Some design features of modern liquid fuel boilers presented in the Russian heating equipment market

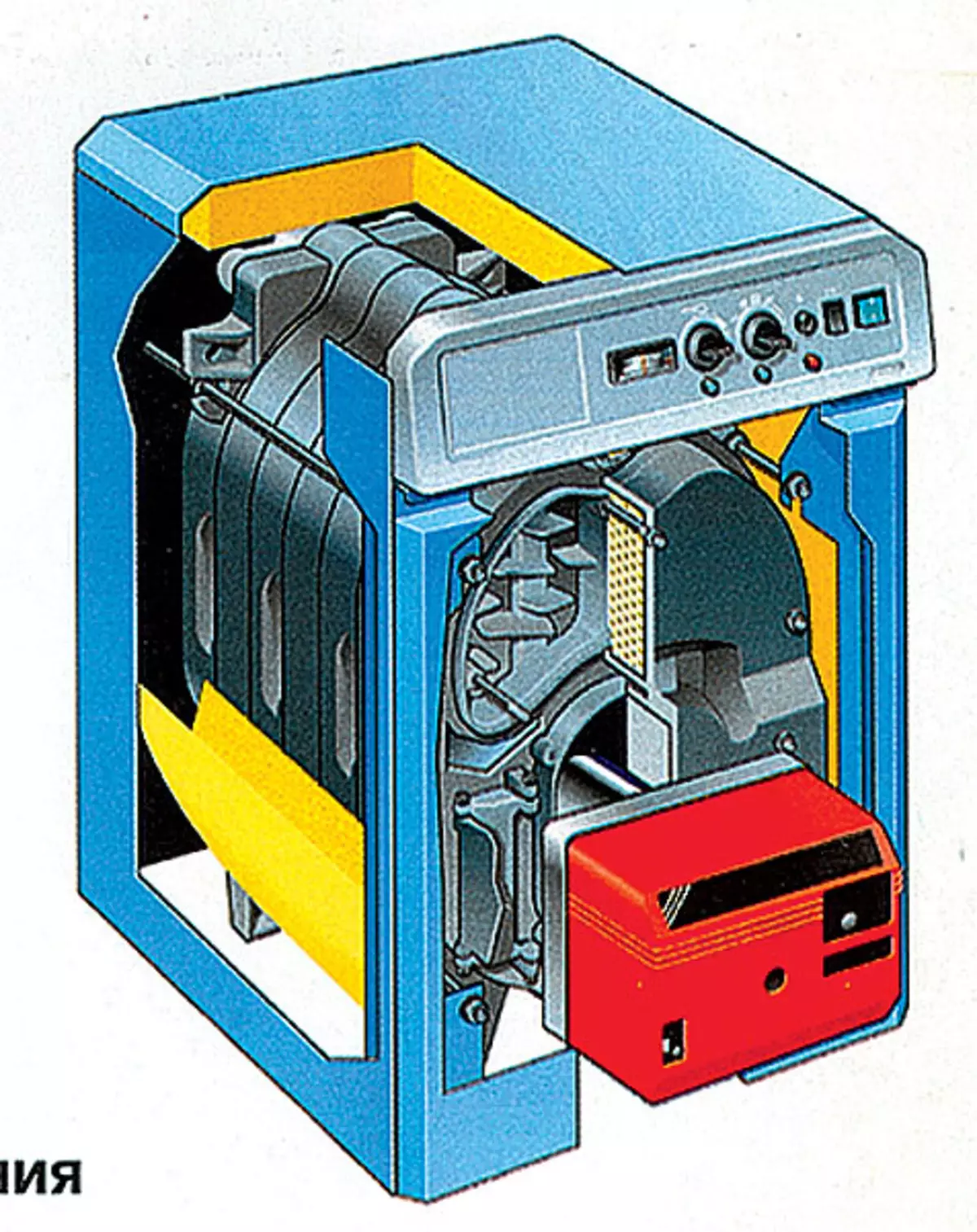

Wirbex 20-200 (CTC) with a cast-iron sectional heat exchanger

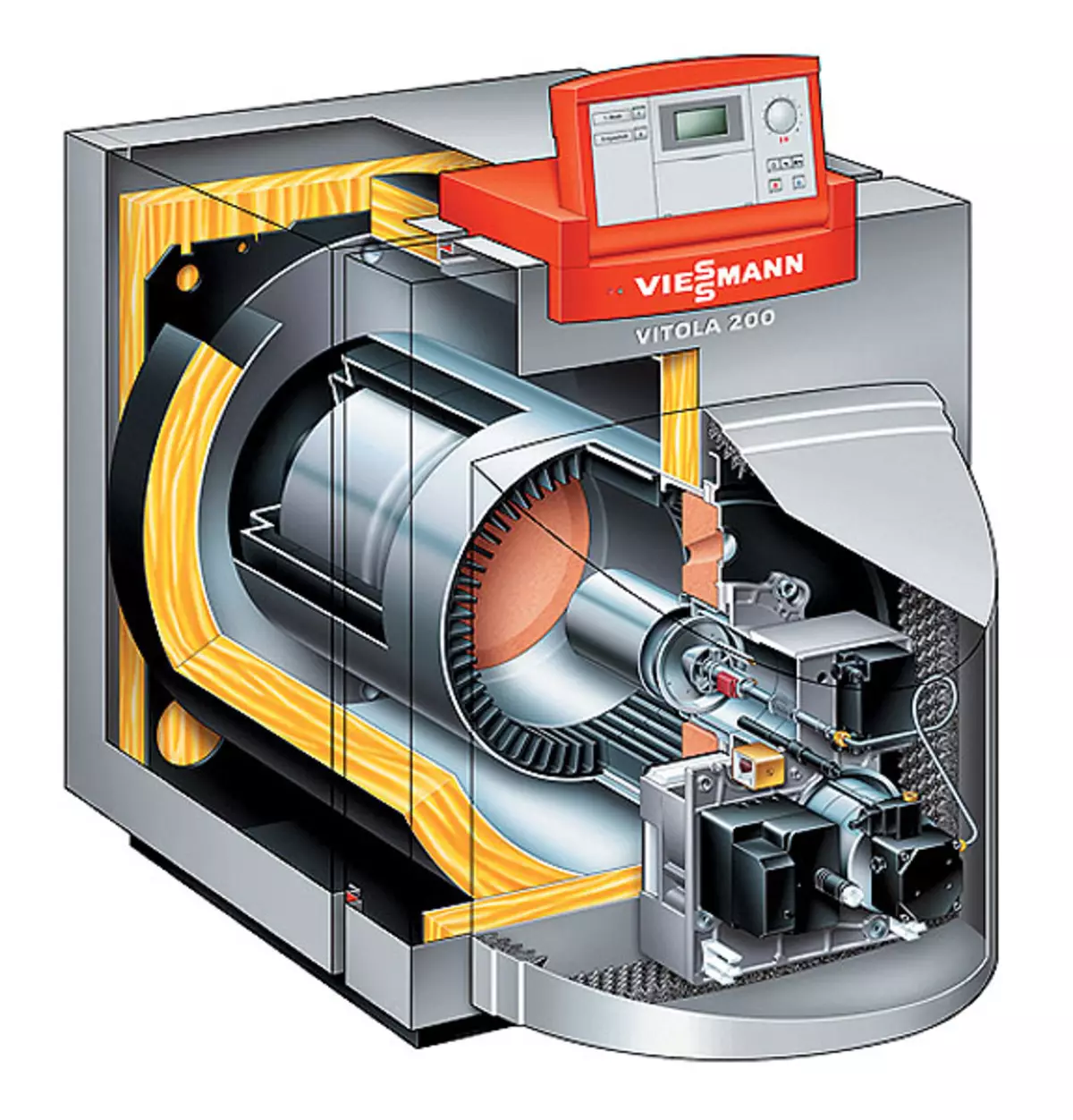

Vitola 200 (Viessmann) with bimetallic heat exchanger (steel + cast iron)

Photo 1.

Photo 2.

Photo 3.

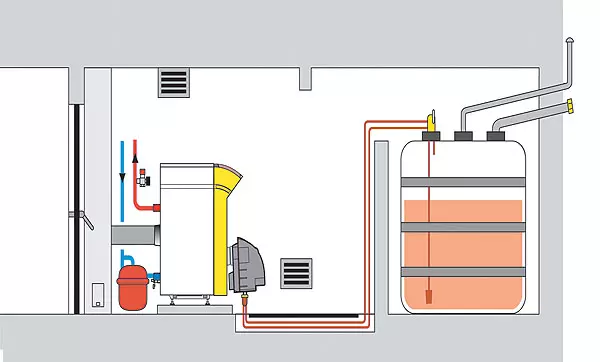

Modern liquid fuel boilers: Vitola (Viessmann) (1), irovit in combination with a capacitive water heater Unistor (Vaillant) (2), SCUDO heat generator (Nova Florida) (3)

Looking like a regular wardrobe for outerwear Storage for liquid fuel Roth can be located close to residential premises - living rooms, cabinets, bedrooms IT.P.

Modern systems of automation of liquid fuel boilers for the convenience of users equip the charts

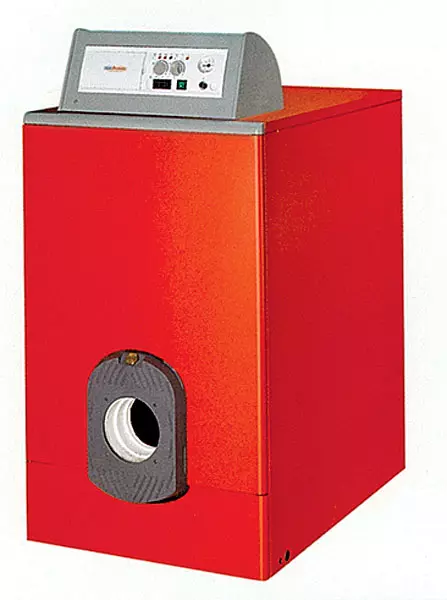

Low-temperature liquid fuel boiler GT 120 (Dedietrich)

Salt the boiler consumes from a tank with fuel, which can be installed in the room near the boiler room or outside the cottage (for example, in an extension or bury into the ground in the IT.P.)

Based on a liquid fuel boiler, you can create an efficient and fully automated system of heating and hot water supply for a country house. It is only important not to be mistaken when choosing heat generating equipment operating on diesel.

The absence of a main gas puts a difficult task before the developer: how to provide a country house with warm and hot water? If there is no gas pipeline next to the dwelling or its laying is the case of a foreseeable future, a good alternative gas can be liquid fuel (diesel fuel), the stock of which (several tons per heating season) is kept in a special capacity in the building or on the site next to it. Recently ("IVD", 2009, №3) we compared the diesel fuel system with other energy resources used for heating, and briefly touched the organization of storage for diesel fuel and the boiler nutrition system. Today it will be about the main design features of liquid-fuel heat generators presented in the Russian heating equipment market.

Depthbed Iron Labyrintha

Most professionals recommend those who prefer heating on liquid fuel, buy a heat generator with a cast iron heat exchanger. It is collected from sections bonded with each other with special nipples. The unsubstituted heat exchanger is a combustrian space where the diesel fuel burns, and one or more channels for flue gases, which are made inside the heat exchanger two, three or four turns ("stroke") before they fall from the chimney. The walls of the furnace and flue channels cools the heating system coolant (the circulation pump of the heating system is driven through the heat exchanger). The temperature of the coolant at the outlet of the boiler is higher than at the input, by about 15-25С.The preference is given to the cast iron because, when burning a diesel flaring containing a significant amount of sulfur, a very caustic condensate may form in the furnace and chimney, due to which the metal quickly corps. But the cast iron walls of the heat exchanger are rather thick, the destruction flows slowly, and the boilers have time to work out to the end-to-end root of some kind of thermally loaded section for 25-30 years, and sometimes live to fantastic age - 50-60 years old!

From the deficiencies of the cast iron as a structural material, its increased fragility should be noted. It is afraid of sudden shock loads. Therefore, if you plan to carry your cast-iron boiler somewhere far away, take care of the proven carrier transported it. Such boilers weigh a lot and are cumbersome, but sometimes you can deliver them to an object in the form of sections and gather already in the house.

Sectional liquid fuel boilers supply to Russia Buderus, Vaillant, Viessmann, Wolf (all Germany), De Dietrich (France), Biasi, Ferroli (Obaalia), CTC (Sweden). In addition, it is impossible not to note the products of Roca (Spain), ACV (Belgium), Chappee (France), Fondital (Italy) and some other manufacturers. Good, for example, boilers with a heat exchanger from high-strength eutectic (low-melting) cast iron GT220 (de Dietrich), as well as proven by the time of the IROVIT model (Vaillant) and Logano (Buderus). There are interesting units in the market and with solid heat exchangers from the cast iron, such a boiler offers, for example, Chappee. According to specialists of the Russian representation of this company, the hemispherical form of heat exchanger is optimal for the distribution of heat loads, which significantly increases the resource of this boiler.

You can buy a boiler with a steel heat exchanger to work on the diesel engineer (they produce the same boiler companies). However, it is necessary to remember that most likely it will last less than a device with a heat exchanger of cast iron, since the steel corps more intense than cast iron. Usually the average model has to be thrown out 15-25 years, but good boiler steel works up to 50 years. But the steel boilers are cheaper, easier cast iron, are not afraid of shock loads (within reasonable limits, of course), and due to low thermal inertia, they are easier to automate them.

Very high-quality steel boilers for burning liquid fuel manufactures STS. For example, CTC Okhotherm Unit boilers have a horizontal cylindrical combustion chamber. Stainless steel plug-in cylinder and the spherical surface of the rear wall create the desired direction of the movement of combustion products. Plots implemented a three-way principle of flue gases, special turbules were used. The curve of the efficiency of the aggregates reaches 98%, and the resource, as the firm trading in Russia, is at the level of 50 years. Arsenal Viessmann has a Vitola 200 Water Heat, equipped with an innovative bimetallic heat exchanger Biferral: one layer in its profiled cast iron, another, of steel. Such a heat exchanger design, according to the manufacturer's testimony, reduces the intensity of condensate education and increase the service life of the boiler.

We will swim in warm water!

Most often, the boilers on liquid fuel supply in one-circuit design. There are no elements of the DHW system. Water is heated in the tank-drive (boiler), inside which is located a tubular heat exchanger connected to the boiler (for a family of four people need a pot volume of approximately 250l). It enters the tank from the cold water supply system of a country house. The boiler must be agreed with a boiler in power, otherwise discomfort is possible due to inadequate operation of heating. The vasserine of the leading boilers is always tanks, ideally suitable for a particular boiler model. For example, Buderus informs its buyers that the Logano boilers of this company are perfectly combined with water heaters of Logalux SU or Logalux LT. De Dietrich Complies GT 2,200 High Performance Capacitive Water Heater with a volume of 160 or 250l, which is mounted under the boiler.

The market shows and models of dual-kinth-fuel boilers of low power (usually up to 45 kW) with a built-in battery tank or flower plate heat exchanger (if rigid water in your region, from heating in a plate heat exchanger, it is better to refuse its slotted channels very quickly " Wean salts ") and all the necessary elements of strapping for DHW. AV cast-iron thermoblocks with a capacity of 24-43kW with a built-in burner on liquid fuel, such as Lyra B (Nova Florida, Italy) or Capri B (Fondital), there are almost all required boiler room elements, docked each other at the factory. There is a built-in boiler for 130l, expansion tanks and pumps for DHW and separately for the heating system, a built-in filter on the diesel fuel supply line. In fact, the device can be attributed to the PlugPlay technique (the possible translation of this term is as follows: "included in the socket and use").

Fire flowers

With regard to boilers, working on liquid fuel, there is no such concept as an atmospheric burner. All models are equipped with fan burners that create a small overpressure in the combustion space and flue channels, thanks to which the fuel combustion products are moving towards chimney, along the way, giving it its heat through the heat exchanger walls. Most often in country houses use purely diesel burners: while liquid fuel is burned after spraying with special nozzles and ignite the fuel-air mixture using the electrodes of the ignition. But on sale there are and substantially more complex technically, notable (B2-3 times more expensive), although less efficient bitoxium burners. In addition to choosing a consumer, they can work on gas or diesel fuel.

By type of power control, liquid fuel burners of household boilers are divided into one and two-stage. The power of the first fixed; They allow you to maintain the temperature of the coolant in a specific range of values (1-2C) as a result of the automatic power on and off the burner. Two-stage burners capable of functioning both on complete and partial (for example, 50% of the maximum) power, more economical, since it is possible to save several hundred liters of fuel per year. They are put on more "strong" boilers - from 40kW.

Wamalous boilers (usually up to 45 kW) liquid fuel burner is often embedded in the unit, it is beneficial for the user, since it is not required to be adjusted. The accumulation of the equipment in this way of devices belongs, for example, the cast iron boilers of the GTU-120/1200 series (Dedietrich) with a capacity of 16-39kW for heating and hot water supply. This boiler is supplied in two packs. Water-collected apparatus with a cast iron heat exchanger and a liquid fuel burner, adjusted and tested at the factory. Emissions level NOx are less than 120 mg / (kWh). In the second system, which is easy to embed to the boiler when assembling, like a drawer of a written table. The built-in burner also equip the GEODIS (BAXI, ITALY) IDR model.

However, more often the boiler is sold separately, and to it as an independent heading, users acquire a mounted fan liquid fuel burner. Such units operate in a fairly wide range of capacity, and at the factory they are not configured to a specific boiler. This should make a commissioner.

From that that liquid-fuel boilers can work with burners of different firms, the manufacturers themselves say. The main thing is that diesel fuel and the burner device have the necessary certificates (European norms, as a rule, are much striking Russian). So, the boilers of the Logano series (Buderus), Irovit (Vaillant) function on diesel fuel EL according to DIN 51603 with any fan diesel burners according to DIN EN 267. Reconciliation with this document, the burner devices proposed on the market on the permissible content of NOX and CO are divided into three classes. . The xamu high (the third) includes burners, in the exhaust of which the number of NOx (in terms of NO2) is less than 120 mg / (kWh), and in less than 60 mg / (kWh). This technique manufacturers are usually positioned as low-emission (burners have Low NOx designation). Select the burner should follow the power of the boiler, sizes and resistance to its furnaces and smoke channels.

Low-temperature boilers

Low-temperature heating systems that have received widespread in Europe today are increasingly used in Russian country houses. Valid dreams from traditional installations in which radiators are sometimes heated to 90 ° C, such heating systems are safe (burning about the battery with a temperature of 43-45s is simply impossible), more economical and comfortable. However, for their normal operation, special low-temperature boilers are required, capable of providing a house with a temperature with a temperature of 50-55C in the feed line and 30-38c- in the reverse.

Higher boilers The temperature in the reverse line is most often dropped below 55c. If this rule is broken, an acid condensate is formed on the inner surface of the furnace, which is rapidly corrosive metal (especially from steel boilers). In addition, the large temperature difference can cause the destruction of the cast-iron sections of the boiler. Therefore, most manufacturers indicate the minimum temperature of the water in the return highway for its safe operation.

The simplest solution is to install the bypass jumper with the pump between the feed and reverse lines. Hot water from the feed line is mixed to cooled in the "return" if the temperature sensor at the inlet into the boiler detects an inadmissible cooling of the coolant.

To eliminate the temperature differences within the heat exchanger, some firms apply technical know-how. So, Buderus implements the thermostream technology in their units (before getting into the boiler, the cold coolant is mixed with heated). VIESSMANN vesicles The JetFlow system directs the flow of cooled coolant through the entire boiler so as to ensure its uniform distribution between sections and rapid mixing with the already heated coolant. This allows you to prevent the formation of condensate in the furnace. AU Boilers de Dietrich The heat exchanger is made of special eutectic cast iron. Its plastic is about 30% more than the usual cast iron, which allows the manufacturer at all not to introduce restrictions on the temperature of the "returns".

The liquid fuel burner market is quite large, as their service life is usually 2-4 times shorter than the "lifetime" of other elements of the boilers. Among the active "players" can be called Ecoflam, Lamborghini, Riello (all of Italy), Giersch, MHG, Weishaupt (all Germany), Bentone (Sweden), ELCO (Switzerland), de Dietrich IDR. The cost of a good two-stage burner for 30-40kW is usually not lower than 55 thousand rubles.

However, the choice of burner "on the side" is not always justified. The proceeding program of boilers, as a rule, presented mounted liquid fuel burners under their own brand (some manufacturers themselves produce burners, others place a trademark on the products of specialized companies). For certain modifications of the boilers, their manufacturers recommend certain model of burners, allowing to make the "boiler-burner" coil triad as efficient as possible.

So, all Viessmann burner devices pass the cycle of computer fire tests and are optimally consistent with its parameters with a boiler. For example, in Vitola 200 boilers, fuel is burned with low emissions of harmful substances largely due to the burner Vitoflame 200. Indicators of harmful emissions at the boiler are significantly lower than very strict environmental standards according to the Blue Angel standard. The G215 WS (Buderus) in the execution of the Unit actually the heat generator and the burner are also ideally coordinated with each other in a number of essential technical indicators. When they work, it is almost not formed soot. In addition, the burner is installed in a noise-absorbing casing, and there is an opportunity to put the boiler in the immediate vicinity of the residential premises.

Generally speaking, the noise level of the fan burner is quite high, and the sound and timbre is comparable to the buzz of a small vacuum cleaner. Therefore, if you do not sound a boiler room or burner, it is better to place a liquid fuel boiler as far as possible from the residential rooms, in particular bedrooms.

It is not worth buying the cheapest burner model, because technically imperfect equipment does not guarantee completeness of the combustion of fuel. As a result, soot is formed, deposited on the inner surfaces of the heat exchanger of the boiler and impede the impact of heat into the heating system. Unused energy is lost, leaving through the chimney. The layer of soot with a thickness of 1mm increases the temperature of the exhaust gases by 50c, which leads to a rapid wear of the heat exchanger, cracking the chimney and increase the fuel consumption.

Data for selection of equipment boiler

Country house is built of red brick. Heated area- 300m2, heat loss building - 35kW. The queen is provided by two contours of heating - radiators and warm floors on the first floor, the area of which is 135m2. Diesel heating is temporary, in the future the transition to gas is scheduled.

The room under the boiler room is located in the brick extension to the house of 25m2. There is also likely to install fuel tanks (refueling them is not more often than two times a year).

Water supply: there are two bathrooms in the house, four people constantly live, who are accustomed to enjoy hot water in urban mode.

System Automation Requirements: To enhance comfort and minimize fuel consumption, plan to apply weather-dependent automation; The boiler power regulates depending on the temperature on the street.

Flame showdown

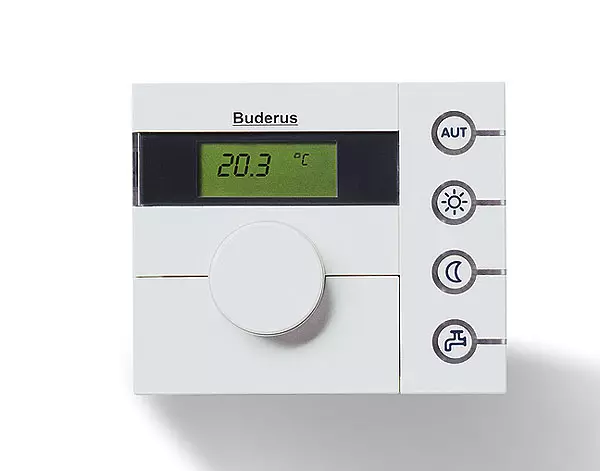

The automation of the boiler on liquid fuel ensures control and maintenance of temperature in a user-defined temperature in one or more heating circuits, the DHW system, and also performs other tasks. It guarantees the performance of the boiler in the absence of a person and, if necessary, protects the heat generator from hazardous modes. The simplest automation blocks are supplied complete with boilers even in their "poorest" configuration, but more expensive and technically "tricky" technique often have to acquire for a fee. Do you need to buy an additional automation unit for the boiler? Decide yourself.It should be borne in mind: the simplest (of supplied with boilers) automatics usually assumes that the temperature in the feed line needed to heat the air by radiators to comfortable, the user sets manually (for this every time you need to go to the boiler room). The knob on the front panel of the boilers is set, as a rule, at a minimum, if the temperature is 10-20 ° C; In the middle position, the temperature of the outer air in the range of 0-10s. Over the temperature approaches -15s, its handle is shifted closer to the maximum. When changing the weather, go to the boiler room will have to be quite often to switch the boiler knob to the appropriate range of heat output. In summer, the heating mode is turned off completely manually, but the boiler continues to work, since the cooking mode of hot water remains active. Cossacks accustomed to urban comfort say that such a system is although acceptable, but not very economical and not too convenient.

From constant trips to the boiler room, you can refuse, trusting the temperature control in the supply line to the room regulator (it will cost 6-15 thousand rubles.). Modern models of these devices have a very understandable, friendly interface with respect to the user. Selecting the desired temperature, you will get the opportunity to relax. Based on the testimony of the thermal sensor installed in the control room (for example, a children's, hall in a country house, a living room at his northern wall IT.P.), the room regulator will give the command to start or stop the boiler when the temperature in the room will be released for the allowable limits.

If you are ready to spend on automation 35-40 thousand rubles. At your disposal there may be a "advanced" weather-dependent system. It allows us without prejudice to comfort at all do not go to the boiler house throughout the year and besides, it is very economical to spend fuel. The weather-dependent system generates a control signal for the boiler, taking into account the temperature in one control room, as well as on the street. This allows in advance (while the cold has not yet penetrated the house) react to changes in weather conditions, increasing thermal power or reducing it to the optimal value. A programmable weather-dependent automation typically has many useful functions that could be written separate item (but now this topic remains beyond the scope of this material).

It is best to equip the boiler by the automation of the company producing the aggregate itself, - Baxi, Buderus, CTC, de Dietrich, Ferroli, Vaillant, Viessmann, Wolf Idre. But sometimes it is justified by the purchase of automation and independent manufacturers, among whom KomexTherm (Czech Republic), Siemens (Germany), as well as Honeywell (USA). Regardless of the type of automation on the radiators in the rooms it is advisable to install the valves with thermostatic heads. This service can be maintained different temperatures in different rooms, except for the control, where the thermal sensor of the room regulator or the weather-dependent system is located (it will heat up to a set temperature controller in automatic mode).

Approximate boiler room costs on liquid fuel *

| Name of product | Units. change | Number of | price, rub. | Amount, rub. |

|---|---|---|---|---|

| Copper de Dietrich GT 1206 with water heater L160 (160l) and weather-dependent control panel DIEMATIQUE 3 | PC. | one | 176 490. | 176 490. |

| Liquid fuel burner de Dietrich M 100-2s | PC. | one | 25 863. | 25 863. |

| Board + Sensor for one mixing circuit | PC. | one | 6364. | 6364. |

| Hydraulic module with three-speed circulation pump and differential valve | PC. | one | 28 379. | 28 379. |

| Hydraulic module for direct circuit with three-speed pump | PC. | one | 16 835. | 16 835. |

| Connecting pipelines for the section "Cotele-hydraulic module" | PC. | one | 3515. | 3515. |

| Wall brackets for expansion tanks | PC. | 2. | 1018. | 2036. |

| Security group in the heat insulated collector | PC. | one | 4477. | 4477. |

| CDI2 dialog module | PC. | one | 7326. | 7326. |

| Expansion tank Reflex NG 50/5 | PC. | one | 2822. | 2822. |

| Expansion tank Reflex DE 18 | PC. | one | 2350. | 2350. |

| COMBI 1-1 fuel tank | PC. | one | 13 501. | 13 501. |

| Main HP Pack for Combi and Quadro | PC. | one | 6513. | 6513. |

| Circulation pump UP 20-1S | PC. | one | 8416. | 8416. |

| TOTAL | 304 887. | |||

| * According to the Russian representative office of De Dietrich at the end of December 2008. |