We tell how to choose the right sip panels and describe the entire construction process: from the foundation before finishing the facade.

The construction of houses from sip-panels allows you to quickly build a residential building, without waiting for a successful season and even build it yourself. We tell you more in the article on the pros and cons of this venture, the choice of materials and step-by-step construction.

How to build a house from sip-panels

Pros and consChoosing materials

Step-by-step construction

Sippan house: for and against

Below we list the pros and cons of the application of the construction technology of houses from sip-panels.

Benefits:

- Savings on heating due to high heat-saving characteristics of enclosing structures.

- More useful area - due to the small thickness of the walls, you can get 15-20% more than useful area.

- Accelerated installation of the box of the house (1-2 weeks).

- No need for an expensive foundation (enough, for example, a screw foundation installed in 1 day).

- Saving on severe lifting equipment can significantly reduce construction costs.

- You can build houses all year round - they do not give shrinkage, so immediately after the assembly you can start finishing work.

- The assembly technology is simple, you can even fulfill the construction of a house from a sip-panel with your own hands - it is under the power of anyone who is guided by the instruction and knows how to keep a screwdriver and saw in their hands.

disadvantages

- A small thermal inertia of enclosing structures is typical of any frame houses.

- The high price of the material is true, it is more than compensated by cost savings on the foundation and a decrease in construction time.

- The enclosing structures do not breathe, and it means that it is necessary to a device for efficient supply-exhaust ventilation - this deficiency is also inherent in all frame houses.

- The combustibility of the enclosing structures - but it is not higher than any wooden buildings.

- The selection during the burning of harmful substances is indeed, a styrene with a specific sweet smell is highlighted when filling expanded polystyrene. When it is concentrated in the air more than 600 ppm (1 ppm = 4.26 mg / m3), it is dangerous for a person. But the smell of styrene becomes intolerable already at a concentration of over 200 ppm, and this is an unequivocal signal to urgent evacuation.

- It is amenable to rodents - although these animals are bred anywhere, there are also cases that even concrete sworn in search of food.

How to choose a sip panel

STRUCTURAL INSULATED PANEL (SIP), or structural insulating panel (SIP), - universal building material for walls, overlaps and roofs of low-rise residential buildings. It is three-layer, consists of plates (two moisture-proof oriented chipboard - OSP) and the core (sheet of polystyrene foam) glued under the press of polyurethane glue.Standard panels have a height of 2.8 or 2.5 m (with a width of 1.25 m) - they are used accordingly for the walls of the first and second floors. In classical technology with overlapping platforms, the height of the panel is equal to the height of the premises without finishing. However, if the house is planned a channel system of ventilation, air conditioning and air heating, and the floors on the lags, the ceilings will be lowered by 15-20 cm. Therefore, it is advisable to order for the first floor of the panel with a height of 3 m (alas, only some firms are manufactured), and for second - 2.8 m.

Products produced thick 224 (12 + 200 + 12), 174 (12 + 150 + 12) and 124 (12 + 100 + 12) mm. From the first, overlapping and roof, the second in the middle band of Russia are optimal for external (as well as inland carriers) walls, are third suitable for interior partitions.

Also on the market are the cheapest products with a thickness of 9 mm thick, but they are suitable only for walls and partitions of small single-storey buildings.

Differences of the factory sip panel

- Inaccurate geometry. The shift of the plates relative to each other, the diamonds or trapezity of the panel is easily detected with the help of the kitchen and roulette.

- The use of low-quality OSP with low moisture resistance. Wash the surface of the panel abundantly for hours to two. If the seams begin to flap, you have a defective product.

- Low strength of the adhesive connection. This is perhaps the main sign of the goods produced by a semi-historic manner. You can check the product only by separating one of the plates from the insulation. The high-quality panel does not break down on the seam, but on the sheet of foam.

- Performing the middle part of the panel from fragments of polystyrene foam plates. To reduce the amount of waste, handicraft enterprises are allowed to trim the insulation, which adversely affects both strength and heat insulating properties. The joints of the plates of polystyrene are easy to see on the ends of the panels.

Step-by-step construction of a sip-panel house

Foundation

Firms that are engaged in the construction of houses from sip-panels, recommend to make a foundation from steel screw piles, fully meet the concept of a pre-facility building. Piles under the house with an area of up to 150 m² can be mounted in two or three days, and with the help of a special installation - in one day; Assembly Schelller or Brous strapping also will not take much time.

The power of frosty powders repeatedly exceeds the load from the light walls from the sip panels. In such conditions, it is best for pile and insulated fine-gulled foundations.

Piles (the most common diameter - 108 mm, length - 2.5 and 3 m) are located under the outer and internal capital walls, as well as the rigels (they are needed to reduce the beams) in increments of 1.5-2 m. Such a base is good It behaves on bunchy soils and practically does not be coats under light walls - provided that the depth of the embedding was determined not randomly, and as a result of a test screwing with measurement of the effort: pile blades should rely on dense soil layers.

To serve the foundation for more than 50 years, you need to purchase piles of steel with a thickness of at least 4 mm with cast tips that oppose corrosion is much better than welded; After installation, they should be filled with concrete. One support with the installation will cost 2400-2700 rubles, that is, the cost of the foundation for the house with dimensions of 8 × 10 m will not exceed 100 thousand rubles. True, the decoration of the basement will require additional costs: they will have to perform a charge from cement-chip or glass edgeless sheets (under tiled or stone) or decorative panels on the frame.

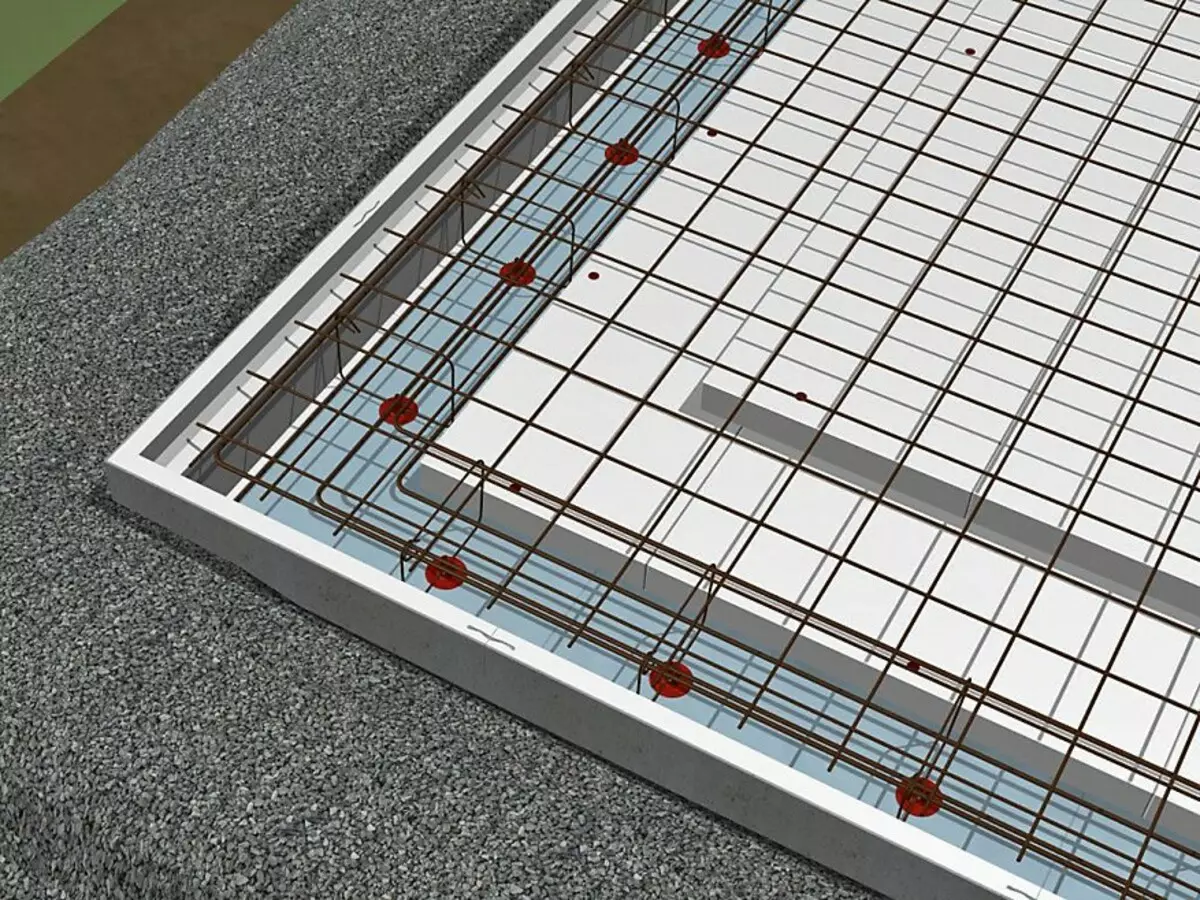

The main alternative to the pile-screw foundation is the traditional for the country construction of a small-brewed tape with a width of 0.3-0.4 m and a height of 0.6-0.8 m. If you cook concrete yourself, and not to buy at the factory, then such a reason will cost a little cheaper Puina, but the construction time will increase at least 3 weeks. The pledge of the ribbon foundation is a properly performed armature framework, it should be designed according to SP 63.13330.2012 (basic requirements - the presence of at least two reinforcing belts and reinforcement coefficient of at least 0.1%). The foundation of this foundation cannot be erected on inhomogeneous soils with floating. Foundation is optimally suitable for swampy sections with severe and weakness soils. The plate is poured over a sandy-gravel drainage cushion, a layer of extruded polystyrene foam in a thickness of at least 100 mm and a waterproofing substrate. The minimum stove thickness is 200 mm, and it must be reinforced with a two-level frame from a rod with a diameter of 12 mm. To protect the walls from the water (mostly melt), along the contour of the slab it is worth building a reinforced concrete base with a height of 0.3-0.5 m. The scene and the base is advisable to insulate the EPPS sheets with a thickness of 50 mm.

The foundation from the steel piles is desirable to strengthen the scaperole or a hesometer. Randbalki Randwarm must be cooked with each other and, moreover, welded to pile. Metal parts must be protected from corrosion and isolate from wooden strapping with rolled waterproofing.

Instead of a metal frame, the strapping is often mounted from a bar, for fastening which reference platforms are welded to pile.

When a floating ribbon foundation device, it makes no sense to break into the clay soil - it is better to increase the above-ground part that will perform the function of the base. The reinforcement frame should be knit galvanized wire. Connections must have durability and be durable, because the frame is obliged to work as a whole throughout the service life of the foundation.

The slab foundation is poured over the layer of thermal insulation and reinforced over the entire area, which reduces the probability of cracking of the plate.

The perimeter is arranged drainaged.

Walls

Despite the fact that the technology is considered a unified, each company and even brigades have its own assembly of enclosing structures - successful and not very.

For construction, products are needed both standard and non-standard sizes - jumpers over the processes, simpleness, elements of the roof, etc. Large companies with their own production line are discreted only in factory conditions. Small firms and "autonomous" brigades often cut out the desired fragments on the object using a circular saw and a foam grater (the grooves are chosen around the perimeter of the panels). With this method, the risk of disruption of the geometric size of the premises and openings, the appearance of gaps at the joints of the parts.

Building technology provides for the installation of a hidden frame, the details of which are inserted into the panels. For the frame, the selected chamber drying lumber impregnated with antiseptic composition should be used, and it is desirable to use a glue bar for the beams or a wooden 2-way. Alas, sometimes underwent inadvertent products, which may turn around, which will lead to the appearance of slots and the deformation of walls and overlaps. The joints of the panels with frame elements are always sealed with polyurethane foam. However, some brigades are accustomed to collecting racks of two boards, simply by tightening them with self-draws without any seal seal. At the same time in the corners can install a ram 150 × 100 mm. It seems that this should increase the strength of the house of the house, however, in practice, such a decision only guarantees the freezing of an angle of harsh in winter.

First of all, the basement platform is built on the foundation, to which the strapping from the boards is attached and then proceed to assembling the walls of the first floor.

Partitions are installed simultaneously with the outer walls. Although the assembly of the floor takes only a few days, the construction is covered with an awning of the PVC film to prevent moisturizing the rain and dew panels.

Sip panels are sealed with polyurethane foam.

In the corners, a warm and hermetic castle compound is performed.

The basis of the intergenerational overlap is collected from a bar with a thickness of 50-70 mm and a width of 150-200 mm. The lattice design allows you to reduce the deflection and vibration of beams.

Load from overlapping perceive panels and mortgage bars between them.

The sip-panels allow you to build a complex configuration building - with indirect corners and erkers. True, it increases labor costs and the number of waste, and therefore the cost of 1 m2 of the area of the house.

Potions do not have quarters; The windows and doors are installed in the plane of the outer OSP plate. It is important to ensure the tightness of the assembly seam.

From the inside it is sealed with a vaporizolation ribbon, then fought.

And arrange an improvised tide from aluminum scotch. Next, the seam is waterproof, and when finishing is closed with platbands.

Roof

The roof of the attic or semicard floor can be erected both with the help of sip panels and by traditional technology with insulation of mineral wool or other materials.

Sometimes you can hear that roofing pie on the basis of sip-panels more racks to the effects of moisture (after all, polystyrene foam has extremely low water absorption). However, the constant presence of moisture (which can leak through the roofing or flow from the bottom in the form of a pair) leads to the destruction of the plates of panels (OSP). In addition, at temperatures above 80 ° C, the thermal destruction of polystyrene foam destruction begins.

Therefore, the venzorzor must be provided between the sip-panels and roofing material. Do not do without a layer of vapor barrier from the premises, as well as ventilated skate.

The carrier part of the roof of the sip-panels includes the skiing bar, runs (parallel driving beams) and sprinkled rafters whose function is performed between the panels. The installed panels are covered with a solid carpet of a rolled vapor-permeable waterproofing, then mount the cutting inches to which the roofing coating is fastened (for example, profiled steel sheets) or another layer of OSP, which serves as the basis for flexible bitumen tiles.

The basis of the roof of the traditional design usually serves hanging rafters (rafting farms), between which the mineral wool plates are placed, then layer of rolling waterproofing, and so on according to the scheme described above. The roof of the traditional design will cost 15-20% cheaper and will provide a slightly better protection against noise, but more time-working in execution. Perhaps other options for the roofing device, for example, with insulation of puzzle plates from extruded polystyrene foam, located on top of the rafter system and milking or sheet rolls. . The advantage of such a scheme is that the solid layer of the insulation overlaps the bridges of the cold created by rafters.

In the construction of the roof of the sip-panels, the skunk bar is installed primarily, the ends of which are based on the frontaths, and the middle - on a pair of sprinkled rafters.

Next, the runs are mounted, the step of which is calculated, based on snow loads and slopes.

Farmers reinforce ribbon ribs from wide boards.

On top of the sip panels, the waterproofing carpet is laid and nailed, which will ensure the ventilation clearance under the roof.

Supply-exhaust installation should be placed in a sound everywhelmed room: noise when it reaches 45 dB. From the installation in the risers, the air ducts are laid off and inside the overlap - usually round-section with a diameter of 100-150 mm.

Forced ventilation for the house of sip-panels

Sip-panels are well insulated warm, but they are not able to accumulate it. As a result, the house there is a so-called thermos effect: after venting the room, a street coolness is still kept. And to ventilate regularly, because in sealed rooms the air is quickly saturated with moisture and carbon dioxide. As a result, the benefit of using an effective insulation is much reduced, and the jumps of temperature and humidity create discomfort.Carefully change the position for the better only forced system of supply and exhaust ventilation with heat recovery, which will provide a zonal air exchange. The main element of such a system is the recovery installation. For a cottage area of about 120 m2, where a family of three or four people live, it is enough to install a capacity of 180-250 m3 / h, the price of which will be 60-250 thousand rubles. Depending on the design and manufacturer's company. The cost of the installation system varies within 350-700 thousand rubles. Excluding the costs of creating hidden cavities for the gasket of Ventkanalov.

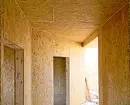

Sip-panel finish

From the inside the walls of the sip panels in the overwhelming majority of cases are trimmed with plasterboard, whose sheets can be attached directly to the inner OSP. The trim make a two-layer, providing for in the first layer channels under the wiring (cables be sure to be placed in protective corrugations or PVC boxes). With the traditional method of installing the GLC (using the root and steel profiles, the pipes and cables are paved in the cavities under the trim.

Outside, most often mounted hinged facade. In addition, plastering is possible, but in order to avoid the appearance of cracks, it is advisable to use the technology of a wet facade, with a decoration of siding, wooden planks, composite panels.