior. Save on the material is not worth: Cheap water-producers made by outdated technology are yellow under the influence of sunlight.

The covering of moisture-resistant plasterboard makes it easy and quickly align the surfaces of the internal slopes. The panels are easy to install "in the dawn" using a professional mounting foam with a small expansion coefficient as glue. Then the angles should be closed with a plaster galvanized profile and derive a thin layer of finishing plaster replacement. And do not forget about the overall, covering the joint with the window frame (in this case, you can also use a white sanitary sealant).

The main disadvantage of plasterboard - its surface is not too durable, and it is easy to damage, for example, when washing windows or moving pots with flowers.

Plastic systems and siding are the fastest and cheapest way to finish. Systems for internal slopes include a starting profile, which is glued or rinsed to a window box, a sloppy panel (maximum width 1 m) and platbands that allow you to hide the joints of the panel with the wall. From PVC, it is mainly produced by white products, but for an additional fee and by pre-order it can be laminate (most of the major window firms are provided). PVC slopes are inexpensive, very simply installed (with the help of the same mounting foam), do not crack, it is easy for them to care. However, due to the electrostatic effect of the surface of the product, dust attracted.

Hollow Distoping PVC panels are enhanced with internal ribbies. They can be cut not only across, but also along; In this case, it is more correct to use the metal hacksaw

Node adjoining the panel to the window box are performed using the starting profile

And the junction with the wall is covered with a platband

In country houses, covered with siding, window openings usually decorate outside the same material, or rather special PVC profiles, which are a combination of a suction plate and platband.

The trim tree is suitable for a country house from a log or bar. It will hide a draft cluster and ensure the unity of the style when the facades are cleaned. Silence strips are painted in the color of the frames, and the internal is pre-grinding, and the outer is only elongated. Internal slopes from glue shields are appropriate in the city - as an addition to wooden windows.

Causes of mold

Sometimes "dew" falls on the inner slopes in winter and with time the fungus is started. This phenomenon is characteristic of houses with walls from materials with relatively low heat transfer resistance (brick, concrete blocks, monolithic reinforced concrete) and without a layer of insulation. In the thickness of such a enclosing structure, a cold bridge appears, aimed at around the window frame. Diaspora freezes are easy to avoid, if you choose and install the windows, to purchase products with a wide (at least 80 mm) box, and when installing the window is located in the middle of the wall thickness or closer to the room. Instead, sometimes the slopes are inspected, laying a layer of mineral wool under the finishing panels. But such a solution allows only to disguise the symptoms. The wall under the trim can still be mocking, and the likelihood is greater, that subsequently the entire discovery will require serious repair.

When finishing internal slopes, sometimes tempted to move away from the canons and use an unusual decor, such as texture coloring or a mosaic. Such experiments are often successful, but only if a professional designer is taken for business.