Wood furnace for a bath: the power of the unit, the main structural types of bath furnaces, solutions of the water heating problem, installation of the Kamenka stove

Well, we love to whine no less than the Finns and other northerners whine, and on our summer cottages as mushrooms are growing individual baths. The wake with them grows the demand for stoves-Kamenka, without which it is impossible to warm up the bath and prepare so necessary for the pair ceremony.

Para Recipe

Livative flame

Masonry furnaces in the bath today are rare. This is not only in the shortage of masters and the high cost of their services. Interestable, the masonry oven does not meet the modern rhythm of life and the idea of saving energy resources. To protruding with it with a bath, even in the summer it takes 4-6h and 60-70 kg of firewood. Celebration, especially in winter, a massive brick construction, if it is in a separate unheated structure, a week has time to accumulate as much cold, that only its own warming will be a whole day and a good fool of firewood. The same freak / thawing freaks will strongly reduce the lifespan of the masonry (it is well known that the brick today is not at all the one that was 100 years ago). In addition, it will take 300-600 bricks for the furnace (15-25 rubles / pcs.). Such a cost of work (usually 150% of the material price) The design will cost 37 500 rubles. By paying the same amount, without having troubles, you can buy a ready-made selection of economy class. However, we do not want at all that readers have the impression that the brick furnace consists of some flaws. She has dignity, which in certain conditions outweighs all the cons. This ability to accumulate heat during the furnace, and after its ending for a long time (up to day) to emit a "soft" radiation characteristic of the traditional Russian bath.

In today's days, most developers are preferred by metallic hemes, providing quick (from 40 minutes to 1.5 h) the heating of the room, easy to install and not requiring the foundation. In addition to wood-haired, there are electrical and gas units on sale. They are significantly less popular for several reasons. Perhaps the main one has rather romantic than practical, character. After all, without a living fire, without crackling, the lamps and light aroma of smoke, the bath loses part of its charms. Well, a pragmatist will noted that the electric heater will cost almost 2 times more expensive than wood and significantly increase electricity costs. To the same way, such equipment requires voltage 380V. As for gas stoves, their choice is very small, and not all homeowners are provided with the main gas (as well as three-phase current).

So, the palm of the championship belongs to the wood chain of factory production. More than ten companies are presented in our market, and even the most demanding buyer will not have to complain about the poverty of the range. But from which end to get to choose the "His" stove? It is possible from design or dimensions, but we first recommend deciding with the power of the unit.

ONLY / HARVIA. |

"Teplodar" |

ITS / HELO. |

ITS / HELO. |

1. Model 20 Pro (Harvia) is equipped with a cast-iron door, and the top wall of the furnace firebox is made of steel with a thickness of 10mm. Price, from 16 thousand rubles.

2. Oven "Rus" ("Teplodar") with a steam generator - from 8 thousand rubles.

3. Steel stove with stone facing safer in operation

4. Model 20 SL (HELO) with a tunnel for passing through the wall. Price, from 21 thousand rubles.

Tweet in Tweet

If the furnace will produce too much heat, the air in the steam room will heat quickly, but the stones will be only a little warm. The bath will have to coat, constantly conducting, that is, heating at his expense. But these are still half. It is much worse if, after buying and installing, you will find that the stove power is insufficient, the temperature in the steam room does not want to rise above 50 s. After all, in this case it will be necessary or additionally warming the bath, or to acquire a new unit and the other means a considerable amount And the postponement of the start of the "Ban Season".The power of bath furnaces varies within 6-27 kW. This technical characteristic is usually contained in the product passport (if not, it should be found out from the manufacturer). There is also an indication of the minimum and maximum volume of steam room, which can be heated with the device, for example 8-18m3. However, this does not mean that the furnace is equally well suitable for all rooms with a cubage stacked in this range. The manufacturer's recommendation is more likely to read this: the furnace is suitable for heating a very poorly insulated pair of 8m3 and a very qualitative insulated volume of 18m3. To evaluate the heat-insulation of the steam room and not to be mistaken with the choice of the power of the device, it is better to take advantage of the following table and take into account when calculating that the glass door will require an increase in the cabin cabbage to 1m3, and each square meter of windows overlooking the windows with double-glazed windows.

Opinion of a specialist

As stones for bath furnaces, the most affordable, peridotitis, basalt, diabases (cost 20kg - 300-400rub.). More beautiful and heatmate talco chlorite is somewhat more expensive - 800 rubles. For 20 kg. There will have a high price will have to pay for a greenish semi-precious jade (similar to jade stone with a fine-grained structure) and white quartz (it is also called hot ice) - up to 1400 rubles. For 5kg. When choosing stones should pay attention to their size (it must be specified on the box). The optimal fraction for a small furnace (up to 12 kW) - 8-12cm. Stones are laid in such a way that the area of their contact with the walls of the furnace was maximum: down-larger and flat, supernissed. At the same time, it is necessary to leave the gap between the stones for free air circulation.

Andrei Slavnov, Chief Engineer of the Construction Department "Group of Companies 95 C"

Lights in the furnaces ...

The most common type of bunny stoves is steel double, that is, having a firebox and a casing. Due to such a design, the external surface of the unit retains a safe temperature, and at the same time, the air circulating between the walls quickly warms the room. Some models - in particular, KO-20, KH-20, KT-S-20, KT-H-20 (Kastor, Finland) are equipped with an additional intermediate casing; The temperature of the outer wall in these chairs never exceeds 60 C.

The furnace is made of steel sheets using electrical or argon-arc welding. The durability of the aggregate depends on the thickness of the steel and its brand, so you must ask you to ask these characteristics. Heavy steel stainless steel should be applied (AISI 310, 316, 321 stamps) with a thickness of at least 2.5mm or carbon housing 4-5mm thick. A number of manufacturers, including HELO (Finland), increases the thickness of the walls of the firebox in those places where the impact of the flame is most intensively, with the help of linings to 6mm thick.

The furnace detail is the stones container, embedded on the top or side, the larger the area of contact with the stones with hot steel surfaces, the better. The casing is usually made from half amelimetime stainless steel or "black" steel 1-3mm thick and covered outside the heat-resistant enamel.

Strain of steel furnaces implemented the principle of grate combustion. The air in the furnace is reduced from below: it passes through the axle door of the ash box (or the holes done in it), and then under the influence of the thrust, it rushes up through the slots in the grade grid, on which firewood is lying. You can adjust the intensity of burning, putting forward / shaking an intrinsic box or manipulating the flap on its door. Since the grate is in the zone of the highest temperatures, it must be made of cast iron. In grate, it is possible to quickly reach the real heat, however, a significant part of the heat due to severe thrust flies into the smoke tube. There is another minus, even special steel during operation in such conditions are subject to scale formation, and over time the walls of the firebox are thinned. Some manufacturers in the desire to facilitate and reduce their products (without a decrease in service life) retreat from the classic scheme. For example, the factory "Feringer and K" (Russia) has released a challenge line without gratepin, with the so-called upper ignition. The burning in them occurs on the courtyard, and the air is fed through the slot in the upper part of the furnace door. True, it should be considered that the room, and the stones such a furnace heats somewhat slower than grate.

"Warm stone" |

ITS / HELO. |

Tulikivi. |

EUROSTROY SPA |

5. Modern version of Bath "in black". Instead of chimney, the furnace is equipped with a smoke

More interesting and, in our opinion, the development of Harvia engineers (Finland) is successful - model Green Flame. Its design provides for automatic control of the direction of the air flow for combustion: during the ignition, the air enters the lower part of the furnace when the firewood flared up to the top, and after they run out, all the air intakes are closed with dampers, thanks to which the furnace cools slower.

Heat the heater from the steam room is not too comfortable. It is more handy to do this from the pre-banner, where it is not difficult to find a place for firewood and furnaces, plus it is not necessary to solve the air supply problem for combustion. Some stove models allow you to remove the remote element (tunnel) through the wall in the pre-banner. Its length is usually possible to adjust in the range of 100-200mm. Of course, such a tunnel is allowed to embed only into the walls of non-combustible materials.

Many modern chambers have a heat-resistant glass door, and some models with a tunnel are equipped with the same "porthole" on the back wall, and you can admire the flames of fire not only from the rest room, but also from steam rooms, in particular, "Kalina" ("Thermophore"). Even more comfort will provide KT-S-20 furnace (Kastor), equipped with two full-fledged doors on opposite walls, "thus see the flame, as well as throwing firewood and adjust the burning intensity will be possible from two rooms.

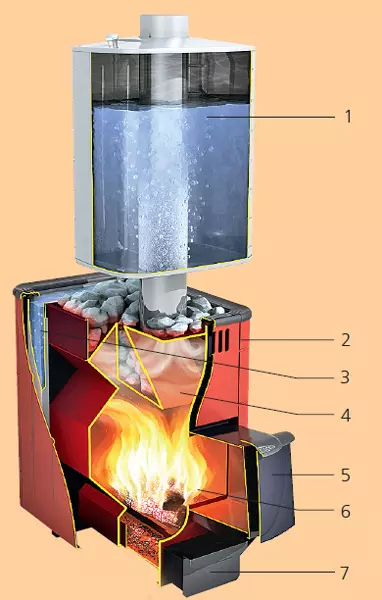

1- mounted tank for water;

2- casing;

3- built-in tank;

4- Capacity for stones;

5 - passing module with door;

6-furnace;

7-rally box

AESLI HEAGE?

A steel furnace with a stone frustration weighing 20-40kg quickly heats up, but also cool and cooled. Akak to be if you have a big family or are you not away to invite "on the bathhouse" guests? After all, then the high temperature in the steam room will have to be maintained within a few hours. Of course, it is possible to throw firewood all the time to the furnace, but it is pretty troublesome, and moreover you risks steps. To arrange bath days, a massive oven is necessary, a long-storing heat. Ivse would like to be heated by it faster brick, served longer and looked more attractive.

One of the possible solutions in this case is a steel aggregate with a lattice casing. Such a design is designed for snowing a large mass of stones between the walls of the furnace and the outer grill made of steel rods covered with heat-resistant paint. Such, for example, Legend 150, Legend 240 and Legend 300 furnaces (Harvia), allowing heat, respectively, 120, 200 and 260kg stones. In this case, the mass of the stones can be increased by 20-40kg, buying a lattice fence for the first chimney module. (It is worth taking into account that in a wooden floating bath for a similar furnace, the foundation may be required!) External stones are not heated too much, which makes the furnace is quite safe, but it is capable of storing heat at least 3h after the end of the furnace. The cost of the instruments of this type starts from 15 thousand rubles.

We need to refresh yourself

Supply-exhaust ventilation in the steam room is simply necessary. First, to be able to adjust the humidity and temperature during the procedure. Secondly, to ventilate the room after the end of the session; Without this, the walls of the walls and the board of the regiment will begin to rot intensively. Finally, if the furnace hole and pondered the furnaces go into the pair, it will take to organize a flow of fresh air for combustion (but in this case there will be a need for extractor). For fresh air, the opening is made in the floor or wall (not higher than 0.5 m) in the calculation of 5 cm2 to 1m3 the volume of the steam room or leave the gap 1-3cm under the door web. The exhaust hole is usually located on the ceiling; The area of its cross section should correspond to the area of the section of the supply hole. The optimal system will be the system of forced exhaust ventilation, at which the exhaust channel is displayed across the floor and is supplied with a fan, - in such a way it is possible to constantly "pump out" the sauna is the most wet and cold air.

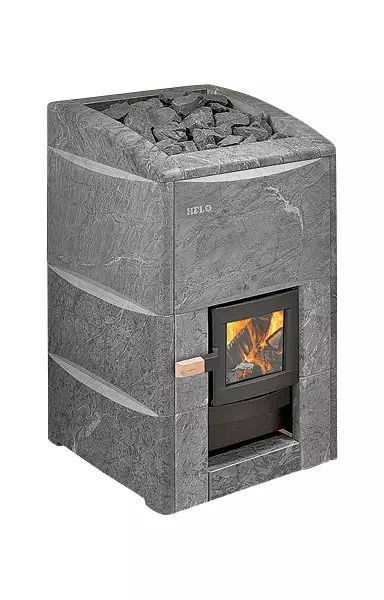

A number of manufacturers offer furnaces with facing from sawn-talco chlorite. Thus, the firm "Warm Stone" (Russia) produces stainless steel furnaces, complete with facade talco chlorinated plates and angular modules that are mounted without the help of glue, inserting holders into the grooves on a small (20-50 mm) distance from the walls of the furnace. The clearance is necessary, firstly, to compensate for the thermal expansion of the metal. Secondly, thanks to this solution, the furnace retains all the advantages of a double design: the outer surfaces are not split, and the room almost immediately after the extracts begin to warm up to convective air flows. Similarly, the products of the company "Injcomcentre VDD" (Russia) are arranged. True, they have a heavier cast-iron furnace, and the outer walls are made of rather thin tiles. The mass of stoves dressed in stone is usually 200-400kg (a column foundation may be required), and the price starts from 60 thousand rubles. Some serial models of Harvia, Kastor, Helo can also be purchased from Talco chlorite, that is, a 10-14 kW cutting oven will cost about 60-75 thousand rubles).

The most massive factory-based bath furnaces offered on the market of bath furnaces are assembly kits from talco chloro modules. To the domestic market, they are supplied by Tulikivi (Finland). Such chains have a lot of 500kg and require the foundation. They are collected in place with a special glue. The cooler and the firebox door are made of cast iron. The cost of modular furnaces - from 130 thousand rubles.

"Ermak-thermo" |

ONLY / HARVIA. |

"Typhoon" |

Tulikivi. |

9. The Legend model is equipped with a glazed cast iron door and adjustable legs. The grid casing is collected using decorative rivets and covered with heat-resistant paint. Price, from 22 thousand rubles.

10. The Legend model is equipped with a glazed cast-iron door and adjustable legs. The grid casing is collected using decorative rivets and covered with heat-resistant paint. Price, from 22 thousand rubles.

11. Model "Vesuviy Skiff" ("Typhoon") with a capacity of 18 kW is designed to bookmark 180kg stones. Price, from 15 thousand rubles.

12. The SK 950 (Tulikivi) model has its own mass of 930kg, and another 130kg stones fall asleep from above. However, due to the large volume of the furnace, the furnace is heated in just 2-3h. Price, from 134 thousand rubles.

Question water supply

Without hot water in the bath can not do. To wetting a broom and receiving a couple, it needs to be quite a bit more than 10l, but 40-60l boiling water will be required for washing. For a bath with a shower cabin, it is best to purchase a furnace equipped with a heat exchanger-small capacity built into the furnace and equipped with connections for connecting to the DHW system. There are also special heat exchangers operating as the first chimney module - by the way, they can be installed on any furnace. We can heat the heat exchanger for 1 h. It is possible to heat the 80-200l water to 60 C. All would be good, but such units can not be dried "dry": the thin metal of the heat exchanger under the influence of the flame "leads", and the welds disagree. This significantly makes it difficult to exploit the oven in the winter, because every time you have to pour water into the system (first - warm so that the pipes do not "grab"), and at the end of the day it is to drain it.If there is no soul, you will have to wash in the old way, right in the steam room. Then it makes sense to purchase a furnace with built-in or mounted (installed on the oven or chimney) water tank. The tank of 25-30l with economical spending is enough even a large family. The lack of one, when boiling water in the tank, the room fills the saturated steam, and it becomes impossible at high temperature at high temperature. However, modern aggregates with a welded tank can be stirred and without water. But every time you have to choose: to bathe or wash. Or drown the furnace 2 times with a break, as it is impossible to pour water into the hot tank.

Session from professional

First stage - Preparatory. Melt the furnace, an hour before the start of the procedure, turn the broom (for this hear the water up to 60 s; I advise you to add the infusion of propolis - 30 g by 10l). Do not forget to boil tea or cook Morse, cook light vegetable or fruit dishes, stock towels, hatches IT.D. Immediately before entering the steam room, take a shower.

Second phase - Were warm the body. The temperature in the steam room is about 85 s. It is better to warm up in several occasions of 5-10min.

Third stage - Inhalation and aromatherapy. At the same temperature, the scents of clean water on the stones (otherwise the smell of Gary appears), and then the infusion of broom, healing herbs or the solution of aromatic oil (several drops on the bucket). The waging of 10-20min breathe a healing steam.

Fourth stage - Warning. Carry the steam room, lowered the temperature to 60-70 C. There is a time to drink a cup of coating tea in a pre-tribbon. After that, you can start steaming by a broom. First, with light movements capture steam from the ceiling and send to the body, almost without touching it. Everyone is appropriate to all familiar to the "Circuit" with a broom.

Fifth stage - Final. Take a shower and drink tea.

Around the focus

When installing a bath furnace will need special attention to the issue of fire safety. At all of the 41-01-2003 "Heating, ventilation and air conditioning" are minimal distances from the inner walls of the furnace and the chimney to unprotected combustible structures - 500mm and to protected - 380mm. However, the question in the document is about a brick heating furnace. Whether these norms are applied to modern steel baths, it is difficult, so when they are installed, they are often focused on manufacturers' instructions in which the installation distances may vary in fairly wide limits (250-1300 mm) depending on the power and design of the product. In love, the case of the wall and the ceiling next to the furnace is better to protect with the help of a thermally insulating "sandwich". For example, in this way: to scout with the wall with self-drawers, a gypsum fiber plate, then glue it with a cement-based tight slab from the stone wool Firebatts (Rockwool, International Concern) with a thickness of 25, 35 or 50mm. Plate jokes should be closed with aluminum scotch. On top to glue another layer of GVL and bind it with an artificial or natural stone. Another variant of asbestos cardboard and cement-fibrous stove LW SAUNA (Minerit, Finland). Some manufacturers of furnaces, in particular Harvia, offer special protective screens to separate models made in one style with a stove. Steel Kamenki Specialists recommend before installing to protrud on the street, so that the oil is burned, which inevitably remains on the metal after rolling, and harmful volatile compounds have evaporated from the paint coating.

ITS / HELO. |

Kastor. |

Raab. |

13, 14. Facing furnaces from Talco Chlorite: Hiidenkivi (HELO) (photo 13) - from 76 thousand rubles. and KL-20JK (Kastor) (photo 14) - from 60 thousand rubles.

Will Conclusion - a few words about chimneys. As a rule, bath furnaces are designed to install a modular steel chimney. It is better not to save on the chimney, since fire safety directly depends on its quality. It makes sense to purchase double-circuit stainless steel modules with stainless wool layers (cost 1M pipe, from 1800 rub.; Price of shaped elements, from 1200 rub. For 1 pc.). For the passage of overlaps and roofs, it is better to use ready-made solutions offered by the chimney manufacturer. Most bath furnace manufacturers produce chimneys. Soda side, not necessarily buy the whole kit from one company, since the diameters of the smoke pipes are standard- 115 (most common), 120, 130 and 140mm. Solid side, it should be noted that the real diameter of the pipes on the ends, due to the features of the connection of the docking unit, in different firms may vary 1-2mm. It is not scary if the pipe will be a large joint can be sealing asbestos cord. Worse, if she does not want to "sit" to the oven. Therefore, when buying it is better to have a caliper with you.

1- module for condensate removal;

2-tee for connecting to the heating unit;

3- bracket for mounting to the wall;

4- cleaning;

5-tie clay;

6- pipes;

7- umbrella-deflector

Extremely durable chimneys from ceramic pipes. In the domestic market, they are mainly represented by SCHIEDEL (Germany). These are modular systems in which the inner tube is made of the burnt chamotte mass and has a wall thickness of 8mm, and the shelter is from light concrete, between the basalt wool layer.

The dependence of the power of the furnace on the design of the walls of the bath *

| Design of walls | Power for 1m3 volume of steam room, kW |

|---|---|

| Laying in a brick one and a half without additional insulation | 2.5 |

| Bar 100100mm or logs with a diameter of 150-200mm without additional insulation | 2. |

| Bar 150150mm or logs with a diameter of 220-300mm without additional insulation | 1,8. |

| Brick or timber (log) wall, warmed by a layer of stone wool 50mm thick | 1,3. |

| Same with additional insulation of radiant heat with aluminum foil | 1,2 |

| Wall, warmed by a layer of stone wool thick 100mm, with additional insulation of radiant heat with aluminum foil | 0.8. |

| * It is understood that the floor and walls of the room are insulated with a layer of mineral wool with a thickness of at least 50mm. |

The editors thanks "Group of Companies of Companies 95 C", "Inzhkomcentre VDD", "ITS Sauna", "Teplodar", "Thermophore", "Feringer and K", "Ermak-Termo", Only for help in the preparation of material.