Massive Board Market Overview: Design Material Features, Factors Influencing Cost Costs, Quality Checking After Buying, Laying and Operation Rules

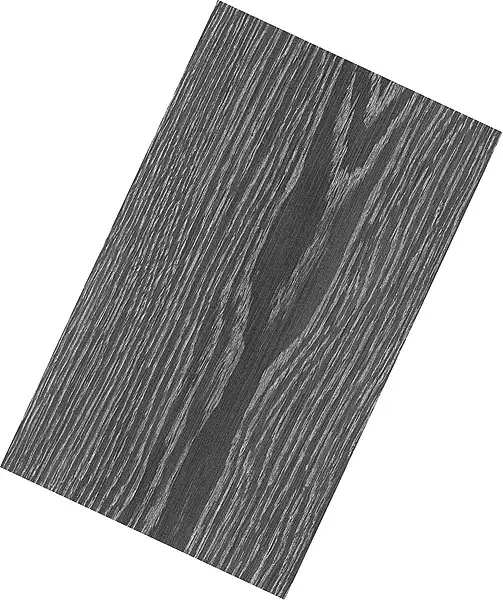

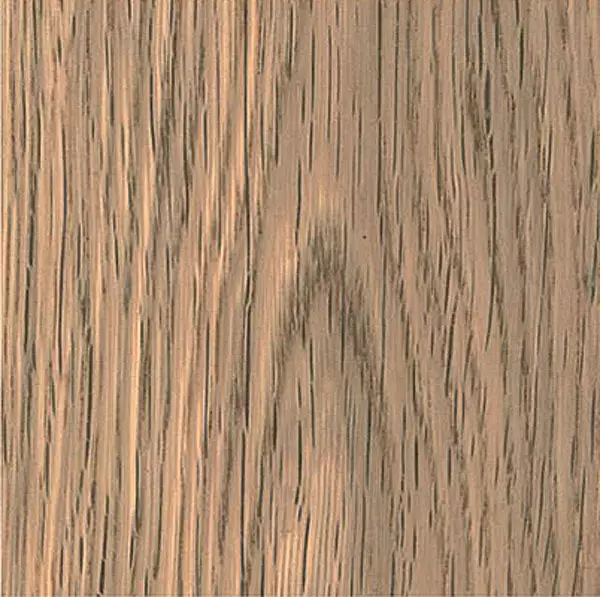

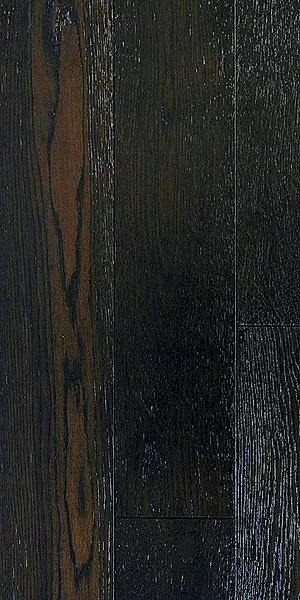

Massive Corsica (SolidFloor): Smoky oak with an underlined structure, Handling surface (3D) to a depth of 2 mm

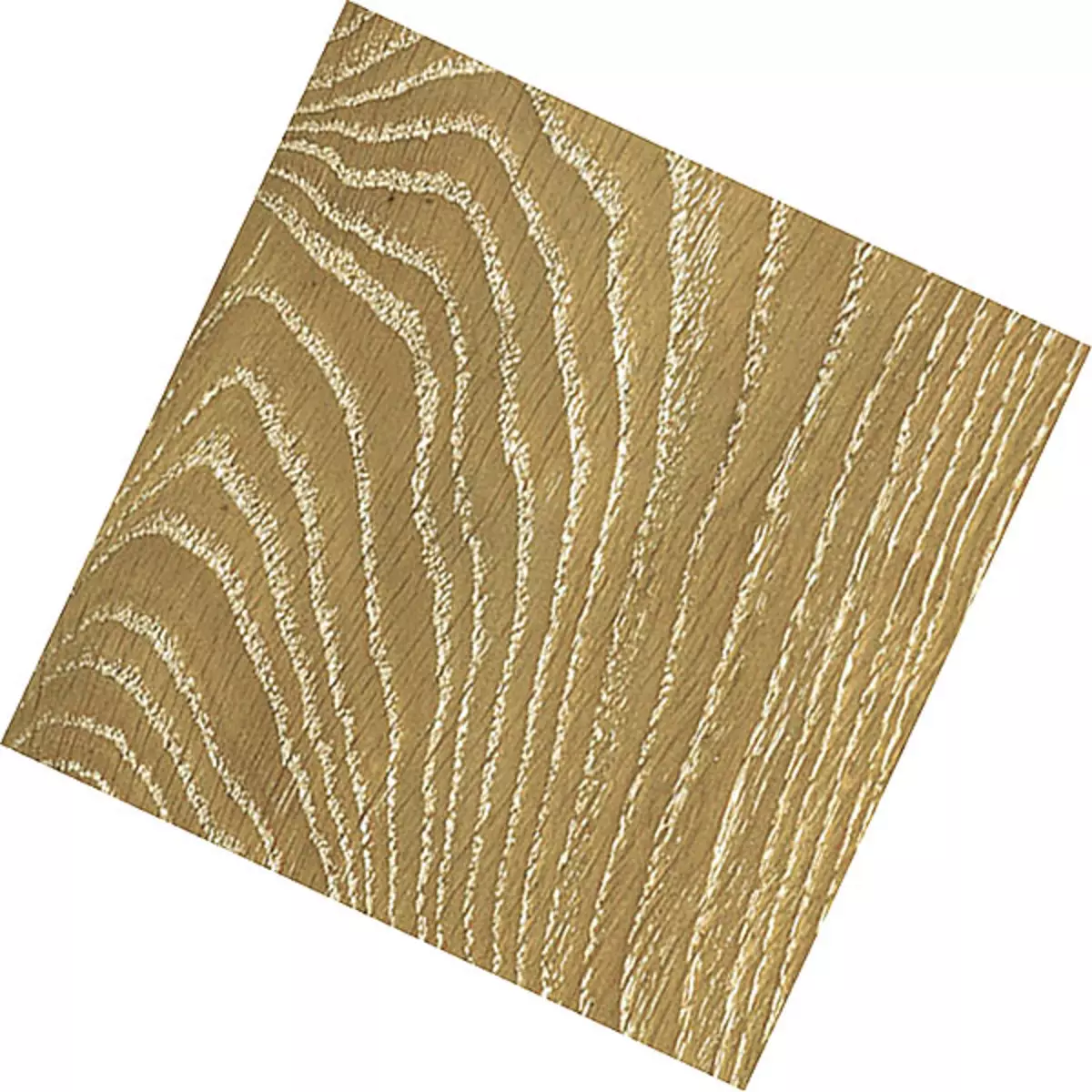

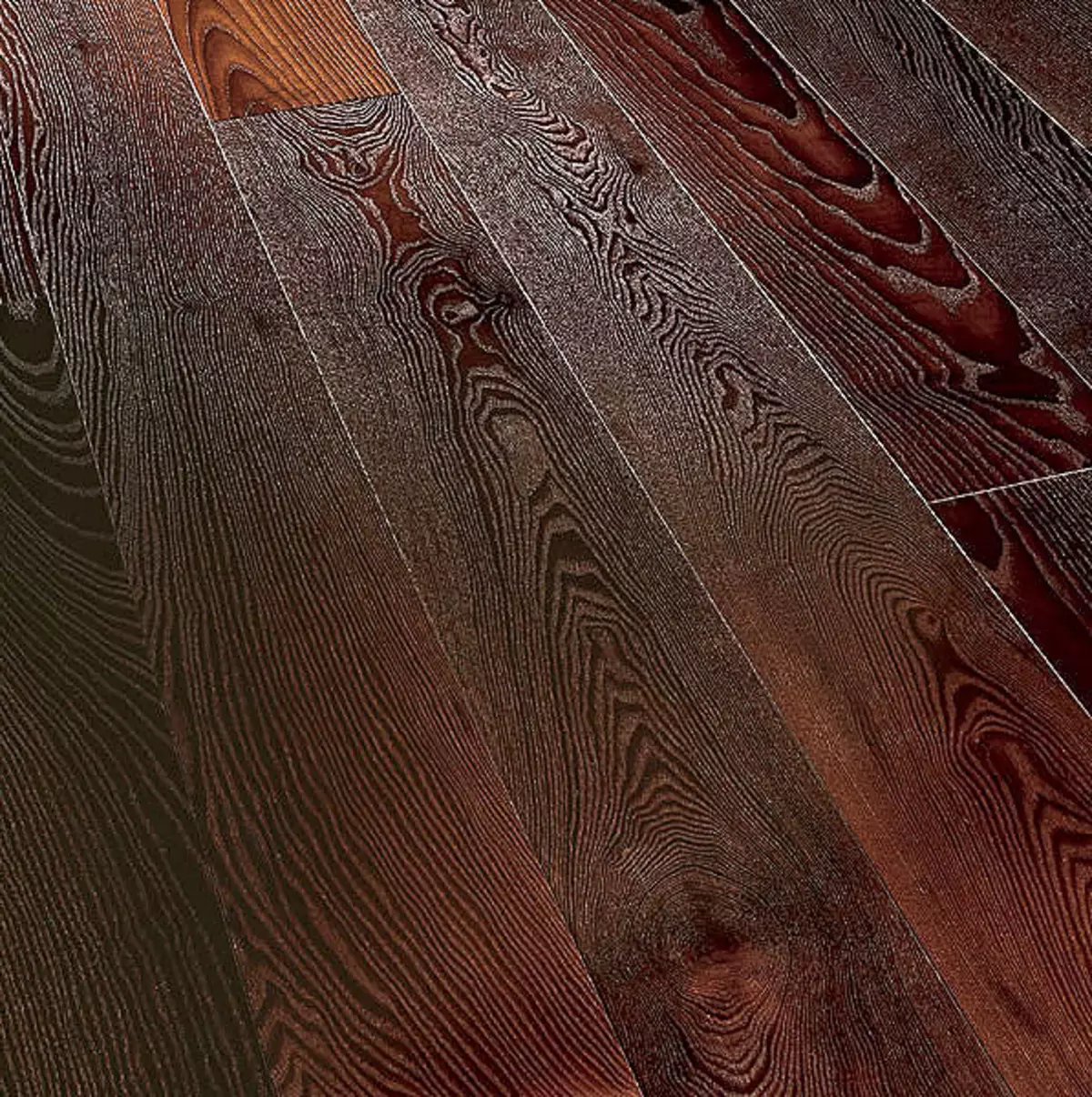

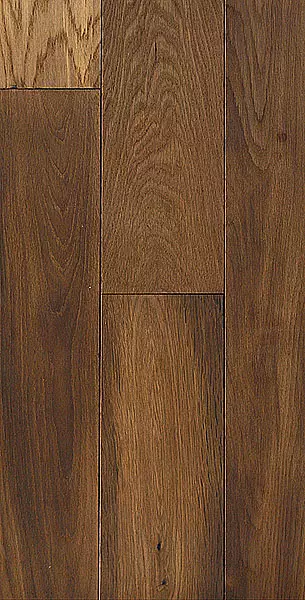

Massif Panmar from oak, manually, under oil

Kentwood strips used to be details of oak barrels in which the Japanese whiskey "Santori"

Unusual floors from bamboo-tree plant

The more short slats and transverse joints, the more crushing the room seems

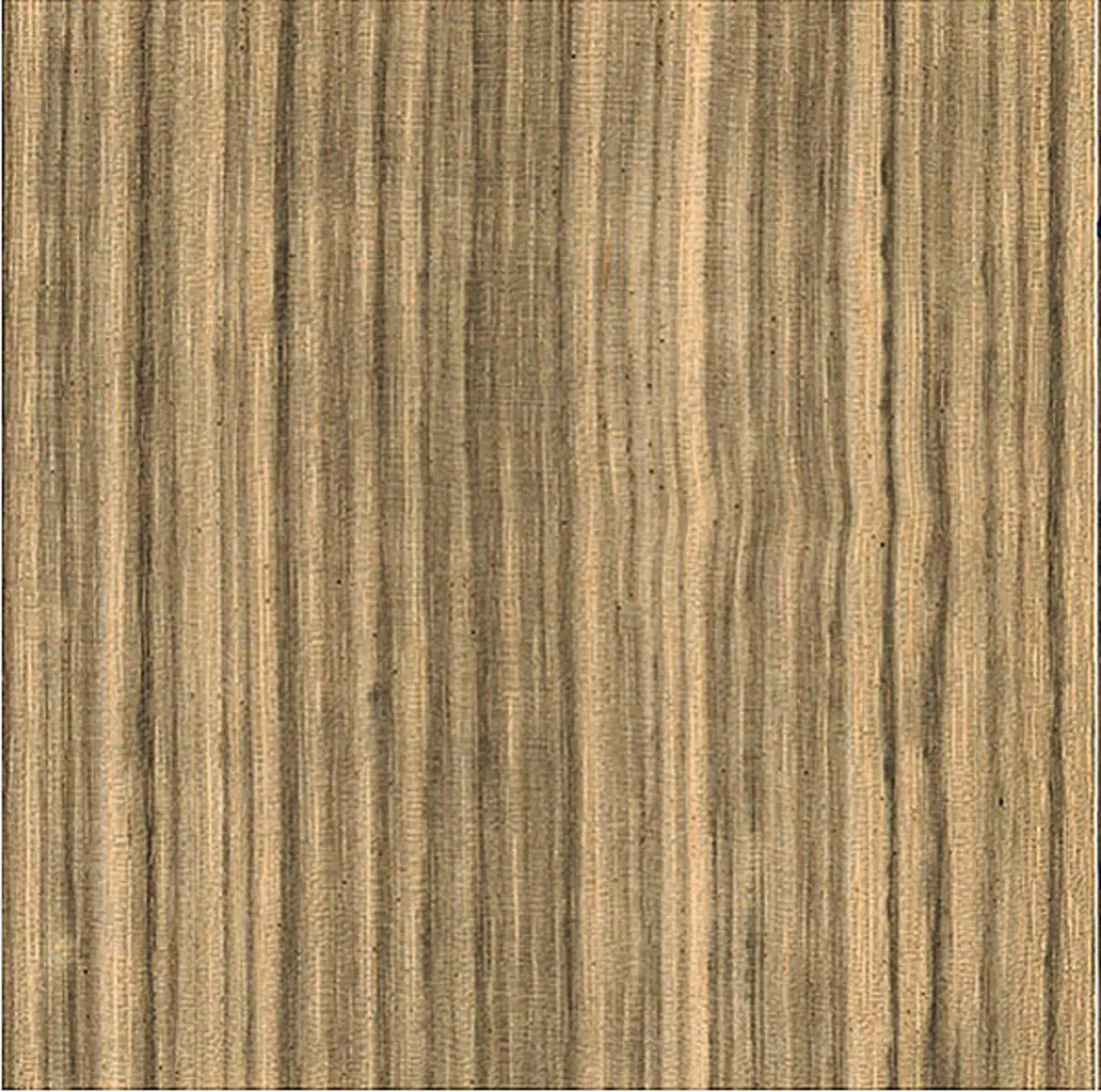

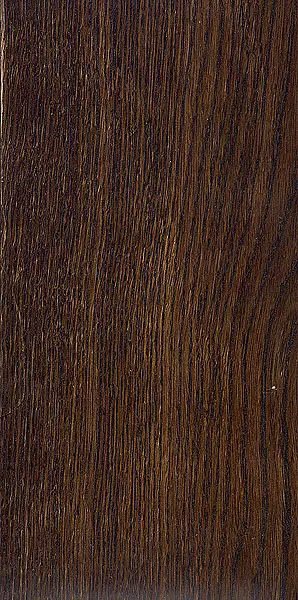

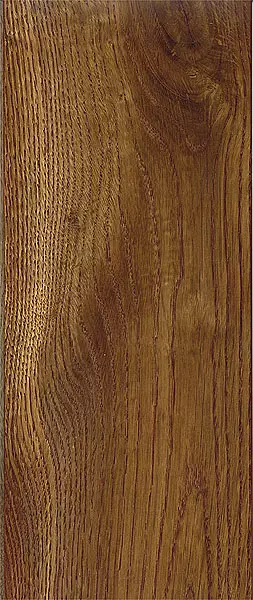

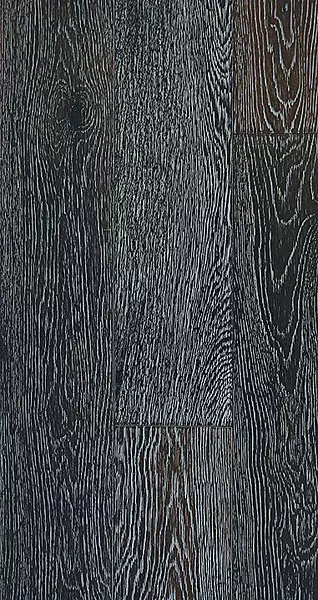

Brightly pronounced woody drawing emphasizes the natural beauty of the coating

White Oil Oak

Massive boards look most advantageously in spacious premises, not cluttered furniture

Oak SERRANT AND SAUMUR Collections (Panmar) Collection Boards with favors, brachified oil-covered OSMO

The floors from the massive board have low heat and sound conductivity, have high strength with a small mass. Over time, dents and scratches may appear on them, but they only add charming and charm

Lange Art Laying (Finex) includes elegant petals inserts and boards of different sizes. They are processed by pigments and smoke on the technology "Smok"

Original, but technologically difficult combination of ceramic tiles and massive board

Special equipment for the care of wooden floors will help keep their consumer properties and beauty.

Russians, time impacts who lived in log houses and who walked on wooden floorings, it would seem that the dignity and properties of such sex were known. However, modern material, referred to as a massive board, is noticeably different from its ancestor, and we are preventing completely different requirements.

Do you know that sophisticated European manufacturers carefully collect and process wooden beams, preserved after parsing old buildings? Of them get a unique parquet or array. Just imagine: oaks that have later become a building material, 300 years grew. House stood 300-400 years. So, the physical age of such a floor is 6-7 centuries! This determines its value, regardless of the fleeting fashion for drawings of laying, colors and wood. But is it less valuable massive floorboards from the Siberian larch, which is 700-1000 years old?

Europool |

Europool |

Europool |

1-3. EUROPOOLs under varnish: heat-treated ash (1), smoky oak (2), oak selection (3). Dimensions: 1160-236012821mm.

The floor from the massive classic element of the interior, designed for decades of flawless service. This wooden coating, as a true work of art, does not age over the years, and unique patterns created by nature, beyond the time. Those who consider it an integral part of the "rustic" style, just unfamiliar with the works of designers and architects, organically enter this material in the most exquisite apartments.

The massive board is presented in our market by companies and trademarks: Trade Forest, William J. HUNT (both- Russia), Finex (Russia-Belgium), Marburgholz (Russia- Germany), Europool (Russia- Italy), Coswick (Belarus), Antique, Dream Castle, Nolte, Parador, Parketoff (All Germany), Junckers (Denmark), Weiss (Austria), Junglewood (Brazil, Indonesia, Portugal), Panmar Wood (Poland), SolidFloor (Netherlands), TINGE (China) .

Opinion of a specialist

Today, the floors from the massive boards, created under the specific interior, when the customer at the design stage chooses the design of the surface: color, type of processing (brash, aging etc.), the type of finishing coating and the configuration of individual modules or the floor pattern as a whole. The service of individual selection of color is relevant. At the request of the buyer, the boards can be tinted under the color of furniture, doors, platbands and other components of the interior. Architectors actively working with this material appreciate the possibility of manufacturing in the same design as the floor, other elements, plinths, window sills, stairs. Increased interest in artistic floors from the massif: traditional and old styling (Versailles, Chantille, Lange), castle modules, decors inspired by Mondriana, Klimt, Malevich, as well as arbitrary "drawings" from the array, performed According to original sketches.

Ivan Melikhov, director of Finex

What is the size?!

A few years ago, only a solid board from the wood array was called a massive board. Today, some manufacturers are referred to as the glued board, consisting of two or three layers, but necessarily homogeneous wood. To conveniently connect separate planks, grooves and ridges are made on their edges.

The total thickness of the pine boards and fir is 28-42mm, from the wood of valuable rocks, slightly less (17-22mm); The working layer (up to the groove or ridge), which determines the number of possible grinding, is 8-10mm. The width ranges in the range of 60-450mm. The most popular length is 1-2m, although it begins with 0.5 m, and when making to order can reach 7-9m.

Outdoor coating from the array looks stylish and over time does not lose its attractiveness. So that it gains pristine purity and beauty, even in the most difficult operating conditions, it is enough to remove the thin top layer in the most difficult operating conditions. Thanks to modern grinding machines capable of removing wood with a thickness of several tenths of a millimeter, the service life of such a gender has no one ten years.

Massive board-ecologically clean finishing material. Therefore, it requires serious investments. Choosing such an outdoor coating, you not only increase the cost of repair, but also improve the image of your real estate, and also make contribution to the future of children and grandchildren. However, for many, the high price of the floor is a significant disadvantage. The reverse side has the impressive dimensions of the planks. It would seem that they demonstrate the true beauty of the material, but the wider and longer the board, the more it is deformed when the moisture and temperature changes. However, modern technologies allow us to successfully solve this problem.

Marbrogholz. |

Marbrogholz. |

Marbrogholz. |

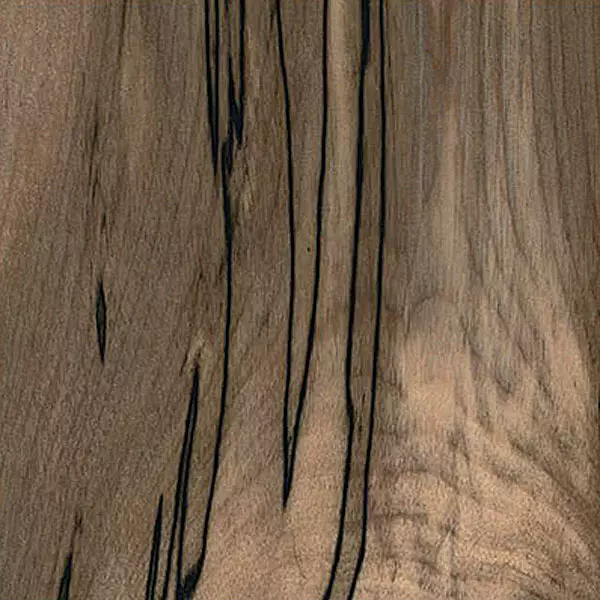

4-6. Odube oak toned with colored oils, looks completely different. The effect of selection of individual fibers emphasizes the natural beauty of the material.

Justice microclimate

In the context of the Russian climate, when the onset of cold weather includes central heating, air humidity in apartments can decrease to 20-30%. Naturally, the wooden planks dry out and decrease in size. Between them appear gaps disappearing with the end of the heating season. It is the formation of such "gaps" it makes itching many of the masses of the massive board.

If you are tremendous about similar phenomena, it is necessary from the moment when the floor is mounted, constantly maintaining air humidity in the apartment or house at the level of 50%, let's say using the humidifier. This device will need about 8l water to increase the humidity of from 20 to 50% in the non-residential room with an area of 30m2 with a working heating. The task is simplified by the fact that in the process of man's daily activities (watering flowers, washing, cooking) in the air there is quite a lot of moisture.

Opinion of a specialist

The heat-treated array is much less than the usual massive board, reacts to the differences of humidity and temperature. Indeed, under the influence of high temperatures, the structure of wood cells changes, the level of its internal stresses and water absorption capacity is reduced. Accordingly, the stability of the geometric dimensions of the planks with changes in the microclimate increases, the hardness increases, which is important for the flooring. True, such a procedure increases the cost of the final product by 10-20%.

As a result of the heat treatment, the usual oak tones or ash is replaced with darker-chocolate, brown, dark red, and these breeds become indistinguishable from exotic. Wood darkens through the thickness of the board. Valid dreams from tinted such gear after grinding will not lose a beautiful and deep color.

Mikhail Durov, Parquet Hall Training Manager

Due to reduced or high humidity, the boards may be sworn. Special propuls on their lower sides remove the internal stresses in the wood, reduce the risk of deformations, make the bar more stable. Another way to increase the stability of a layer of multilayer (glued) array, less susceptible to seasonal climatic fluctuations in humidity and temperature. Externally, it is indistinguishable from a solid massif, has similar dimensions (including the thickness of the working layer), but consists of two or three layers of wood of one rock with a mutually perpendicular location of the fibers. Such a product is produced by Trade Forest, "Parquet Hall" under the brand name William J. HUNT.

Visually mimic a massive board can single-band parquet board. This is a three-layer design with a top layer of the valuable wood (3.5-4mm) and two layers of wood conifer. In the extraordinary range of humidity and temperature, it "behaves" is better, it is cheaper, and it is much easier to want it. But from the point of view of durability, environmental friendliness and sustainability to extreme conditions, this material still loses the array.

Parketoff |

Parketoff |

Parketoff |

Parketoff |

Parketoff |

Parketoff |

7-12. Massive ParketOff makes a variety of valuable breeds from wood: birch (7), oak (8), northern birch (9), oak brash (10), oak, toned under African wenge (11), Palo Santa (12) .

What does the price grow from?

The cost of 1m2 massive boards starts with 850 rub. and comes to 8-10 thousand rubles, and in some cases exceeds 30 thousand rubles. (exclusive products). What makes it going? One of the main criteria is the size. The thicker, longer, and most importantly, wider the board, the more expensive it is, because for its manufacture you need big adults (and therefore more expensive) trees. Thus, the massive board of the spectacular collection of Signatur (Weiss) width of 200-450mm and up to 9m is impressive not only with its size, but also at the price of 1M2- 45 thousand rubles.At the price, sorting, or selection has a significant effect. Moreover, the names and the number of sorting from different companies may differ. Suppose the manufacturer subdivides boards into three classes:

"Select", with a small varnotone (the difference in colors) of natural color, random bitch with a diameter of no more than 5 mm, insignificant "marble" splashes;

"Natur", with a large varnotone, bitch with a diameter up to 15 mm, "marble" splashes, the presence of Collus;

"Rustic", with a characteristic difference, bitch with a diameter up to 25mm, a small number of drop-down bitch, stains, bright "marble" splashes, sometimes cracks.

Of the usual oak billet, 5-10% of the most monophonic and most expensive SELEKT boards are obtained, 35% - "Nators", and everything else belongs to the motley sorting "Rustic".

The cost of massive boards of the same sizes from domestic wood and Overseas-Merbau, Tika, Wenge, Bamboo is different. Here are some examples of the most democratic prices. Products from traditional pines and spruce from 500 rubles. For 1m2 (dimensions - 14542mm, length, 2-4m), from Siberian larch, 700-1500rub. For 1m2 (80/11027mm, length, 2-4m), from oak or ash, 800-3000 rub. For 1m2 (110/130 / 15028mm, length, 2.5-4m). All prices are on the board without finishing.

Various surface treatment methods contribute to the formation of value. First, the brushing, or structuring of the boards (the surface is rushing with metal brushes and combed the most soft fibers). Secondly, the creation of vintage effects, volumetric "waves" (for this board is placed manually or on special machines, and then grind). Inacontal, traditional methods, tinting, oil treatment or varnish. Indeed, mostly massive board is sold with finishing coating applied in the factory.

Opinion of a specialist

A multi-layered massive board has a sufficiently stable geometry and high-resistant to warp during operation. One of its varieties is a three-layer design: the upper and lower layers are whole lamellas of solid wood, and the average consists of glued bars framed by the edges of the rails, along the cross-cross inserts. Small details in the middle make the "insensitive" board to changes in the temperature-humidar mode, give it anti-informational properties in the most critical cross section.

All three layers are made of one tree of wood. Their high-quality gluing practically eliminates the possibility of detachments. The top layer is made of various solid high quality solid rocks, and for the lower and middle, the same wood is used, but with zabol, bitch, sharp color transitions. This allows you to minimize waste.

Anna Zemtsova, CEO of Trade Forest

Keeping style

What is better: to buy an array covered in the production of oil or varnish or only polished? The answer to this question is far from unambiguous. Of course, if there are boards among the finished samples, which are quite suitable for color and price, preferably take them. Those who want to have the original floor can go in two ways. The first is to buy a raw array, put it, and then perform all the necessary procedures: finishing grinding, toning, applying color or colorless varnishes, oils IT.D. The second is to order a similar processing in the factory conditions, and then put the boards. The first option may be less costly if used not the most expensive varnishes or colorless oils. But the quality of the finish coating will be somewhat different from the factory, as the conditions for carrying out work at the facility are far from optimal.

Those who decided to cover the finished half the lacquer at home, experts advise you to choose a massive chamfering chalkboard, otherwise the varnish will fill in the deepening between individual elements, and they will be tightly glued. Celebration, when the most likely changes in the geometry of planks, lacquer will begin to crack: first the ugly white stripes will appear, and then noticeable gaps.

In fairness, we note that massive boards without chamfer are now rare. A small cut (1-1,5mm around the perimeter) emphasizes the boundaries, highlights each bar. Due to this, the surface of the floor becomes more interesting and spectacular. At the same time, the champers are leveled between the individual elements of the array that are laid on a non-ideally aligned base. They also make less noticeable gaps arising from seasonal narrowing of boards. In the absence of chamfer, even small height differences (0.2mm) are noticeable if we walk on the floor barefoot.

Tiege. |

Tiege. |

Tiege. |

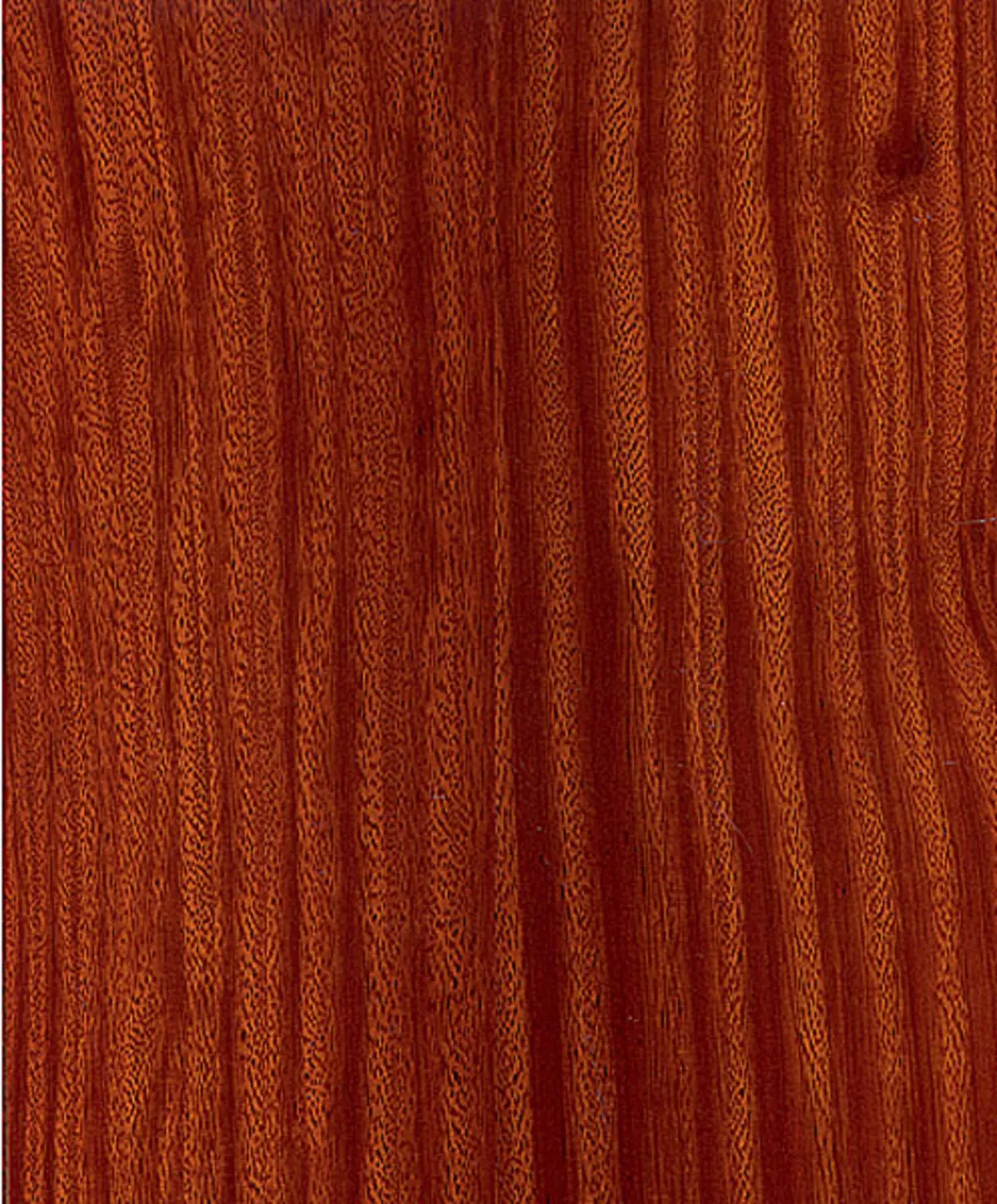

13-15. The tropical exotic is less popular with a classical massive TIANGE board from oak (13): Tropical exotic: Tali (14) and Tauari (15) with juicy saturated colors, original wood texture.

Quality checking

A high-quality massive board is properly dried to 8% humidity and has a high accuracy of geometric sizes. However, the usual buyer to evaluate such parameters is very difficult, especially in the absence of an array, where all the necessary characteristics and tolerances for deviations of the dimensions were clearly spelled out. Determine whether the claimed sizes of the plank are realistic, the easiest way with the help of roulette or caliper. Check the geometry of the slats can be given several pieces on a flat surface. See how they are joined and adjacent to the base. Pay attention to the ends - there is no cracks there, which indicate the irregular technology of drying.After the packages with the boards were delivered to the object, one should open one and check the moisture content of wood using a moisture meter (hygrometer). Such a device should be professional stackers. If the moisture content of the material does not correspond to the specified in the specification, it can be returned within 14 days. But there should be no guilt in it (for example, you did not carry the packaging in an open car under a torrential rain).

Opinion of a specialist

By choosing a massive board as an outdoor coating, do not try to save on the laying. We strongly advise you to use the services of professional stackers recommended by those companies in which you order an array. Of course, it will cost 10-20% more expensive than when contacting private "crafts." Specialists in a massive blackboard or parquet have a higher qualification, are engaged only by the floors and will never separate the ceilings or painting the walls. And "International Brigades" are taken for any work, but after some time, if something happens, find them at all. At the same time, sellers and producers of the array do not accept claims if the material is spoiled due to non-compliance with the technologies for the preparation of the founding of the floor and flooring. Sometimes massive boards offer for their products a specific method of laying. Therefore, buying an array, be sure to ask the seller how to work with it and what consumables must be purchased.

Alexander Gvozdik, General Director of Atelier de Parquet

Format and neforma

Choosing a massive board, be sure to ask the package of packs. Some manufacturers offer bar equal lengths, different. For example, in the package of the company SolidFloor, the entire array of standard size: width - 190mm, length, 1800mm. Popakka Panmar Wood 70% long boards (1.2-2m), and the rest are short (0.6-1.2m).

When laying, the bar is placed with a shift, and the long elements often have to be trimmed. From the diverse easier to form a "deck" drawing, waste will be less, and it is worth the packaging "differedies" cheaper. Keep in mind that in the account imposed on the array must be specified which boards you acquire: one length or different. Hospital, unscrupulous vendors often enjoy the ignorance of buyers. They call the price for a two-meter array, modestly silent that there will be one or two such boards in the package, and "short" - 50%. But by paying for one thing, and having received another, you have the right to present a reasonable claim.

The boards are longer than 3m are more meant for country houses. The intensive apartment is inconvenient to transport them: they do not turn around in the entrance, not to enter the elevator.

Antique. |

Antique. |

Antique. |

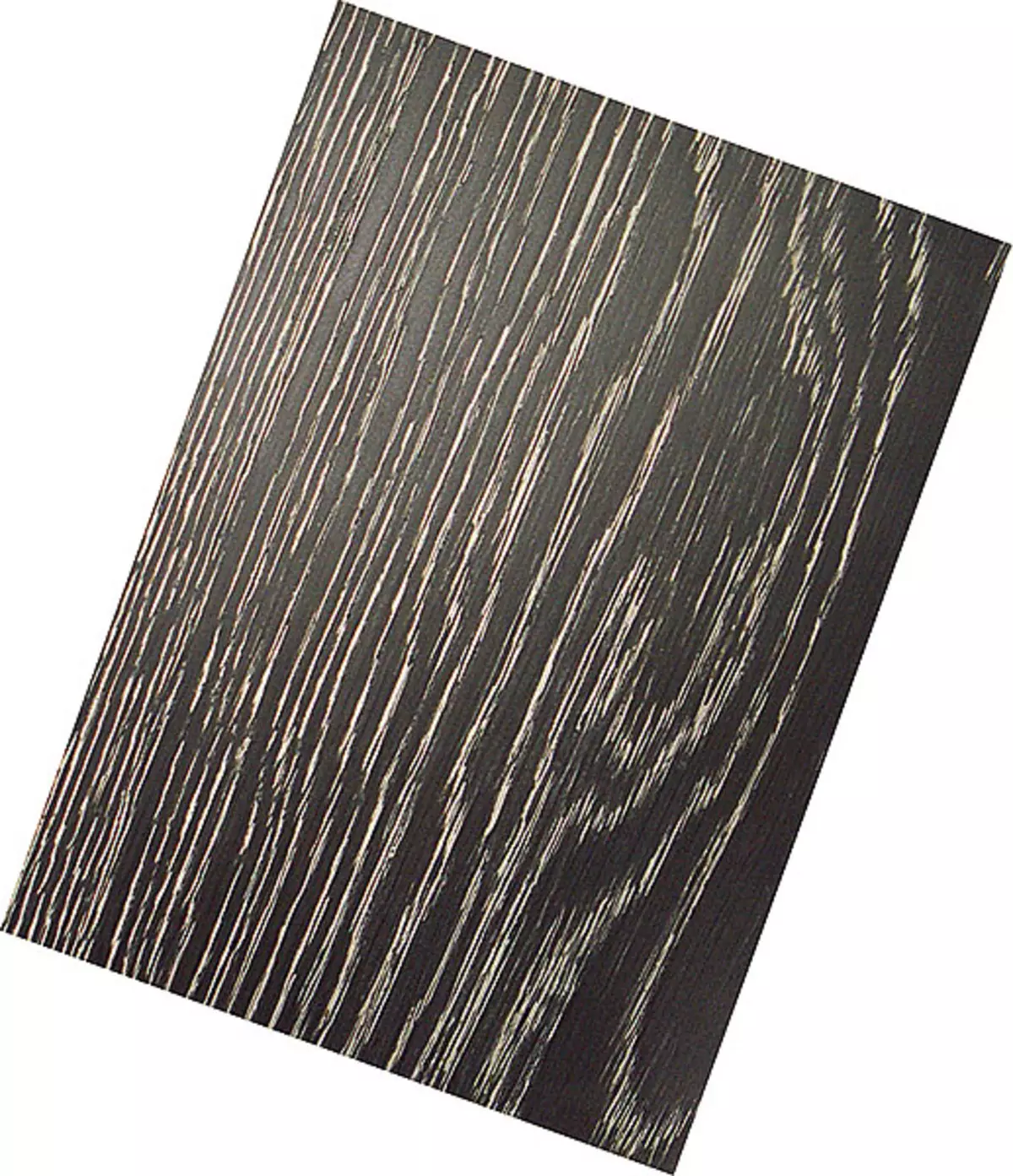

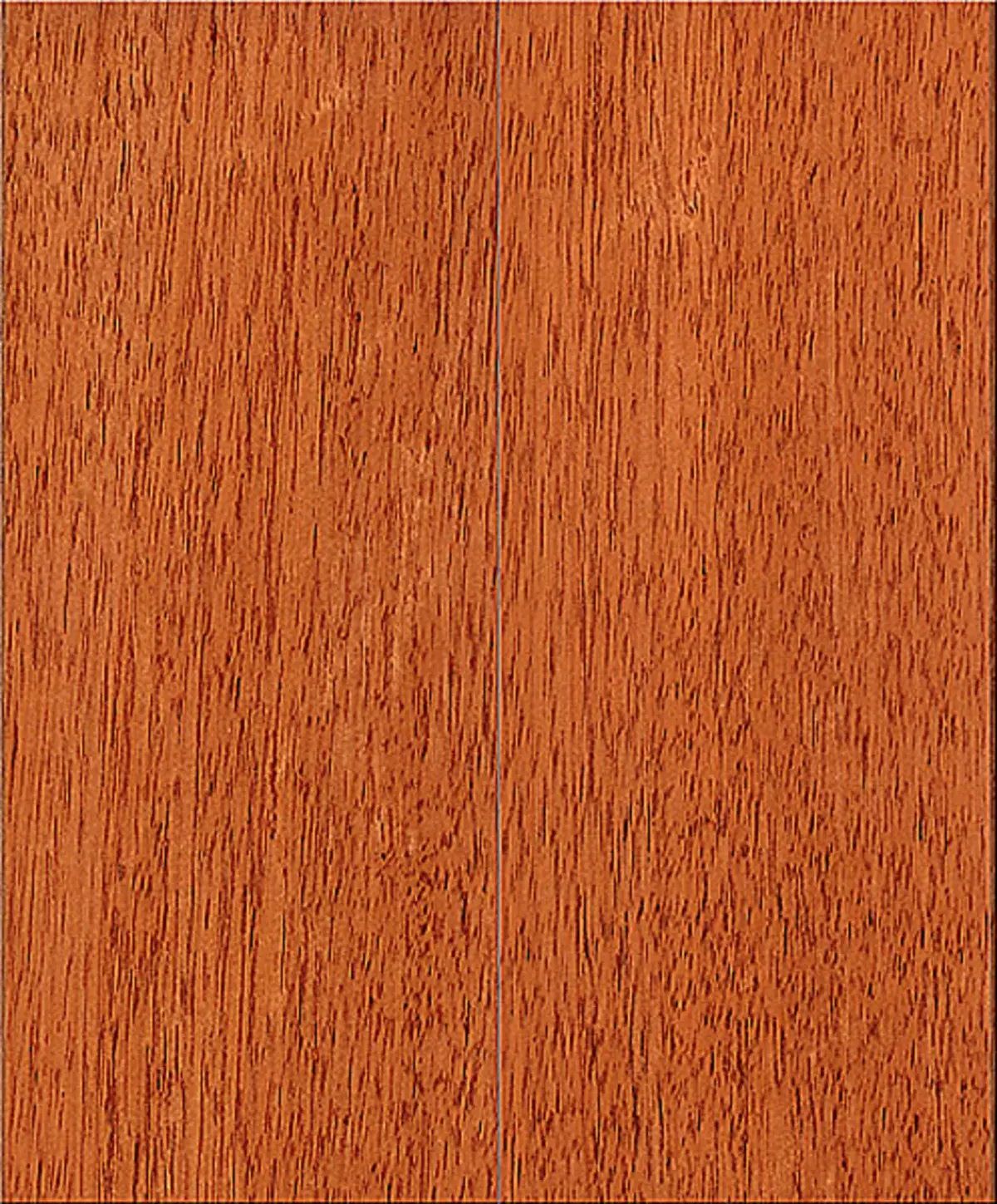

16-18. Lands from a smoky oak: Natur (16); structured and tinted (17); With additional bleaching (18).

Be generous!

Having spent a considerable amount to the material itself, it is worth the flooring to the process. There are several ways to lay a massive board. What preferably in each case, a specialist-stacker will be prompted. Sometimes the flooring method is dictated by the design of the board or is recommended by its manufacturer.

For example, BERTHOLD (Germany), Parador, Tiange produce a massive plaque with a lock connection. On the area to 25m2, it can be laid with a "floating" manner, without hard fastening to the base, like a laminate or parquet board. In the same way, the Junckers board with Easiklip mounting system is laid. All planks are equipped with aluminum brackets, with which they are easy to connect with each other. The costs of time and money are minimal. Price of work- 500-800 rub. For 1m2.

Classic and, perhaps, the most reliable version of the laying - on Phaneur. Waterproof plywood sheets are laid on the aligned base, glued, fastened with self-draws, grind. Then glued to them and additionally fasten with self-made massive board. The cost of work is from 1500 rubles. For 1m2 (material with the factory finish layer). The price of laying a raw board with subsequent grinding and finishing coating can reach 5 thousand rubles. For 1m2.

Thrust houses or in apartments with large heights of the ceiling plates, it is more expedient to use wooden lags (most experts recommend covering them with a layer of waterproof plywood). Innovative methods of laying - the adhesive substrate "Elastylon" (OSBE, Netherlands), elastic glue (without plywood, directly on the leveling base) - you should trust only professionals with experience with similar materials. Then you will become the owner of a natural coating, which was and remains a symbol of prestige, solidity, fine taste.

Care for massive board

The massive board should be transported in closed machines. After delivery, the material should only be stored horizontally. Vertically delivered boards will inevitably arouse off.

After laying, a massive board requires a simple, but regular care. To support cleanliness in the house, the floor is enough to sweep or vacuum. Many manufacturers offer facilities for natural wood floors under varnish, oil or oil-wax coating, neutral to the composition of a specific finishing coating.

With a wet cleaning, the floor is wiping well with a well-fried piece of fabric so that the surface is humid, but in no case is not wet. The introduction is added a special concentrate for wood cleaning. Strong pollution is removed by a special makeup for deep cleaning, wetting the napkin and processing every problem area. Once every six months after cleaning the surface of the floor, it is desirable to apply a protective means of a long action.

Soft felt lining, fixed on the legs of chairs and tables, will prevent the formation of scratches when moving the furniture.

The editorial board thanks the company "Atelier de Parquet", "Parket Bureau", "Parquet Hall", Finex, Parketoff, Trade Forest for help in preparing the material.