What is the advantage of polyethylene gas pipes in front of steel and is it possible to mount the gas distribution system on their own.

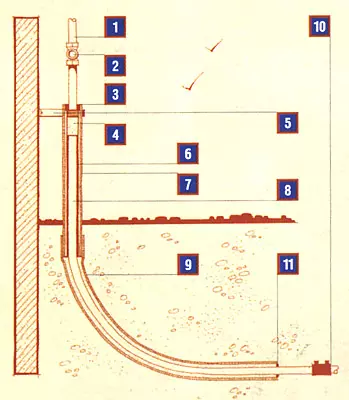

1. Steel pipe with compensator

2. Crane Sharova D.25 (Du.20)

3. Ring rubber or sealant

4. Connection in-block "Polyethylene-Steel"

5. Bracket with a sliding clamp

6. Steel Case DU.403.0

7. Heat-resistant plastic case

8. Polyethylene tube 32 (30)

9. Polyethylene Curved Case

10. Coupling Polyethylene electric welded

11. Ring rubber or sealant

How to answer this kids, but far from idle question? There are gas in our homes, only here is quite often imported in the cylinders. Watercard gas pipeline from the main line. Local gas farm to spend either can not, or does not want: they say, the conditions of the terrain do not allow, and even expensive. A familiar situation, isn't it?

Laying of any communications, including in the settlement of traditional metal gas pipe, requires serious material costs. There is an alternative option - instead of steel to use a special polyethylene tube for gas supply. Just the diva is given why, with the obvious benefits of the use of polyethylene pipes in the construction of inter-settlement underground gas pipelines, morally obsolete prototypes of steel are still applied in the gas economy.

If you calculate the benefit when installing and operating, the comparison will not be at all in favor of the metal (according to the data provided by the Lenoblgaz AOOT).

Metal pipes in the ground are subjected to intensive electrochemical and chemical corrosion, which over time leads to their partial or complete destruction. Maintaining communications from metal pipes in working condition entails large operating costs. The maximum service life of the metal pipe in the gas economy, provided that the pipeline is installed cathode protection and the insulation of the pipe is not damaged, calculated in 20 years. The exploitation of the steel gas pipe is becoming more dangerous than the polyethylene of the same service life.

In the USA, Canada, Great Britain, Japan used to understand the advantages of using polyethylene pipes in gas supply and further than others advanced in the field of technology and the practice of transportation and gas distribution. B1998g. In Russia from 36 thousand CM, 5517,2km gas pipelines were laid using polyethylene pipes.

What is the advantage of polyethylene pipes in front of steel? They have significantly higher frost resistance, plasticity, resistance to aggressive chemical compounds, they are not terrible electrochemical corrosion, the action of wandering currents. Polyethylene pipes are placed directly into the ground without special protection and isolation in which steel pipes need. They weigh in 7 times less than steel similar diameter and shipped in bays (diameter of up to 160mm), wound on the drums (with a diameter of from 63mm or more) up to 1200m long, or in segments (diameter 110 and 160 mm). Pipes easily cut and welded. The complexity of their installation is 2-3 times lower than steel. High plasticity of polyethylene pipes and tensile strength allow you to lay them in bubbly soils and in regions with increased seismic activity. But the most important thing is the warranty period of their service - 50 (!) Years at low cost of laying and operation!

In Russia, polyethylene pipes for the needs of the gas industry today produce 14 enterprises. Among them are two factory in Kazan- "Orgsintez" and "Gazplast", the enterprise "Livnyplastik" in the city of Livna Oryol region, "Agrigazopolymer" in Obninsk, "Sibgagazararat" in Tyumen. Hospital, domestic pipes are still completed with connecting details of foreign production. However, in 1999. The implementation of a large-scale project of joint production of polyethylene fittings using the technology of the English company Fusion is scheduled.

The first manufacturer of plastic gas pipes that meet the progressive European standards was the Moscow Plant "Andgaztrubplast". Its pipes from polyethylene type PE-80 and PE-100 correspond to the norms of GOST R 50838-95, TU 6-49-04719662-120-94. The plant produces pipe with a diameter of 20 to 225mm with a wall thickness of from3 to 20.5 mm, calculated on the nominal working pressure of the D12ATM. All pipes are completed with the necessary connecting elements of the production of fusion-saddles, couplings, discharge, tees, various adapters, couplings for compounding polyethylene pipes with steel and brass products, etc.

Is it possible to mount the gas distribution system on your own? Do they come so with water supply and heating systems? All questions with gas is much more complicated. The gas distribution network, as well as electrical, belongs to the means of increased danger. For any work with gas, a license of Gorgostechnadzor of Russia, issued by firms, whose personnel has been trained in specialized training centers and has the necessary practical experience.

All this means that in the field of gas distribution, amateurness is categorically prohibited. You can only lead gas to the village and you can only officially, with the participation of licensed specialists. Forward the queue for connecting to the gas highway in the regional (urban, district) operational service, technical conditions must be obtained, after which the license is developed by the project. At this stage, the optimal gas supply scheme of the village or cottage can be developed with your participation. Ilishly then a licensed construction company implements a project using technologies that can also be specified with you. Performed work accepts the Acceptance Commission, which includes a customer, a contractor, a representative of the gas management service and the Gosgortkhnadzor authority.

To reduce gas pressure on inputs in the house of consumers, cabinet regulators can be installed. This allows the liquidation of low pressure pipelines and parallel gaskets to reduce the length of the underground gas pipeline, which gives significant cost savings.

Gas entry into the house is carried out through the individual cabinet item (SP) directly from the gas distribution network of the average pressure. The construction of the main distribution point (GPP) at the input in the village is not required, hundreds of pipe meters are saved. As a whole scheme, this scheme costs the consumer in a 40% cheaper than the traditional gas distribution network of low pressure with hydraulic hydraulic network.

The question is appropriate "How to be if the gas communications have long been laid using metal pipes?", After all, the moment will come when they need to replace them. Oddly enough, the task in this case is solved much easier. There is a technology for pulling polyethylene pipes inside the worn pipelines. Since the diameter of your gas pipeline will decrease, the gas supply system will be translated from low pressure on average. For another technology for repairing a gas pipeline instead of polyethylene pipes of smaller diameter, special, longitudinally folded in the form of the letter U pipes from polyethylene PE-100 brand can be used. They are tightened into the steel pipe, under the influence of pressure and temperature they become round (U-Liner technology). In this case, the pressure in the recovered gas pipeline will remain the same.

Another technology is "Phoenix" - allows you to restore a steel gas pipeline worn through it through it a synthetic tissue hose, glued to the pipe walls with a special two-component glue. In this case, the diameter of the pipe is practically not changed and its former pressure is preserved. It should be noted that such a technology is quite expensive.

There is an important nuance that you should know about. The gas to the house can be brought along a plastic pipe labeled in the ground, but the gas entry into the house and the wiring inside it is allowed only using the steel pipe of the corresponding diameter. Those who have been abroad will return: they say, you can make a layout and using copper pipes. This is certainly so, only Russian low-speed and GOSTS are far from perfection, but no one has canceled them. Something in Russia in Russia on the basis of departmental permits copper layout is already being done today, by local government bodies, it is not officially permitted by the lack of regulatory documents. It is allowed to connect gas stoves to a pipe with special flexible reinforced hoses that have yellow marking, the length of which does not exceed 1,5 meters.

The welding of polyethylene pipes is possible both using parts with mortgage heaters and jack. For these purposes, welding machines and domestic cars ("Protva-4") and foreign production (Fusion, Vidos, Soron, Friateck, Uponor, George Fischer, etc. are used. The device for electrical welding works both in automatic and manual modes and is used to welding pipes with a diameter of from16 to 315mm. The device has a built-in device that automatically controls the quality of the welding. The machine for welding pipes is an automated installation controlled by a computer that controls the execution of all welding operations. It is used to welding pipes with a diameter of from63 to 250mm.

The use of polymeric materials in the gas supply of the village and the cottage for a long time will provide a safe life to all its inhabitants and with time will allow to save a very solid amount.

The editors thanks the administration of CJSC Polymergaz, the Andgaztruplast plant and the joint venture "FIT-PLAST-FUSION GROUP" for the materials provided