Market overview for insulation and sound insulation: mineral wool, gas-filled polymer and natural isolation, methods of heat and sound insulation in the apartment and a residential building

How to ensure a comfortable temperature of the floor surface in apartments located above the cold basements, entrances, arches? How to reduce shock noise, felt by neighbors from below, or protect yourself from sounds that are coming from the store or cafe on the first floor of a residential building? All these problems will help successfully solve floor insulation

Recompute with GOST 30494-96 "Buildings Residential and Public. The parameters of the microclimate in the premises" The optimal air temperature in the residential room during the cold season is 20-22 s (permissible - 18-24 seconds). For a warm period, these values are somewhat higher: optimal - 22-25 s, permissible - 20-28 C.

At the same time, according to SNiP 23-02-2003 "Thermal protection of buildings", the difference in air temperatures and floor surface should not be more than 2 C. After all, if a person for a long time or is systematically in a room with a cold floor, he feels discomfort, It worsens well-being, performance decreases, an additional stress of thermoregulation mechanisms arises, and as a result, health suffers.

|

|

|

Plates of extrusion foamed polystyrene foam "Penopelex" (A); Hard sounding Glossing plates based on fiberglass "IsOver floating floor" ("Saint-Goben Construction Products Rus") (b)

The interolation of the apartment in a multi-storey building (a) is placed insulating material. At the same time, the air noise is reduced, which is coming from the bottom apartment, and shock, directional down (b)

Also a negative impact on people, first of all on their nervous system, have extraneous sounds and noises. Therefore, all building structures should have sound insulation qualities that correspond to the requirements of SNiP 23-03-2003 "Noise Protection". At the same time, overlapping (i.e., horizontal structures) are designed to provide insulation from air and shock noise. The regulatory value of the index of the air noise isolation of inter-stacked RW floors in multi-storey buildings is 50-54DB (depending on the category of the building). The index of the reduced level of shock noise under the overlap of LNW is not more than 55-60DB.

|

|

|

(a) - "Cork Center"

(b) - Knauf Insulation

Panels (black plug agglomerate) izora (amorim isolamentos) (a); Mineral wool insulation Knauf Insulation, manufactured by new Ecose technology based on natural components, without phenol, acrylic and formaldehyde (b)

During repair, it is important not to degrade the parameters of existing structures. However, many live in homes where the necessary norms were not withstanding initially. Therefore, for those who are not indifferent to their health and well-being of loved ones, repair work - a great reason to draw attention to the heat and sound insulation of the home and bring it to the normative values by their own forces. And this should be done at the initial stages of the finish.

Materialism: Short Excursions

A variety of heat and sound insulation materials presented in the domestic market are divided into three large groups.Mineralovate. This is primarily a stone cotton wool made from the melt of volcanic rocks (basalts, porphyrites, diabases) or metallurgical slags. It has an open porous structure and consists of thin (diameter 3-12 μm) 2-20mm long fibers, synthetic binding, as well as dust and hydrophobic additives. The material is resistant to temperature fluctuations, chemical and biological effects, is durable, durable, hygroscopic. Stone wool does not burn and even prevents the spread of the flame, it has a negligible shrinkage, including thermal.

Opinion of a specialist

Quite often from the owners of housing, as well as developers have to hear the question: "Do I need to lay a layer of heat insulation under the system of electric warm floor?" The answer to it is ambiguous. After all, this system is an addition to the already existing radiator heating. It means that the device and operation of the heated floor, in addition to the increase in comfort, will cause additional energy consumption for which they have to pay. You can minimize power consumption in several ways. For example, establish intelligent temperature controls with automatic power on / off modes, or apply a heat insulating substrate from rigid mineral wool slabs with a reflective layer of aluminum foil. The fact is that the foil partially reflecting the heat coming from the heating element directs it to warm the screed, providing a comfortable floor temperature. In this case, the screed is warming up more efficiently, quickly and with less energy consumption.

Nikolay Eremin,

Head of "Acoustics"

Companies "Saint-Goben Eau

|

|

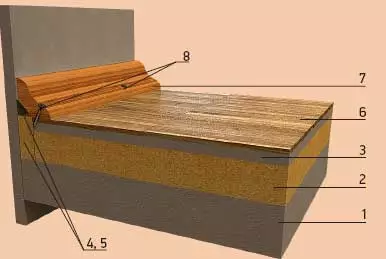

(but)- Floor floating design scheme:

1 - stove of inter overlap; 2 - layer of rigid insulating material;

3 - cement-sand screed or a layer of solid wood-fibrous plates;

4, 5 - soundproofing gaskets;

6 - finishing floor covering;

7 - plinth;

8 - nail or screw

3D graphics N. Samarina

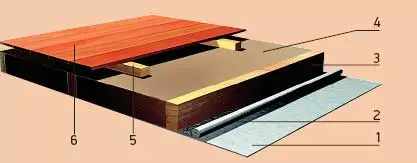

(b) - Scheme of the design of insulation by lags:

1 - black floor;

2 - a vaporizolation membrane (for the attic and basement overlap it is installed from the heat of the warm room in front of the insulation);

3 - Wooden beam overlap;

4 - insulating material;

5 - lag;

6 - Finish flooring

Knauf insulation

Another popular representative of this group is fiberglass. It is made from the raw material charge (quartz sand, soda soda, sodium sulfate IT.D.) and glass battle. The non-combustible and resistant to various aggressive effects of the insulation form a chaotic glass fiber with a small amount of synthetic binder and hydrophobic additives. The diameter of the fibers is 3-5 microns, and they are several times longer than that of stone wool, therefore fiberglass more elastically. Materials from it used to isolate buildings are usually not so dense as "stone", and give a smaller load on the supporting structures, while maintaining thermal insulation capacity. Large compressibility, flexibility and elasticity make them indispensable when used on uneven surfaces and in geometrically complex structures.

Opinion of a specialist

Adherents of the environmental direction in from a housing is worth paying attention to the cork panels (black agglomerate) of various thicknesses (from 10 to 100 mm), consisting of pressed granules of crushed cortex of cork oak. The material does not contain artificial chemical additives, completely immune to moisture, does not support combustion. If the flame from the external source is in long-term contact with the panels, they begin to fly slowly, without highlighting toxic substances. The cork agglomerate has a low thermal conductivity - 0.037W / (MK) - and provides for personal thermal insulation of residential buildings. The thickness panel of only 30mm holds heat as well as a brick wall thickness of 400mm or a wall of an oak bar with a thickness of 150mm. Therefore, the cork agglomerate can be used for the outer and inner insulation of the facades, inter-floor overlaps, walls, underground spaces. Av combination with other finishing materials - in multilayer structures (including floor) for insulation, noise reduction and reverb.

Andrei Aleksandrov, General Director

Companies "Cork Center"

Gas-filled polymers. The books include materials manufactured by foaming and extrusion of plastics based on styrene, polyurethane, polyesters, synthetic Rubber IDR. The most famous polyurethane foam (gas-filled plastic with the structure of semi-closed cells), polystyrene foam, consisting of pressed strollers, and extruded polystyrene foam. The structure of the latter is a lot of small closed cells that do not communicate with each other. They provide lower thermal conductivity, water absorption and vapor permeability than those of this group listed.

Natural isolation. These are products based on cellulose with the addition of different fillers (sawdust, perlite, peat, waste of ceramic production) and binders. Insulating panels made from cortex cork (black agglomerate), as well as cork crumb, deserve special attention. The choice of concrete material for the floor isolation is influenced primarily by the type of overlap design. In addition, its protective properties are important and the price.

|

|

|

|

|

|

|

|

The device "floating" floor with rigid slabs Glasswool P-60 (URSA) under the "wet" screed:

And - prepare the base of the floor. It should be dry and smooth (the coating service life increases). The deviation from the plane on a length of 2m should not exceed 10mm;

b - to prevent the appearance of "acoustic bridges" that reduce the noise insulating effect, it is necessary to isolate a rigid "floating" layer from the walls or partitions, for this, it is set to a temporary formwork from thin boards or pieces of plywood with 1 cm thick;

B - the insulating material uses staple fiberglass plates. Place the plates begin from the angle of the room to reduce the amount of waste;

G - electrical cables and other communications hide in the design of the "floating" floor, instead of conducting them on the walls and corners of the room, where they will be in sight, especially since fiberglass - a non-flammable material and non-flame;

D - the plates of the material are placed, tightly pressed to the formwork and to each other;

e - cover plates with plastic wrap. The canvas of the film are connected to the overlap and samples with scotch. The edges are cutting onto the walls and also stick to the formwork. On the entire floor of the floor, supporting beacons with a height of 10-15mm, on top of which the reinforcing mesh is placed so that it is in the middle of the cement-sand layer;

g - on the grid set guides (for example, metal profiles) and regulate their position using a level;

h - the entire design is poured with cement-sandy solution with a total thickness of 30-40 mm, then it is thoroughly aligned and rubbed. When the screed dry, the film is cut off, and the formwork is removed. The resulting gaps are filled with residues of insulating material. The joint of different coatings in the doorway decorated with special polyvinyl chloride or metal threshments, they also compensate for minor height differences

Big "Swimming"

Currently, reinforced concrete plates are usually served by interleaved floors in high-rise buildings. The easiest way to heat and sound insulation of this design is the device "floating" floor. At the same time pay attention to some nuances.First, appreciate the deviation from the foundation plane. (Making repairs in an old apartment, before this stage, the old flooring is removed to maintain the height of the room.) It is no secret as in new, and in the long-existing buildings, the bearing plates are crooked, so the thresholds or noticeable height differences are formed throughout Square. Such a base should be aligned. The budget option is to pour the sand layer, more costly - to lay a cement-sand tie, the most expensive - use a self-leveling mixture.

Working with mineral wool materials indoors should be in clothing with long sleeves, headdress, gloves, as well as in a multi-layer gauze bandage or respirator. With properly organized ventilation, dust becomes much smaller

Then, on the prepared dry base (in wet rooms, it is pre-protected by a layer of waterproofing) lay insulating material. In addition to low thermal conductivity and good sound insulation indicators, it must have a small degree of deformation during compression, and most importantly - to maintain all these properties for a long time. After all, the design of the floor, including isolation, during the entire operation is exposed to increased mechanical loads. Punching insulation materials can be used, for example, the "IsOver floating floor" plates ("Saint-Goben Construction Products Rus", France - Russia) with a pinned edge (dimensions - 1380 1190 20mm, price 1m- 117rub.), Flor Batts ( Rockwool, Denmark - Russia; 1000 600 25mm, price 1m- 240rub.), Glasswool P-60 (URSA, Spain - Russia; 1250 600 25mm, price 1m- 130руб.), Penopelex Type 35 "(Penopelex, Russia ; 1200 600 30mm, price 1m- 130 rubles), Izora cork panels (Amorim Isolamentos, Portugal; 1000 500 20mm, price 1m- 360rub.).

Opinion of a specialist

The value of the air noise isolation insulation index in multi-storey houses meets the requirements of SNiP 23-03-2003, if their thickness is at least 220 mm. But if they do not have the necessary damping characteristics, a knock of the heels and a ringing of broken dishes, a knock of closing doors (shock and structural noise) will be loud echoing from the neighbors from the bottom and spread over all other house designs. Therefore, the desire to soundly insulate the floor is natural for every sensible person who wants claims to be smaller. However, the design of a "floating" floor, improving acoustic comfort, reduces the height of the room for several centimeters. For those who seek to minimize losses, it is worth using soundproofing plates with a thickness of only 20 or 25mm. They are in the assortment of many large manufacturers of insulating materials. For example, if you apply the 600,200 25mm 600 25mm rigid slabs as a sound insulation layer in the design "floating" screed, the value of the exposion level of the shock noise under the overlap decreases by 35DB (according to the results of the tests in the establishment of building physics).

Tatyana Andreeva, Technical Director of Rockwool Russia

Tightly laid, without gaps and slots, insulating plates are poured by a "wet" cement-sand tie with a thickness of at least 4cm, be sure to reinforcing it with a metal grid or a facade glass. After all, it is the screed that will perceive the load on the floor. Porous materials are pre-covered with polyethylene or geotextile with overlap of cloths at least 20cm. If this is not done, the wet mass leaks into isolation and will freeze in it, which will lead to partial loss of the calculated characteristics.

The role of a hard carrier layer over elastic insulation can also be performed and "dry" screed of sheet materials: plywood, gypsum or fiber sheets, oriented service plates IT.P. They are placed in two layers, fastening with glue. The result is a solid surface formed over the insulating material, which will serve as the basis for the flooring of any finish coating.

|

|

|

|

|

Warming of concrete overlap in the apartment "Flor Batts" plates (Rockwool):

A - Before the insulation of the floor, the defects of the reinforced concrete plate and the height differences exceed 1cm are eliminated. Then prepare the required amount of material. It should be equal to the entire area of the room with the addition of 10% on trimming. If the room has a complex geometric shape, the insulation material is taken from 15-20% incentable. The perimeter of the room establishes soundproofing gaskets, sliced from the plates "Flor Batts" with a thickness of 25mm, a height equal to the overall thickness of the "floating" floor structure (thermal insulation + screed + flooring);

B - Installation of pads and plates lead in parallel: First, narrow strips of material are installed along the walls, and then they are pressed with insulation plates;

In - Properly laid stoves necessarily have disintegration of the seam;

G - to reduce the time of repair and get away from the "wet" processes, instead of a cement-sand screed over isolation, it was decided to perform a "dry" screed of two layers of waterproof plywood (can also be used drywall or chip-fiber sheets, oriented chipboard). It is placed so that the seams between the sheets of the lower layer be sure to overlap the tops of the top. Layers of plywood fasten with self-drawing;

D - on top of the rigid base, the finish coating (linoleum) is placed and fasten decorative plinths.

It is extremely important that all layers lying on the insulation did not have rigid bonds with carrying overlap and not adjacent to the walls or partitions, and no matter how "floating" on the spring base, since the rigid connection creates conditions for the distribution of structural noise by constructive elements building. Therefore, around the perimeter of the room leave a small air clearance width of 10-15mm. It is filled with elastic foamed ribbon or insulating pads (usually from the same material that is used as insulation), and subsequently closed with decorative plinth.

Eh you, my lags, lags ...

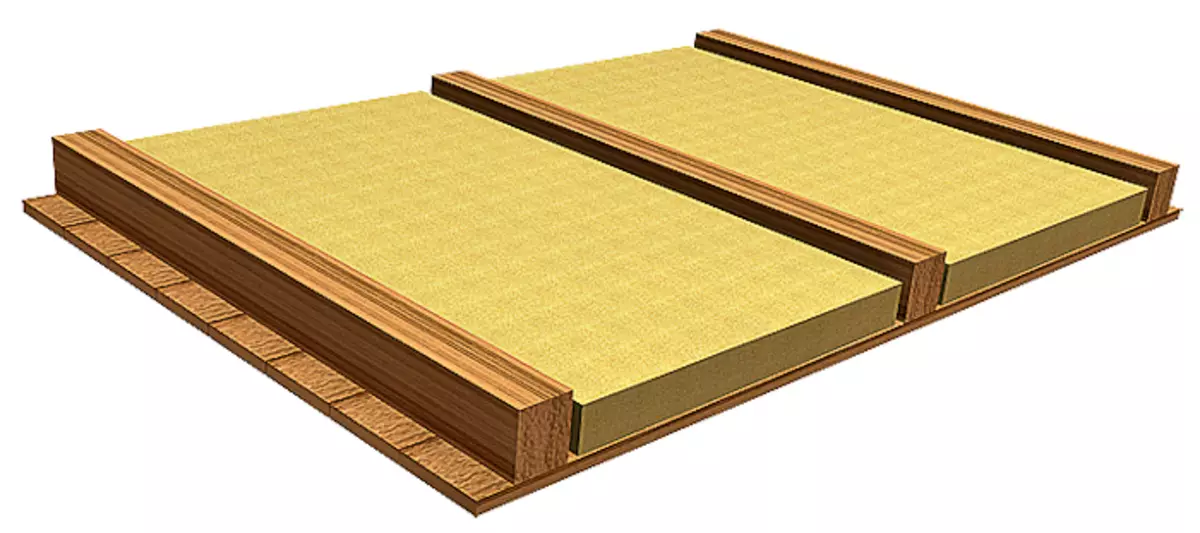

Overlapping on beams and wooden lags, as a rule, are found in urban buildings of the old building and private houses. Their heat and sound insulation does not require complex technological solutions and quite economical, because the material used does not experience mechanical loads - they take over only the floor design.

Wooden lags are first treated with antiseptic and fire impregnation. Then the insulating material is tight and without gaps put into the space between the lags. Not only tough plates are suitable for this, but also soft rolled insulation. For example, Materials "Thermo Roll" 044 Ecose Technology (Knauf Insulation, Germany - Russia; Dimensions - 1200 7000 (2 50) mm, Roll price - 900 rub.), "Classic Plus" 50E (ISOVER; 1170 610 50mm, packaging price - 740rub.), "Light Batts" (Rockwool; 1000 600 50mm, packaging price - 550 rub.).

|

|

|

|

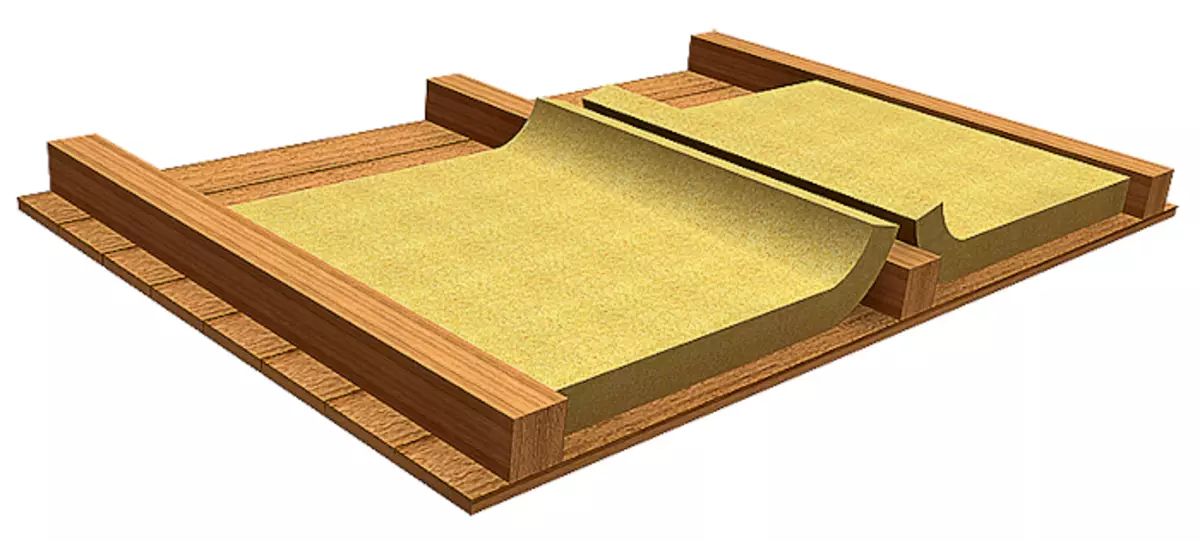

Typical errors when laying insulation by lags:

a - insulating material is too narrow, so gaps appear between it and frame design;

b - layers of insulation are not driven to each other and form clearances and cracks;

B - the insulating material is installed incorrectly and easily adjacent to the frame structure;

G - the width of the insulating material is chosen incorrectly, and because of this, the space between lags seems crowded

3D graphics N. Samarina

If under the overlapping is underground or other cold room, the thermal insulation material is necessarily protected from the bottom using the diffusion membrane. She does not give moisture to penetrate the insulation, but he releases couples from it. Moisturizing can occur if the temperature in the underground will be higher than on the bottom surface of the base (this situation is possible in unheated homes).

Between the first floor and insulation, it is also necessary to lave a vapor barrier film so that the moisture from the room did not hit the insulation. It is important that its joints and places of adjacent to the walls were hermetically punctured.

|

|

|

|

Warming overlap for lags Light Batts plates (Rockwool):

A - Plates of thermal insulation are installed by the versius between the lags. The stove has one spring edge, which provides fast and reliable fixation of the material in the design;

b - when laying thermal insulation in several layers of the seams between the top plates, with a displacement relative to the latter seams;

In - If there is a room under the overlap, the temperature in which is much lower than in the insulated room, the plates are covered with a vapor barrier film. It is placed close to the insulation and attach a construction staple to lags. If the height of the lag is equal to the thickness of thermal insulation, the rails are stuffed along them so the air clearance formed over the insulation. When in rooms above the overlap and under it there is no large temperature drop, vaporizolation is not required;

M - Mount the finish flooring.

So, if the masters accurately follow the instructions on the package, have the necessary tool and work skills, the qualitative result is guaranteed.

The editors thanks Rockwool Russia, Cork Center, Penopelex, Saint-Goben Construction Products Rus for help in preparing the material.