Errors in the design and construction of houses from a rounded log: causes and ways to save the situation

Interest in the construction of country houses from a rounded log of natural humidity does not weaken. But for the seeming simplicity of working with this material, serious problems are hiding both for builders and for the owners of future housing. They will tell on a specific example.

First, they turned into a fame of the architectural workshop. There, on the basis of the sketch-made sketch, the project and working documentation (layout of logs on the crowns of IT.P.), which was immediately sent to the production to the Kostroma region. After some time, they accepted the site, unloaded and folded in a stack of a complete set of details from the rounded log. The joyful owners did not embarrass that the bows and gutters are cut in the details and gutters, and 70% of parts are made of ate, and not from pine (as provided in the project). Attention to these shortcomings they drew much later. Away was not before, it was necessary to finish the foundation.

|

|

|

|

|

|

1-2. Ground gaps (50-60mm) gaped in walls (1) next to the logs, the second end of which relied on the support racks on the perimeter of the veranda (2) equipped with screw "jacks". The reason for the formation of these slots was obvious: the logs had already started to sit down, the gaps between the logs were gradually decreased, plus the natural "destruction" of wood, and no one thought the covered rust "jacks".

3-5. After you went through the defective crown crowns, his construction continued, and the builders needed forests. They were attached to the walls (3) and moved as a church grows. When splitting the logs in the rearries, they were bonded by studded plates (4), and in the window and doorways (5) left the unuplicated logs (this increases the rigidity of the structure of the house as a whole and contributes to its proper shrinkage). For overlaps (6) used beams with a cross section of 250150mm.

First Zaminka

The foundation chose economical and almost universal-shallow concrete tapes, on top of which they decided to lay hollow concrete slabs. It began to do it in advance, and the owner of the neighboring cottage agreed at the hired brigade. But whether the workers got ineptly ineptly, whether the neighbor did not immediately lead them, only at the time of the arrival of the kit finish the foundation did not have time, did not have enough 3 week. He had a non-zero-plates, he was slightly curved, gap gap between them. "Well, not trouble," our heroes thought, "he also, in principle, even, it means that the house as a whole would stand smoothly." Istaly wait for the arrival of the brigade of the builders from the manufacturer.

|

|

|

|

7-9. Crooked crooked, and in the process of finding, they were deformed and accepted the ellipse form. A similar form has been acquired and occurring in the lower part of each gutter log. Some logs curved, unscrewed and did not go to the place. As a result, the magnitude of the gaps between them is not that did not fit into the requirements of the SNIP (no more than 5mm), but, as they say, did not climb into any gate.

10. Few. ATTENTION The builders began to pay the adjustment of the screw "jacks" - they were gradually released, and as a result, huge slots on the walls under the logs based on "jacks" began to gradually decrease, and then equalized in width with others.

Started! But this ...

The brigade was waiting for a short-term approximately 1.5 week. Finally she arrived and immediately began to work. The workers were calm and delusito in the stacks of the details with the necessary numbers, transferred to the foundation, laid into place (at the same time cut something, peredalized, sometimes they tried to even bother or unscrew the log) and fastened vertically with wooden braces. At the same time, the gaps between the logs were only 1.5-2Cm.

Only a brigade worked on the site for a short time and managed to put only five crowns. Deciding that the amount requested by the builders is too large for an easy-to-look at work, the owners have refused their services. Hired a new brigade, the claims of which were significantly lower. These experts had no longer peredalized anything, did not customize, they simply put the details one by another to the place allotted and fastened with wooden brazers. True, the gaps between the logs increased to 3-5 cm. The construction was promoted pretty quickly, and the walls of the first floor were almost completely erected.

Looking at what happened, the owners stopped work. Then, remembering the article "Cunning otling" published in our magazine (see

"IVD", 2007, №2), called an expert on the quality of construction of Sergey Zelensky, who helped us in the preparation of this material. Aon, of course, called the editor and invited to go with him.

|

|

|

|

|

|

11-16. The builders have created a more suitable roofing system for this configuration of the roof of the samstaya roof. To do this, there are racks that do not interfere with the logs in the tower, which do not interfere with the logs are cut during shrinkage, they are opened on them the ends of powerful gaming of glued wood (11, 12, 14). On the perimeter of the walls, rectangular bottles were secured (13), putting them so that the top was in the same plane with the supporting platforms of the frame racks (15, 16).

Where is the dog buried?

Together with the expert, we examined the log house (by that time he was erected to the interoching overlap), they looked after the history of construction told by the owner of the house and, to be honest, they were horrified. The way the bottom logs of the walls lay on the foundation, do not even want to comment on: they simply hung over the crooked plates on the crookedly, and some reference racks the veranda batted in the air.

There were huge gaps between the logs, and even with the naked eye it was clear that they were smaller between the lower crowns of the walls, and between the top. Linen fiber (package) laccped between the logs, absorbing, and then pulling on the fibers in the gutter and the bowl of the rain moisture.

|

|

|

17-19. Strecks made from the board with a cross section of 15050 mm and before installation was treated with antiseptic composition (17). Under the skate run, the rafting legs were covered with drains, made from the board of the same section as rafters. Karkasu roofs and each other elements of the rafter structural structural structural with galvanized corners and their similar metallo elements and self-tapping screws (18, 19).

An expert, analyzing the situation, gave his explanation that happened. The fact is that sets of parts from the rounded log, as a rule, will not be taken to the site entirely. The video of them is delivered by small batches and immediately laid into the wall. The calculation is simple: from the moment of the manufacture of each element before it laying in place should pass no more than 2nd (maximum 4ned). Otherwise, when fermented, their geometry changes: the grooves and bowls are twisted, and the item itself, especially if it has a big length, begins to get out, as specialists say, propeller. The wines of the whole lead (twisting of the fibers), laid in the logs even with the growth of the tree, because it turns the crown after the sun. If the logs are stored for a long time, there is nothing terrible in that at the same time they will turn out. Log in Cuscat, cut into parts in which the grooves and bowls will make, and each of the elements without effort will be laid in place. The made parts made by the manufactured details were first stored at production (there were the first of them 3-4nd waited when they would make the last), then they lay in a stack on the site (another 5-6nd). The same weather stood such that the wood scored moisture (to the joy of the owner, no log in stored for storage), and it was even more twisted. A pate "curves" logs had a brigade of unknown specialists.

|

|

|

|

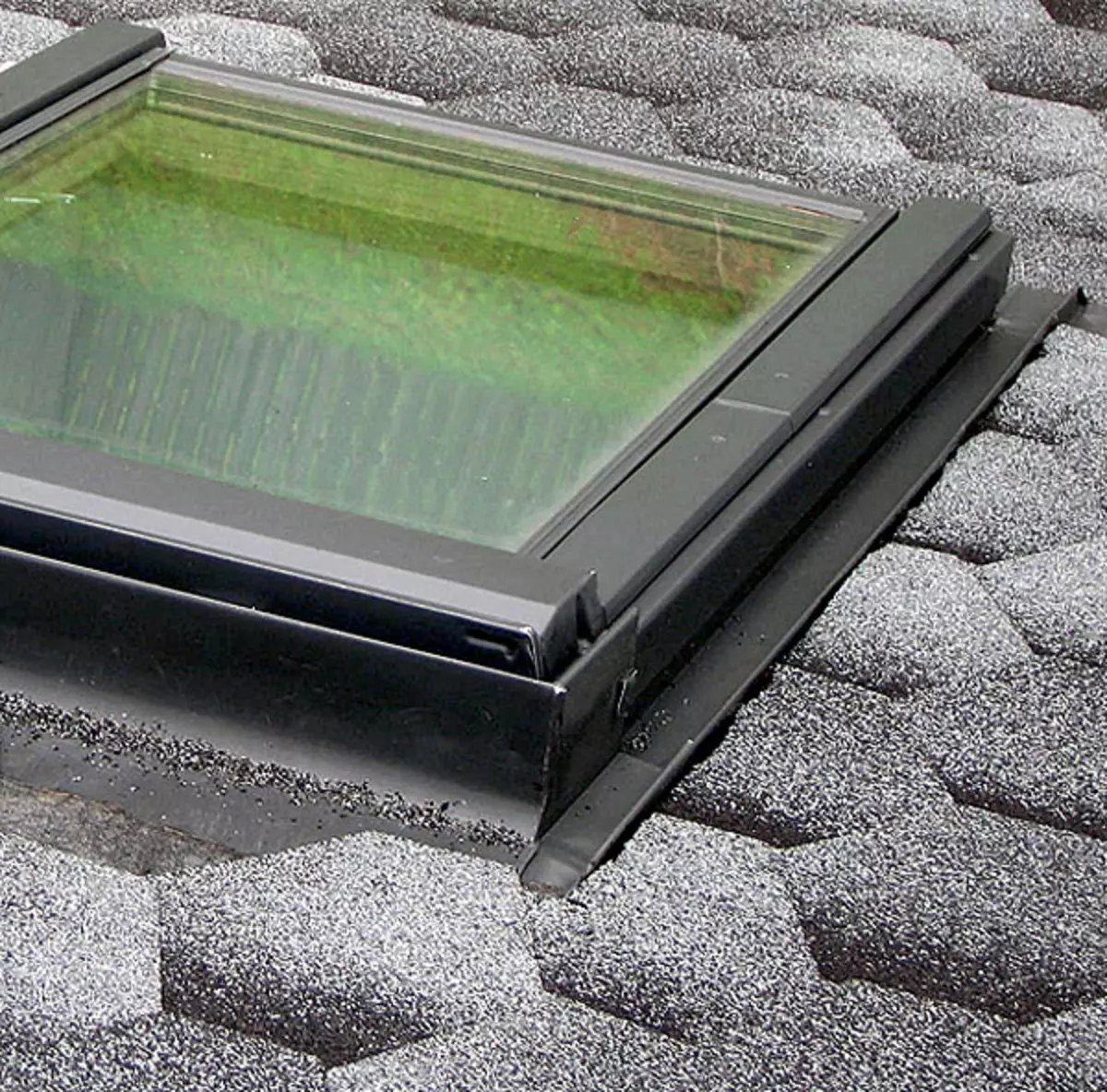

20-23.Pover rafter put a moisture insulating membrane, pressed its counterclaim. Then they created flooring from OSP-plates, which was embedded by ventilation elements (20, 23), lug-and -ana (21), mansard windows (22). Inscribed glued bitumen tiles.

What to do (not at all in Chernyshevsky)?

After hearing the explanation of the expert, the owner was even more upset and asked the questionally logical in his position: "So what now to do with all this?" Having consisted, outlined two possible solutions to the problem. First, try to sort out the log house. To do this, first of all, it is necessary to find a firm that, in principle, can embody such a way into life. Then call it specialists to the development site so that they are at the spot appreciate the ability to conduct the bulkhead and the cost of work. The second way is to leave everything as it is and continue to build. In this case, two options for the development of events are possible. In the case of a log log, under your own weight and weighing the roof "will" sit "in place. Whousche - do not "sit down", and then the house will have to be insulated outside the mineral wool (thus it will be able to cover the gaps), after which it is a blockchus. Actually, on this expert with the owner and parted.

Professionals who are able to sort out a log house were found quickly called the company, which in our eyes the house was saved in the situation described in the article "Cunning otillization". We were answered: "There is no problem, tomorrow our specialist will come to the site." Ion really came. I looked attentively, but the bulkhead refused the logs (as the remaining in the stacker and laid in the walls) was strongly led. The geometry of the connecting bowls is changed, they must be cut. Thus, the first way to solve the problem was rejected. Stayed the second - to continue construction. But who will take for such a difficult job?

|

|

|

24-25. So, we expected the shrink shrink will be very large, the glands above the windows and doors, the magnitude of which is more regulatory: above the windows - 6cm, above the doors- 8cm. Instead of the usual 8% of the gaps, there were 10-12% of the height of the opening, because they needed to lay the passage, and it is permissible to compress to a certain limit.

26. The house, at the very end of the site, mounted a multi-stage autonomous sewage system Green Rock. Landscape it absolutely did not spoil: only squat mushrooms can be seen from the grass.

Did not translate in Russia Ratriyri

Then the owner remembered his acquaintance - Dmitry Zykov, designer, restorer and generally the master for all hands. He called him, and Dmitry immediately agreed to come and inspect the house.

Do not say that he felt, examining an unfinished log house, but only the owner did not express a single comment. On the contrary, soothing and said that everything will be fine. It was not to lead the construction, but not as a pro, but on the rights of the consultant.

First of all, using a powerful jack, tried to fill the foundation plates. Where it was impossible, put under the walls treated with an antiseptic board, and for them, two layers of rubberoid. Later, the remaining irregularities and cracks between the plates hide a concrete screed with a thickness of 100mm.

Then the specialist examined the log house, estimating the quality of each site of the walls. To begin with, I showed a worker, as it should be condescended and join the pass, so that it does not hang ramp, collecting rainwater moisture. Further determined which parts of the walls should be disassembled and gather again. At the same time he taught how to lay curved logs in the wall. As a result, the upper crowns of the cut were laid much more tight. The brigade techniques shown also used in the further elevation of the walls of the second floor and log filtonons. Everything went as a woman, and neither the owners nor the professional help them still suspected that the troubles prepared by him were not exhausted for them.

|

|

|

|

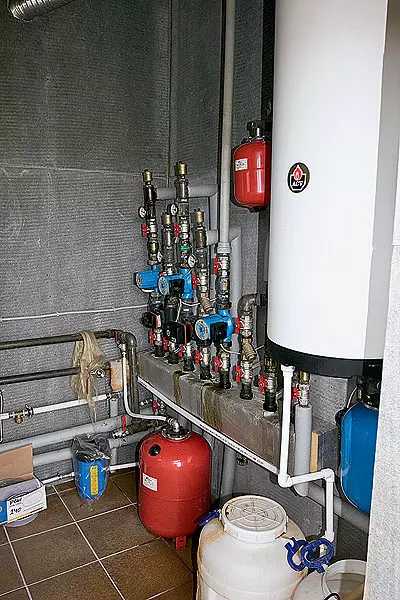

27-28. The heat supply pipes and heating pipes were laid through a concrete tie at the overlap. So that they are not deformed at home at home, they were attached to the walls with sliding elements (27). Heats the house electric boiler ACV (28) with a power of 24kW.

29-30.Mantry roof, leaving a ventilated gap, inside the house insulated with a mineral wool, which is covered with a layer of foil vapor barrier, pressed to racks of crates (29). The lifting planes of the rods and frame filons decided to have been solved by plasterboard, which expanded the possibilities of designing interiors (30).

Roofing epic

According to the project prepared architectural workshop, planned to make a male roof with hanging rafters. But by the same project, due to the complexity of the roof (multi-volume with endowers), the rafters must be rigidly attached to the top logs of the walls, which is absolutely unacceptable in the self-roof. The reason is simple: the fronton during the shrinkage pulls down the running beams resting on it, the lower ends of the hanging rafters at the same time come out and, in turn, pulled the walls. The situation aggravated and the numerousness of such runs based on a different number of frontone logs (upper 25, Middle-20, Nizhny - by 15). Each of them, in the shrinkage of the front, go down on its height and dragged the rafter legs, which will certainly lead to their bending. As a result, the rafter design either ruins the walls, either breaks away from the runs, that is, the rafters in the upper zone simply will simply lose their supports. What it can turn, we think, and without tips it is clear.

This error in the project is the owner who read our article about the insidious otlindrovka, discovered himself. Inspeven, addressed to Dmitry with a request to confirm or disprove the suspicion. I must say what he did it very timely when the log filtonians just started collecting. The specialist confirmed that the fears of the owner are absolutely justified and the rafter design in the form in which it is designed, it is impossible to erect. It is necessary to radically change it, turning into the frame-skewedly safe in terms of shrinkage. Israza explained than such a roof is better. If the lower ends of the frame racks will be on the same level, and the run beams across the area of home- to build on them, and not to the fronton, as a result, with the inevitable shrink shrink (it is due to large gaps between the logs, although enlarged, but The perimeter of the wall-approximately the same) roof frame will move down together with the walls without any deformations.

|

|

|

|

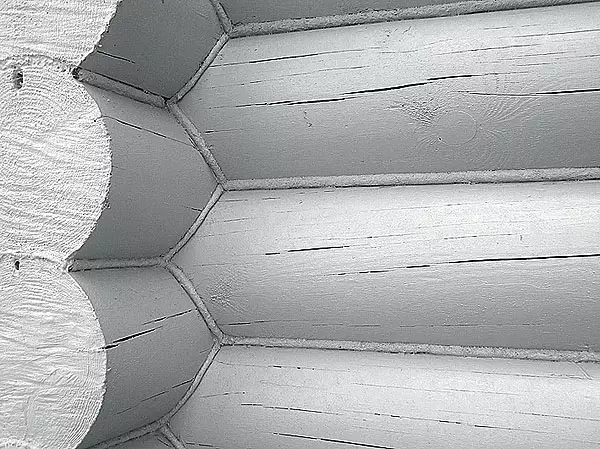

31-34. Therapy walls are carefully proofatal (31, 32), which partly hid the uneven gaps between the logs. The monsard walls were trimmed with drywall, and the walls of the baths spo-slabs and tiled, in both cases, the trim was mounted on the frame from profiles attached to the walls by sliding elements - "crabs" (33, 34).

The solution and this rather difficult task fell on the shoulders of the invited consultant. Since the electronic version of the project was absent, he had to urgently make new, corrected drawings. Both fronton, the assembly of which was just started, it was decided to disassemble, and instead, create frameworks. To connect the frame with a log wall "Tower" (it cannot be disassembled), the specialist suggested a very original idea. Wblenks Walls "Towers" It is necessary to make vertical grooves depth 100-120mm, and install the racks of the future frame. Their lower end will rely on the crown, located on the same level with the top of the rest of the houses at home. The embedded racks are attached to the wall with the help of powerful coarse screws with washers, swirling through the vertical slots available in the racks. According to the plan, the log logs during the shrinkage will "slide" along the rack, without causing it harm. The owner has approved this plan, and the builders have begun to implement it.

Cut in the wall of a rack from a bar with a cross section of 250250mm. Over the logs throughout the perimeter of the future roof, using depth, rectangular bottled bars 250mm width. First, it is easier for them than to log, attach rafting legs. Secondly, with the help of these bars, the supporting platforms of the rafter legs were raised to the necessary height, bringing them into one plane with the supporting ends of the frame racks. The latter made from a bar with a cross section of 250250mm, drives - from a glued timber cross section of 400250mm, sprinkling them in length above the frame racks.

|

|

|

|

35-38. For the design of the interiors built with such difficulty, the designer's house was not invited. This task, in our opinion, a hostess has coped very successfully. Library love here is literally all: and a two-bedroom living room with fireplace (35, 36), and a library (37), and a kitchen (38) located on the balcony of the second floor (38). The only thing that is now reminiscent of the difficulties of construction is the glued beams and embedded in the wall of the rack remaining visible in the interior.

Hooray, surprises ran out!

Fortunately, on this, all the "surprises", prepared by the fate of the owners of the house, ended. All further construction was, as they say, the case of technology. Slinged legs were put on the undercoal frame, the OSP plates were used on top of them, on which the waterproofing layer was stuck and then the bitumen tile. Both skeleton fronts were chosen by block mobile. Complete these works managed just by the beginning of the autumn rains, and the roof insulated already from the inside of the house.

Next, started interior decoration. First of all, carefully proofing the seams, and as a result they began to look even, although they remained unequal from different sides of the log. But it is possible to notice this by letting the logs on the corners of the cut, and even then carefully look closely. Then the logs were ground and covered with colorless protective and decorative composition.

|

|

|

39-41. The external finish of the house is connected by traditions and modernity. Tribute traditions - log walls. Elements of modern-color logs with a crumbling antiseptic composition and finishing with an artificial stone of the base (its color is combined with a "blocking" of the scene), as well as the translucent roofs of the veranda.

Overlapping pipes, water supply and sewage pipes, as well as electrical cables and raised them on the walls in those places where the project provided for the installation of engineering equipment. At the same time, Dmitry strictly followed that the vertical pipes can slide in the attachments during the shrinkage of the walls.

When it came to the skin of the roof rods and the walls of the attic floor, the plasterboard had to look for another original solution. When performing these operations, the main trick is not to set the objects on the frame from the profiles attached to the log walls using the so-called sliding fasteners, and how to correctly mount the frame in the ceiling pairing zone with walls.

Noah-how was that the cutting frames of the ceiling and walls did not touch rigidly with each other, but left a small gap between them so that the ceiling down with the log walls slid along the wall frame. The gap was covered with a plinth ceiling attached only to the ceiling. The resulting interior can be seen in the photos.

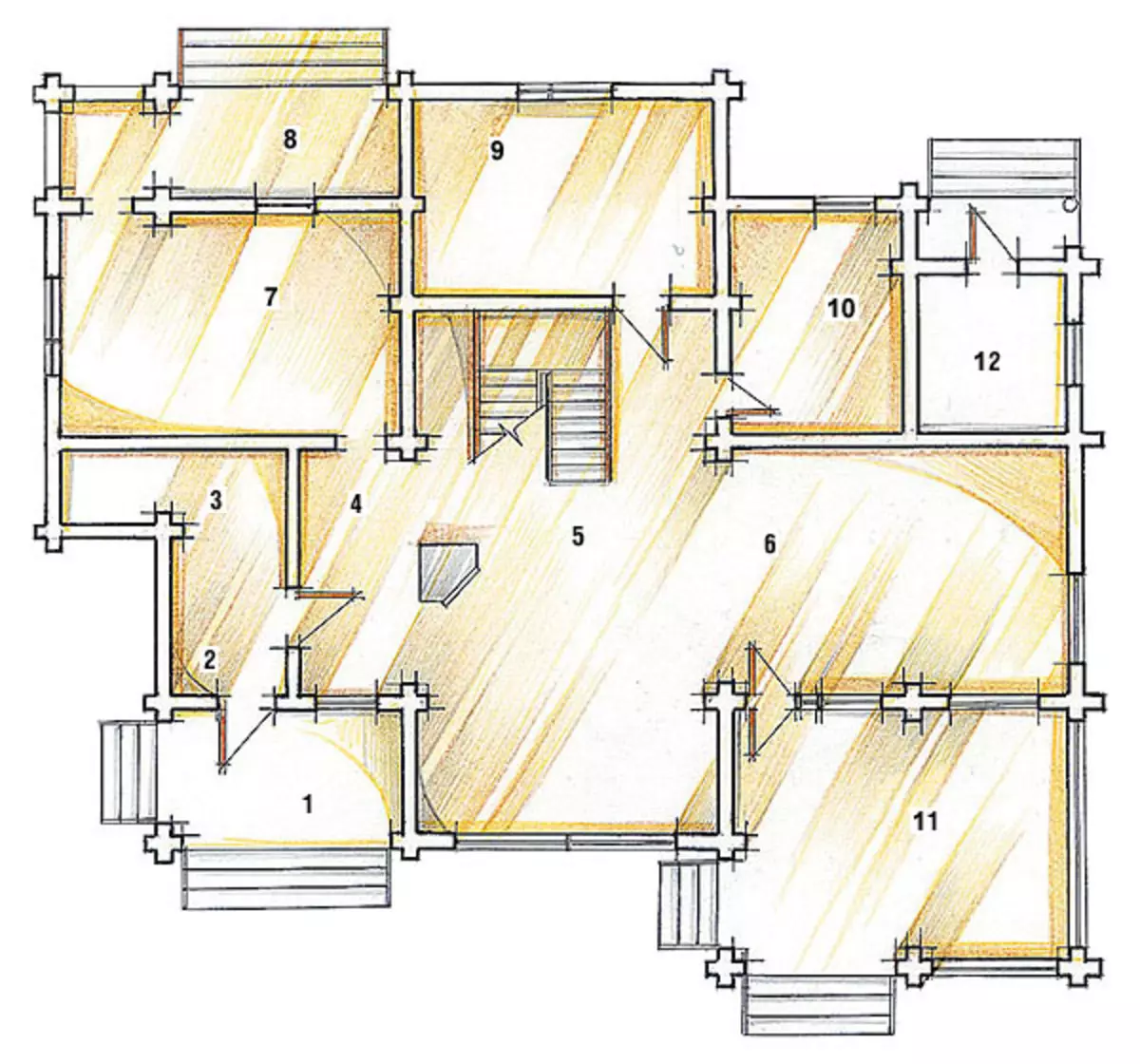

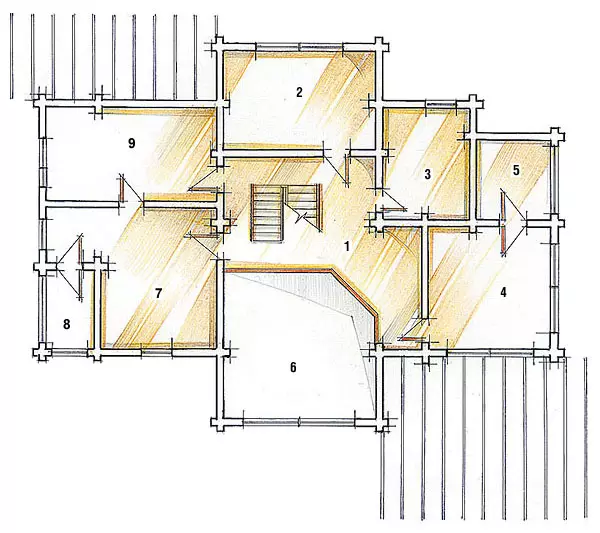

1. Veranda ................ 8,6m2

2.Nambour ................ 4,9m2

3. Wardrobe ................ 4,3m2

4. Hall ................ 7.2m2

5. Living room ................ 39,4m2

6. Kitchen-dining room ................ 21,6m2

7. Bedroom ................ 19.1m2

8. Veranda ................ 9.1m2

9. Bedroom ................ 14.8M2

10. Bathroom ................ 9.7m2

11. Veranda ................ 21,3m2

12. Boyler ................ 5.9M2

1. Hall ................ 23,4M2

2. Bedroom ................ 14.8M2

3. Bathroom ................ 9.7m2

4. Cabinet ................ 14.7M2

5. Balcony ................ 5,9m2

6. Second light

7. Bedroom ................ 19.3m2

8. Balcony ................ 3.7m2

9. Bedroom ................ 16,2m2

Lucky (instead of an epilogue)

Honestly admitting the heroes of this story were lucky, and twice. First, I found among the familiar people who could save the situation and agreed to do it. Secondly, the logs in the walls of the "Seli", taking the place allotted. And the house as a whole donkey, as it should be and without any special incidents. But with a high probability, such a prosperous precipitation could not happen if the empty wicking of the logs began to benthended even more and twisted. It is the result of the construction result would be completely different, but to bring the construction, let's say, in a normal form, it would take to spend much more significant means.

Understanding all this, the owner of the house at the end of the last conversation smiled with us and said: "Now I know for sure that there are not even pitched stones at home from the rounded logs, and non-rocky rhythns can be burned. It is necessary to save on construction extremely carefully, And with the mind. Publish this story, and let by using my experience, these truths will be diverted by other developers and do not repeat the mistakes made by me. "

Opinion of a specialist

The depressing picture, which appeared before us, at the first visit to the object, unfortunately, is very typical for the construction of houses from the rounded log. This is due to both the seeming simplicity of the assembly technology, and with a widespread dismissive attitude to the centuries-old experience of Russian wooden house-building.

In the case, the architects did not fully understand the specifics of the "behavior" of the roofing design, laid them into the project, which almost led to sad consequences. The error was not even that the hanging rafters "forgot" to equip with sliding elements (this happens completely and nearby), and that with such a configuration of the roof, it was simply unacceptable to use a similar design. Whereas our ancestors firmly remembered that hanging rafters are good only for a simple duplex roof, and with a multicate one, it is necessary to abandon the samstyle frontones and describe the roof to the substropsy frame. Eggs at home together with the consultant adopted exactly this, the only right decision. This, in my opinion, not only saved the roof itself, but also helped unevenly and loosely laid into the walls on the walls under their own weight and uniform roof pressure to take its place.

And "Professionalism" builders? None of the collectors sent from the factory did not indicate the owners to another error of the project: under the lower crown of the wall was not laid with an antiseptic-treated board. Did you have a self-respecting master in the good old days so? After all, for the wooden house, the lining board is the extremely necessary element: it serves for additional horizontal waterproofing of the crowns, which eliminates the replacement of the lower crown of the structure (only the board will be changed). To extend the life of such a board, you need to protect it from moisture, rising from the foundation for capillaries, using a rubberoid laid in two layers.

Separately, I want to say about the pillars and "jacks". Screw "jacks" over the stands The veranda is universally installed at the top of the pillars. This complicates access to them and leads to the fact that they are rare on the eyes. As a result and about them, and about the need to regulate them during the operation of the hosts just forget. "Dombrarat", mounted below, constantly in front of you, and follow its condition much easier. It is possible to embellish it, for example, with a metal ring. Iochen is good that in the sea of unprofessionalism, let them be infrequently, but still there are specialists who remember the traditions and try to revive them.

Sergey Zelensky, director of the company

"Independent examination of quality of construction"

The editorial board thanks the owners of the House of Alexey and Marina and D. Zykov for help in organizing the shooting and preparation of the material.

The material is prepared according to the results of the survey of readers on the website of the action "Create new ideas."