Warning and elimination of wooden flooring damage, replacing a spoiled parquet board.

Accidentally fallen a hammer or a broken vase, unsuccessfully moved heavy furniture, but something else, which is on the surface of the parquet board, there are ugly scratches, chips and dents! .. Constantly attracting look, they become a reason for a bad mood. But, as they say, everything is fixable!

The natural beauty of the parquet board (more on this material can be read in №7 "IVD" for 2008.) Keep a variety of varnishes or oils. However, over time, scratches and scratching appear on it. Return the initial view of the sweat surface helps the floor renewal tools that are used with certain frequency.

More or less deep scratches, irregularities and dents will become imperceptible if they are lined with a putty for wooden floors, and then cover the renovated areas with a special repair oil or varnish. To eliminate serious damage to the parquet board in each specific case, an individual approach is required.

Tarkett. |

Khrs. |

Tarkett. |

1. With the premises of the kitchens, where water often use and there is a danger of its falling to the floor, manufacturers recommend applying an extra protective layer of varnish or oil to a parquet board. It will protect the joints from the penetration of moisture and will provide additional waterproofing of the connection of individual boards.

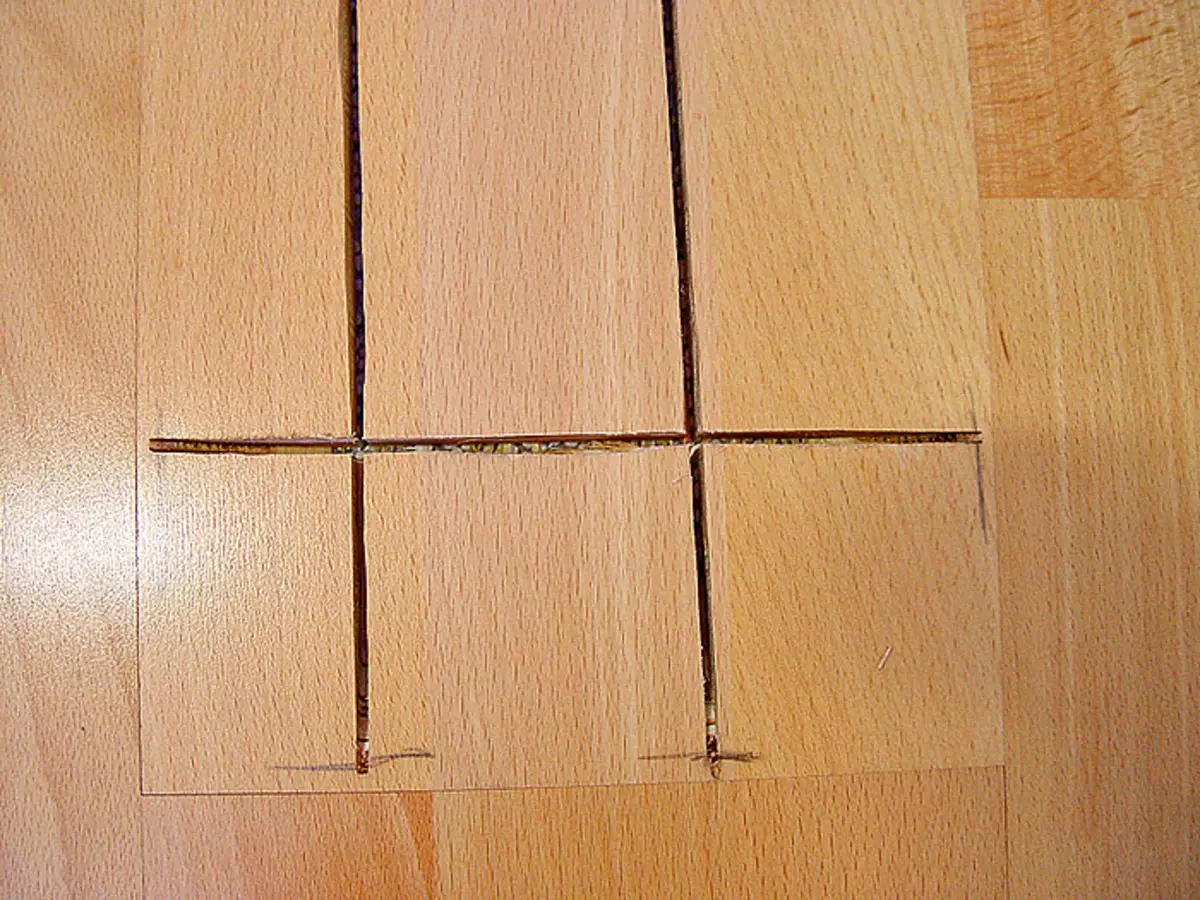

2. Laying a parquet board "floating" way simple and does not take away a lot of time. Thanks to the built-in mechanical locking system, separate boards are tightly closed with each other, forming smooth invisible joints. To replace the spoiled board in the coating, laid in this way, you need to disassemble several ranks of the floor

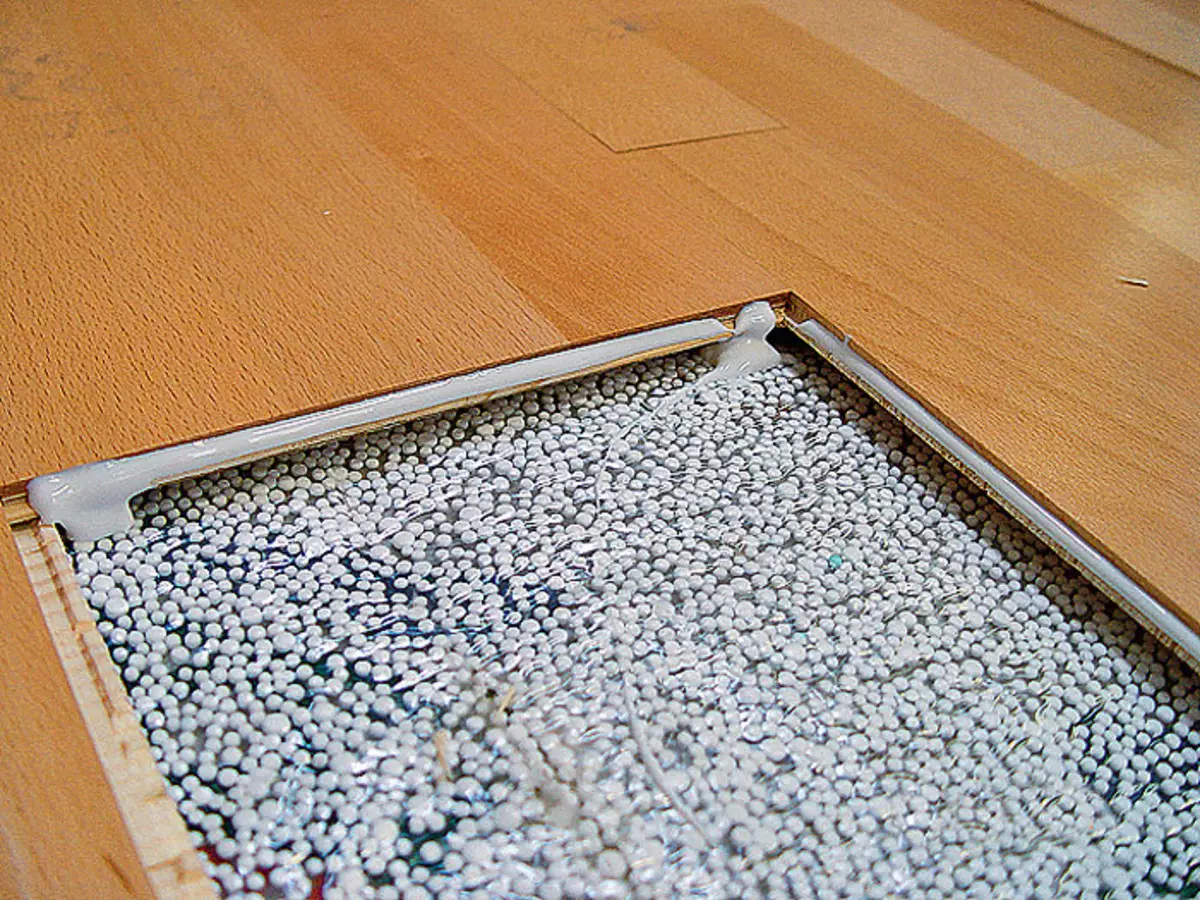

3. Supported traces from shoes on black rubber soles Easily remove ordinary school eraser

Outdoor disassembly

The maternity hosts after installing the floor preserve several boards for possible repair. Those who do not like to make stocks "for a black day" can acquire and use new boards. Moreover, choosing them, you should certainly consider the tree of wood, selection, lamella design, surface treatment, sizes, and mechanism for closing parquet boards of an existing floor.

One of the options for removing the damaged parquet board from the coating, laid by the "floating" method (without rigid fastening of boards to the base), is a partial dismantling of the floor. Especially since the castle connection of modern coatings without problems withstands such procedures. The process starts with dismantling the plinth. Then disassemble several rows to the place where the defect board is located. Replacing it, after which they collect all the ranks.

|

|

|

|

|

|

|

|

|

|

|

|

There is no unified methodology for the work. Specialists of some companies believe that the floor should be disassembled in the order, reverse sequence of laying, regardless of the location of the spoiled area. At the same time, all the boards must be labeled so that when re-assembling each of them is in its place. Others argue that the disassembly of the installed floor should be started from the wall closest to the damaged board in order not to affect the coating more than necessary. Therefore, it is important to entrust the implementation of these works by a professional, which in any case guarantees the success of the operation.

There is a certain nuance: the newly installed parquet board may look a kind of "patch" on the floor of the floor, because it has not yet stealing a man's leg and did not touch the sun's rays, under the influence of which the natural change in the shade of wood occurs.

Of course, gradually the differences will be practically imperceptible. However, this problem will not arise if you produce a "castling": a spoiled board replaced any other from a secluded room of the room, and to put a new one where it will not be too rushing into the eyes.

Replacing a separate plank of a three-row parquet board

Point

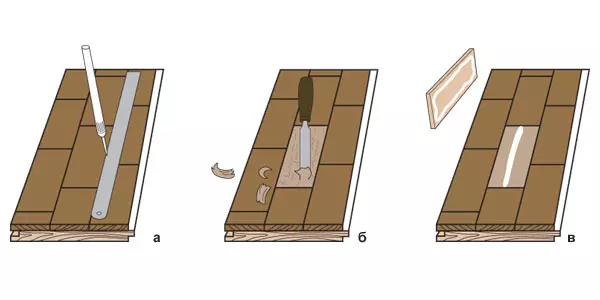

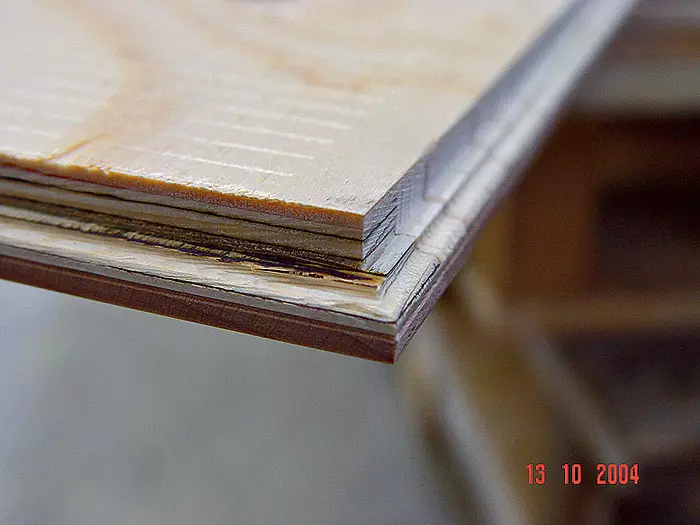

A different approach to the removal of a defective parquet board requires a floor covering glued to the base. In place, instead of partial dismantling, the floor is carried out a local operation with the help of an angular grinding machine, hammer and bit. With minor damage to the three-row parquet board (its top layer consists of three rows of planks) not the entire board, but only one spoiled bar. Pay attention to photos and schemes with a detailed description of the installation sequence.

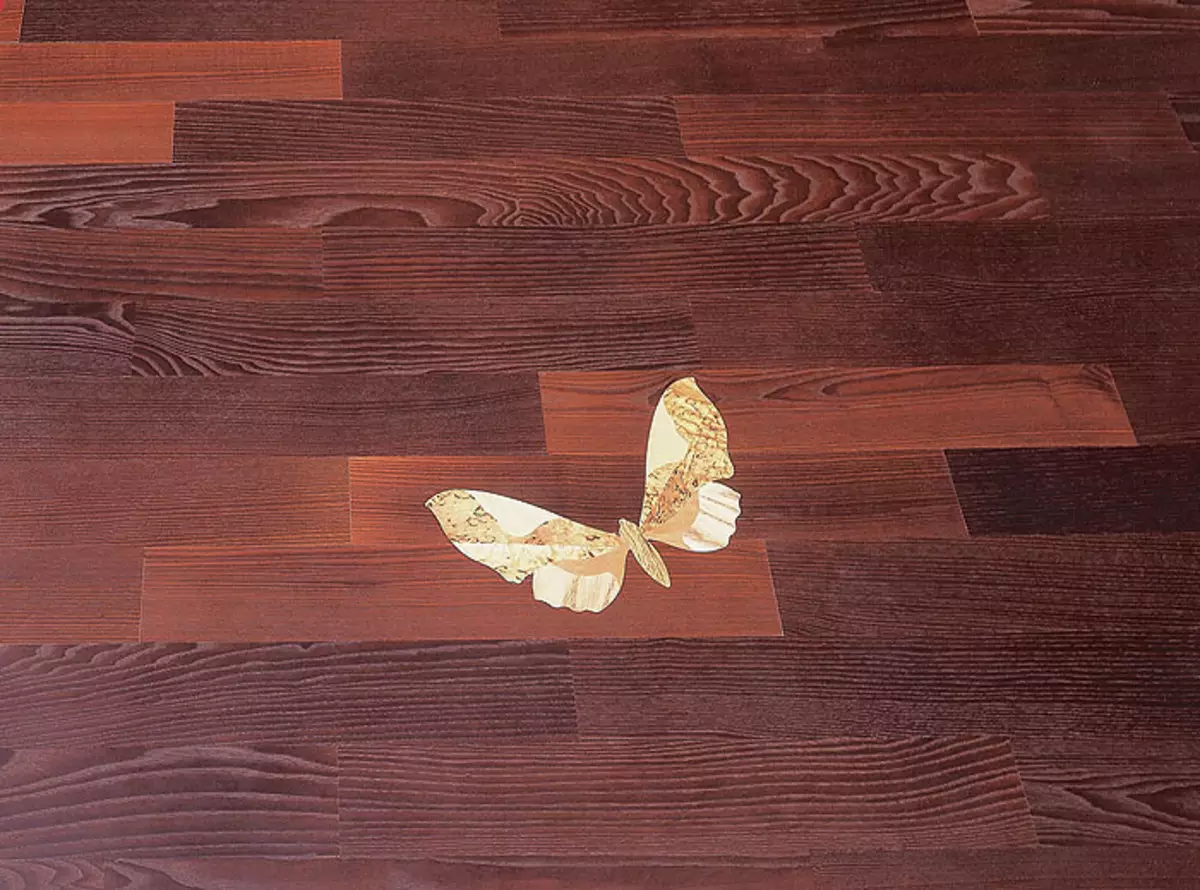

Skeptics may fairly notice that such situations are quite rare. After all, about 80% of the floors from the parquet board are mounted "floating" in the way, and only 20% of the boards are glued to the base. That's right. However, the rare owners of such floor coverings should know that there are no irreparable situations. Moreover, coming to the case creatively, banal repair work can be turned into designer: transform the floor covering, and at the same time you make new strokes in the face of the interior. For example, on the site of a long slot in the floor, which often remains after the removal of disassembled embedded furniture, wardrobes, dismantled interior partitions, looks perfectly a decorative curb. It may be necessary to create a harmonious composition "operational intervention" and in other sections of the floor, but the result is usually worth it. Separate defects scattered over the entire floor surface decorated with elegant inserts in the form of geometric shapes, colors, butterflies, animal IT.P.

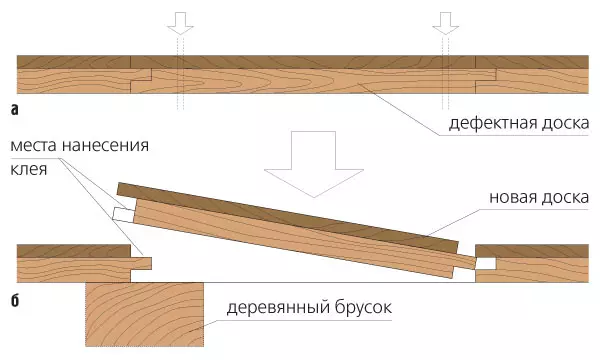

Features of the replacement of a parquet board laid on the lags:

B-when replacing the boards laid on the lags or beams, to the bottom side of the board having a comb, as well as to the bottom of the end side of the new board in each compartment of the lag gluits wooden bars, which serve as a hardening element

Forewarned is forearmed

There are several obvious and simple rules, neglect which most often leads to more costly and labor-intensive repair work.

For example, chairs of chairs, chairs and other frequently moving objects of the situation have a sufficiently strong effect on the floor surface, which is why prints appear on it, potholes and dents. There are two outputs: either completely abandon such furniture if the coating indoors is from soft wood (pear, cherry, alder), or take care of additional floor protection. Moving large household appliances (refrigerator, stove), furniture items, musical instruments (harp, piano) equipped with wheels or legs, as a rule of small diameter, is fraught with the appearance on the floor of ugly traces or scratches.

Technology for replacing the damaged parquet board on the coating, glued to boost

Upofloor. |

Upofloor. |

Upofloor. |

Upofloor. |

4. On the board to be replaced, stick the laying lines to the ends in order not to accidentally cut the adjacent elements. The last damaged board, at a distance of 3-5 cm from the edges, they make rugs.

5. Activity should be extremely gently so as not to damage the boards in adjacent rows. The depth of the cut is selected in accordance with the thickness of the board (the most common thickness of the parquet boards - 14mm). First remove the middle cut part of the board. Since the coating is glued to the floor, a chisel is used to remove individual fragments. All long parts remaining on adjacent boards, carefully disconnect and emit.

6. The need is fixed (pressed) adjacent to the knee board. 7. Then remove the end balance sheets.

Upofloor. |

Upofloor. |

Upofloor. |

8. Harves are cleaned with a knife. Carefully purify the connections of the "spike" adjacent boards and the basis of the floor from the waste of wood material. If you need to close random damage on the substrate, adhesive apply. On the short and long sides of the new boards spill the lower edge of the groove.

9. The surface of the glue is stuffed to improve the grip. Check the size of the board for compliance with the cut area.

10. On two short sides of the boards on the floor and glue glue on the thorn side.

Upofloor. |

Upofloor. |

Upofloor. |

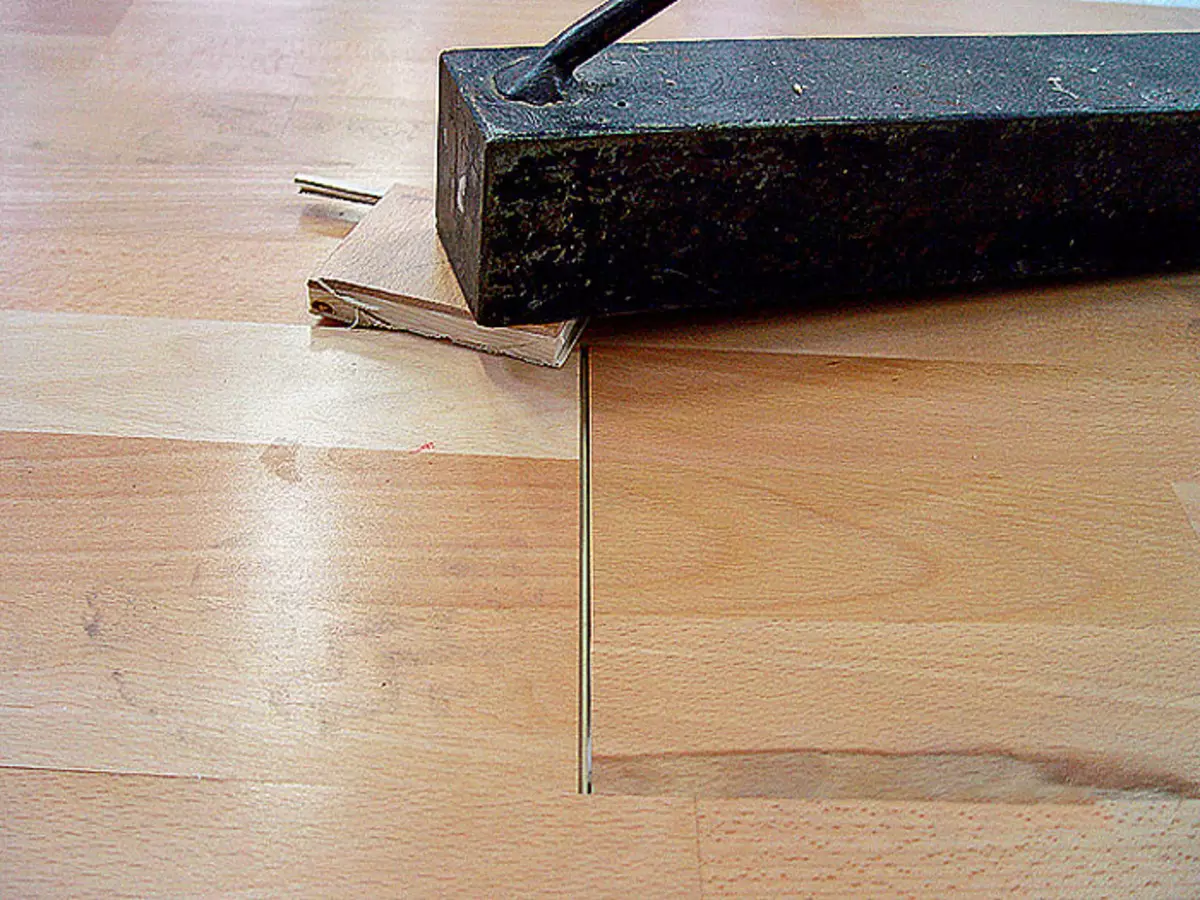

11. The new board is installed, carefully customizing the slot side of the slight side of the short side. For proper adjustment, on the other hand, the loads are used.

12. The board along the ends and immediately wipe the glued with a wet cloth.

13. On the glued side of the board set small loads and leave them until the glue drying. The process of replacing the board is desirable to finish, applying a suitable putty putty for parquet floors to joints with adjacent boards

The polarized consequences sometimes lead and excessive thrust for cleanliness. So, the soap, added to the water during a wet cleaning of floors from a natural tree, leaves a muddy white flare on the surface. VcRidors and kitchens under the influence of water and aggressive liquid-chemical reagents, highlights on time not for a walk, the wooden floor is bleached or covered with spots. Basic rule: any liquid must be immediately wiped from the floor surface. Catering spots are removed by special cleaners. The consequence of unjustified savings on the means of cleaning wooden floors and the care of them - irreversible changes in the appearance of the coverage and the need for repair work.

Barlinek. |

Karelia |

|

14. Parking board is characterized by large size stability. Is the same when laying a coating "floating" way around the perimeter of the room and in places of its adjoining to fixed structures necessarily leave small compensation gaps (10-15mm)

15. Care of natural wood floors involves dry brushing or vacuum cleaner. If necessary, the surface is wiped with a well-pressed cloth, and the floor you only need to moisten a slightly. According to experts, after a wet cleaning, it should dry over 1min. It is desirable that the washing vacuum cleaner leaves the spots

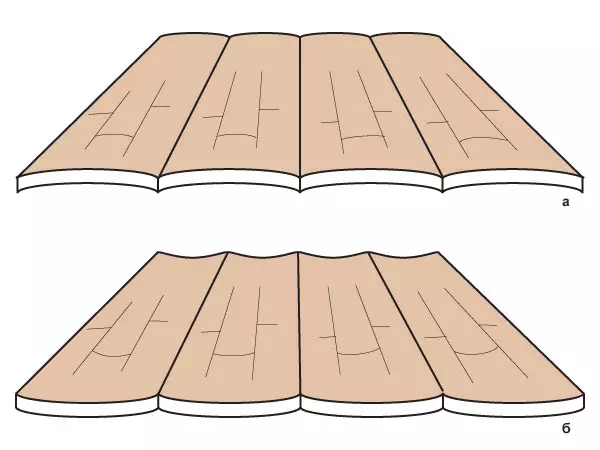

16.The (a) surface on the width of the parquet board is evidence of excessive air humidity, concave (b) is insufficient

Liquidation of parquet board damage

| Damage | Cause | Warning method | Remedy |

|---|---|---|---|

| The appearance of cracks between the boards | Shrinkage of boards as a result of an increase in air dryness | Do not allow laying of wooden floors to an unetebled tie (for example, in new buildings) | Maintain permanent air humidity 30-60% and temperatures about 20c |

| High temperature in floor heating system | Do not lay some tree species (beplace, maple), especially sensitive to climatic changes, on a warm floor system to avoid the risk of cracking | Make sure that the heating system of floors does not create extremely high temperatures on the surface (maximum allowable - 27C) | |

| Swimmed surface on a width of a dice or board | Increased air humidity or moisture penetrating from below | When laying parquet boards in a new building, a layer of waterproofing is required based on | Perform waterproofing |

| Concave surface on the width of the dice or board | Shrinkage due to increased dry dryness | Support relative air humidity in the range of 30-60% | Support relative air humidity in the range of 30-60% |

| Beach curvature | Impact of moisture or no compensatory gaps | Leave compensation gaps around the perimeter of the room, in doorways, in heating pipes, columns, fireplaces | Cut the required compensation clearance, make sure that waterproofing |

| Uneven surface of the draft floor | Align the surface of the rough floor before laying the parquet board. Surface deviations horizontally on Square 2M2 are allowed not more than 2mm | Disassemble the coating, align the draft floor | |

| Insufficient displacement of end connections | The floor from parquet boards, laid "rotary" (minimal shift of end connections in adjacent rows - 500mm, for boards with a length of 1,2m-300mm) has a greater stability. | Re-lay the coating with the correct displacement of the end connections | |

| Pumping slats under pots with plants standing on the floor | Impact of condensate formed after watering colors on the bottom surface pot | Never put pots with flowers on the floors of natural wood - only on the stand, so that under the pots there is a place for air circulation | Replace dies or boards |

| Changing timber color | Impact of ultraviolet radiation | It is impossible to avoid exposure to UV radiation. We must know that different breeds react to it unequally | Immediately after laying, no carpets on the coating of a natural tree should not be treated. He needs to "mature" |

| Irregularities, chips on the surface of the parquet board | Mechanical damage to the surface of the parquet board | Carefully handle parquet board | Make local repairs with varnish, oil or putty. With substantial damage to replace the cry |

The editors thanks the company "Ark-parquet", "Tarkett Rus", Barlinek, Karelia, Khrs, Upofloor, Weitzer Parkett Rus for help in preparing the material.