Technology construction of buildings from technoblocks on the example of the construction of a two-story cottage house with a total area of 124 m2

In this article, we will introduce readers with a relatively new and therefore not yet received a wide application of the technology of building buildings. Its main advantage is that the walls built according to her houses do not require additional finishes.

|

|

|

|

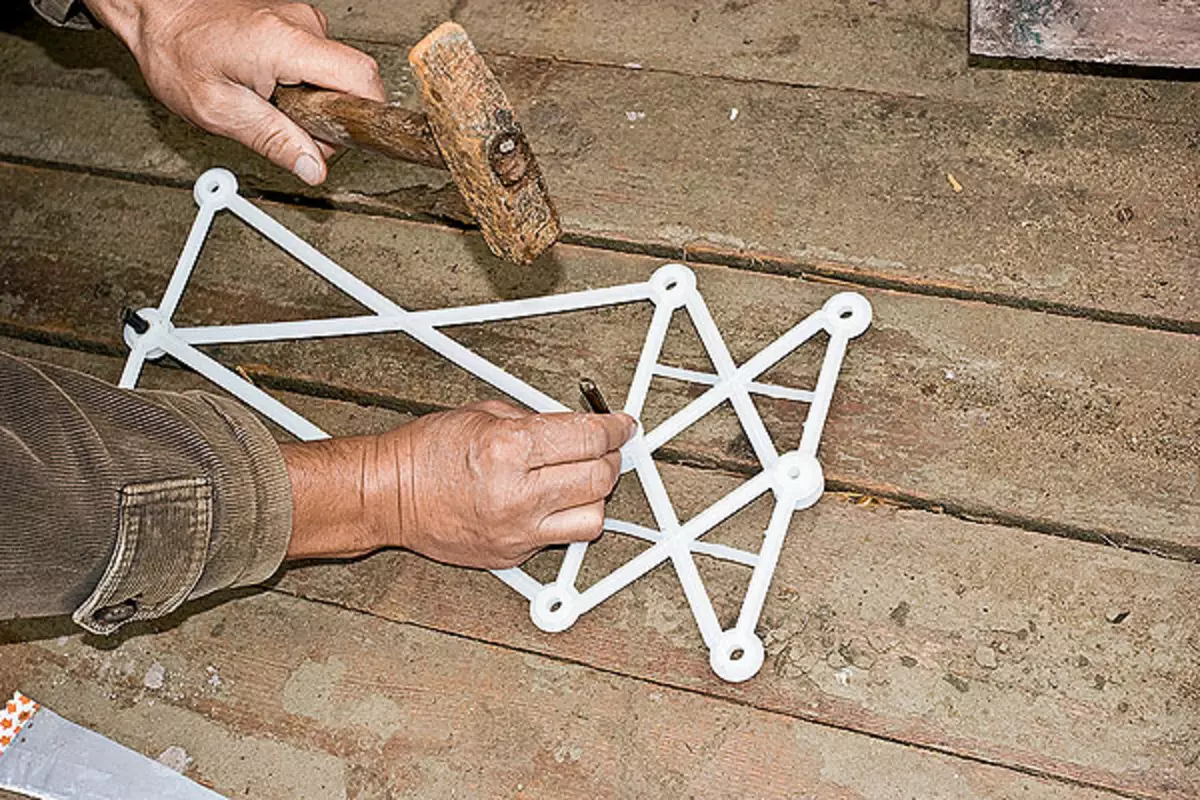

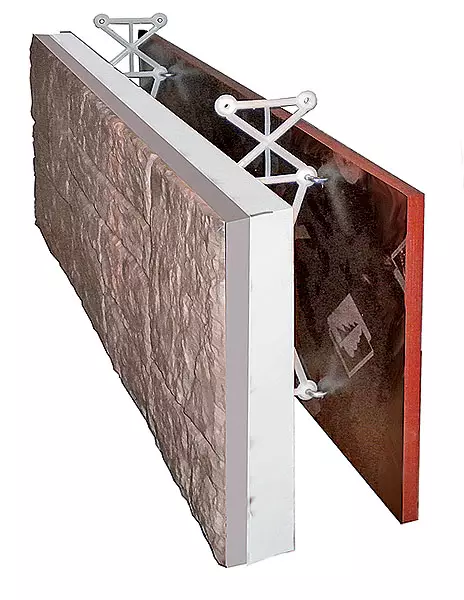

1-4. The sequence of the block assembly: the outer plate is placed face down and the foam polystyrene plates (1) are placed on the holes of the mixed nuts, then the holes are drilled in it. Using this stove as a pattern, manufactured the following, impose it on the outer plate and wrapped M-shaped hooks (2). Then screwed the hooks into the inner plate (3) and put on the hooks of both plates plastic ties. If a block is needed more than standard, the screeds are connected to each other rods (4)

Let's think about the finish of the built housing often costs such an amount that it is simply a diva, it could take the building at least 1/4 more building for this money. Ima tighten the belt tighten and agree on these costs, how do not make a worthy house that you dreamed about so long? Do there exist construction technologies that give the opportunity to do without additional decoration of the walls of the built home? It turns out that engineering thought does not stand still. Not so long ago there was a technology that allows you to build a building, the walls of which will be immediately finished both outside and from the inside. She was named by the name of the element that makes the basis of the wall structure - "technoblock".To believe in a fairy tale

And everything began, as in a fairy tale. There were two brothers. They argued like all the boys, and even fought, but then necessarily put up, they played together and dreamed. Instantly close people, the brothers grew up that even in the mature age of dreams they had the same. For example, everyone wanted to have its own home. It is just a house, and the construction of which, if using modern terms, it would be very economical. Approxy saying to both in a fairy tale, and you can settle.

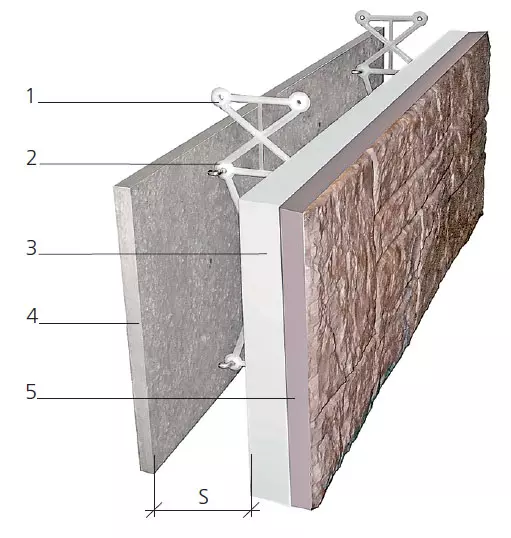

Facial formwork module design:

2-g-shaped hooks made of galvanized steel, for which ties engage (hooks screw into mortgage nuts, filled into facing plates at the stage of their manufacture);

3-stove of polystyrene foam (50mm);

4, 5 - internal (4) and outer (5) facing plates from vibrolyt concrete having various textures and coloring.

The distance S between the two walls of the block (the thickness of the future concrete wall) can vary with increments of 5 cm in the range from 15 to 30cm due to the use of M-shaped hooks of different lengths and a sequential connection of several plastic screeds.

For a long time, this dream was not possible, did not know the brothers, as in reality to build such a house. But once, having visited the enterprise producing paving and facing tiles, they suddenly understood: here it is, the long-awaited solution! We take two large, decoratively decorated facing plates, install facial planes in different directions, at some distance from each other, bonded with each other - and we obtain the finished block of the non-removable formwork with the already decorated surfaces (technoblock). We collect the wall from such blocks, pour into the concrete and please, before us completed the design. You can sit down and live.

|

|

|

|

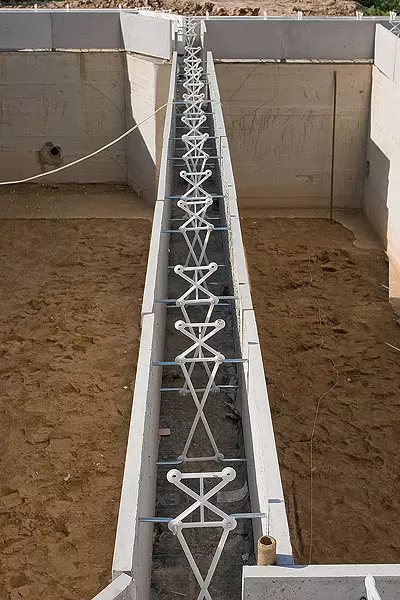

5-8. The first number of external technoblocks are installed on the surface of the foundation, ranging from one of the corners of the house (5). After layouts, determine which parts of the internal plates of blocks at the corners and in the erkers (6) must be cut off so that they do not "cut through" the future concrete wall. Then the "excess" is cut off. The blocks are thoroughly aligned both horizontally and vertically (used lining), tightened with a knitted wire, after which the inner wall of the wall is poured with concrete. Internal bearing walls (7, 8) are also manufactured

How long was the brothering technical solution for fastening the elements of the block, hardening additives for concrete and the method of insulation of the design, the story is silent. But only as a result they received Patent RF N 2342502 dated December 27, 2008. And even organized their own small production of blocks. Well, what do you say? It turns out that if firmly believing in his almost fabulous dream and attach to this faith's own experience and knowledge, the fairy tale may well become a better.

Dreams and reality

Each technoblock consists of the facade and internal vibrating concrete plates of 100x 403cm (such dimensions make it easy to make window and doorways). They are connected by screeds fixed on metal hooks. Frost resistance of the concrete-f 350 used, compressive strength is 45 MPa.

For the insulation of walls inside the technoblock (its width, 26-39cm), both one and two plates made of polystyrene foam 50mm can be installed. When installing one plate (it is closely pressed against the outer plate of the block) the resistance to the heat transfer of the finished wall (the thickness of concrete - 200mm) is 1,6m2 x C / W. Arad sets of two (the second plate is closely pressed against the inner plate of the block) - 2,8m2 x C / W.

What cutting tool to apply?

The texture of the outer and inner plates can be different: smooth, resembling a brickwork or from wild or treated stone. Coloring also differs in variety - the choice is offered 90 colors and drawings, including imitating marble and malachite. The blocks are delivered to the construction site into a disassembled form (this makes it possible to significantly save on transport costs). Collect them before installing in the wall structure. The price of "set" to assemble the block depends on the coloring and texture of the outer and inner walls and ranges in the range of 500-920 rubles.

|

|

|

|

9-10. To create a formwork, adjustable racks applied from the monolithic concrete to the basement of the monolithic concrete, they laid "lags" (9), and on top were made of solid flooring from waterproof plywood (10). Punching of the side walls of the formwork was used by wall blocks, in the internal plates of which the holes cut the bottom and started the ends of the ceiling fittings. When pouring overlap concrete, it raises these holes and "grows" with walls.

11-12. Window and doorways were performed as follows: the blocks of the row on the required distance were shifted, and their ends were covered with plywood held by a wooden strut (11). As the walls are gross, the "flap" and the strut was moving up (12). To create the beam overlap over the opening under the blocks of the row, they did a flat formwork

Practice of construction

We will consider the practice of building buildings from technoblocks on the example of a country house, which built a private construction team hired by the owner, who first had a job with this technology. Produced and delivered blocks, and also carried out technical advice from our town (Russia). It must be prevented that the main one can be seen in the photos and accompanying their signatures. AB Text Articles We will only tell me about what remains, as they say, for the scenes.

The house was erected by four people, and only one of them was quite an experienced builder. Some confusion from them arose only at the first moment. But it was worth a consultant only to show how to collect a block and install it on a somewhat uneven surface of the foundation, and the brigade enthusiastically began to work.

|

|

|

|

13-15. Whether the design of the inner walls of the house, lined with standard plates, did not like the customer, whether he decided to just save on the blocks (had the right!), Only the inner walls of the first floor on the technology of sliding opahbka were erected. It was made of CSP sheets, which pulled them with threaded studs, inside the formwork they were hidden in plastic tubes (13). As the wall grows, the formwork was removed and rearranged above (14). On the second floor, the inner walls elevated from the blocks of cellular concrete, and a monolithic frame (15) was used as a force structure.

16. Despite the abundance of new technology for the construction of the foundation, the owner preferred to "classic" - a powerful construction of monolithic reinforced concrete. As a result, an extensive basement arose under the house, which the owner intends with the time to "obsoad".

To make it easier to raise blocks on the wall, the plates of the insulation and the hooks were installed in them yet on the ground, and the plates were connected to the ties with each other directly at the installation site. Putting the first and subsequent ranks of the blocks, they were aligned with the help of a lace. The accuracy of the horizontal installation was controlled using a level 2m level. Dense connection of blocks with each other in one row provide wire ties. They associate M-shaped hooks of neighboring blocks.

Technoblock and engineering communications

Having completed the installation of the entire row, the horizontal fittings of 12mm with a diameter of 12mm, which were put on the crosshair of plastic screeds, was laid into its inner space. Then in the places stipulated by the project, the tubes of ventilation and electric cabbage were laid inside the wall. After that, the M400 concrete was poured into the walls of the M400 concrete (it was made here in a small concrete mixer). After completing the installation of the first row, the blocks of the next row began to install the blocks in the same sequence. At the same time, the lower M-shaped blocks of blocks fastened in the top-ears of plastic screeds of the lower row towers above the surface of concrete. By the way, depending on the wishes of the developer, the adjacent rows blocks can be installed vertically above each other or with a dressing, as in brickwork.

|

|

|

|

17-18. The technology of creating overlaps of the first and second floors at the request of the Customer has made a small change, which reduce both material and labor costs. The side formwork was made only from the external plates of the blocks, attaching them to pre-stuck in the concrete wall reinforcing bar (17). After the casting of the overlap (its thickness is 200 mm), the internal blocks of blocks were attached to plastic screeds and continued the construction of the walls (18).

19. When erecting triangular frontones from blocks, collecting the next row, on both walls of the extreme blocks, the lines were noted along the border of the fronton. Then these blocks were filmed, disassembled, too much cut off, collected, installed in place and covered the cutting plates along the cutting line, which were attached to the hooks of the knitting wires.

20. On the "Earth" floor of the garage made a sandy pillow with a thickness of 20cm, a concrete tie with a thickness of 120mm was filled over it on top of it. The walls of the garage owner decided not to separate themselves - later they would just paint them.

Improving technology

Some results

Let them take advantage of the materials provided to us by the technology developer, but complement them by their comments. So, the new method provides the following advantages:

1) "allows you to implement any finished design solutions." In general, we agree with this statement. However, we note that when incarnation of any project, due to the need to customize blocks for the planned dimensions of walls and openings (and therefore cut them) the complexity of the process and the number of waste can increase significantly. Another case is a project made specifically under the "technoblock": it is the length and height of the walls, as well as the size of the openings will be multiple block dimensions. Reduction of cutting and waste and, therefore, a significant reduction in construction costs;

2) "It is possible to create a unique design of the facade of the building through the use of plates of different colors and textures";

3) "You can build fences and retaining walls in a single style with a house." Sethim statements will not argue;

4) "You can do without interior decoration." In principle, but provided that the inner plates of the blocks, as well as external, painted in various colors, their combination is carefully thought out, and the owner loves the interiors in the style of techno.

|

|

|

|

21-24. The creation of a rafter design began with the fact that the frontones were combined with a skate run of four cohesive boards 20050mm (21). Then the anchor bolts were attached to the walls and frontions of the strapping timber with a cross section of 150100mm (22). Stropile legs made from a bar of 150100mm (23). They were caught by the crate (bars 5040mm), to which they attached the moisture insulation film, and on top of it, and metal tile (24).

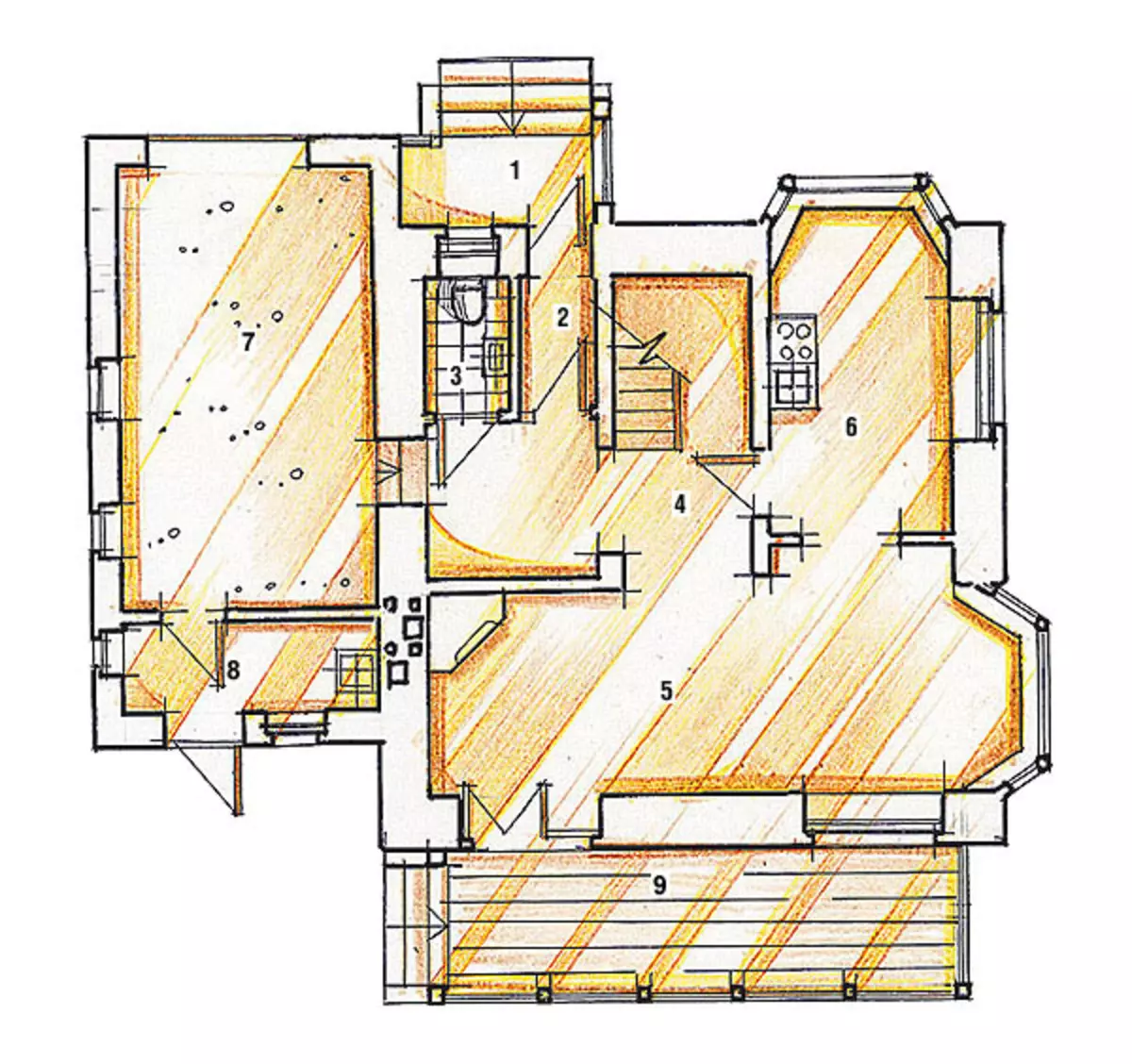

1. Porch 1M2

2. Tambour 2m2

3. Bathroom 1,7m2

4. Hall 9.7m2

5. Living room 25m2

6. Kitchen 11m2

7. Garage 20,3m2

8. 5m2 boiler room

9. Terrace 4,8M2.

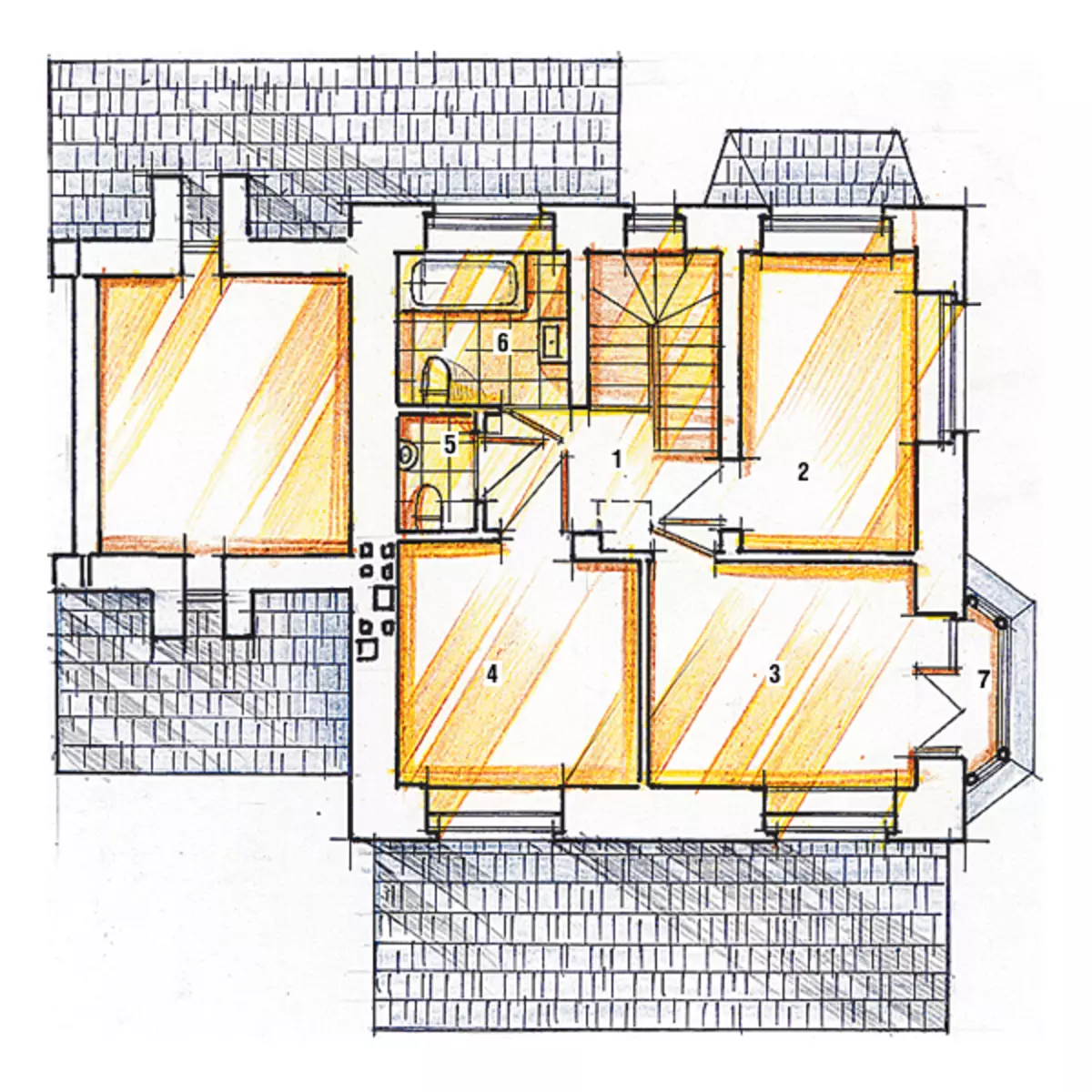

1. Hall 5.3m2

2. Bedroom 10m2

3. Bedroom 11,3m2

4. Bedroom 10.2m2

5. Bathroom 1,6m2

6. Bathroom 4,6m2

7. Balcony 0,4m2

Achto in general? In our opinion, this so far the little-known construction technology "technoblock" using a non-removable facing formwork is quite worthy of paying close attention to both professionals (designers and builders) and those who are going to build a house.

The enlarged calculation of the cost * construction of a house of technologists with a total area of 124m2 similar to the submitted

| Name of works | Number of | price, rub. | Cost, rub. |

|---|---|---|---|

| Development and garbage | 350m3. | 650. | 227 500. |

| Foundation base device | 32m3 | 420. | 13 440. |

| Foundation plate device | 28m3. | 4500. | 126,000 |

| Device of reinforced concrete walls and walls of basements | 65m3 | 4600. | 299,000 |

| Waterproofing horizontal and lateral | 430m2. | 370. | 159 100. |

| Installation of non-removable formwork | 350m2. | - | 235,000 |

| Device of reinforced concrete walls and partitions | 56m3. | 4600. | 257 600. |

| Collection of overlaps | set | - | 126,000 |

| Device slabs of overlaps of reinforced concrete monolithic | 52m3 | 4200. | 218 400. |

| Isolation of overlaps and coatings insulation | 360m2. | 90. | 32 400. |

| Hydro and vaporizoation device | 360m2. | 60. | 21 600. |

| Assembling roof elements | 160m2. | 690. | 110 400. |

| Metal coating device | 160m2. | 580. | 92 800. |

| Installing window blocks | set | - | 47,000 |

| Total | 1 966 240. | ||

| Applied materials on the section | |||

| Concrete heavy | 188m3 | 3900. | 733 200. |

| Gravel crushed stone, sand | 20m3 | - | 26 000 |

| Waterproofing | 430m2. | - | 77 400. |

| Technoblock, hooks, ties, insulation | set | - | 382 200. |

| Sawn timber | 20m3 | 6700. | 134,000 |

| Metal tile with bad peers | 160m2. | - | 138,000 |

| Window blocks with double glazing | set | - | 152,000 |

| Other materials | set | - | 186 600. |

| Total | 1 829 400. | ||

| * The calculation was completed without taking into account the overhead, transport and other expenses, as well as the profit of the company. |

The editors thanks the company "Our town" for help in preparing the material.