The facade decorated with natural stone is striking the wealth of forms and natural shades. However, two dozen years with this proven time, the material successfully competes the decorative stone created by man. What is the secret of the success of artificial cladding?

Photo: White Hills

Concrete products well hold the form and accurately copy any texture, whether it is a tread print or exquisite embossed ornament. And the idea to reproduce with this material, in fact, the unique texture of natural stone is fully justified. Her embodiment was the decorative facing stone.

The elements are based on portland cement used as a binder component. Due to the addition of porous fillers (clay sand, perlite, pembol and air ducting additives), each stone has a small mass, which is important when carrying out installation work. The necessary consumer properties provide modifying additives (plasticizers, hardening). Pigments are responsible for a wide flower range. Moreover, conscientious producers in the manufacture of decorative stone use high brand cements and imported dyes.

It is desirable to use no more than two-three collections of facing stone, otherwise the facade will seem too flying. Such a finish looks organically even with fragmented use, it is combined with painted, plastered or made of wood parts of the walls. Photo: Kamrock.

The cost of quality products cannot be low, which naturally affects the price of products: 1 m2 of stone facing costs from 850 rubles. By the way, it is quite acceptable, especially in comparison with the price of a natural analogue. Among the famous manufacturers of decorative facing stone - EUROKAM, Foreland, Kamrock, Leonardo Stone, White Hills, "Perfect Stone", "Stone Art", "Facade Material Workshop".

In the assortment of each of them more than 20-30 collections of elements (flat and angular), differing in the natural prototype and color range, as well as several types of thin-walled facing bricks, decors, paving slabs, border stones and flows.

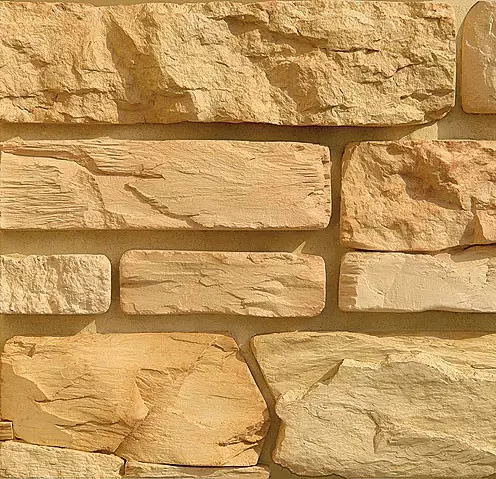

Photo: White Hills. The base of the house is lined with a stone "Rutland", the price is 1 m²: 1290 rubles., Size: 5.5-38 × 7-49 cm, thickness: 2-5 cm, extinguishing: 1.5-2.5 cm

Stone resistant

We list the main characteristics of the decorative stone: density (400-2200 kg / m), compression strength (15-40 MPa), water absorption (5-10%) and frost resistance (150-400 cycles). By the way, in addition to the frost resistance of the facing material, this indicator is no less important for a system consisting of stone and cement glue.When laying the back side of each element is completely labeled with adhesive composition, applying not toothed, and a flat spatula, so that the voids do not occur behind the lining. At the time of the connection with the wall of the surplus of the solution, the seams between the elements are slightly filled. The scanning of the seams completes the sealing of the structure. The consequences of poorly performed works are obvious: water penetrates the seams and further for the lining, and after some time the stones begin to fall off. Such troubles occur most often in the first year of operation.

Specialized cement glue compositions

Photo: White Hills. The facade is decorated with a stone "Cologne Brik", the price of 1 m²: 920 rubles, the size of the element: 6.5 × 21 cm, thickness: 1-1.1 cm, 1.2 cm

The facade of the country house, as well as gazebos, fences and other elements of landscape architecture, decorated with decorative facing stone, are subject to aggressive environmental impact. Specialized cement adhesive compositions helps reliably to secure the stone elements on the surface. Their clutch force (adhesion) is determined by the tile strength and is measured in MPa. The higher this indicator, the more difficult to tear the material from the base.

For example, for pre-plastered surfaces, compounds with adhesion 0.8-1 MPa are suitable. If there is a facing of complex elements, say columns or intricate columns, use even stronger adhesion adhesion 1-1.5 MPa. When choosing a glue mixture for mounting a decorative facing stone, it is important to take into account the mass of 1 m² of material, since some collections consisting of large-format and volumetric elements can exceed 50 kg / m². Corner elements help create a reliable look of construction made of natural stone or building bricks.

Photo: EUROKAM. A special flashes of the facade finish give decorative elements: eaves, arched and rectangular bypass for windows, rusts, castle stones, window sills, foams for socle. All of them are made of the same material as the stone

Professional stackers appreciate qualitative solutions for the ability to move the glued element for sufficiently long time (15-30 min), and the material does not slip from the wall. That is, glue does not dry out immediately, but at the same time holds a stone. So, the basic requirements for glue composition: high adhesion (clutch strength); High initial adhesion force; long-term "open time"; high stability for climbing; High frost resistance.

8 reasons to choose artificial stone instead of natural

- Small weight. The decorative stone on average weighs 1.5-2 times less natural. Depending on the type of elements, their mass varies from 13 to 50 kg / m². Such facing is less loading the facade and the foundation of the building, which allows it to use it during the reconstruction of old and even dilapidated buildings.

- Convenient size. All elements of geometrically correct forms have standard dimensions, which simplifies their installation. If necessary, in places of the adjoint, say, the unnecessary part of the product is easy to cut off with an ordinary grinder to the windows and doors.

- Constancy color. Each color of the decorative stone manufacturer refers to the corresponding encoding. Therefore, at any time you can buy exactly the same facing material. But to choose natural stones to the tone available is almost impossible.

- Ecology. Artificial stone - environmentally friendly material. While some sandstone breeds, marble and granite have a natural radiation background, which limits their scope depending on the category.

- Simple installation. The form of a decorative stone is a tile, flat and rough with the back side, the installation of which is not more difficult to lay the ceramic tile.

- Corner elements. Each collection of facing stone is complemented by angular elements. They simplify installation and contribute to creating a holistic image of a stone house. Production of angular elements from natural stone is time consuming and expensive.

- Democratic price. The cost of decorative stone is lower than many other materials for facade cladding (natural stone, clinker brick, etc.).

- STRENGTH. The decorative stone is stronger than some breeds of natural, such as travertine and sandstone with a porous structure. Due to insufficient strength and frost resistance, they are used mainly in countries with a warm climate. Facing of artificial stones, externally imitating travertine or sandstone, can be used without any restrictions even in regions with a harsh climate.

Thermophali.

Photo: "Perfect stone." When complying with the norms and rules of installation, the stone will serve for several decades

The hosts of country houses, rationally suitable for decoration, necessarily take into account the harsh conditions of Russian winters. After all, in addition to beautiful and durable design, the facades must be inspired. In order to solve this task, it is not necessary to abandon the facing stone at all - it is enough to pay attention to the thermopanels. They are products from rigid extruded polyurethane foam or polystyrene foam with an outer layer of decorative stone clicked into it. Panel size - 1000-1250 x 600-650 mm, while the thickness of the insulation is 40-110 mm, and the thickness of the stone is 10-20 mm. Such finishing simultaneously performs the functions of heat insulation and decor. Like a decorative stone, it is used on facades from a variety of materials: bricks, concrete, timber or made of frame-shield elements. Price 1 pc. - from 1200 rubles.

The hydrophobic solution caused to cladding will protect it from possible contaminants, dampness and the appearance of mold.

Minimizing the costs of decoration, and in the future and during operation (to maintain comfortable temperatures in the winter and summer house) will help specialists of producers of thermopadals, such as Foreland, Kamrock, "perfect stone", "workshop of facade materials". In accordance with the standards, they will select the elements of the optimal thickness, taking into account the density of the outer wall material, which characterizes its heat transfer resistance R (M2 x ºС) / W, and also advise effective fasteners.

Say, to smooth brick, concrete bases of thermopanels are attached with a dowel-nail. But most often the walls are far from the ideal, and their preliminary alignment can take a lot of time and turn out to be very laborious. Comable option for uneven walls or folded from a wooden bar - installation on the cut.

Photo: "Workshop of facade materials." Thermopanels attached directly to the walls from OSB. The seams between the bricks of the decorative layer were filled with frost and moisture-resistant grout for wide seams

Wooden bars or metal profiles are fixed at a distance of 30-40 cm from each other. After that, the thermopanels are applied to them, so that each three or four vertical bar accounted for each, and secure, using at least six sams. All puzzle compounds of elements necessarily wake up silicone sealant for outdoor work to further protect against moisture. The option of finishing facades by thermopanels cannot be called budget. But the desire to save is fraught with the acquisition of poor-quality material and the unpredictable result of the work of the assembly dilettant. Choosing a beautiful and durable cladding, which should serve at least half a century, should not refuse professionals.

Quite often of those who want to decorate the facade of their home with artificial stone the question arises: is it possible to carry out external facing work in the winter? The optimal air temperature for the trim of the facade with decorative stone is from 5 to 25 ºС, that is, we are talking about a warm season. If the temperature on the street is from -6 to -10 ºС and below, then the outdoor work on the finishing of the facades, we recommend to postpone before the onset of heat. However, when the thermometer is located on a zero mark or slightly lower (up to -10 ºС), you can make a special method. In particular, using frost-resistant glue White Hills "Winter", designed for mounting in harsh climatic conditions. This glue mixture on a cement basis is intended for external work at low temperatures and is suitable for facing not only artificial, but also natural stone, porcelain stoneware, ceramic tiles.

Vitaly Pavlyuchenko

Head of Technical Laboratory of WHITE HILLS

About frost resistance

Capacity of the material in a moistened condition to withstand without destruction, multiple freezing and thawing is called frost resistance. This quality must be considered when choosing a decorative stone for the facade. After all, water, filling the pores of the elements, is expanding during freezing and destroys them. On average, this indicator for facing stone is 150-200 cycles, and the products of WHITE HILLS reaches 400. The number of cycles, characteristic of the winter near Moscow, is from 15 to 22. And the stone, the importance of the frost resistance of which is 200, will serve at least 20- 30 years. But the actual frost resistance of products is usually higher than specified in the technical documentation.How to check the quality of decorative facing stone?

The quality of the decorative facing stone can be estimated by a slice or different. It is desirable that the material has a homogeneous structure, and the size of the largest particles did not exceed 5 mm. Otherwise, the strength of the elements will be uneven, the likelihood of cracks on the surface will noticeably increase and, as a result, the fault of the stone. In addition, the cut is easy to determine the coloring method. If the color of the inner part of the product differs significantly from the surface tone, it means that the stone is painted only from the front side, and any damage will immediately become noticeable.

Minor differences in false and surface shades are suggested that the stone is scratched on the entire depth during the mass of the mass. Therefore, small chips and scratches on its surfaces, which may appear during operation, do not worsen the appearance of the masonry. Capacity of the material in a moistened condition to withstand without destruction, multiple freezing and thawing is called frost resistance. This quality must be considered when choosing a decorative stone for the facade. After all, water, filling the pores of the elements, is expanding during freezing and destroys them. On average, this indicator for facing stone is 150-200 cycles, and the products of WHITE HILLS reaches 400. The number of cycles, characteristic of the winter near Moscow, is from 15 to 22. And the stone, the importance of the frost resistance of which is 200, will serve at least 20- 30 years. But the actual frost resistance of products is usually higher than specified in the technical documentation.

Photo: "Perfect stone." Collection "Thin Plast", Price 1 m²: from 1356 rubles., Size: 9.4 × 20.5 / 30 cm

Photo: "Perfect stone." Collection "Weathered Scala", price 1 m²: 1356 rub., Size: 8-11 × 11.5-35 cm

Photo: "Stone Art". Series "Old Prague", price of 1 m²: from 500 rubles, element size: 6.4 × 28.5 cm

Photo: Kamrock. Collection "Grade Tuf", price 1 m²: from 1539 rubles, element size: 8-33 × 8-33 cm

Photo: White Hills. Dunvegan's collection, price 1 m²: 1290 rub., Size: 6-15 × 10-58 cm

Photo: Leonardo Stone. Bergamo collection, price 1 m²: 1290 rubles, consists of different elements

Photo: Leonardo Stone. Collection "Venice", price 1 m²: 1470 rub., Element size: 6-20 × 20-50 cm

Photo: Kamrock. Collection "Linear Relief", Price 1 m²: 1759 rub., Element size: 8 × 50 cm

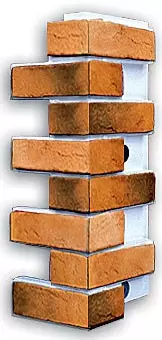

Photo: Kamrock. For the outer layer of thermal panels, the stones of a small mass are used, most often in the form of a facing brick

Photo: Kamrock. Thermopanel "Old Brick" (Kamrock) based on PPU, Price 1 Piece: from 1152 rubles, element size: 656 × 750 cm

Photo: Kamrock. For convenience, thermal manufacturers offer ordinary, angular and challenges. The package includes the necessary consumables.