Features of the installation of steel, plastic, copper and zinc-titanium drainage systems: specifications and design features

We also note that the drainage system is not only a functional, but also a decorative element of the building, which is largely affecting its architectural appearance. Father, what options offer modern manufacturers than should be guided by choosing a drainage system, as it competently to design and install, we will tell in this article.

Winter Extreme

For every taste

Systems from PVC are not subject to corrosion, have a small mass, easy to assemble, damage the noise of rain, and due to modern plasticizing additives they have sufficiently high impact resistance even at negative temperatures. Plastic drainagers are mainly delivered to Russia from abroad. They produce Plastmo (Denmark), Hunter Plastics (United Kingdom), international companies GALECO and WAVIN, GAMRAT, KACZMAREK, PROFIL (All Poland), S-Lon (Netherlands), Inefa, Rehau (Burg Germany), Nicoll (France ), First Plast (Italy), Scala Plastics (Belgium), Plastika (Brand Nitra-R, Slovakia) IDR. Not so long ago, the manufacture of hydroelectric systems from PVC was established in Russia (RupLast).

Rheinzink.

RHEINZINKO Many sets of modern drainage systems include additional accessories:

1. - Eaves, preventing leaks between the roof and the chute;

2.- Mesh protection against foliage foliage (due to the lack of such a design can be closed)

Elements of plastic drainage systems can be round, rectangular or curly sections. The last two types are used to give the original appearance of the facades of the building. But it should be borne in mind that their throughput is slightly smaller, and the probability of clogging is slightly larger than round, with the same cross-sectional area. As a rule, plastic mass used for the production of waterproof elements is painted in four main tones: white, brown, gray (or beige), black (or graphite). Nicoll's vasserin is also cherry and green waterproof. Elements with curly cross section are more expensive than with a round, by 20-30%, and color more than whites is about 15-20%. PVC can be painted in copper color, for what, however, it is required to add to the plastic mass of polymethyl methacrylate. This is quite expensive technology, and only a few companies apply it, for example, Braas (Germany).

PVC parts change their dimensions in temperature fluctuations (the change in length is approximately 0.7mm per 1pog. M when the temperature drop is 10c), so it is possible to secure the gutter using special brackets. They firmly hold the chute, but at the same time do not interfere with it to move along the eaves.

Where to go?

Perhaps the only drawback of plastic systems- gradual fading under the influence of ultraviolet rays (the side of the head of the gutters and pipes becomes the ashes shade).

No less widely in the domestic market is presented steel drainage systems produced by Metalist enterprises (brand Grandline), Metal Profile (MP Modern and MP Models), "Stroypromet" (including the Knudson trademark), Aquasystem (all- Russia), Lindab, Rlannja Siba, Wijo (all Sweden), ORIMA (including Takotta and Weckman trademarks), Ruukki (Windingland) IDR. Galvanized steel thickness is used for the production of metal systems. 5-0.6mm with double-sided polymer coating. The lastness of the latter to atmospheric factors is the ground condition determining the durability of the drainage . PVC-based coating (the so-called plastisol) has a thickness of 100-200mkm and due to this steadily mechanical impacts. There is one minus, over time he Flowers. This shortage is deprived of the PVC coatings of a new generation that contain additives that increase resistance to ultraviolet. They are designed and applied by the famous metallurgical enterprise Arcelor Mittal (Luxembourg), which purchased sheet steel for drainage systems Some domestic firms (for example, "metal profile"). Foreign companies are mainly used with polyurethane coated, polyamide modified (Pural). It is very resistant to atmospheric factors and a durable coating, with a relatively small thickness (50 μm), it effectively protects the metal from local damage. In the production of parts that cannot be made from sheet steel coated (for example, chute holders), domestic and foreign firms are usually used powder paint, capable of properly protect the metal from corrosion for 20 years.

The number of primary colors varies from various manufacturers from three (ORIMA, LINDAB) to five or even seven (Aquasystem, "metal profile"). Almost all firms to order can paint elements in additional tones. But if you need carpal drains, be prepared for the fact that it will not only derete your purchase on 2-3ned, but also affects its price (the system costs about 15% more expensive).

Steel drainage systems should be purchased only at well-known manufacturers, so as not to receive chute holders from steel 2-2.5mm thick as a surprise (instead of the necessary 4mm) or, even worse, components from the non-dissolved painted metal.

In the Russian market, in addition to steel, you can find other metal drainage systems. Their "metal profile", Aquasystem, FRISKE (Germany), Lindab are manufactured from copper. From zinc-titanium (zinc alloy with small amounts of copper and titanium) - Rheinzink, VM ZINC (UMicore trademark), FRISKE (GROMO trademark), Aquasystem. From aluminum - the enterprise Prefa (Germany), Ukhner Manufacturing (Canada). These very expensive systems, as a rule, are equipped with roofs from the same material or genuine tile. Such waterproofs are practically not corrosive, but copper and zinc are very soft metals and therefore require very careful handling during transportation, installation and during operation. Zinc-titanium drains are stained in different shades using patinishing compositions; Aluminum- Anodize and covered with weather-resistant enamels.

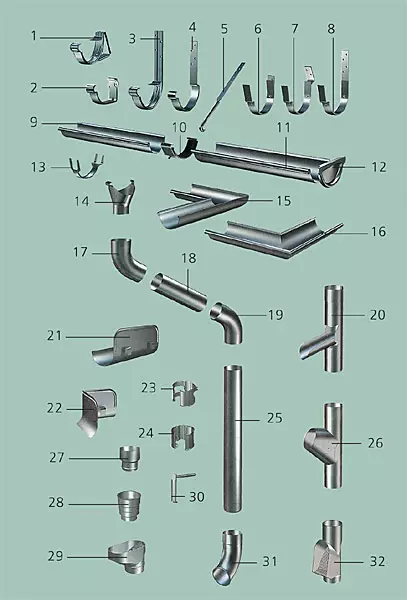

Details of the drainage system:

9,11-gutter;

10-gutter connector;

12-plug;

13- connector bracket;

14- funnel;

15,16 - chute corners;

17,19 - knee;

18-nozzle;

20- collective tube with spill;

21,22- Limiters of the transfusion of the gutter;

23,24 - pipe clamps;

25- pipe;

26-tee;

27- coupling;

28-adapter universal;

29,32- Draps drainage;

30- Khomut bracket;

31 - Knee delay

We must make us a calculation ...

At first glance, the drainage system is a very simple design. However, that it properly functioned and effectively coped with water flows, and the installation did not bucks due to the lack of necessary parts, the parameters and the product range should be calculated. We recommend to make measurements and make a preliminary calculation until the trading company is visited. Then you will be guaranteed from errors that are often performed during the quick calculation "on the knee", get rid of the need to feverly remember the required dimensions, and the conversation with the sellers will be more subject.

First of all, you should choose the desired section of the section of the elements, it is determined depending on the area of the catchment (it is usually taken equal to the area of the roof of the roof), the number and location of the descents (receiving funnels). The speeds of each model of the drainage system of sizes can be two (Profil, Ruplast, S-Lon IDR), three (Hunter Plastics, Lindab, Nicoll Idr.), And sometimes more. The most inquired in private construction options that ensure the flow of water from the rods of up to 100m2 and 100-200m2. For the first case, a gutter 100-120mm wide and pipes inner diameter of at least 85mm are used. In a second-gutter 120-150mm wide and pipes with a diameter of 100-125mm. Some models, such as LG25 and LG33 (Nicoll), allow you to combine a certain type of gutters with pipes of different sections, "Customizing" thereby the system for a large or smaller coating area.

In terms of plane

Until recently, flat (including exploited) roofs were practically not applied in private construction. But since European technologies have come to our market, the popularity of this attribute of the Mediterranean architectural style has increased significantly. Organization of water flow with a flat roof - a special problem, because without a drainage system, such a roof will last quite short. Typically, the surfaces give a small slope to the median longitudinal axis, where the receiving funnels are placed. At the same time, the drains pipes undergo inside the building - usually they are placed in plumbing risers. Along with the working system, you need to establish a system of emergency storm discharge of water to the ground through the facade of the building. Flat roof drainage systems are presented on our market by Hunter Plastics, Sita Bauelemente IDR.

The larger than the chute is equipped, the better the system copes with its task, but in the point of view of the architectural appearance of the building and cost savings, their number is required to reduce the minimum. As a rule, one pipe is enough for each 8-10m. But if, for example, the length of the eaves exceeds 10m, in any case it is recommended to install drainage pipes at both ends of the gutter and make the latter's flap from the center to the receiving funnels. This is due to the fact that the flow rate in the groove is significantly less than in the pipe, and if the groove is too large, the receiving funnel will be "chopped up" the receiving funnel - in this way, during the shower, the long chute will certainly become overflowing.

Deciding with a sizernary and amount of descents, proceed to the calculation of the total length of the gutters and pipes, the number of shaped and fasteners. Due to the fact that manufacturers produce gutters and pipes of different lengths (usually 2, 3 and 4m), it is possible to reduce the amount of waste to a minimum. Determining the length of the drain pipes, it is necessary to take into account the width of the eaves, otherwise you may not have enough small cutting pipe required for the "Swan neck" device connecting the vertical tube with a chute.

In addition to the gutters, pipes and knees for the equipment of a simple double roof with a drainage system, the holders of gutters and pipes should be purchased (their quantity depends on the material of the drain), receiving funnels, chute plugs, extensions, gutter connectors and pipe connector (for plastic systems). For a more complex roof, external and internal angular gutter connectors, tees of water pipes IT.D. For non-standard angles (if the eaves of the cornice line differ from 45 and 90 or when the slope is changed), many manufacturers (Aquasystem, Nicoll Idr.) Take it to make the necessary elements on special order.

Dr. Schiefer (FRICKE) |

Dr. Schiefer (FRICKE) |

"Metal Profile" |

Aquasystem |

3. Original Fricke system from patinated copper. Hope Copper acquires a similar shade after 10-15 years

4. If the length of each bartal roof cornice exceeds 10m, it is required to arrange 4 descents so that the gutter does not overflow during the shower

4. Metal elements of rectangular section, as a rule, are 15-20% cheaper than round

6. When calculating the system for a multi-circuit roof, the number of descents are determined, based on the total length of the gutters.

Convert parts into an integer

The cost of the drainage system compared to the price of the house is low. Its installation of modern components is not a great difficulty, and therefore, these works themselves are relatively inexpensive. Why is the installation of the drainage system sometimes turns into a problem, and some at home and stand without drainage for many years? The answer is simple: To mount the system, as a rule, scaffolding is required (neither from the roof, nor from the stairs to install a gutter on a two-story building). It is extremely unprofitable for it. Therefore, to save funds, it is advisable to install either during the roofing work (taking advantage of those forests from which the eaves are laid and the wind boards are nourished) or during the exterior wall decoration. While the roofing coating is not laid, it is possible to strengthen the gutters brackets, having screwed them to the shell boards. This method is the most reliable, but it is not recommended to be applied if the roof is covered with flexible tiles, since this material is not able to hide the irregularities of the base.

|

|

|

|

|

|

|

|

|

|

The first stage of installation of the hydroelectric system from PVC (chute installation):

The first holder of the gutter is fixed with such a calculation so that the outer edge of the gutter is 30mm below the roof slide line (for compensating for the wind board, support wedges are applied);

The last holder is exhibited on a water level by 20mm below the first (total gutter length - 6m);

In between the shelves of extreme holders stretch the cord and, focusing on it, screw the remaining holders;

G-making markup, with a hole with a metal cutting hole under the water drone;

Dracking the funnel and chute plugs with dichloroetane-based glue (this substance dissolves the top layer of plastic, thereby ensuring very high strength of the compound);

It is installed a chute, sequentially snapping it in holders

The second stage of installation of the drainage system (fastening of pipes):

Jumping through the trim and crate of the holes in the walls, screwed screws with a length of 120mm and a diameter of 6mm brackets, after which the pipes are fixed with the hose;

s, and - of two knees and the nozzle collect "swan neck";

K- attach to glue drain knee

In addition, it should be noted that the water pipes reinforced on the walls in the corners of the building significantly make it difficult to the outdoor decoration of the walls (plastering, siding siding). If such is planned, then the drainage should be mounted in two stages: during roofing work, you can hang the gutter, and after decorating the walls, install pipes. But it is possible to fully mount the system in the process of finishing the facades. There are two options for fastening brackets to finished cornices:

to the face of the carnice board (you should certainly take care that this board is firmly applied to the ends of the rafter, otherwise when filling the gathered with water or ice, it will simply turn it out);

Through the roofing coating to the crate (use special brackets and roofing screws).

It should not be attached to the holders of the gutter to the lower side of the cornice sink, since the hematic material will not be able to keep it during operational loads.

The maximum distance between the brackets for steel gutters is 600-700mm, for plastic - 500-600mm, for copper and zinc-titanium- 300mm. The greatest distance between pipe holders for all listed systems is not more than 2 thousand km. If there are pipe connections, one of the brackets are certainly placed under the joint at a distance of no more than 150mm from it, and each pipe segment is fixed at least two brackets. The plastic tube (or cut pipe) is hardly fixed by the clamp only in the upper point, the remaining holders only serve as guides. Pipes insert each other not until it stops, but leaving the gap (5-10mm) to compensate for the linear thermal expansion.

ORIMA. |

Rheinzink. |

Ruplast |

|

7. Sometimes the roofing drainage is connected to the drainage system, connecting the pipes, but more often the point receivers under the poles are satisfied.

8. Systems from roofing zinc make to order

9. The choice of the material of the drain system is practically independent of the type of roofing - so, plastic gutters are perfectly combined with genuine tiles

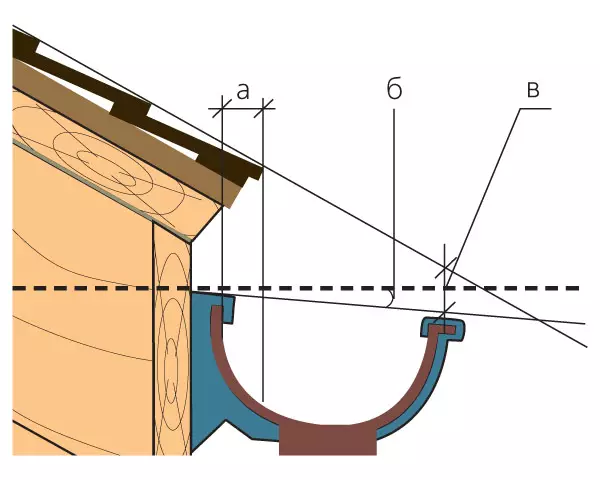

10. Required parameters for fixing the drainage gutter:

a) - Svet skate over a chute - 0.2-0.3 gutter widths;

b) - bias from the cornice - 3-5;

c) - distance from the row line to the outer edge of the gutter - 25-40mm

Installation of systems from various materials and from different manufacturers has its own nuances. Thus, metal elements are quite often fastening with each other with rivets, and the joints are sealing with silicone sealant. PVC systems are mounted using dichloroethane glue (Nicoll, Plastmo, RupLast). Doblyo elements of some systems (Gamrat, Profil) are already equipped with rubber seals, which facilitates the assembly and, in addition, it makes it easy to replace damaged (for example, fallen by the branch) Detail. The equipment of the building by the drain system is best entrusted by the brigade of roofers or seller specialists.

Comparative value of some elements of roping rowing systems for roofs with rods up to 100 m2

| Firm | Material | Price of element, rub. * | |||

|---|---|---|---|---|---|

| Chute, pog. M. | Pipe, pog. M. | Knee | Kractein Zuty. | ||

| Ruplast | PVC | 150. | 170. | 180. | 60. |

| Gamrat. | PVC | 130. | 170. | 170. | 70. |

| Nicoll. | PVC | 210. | 220. | 200. | |

| Scala Plastics. | PVC | 150. | 150. | 120. | fifty |

| Plastika. | PVC | 170. | 200. | 160. | 140. |

| Aquasystem | Polymer coating steel | 200. | 260. | 230. | 110. |

| Ruukki. | Polymer coating steel | 250. | 320. | 200. | 150. |

| Lindab. | Polymer coating steel | 230. | 280. | 270. | 130. |

| "Metal Profile" | Polymer coating steel | 525. | 720. | 220. | 140. |

| Lindab. | Copper | 1650. | 2150. | 550. | 400. |

| Prefa. | Aluminum | 600. | 650. | 690. | 350. |

| Rheinzink. | Zinc-titanium | 1200. | 1350. | 670. | 500. |

| Braas. | PVC | 330. | 420. | 230. | 200. |

| * - PVC prices are indicated for white elements, for steel - on standard elements |

The editors thanks the company "Metal Profile", Aquasystem, Braas, Dr. Schiefer, Lindab, Nicoll, Orima, Rheinzink, Ruplast for help in preparing the material.