Flooring device in the apartment: types of flooring, base types, laying methods, joint design. Market Review

Due to the quite affordable price, high performance characteristics, the ease of installation and ability to very well imitate other materials of the laminate, perhaps today has become the most popular flooring. Life service life of laminated HDF wear resistance class 32- more than 20 years

One of the fashionable tendencies of the floors of saturated tones with a pronounced pattern of wood fibers. Such a solution is not suitable for spacious premises.

The impregnation of the ends of the laminate panel panels in combination with the use of special sealants and sealing tapes allows you to adapt this coating for bathrooms

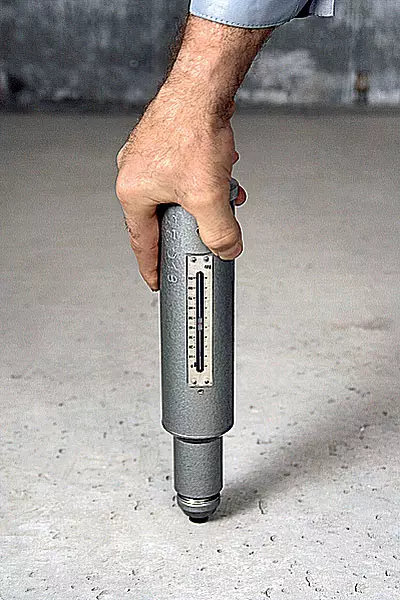

but.

b.

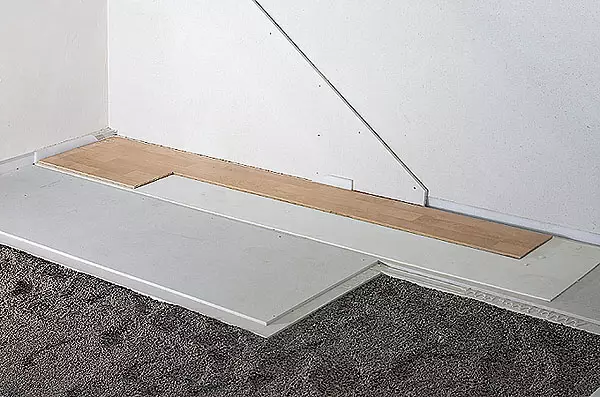

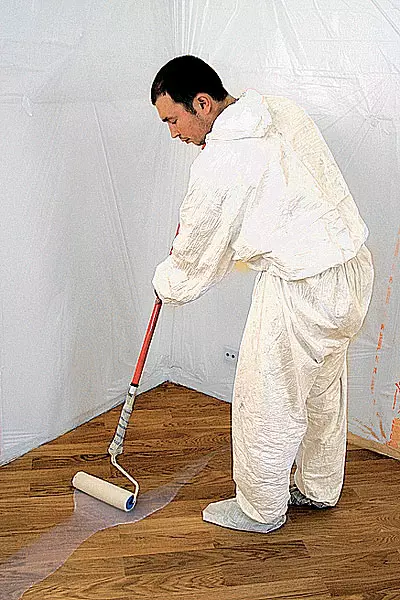

Before starting to lay the flooring (especially the parquet, parquet and massive board), it is necessary to conduct a base examination that includes the measurement of its humidity ( but ) and hardness ( B. ) with a moisture meter and sclerometer

Thanks to the constantly improvised production technologies, modern household linoleum based on PVC has become practically universal flooring. Service life of such material - over 10 years

Increased requirements are presented to flooring for children: it should not be distinguished by harmful substances, accumulate dust, be cold and tough

Laser device beam allows you to quickly and with high accuracy check the screed level

Ceramic tile does not require alignment of cement-sand screed by self-based solution

but.

Duuri.

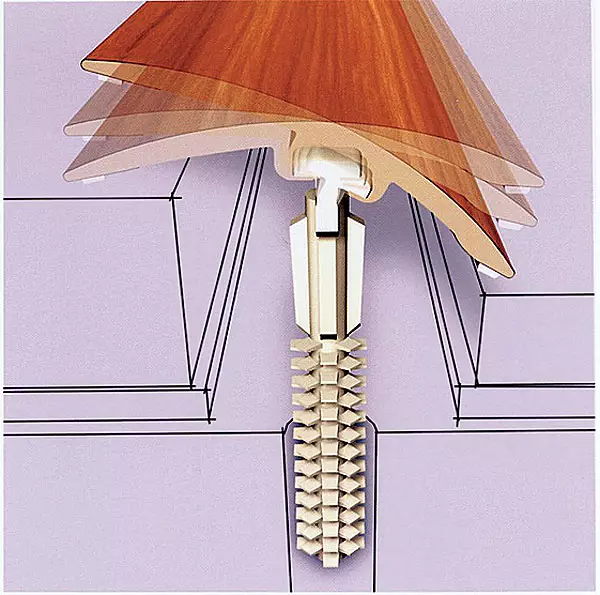

The docking profiles are mounted after completing work with both adjacent coatings ( but ) or only with one of them ( B.)

In the kitchen it is recommended to lay a unlawed ceramic tile

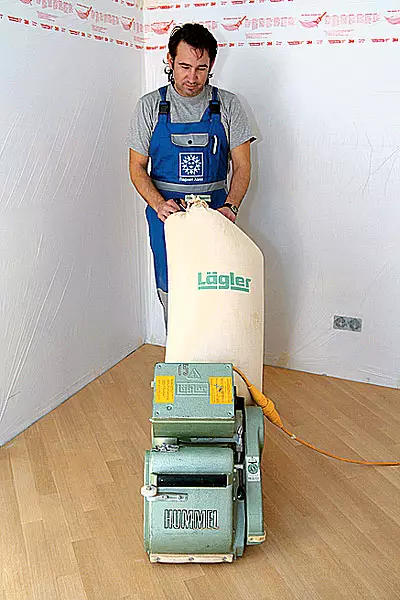

One of the main advantages of the floor from the massive boards is the possibility of repeated repair by complete permissions

The structure of which, when repaired, is customary to pay special attention, because during operation it is experiencing significant loads. However, if the hole on the wallpaper can, as you know, close the picture, then the appellands of the floor defects to correct much more complicated.

What should be the floor in the apartment? This question is easy to answer: practical, durable and smooth. Cranes and attacks today are not in fashion. One-level floor is not just convenient, it is able to visually increase the area of the apartment, as it turns individual rooms into organically related parts of the common space. It is easiest to equip such a floor with universal coatings (for example, linoleum or moisture-proof laminate) that are suitable for both the kitchen and the hallway and the bedroom. However, we usually strive for a variety, and most importantly, we want the material as efficiently as possible confronted by one or another operational loads and ensured the maximum comfort. That is why in the overwhelming majority apartments are combined by several coatings. They have an unequal thickness, fit differently, require different preparation of the base and competent docking. From the type of base, the total cost of the floor design, the costs of time and labor on its construction is dependent. At the design of the draft floor, they decide whether it is impossible to improve the technical characteristics of the overlap, as sound, heat and waterproofing, and where it is simply necessary to do this. Thinking and having calculated the entire design in advance, many problems can be avoided. But let's tell about everything in order.

Where the overlap ends

Terminological disputes arise in any area of knowledge, although, as is known, the term is a very low product about the meaning of the meaning. It is much better to agree about them.

What is the floor actually? Where does he "begins"? Is he part of the overlap or is it an independent design? In verbal battles about these questions, a lot of copies are broken. One of the difficulties is associated with the fact that there are two main types of carriers of overlapping-slabs (from whole or hollow reinforced concrete slabs, sometimes monolithic to the whole floor) and beams (beams can be wooden, metal or reinforced concrete). The first type "separate" from the floor is quite simple: the layers located over the stove and are responsible for heat, hydro and sound insulation and the flatness of the base are called the black floor, the floor covering is fill on top of it. In the second case, in order to save the height of the room, insulating layers, as a rule, placed between the beams of overlapping, and the floor can only be called the "pie", which rests on the beams (usually aligning lags, a draft board, and clean floor, sometimes additional layers from insulating materials, concrete ties).

The floor and the overlap are closely interrelated and "work" together. Therefore, in order to competently design the floor, it is necessary to clearly imagine the design of the overlap and know its technical characteristics.

Flooring: Ways of Evolution

Nowadays, it is extremely difficult to give tough recommendations about which coatings should be applied, for example, in the hallway, kitchen or bedroom, and there are no. There are materials traditionally used for sex in certain rooms. Thus, the kingdom of ceramic tiles and porcelain stoneware (standard thickness - 8-12mm) are still "wet" zones and places with a high load on the floor. Gostny and cabinets, according to the installed canons, preference gives a barbell parquet (standard thickness - 14-16mm), massive (20-35 mm) and parquet (14-20mm) board. Now, the manufacturers of most outdoor coatings seek to make their products universal, with the help of modern technologies giving it new properties and creating excellent imitation (for example, laminate under the tile, ceramic parquet IDR.). Ceramic tile "Mixed" in the living rooms and bedrooms. The use of a warm floor system allows to eliminate such a lack of tiles, as a "tactile" coldness (although due to the extreme hardness of this coating it is impossible to be laid in children's). Inappropriate, laminate (thickness - 6.5-12mm) and a massive board conquer living space in kitchens, hallways and even bathrooms, which has become possible due to modern production technologies and methods of laying.

Like tight?

Fundamentally new coatings, in particular, bulk floors based on polymer resins (thickness - 0.5-3mm) appear. Previously, they met exclusively in public buildings, and in the apartments it was only an expensive (but also very effective) method of leveling the foundation. Today, the introduction of colored quartz sand or small ceramic chips to the mixtures of color quartz sand, it is capable of imitate a stone or linoleum, which allows you to apply this coating as a finish. Do not take predict, but perhaps in a few years such bulk floors will get widespread, as they are great for bathrooms and kitchens and make it possible to do without expensive tile work.

Black floors

The appearance and durability of the outdoor coating, as well as labor costs on its laying, are largely determined by how qualitatively the foundation has been prepared. The main requirements for draft floors in the apartment are evenness and compressive strength. But the operational characteristics of the overlapping depend on their design. Often, new seals ignore this issue, believing that the design decision of the overlap itself takes into account all the necessary norms. The results of this approach are sad: the inhabitants of the first floors are forced to further damn the apartments with electrical appliances, but even with their help cannot achieve thermal comfort. Due to insufficient sound insulation of overlaps, residents of most urban apartments suffer. There is nothing to talk about the consequences of a frivolous relation to waterproofing when redeveloping a bathroom associated with the liquidation of the cabin of factory manufacturer (its floor includes the necessary insulating layer and has a pallet shape). Modern building technologies offer several basic ways to prepare the foundation for the finishing coating, and there are many technological options for performing each of them.Stages of work on the casting "Wet" screed

|

Photo by D. Minkin |

|

Photo V. Chernyshova |

"Wet" ties from cement-sand or gypsum solution (and the other, as a rule, with polymer additives) - perhaps the most frequently used component of the draft floors in houses with slab floors. When repairing old beam overlaps, the screed is cast over the beams in a non-removable formwork from the professional flooring.

There are three main types of draft floors using "wet" screed: single, two- and multi-layered. One- and two-layer ties are used solely to correct the defects of the overlap plate. If you need to eliminate significant height differences (20-120mm), a cement-sandy solution is usually used or special mixtures for coarse alignment. But, since the surface of such a screed is still far from the ideal, often the need for a device of the second layer - from the finishing self-leveling mixture. In this way, you can create a perfectly flat base for laminate, linoleum, carpet (under the piece parquet and a massive board over the screed usually laid waterproof plywood). Single-layer ties made of expensive finish mixtures. It makes sense to apply with limited (up to 15mm) plates level drops. Among the advantages of "wet" screeds will call the comparative cheapness of materials, high strength and moisture resistance, a small thickness, fire resistance. Kednostats should include the duration of drying, bad sound and thermal insulation, high laboriousness. The price of two-layer "wet" screed (material plus operation) 40-50mm thick is about 600 rubles. For 1m2.

|

Photo V. Chernyshova |

|

|

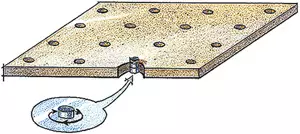

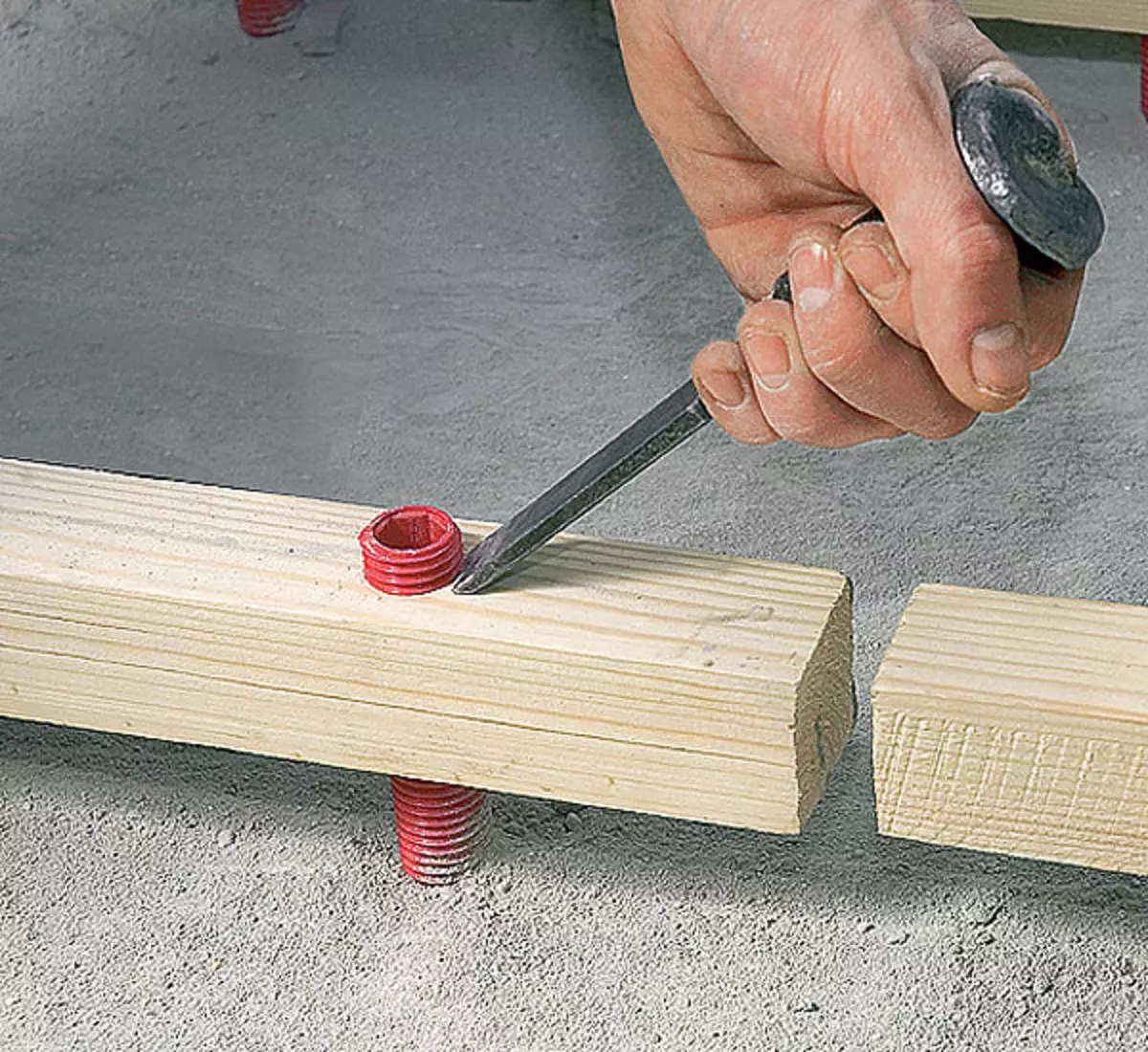

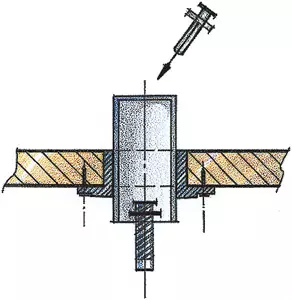

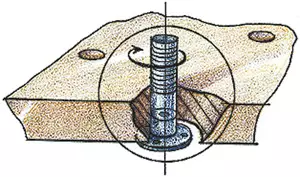

The sheets of adjustable plywood exhibit at the right level, screwing into the sleeve plastic threaded racks ( A, G. ) who are attached to the plate dowel-nails ( in ) The racks adjustable lag are screwed directly into the tree; The protruding part of the rack is then spilled or cut down ( B.)

To improve the heat, hydro and sound insulation characteristics of the overlapping under the layer (layers) of the solution, it is necessary to place the appropriate materials. The highest sound insulation indicators allows you to get a "floating" floor system. It does not allow hard ties of the fill with the slab of the overlap, nor with walls, along which the "border" is placed, made of soundproofing material. With the thickness of the last 20-30 mm under the screed (in this case, it is necessarily reinforced) with a thickness of 50mm, you can reduce the index of the shock noise under the overlapping by 36DB. However, such a draft floor will cost 1.5-2 times more expensive than a regular two-layer screed.

|

Photo V. Chernyshova |

|

Variants of draft floors using "Dry" tie:

A- two layers of GVV, laid on sheets of polystyrene (possibly only with a fairly smooth surface of the ceiling plate);

B- Precious Hydroebular Elements on Filing;

Two layers of GVL on the boardwalk, arranged on lags, with vapor barrier

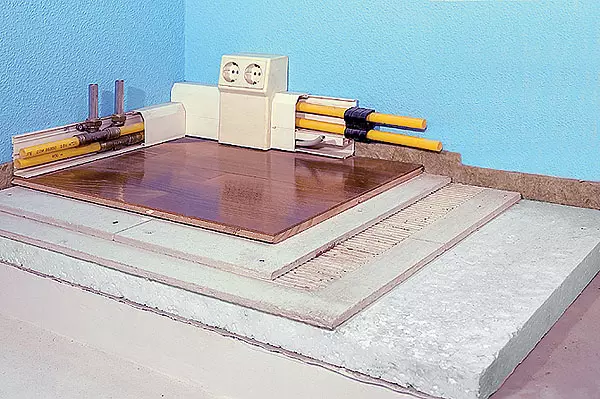

Prefabricated floors Otherwise, called the "dry" tie, can be mounted on a slab base or on top of the board flooring. They are various combinations of leafy, rolled materials and dry fridge. The national teams provide quick installation of the base for most coatings and significantly increase the soundproofing of the overlap (with a thickness of 70mm, more than 20 dB). They are more than 1.5 times easier than the screeds from the solution, but they have a significant thickness and are not suitable for laying thin rolled coatings. Comprehensive systems for "dry" screeds (backstage plus flooring) produce KNAUF (Germany) and Optiroc (Finland). The cost of materials with installation is about 700 rubles. For 1m2.

Floors on lags There are in old low-rise buildings with both beetroot and slaughterhouses. Lags are used for leveling, facilitate the installation of the adhesive floor, in combination with which most often apply. Located in a step of 300-600mm, they practically do not load the overlap and allow you to save the material - not too thick boards for the finishing flooring. Lags are also needed in order not to loosen the carrier wooden beams of frequently located fasteners. With apparent simplicity, the floors on the lags require a very qualified approach to installation. Lags should rely on the plate with the entire plane. If you align them, picking up wooden wedges, inserting gaskets from a pinch or pieces of fiberboard, after several years, and sometimes, and almost immediately, these "settings" are knocked down, the lags begged and the floors begin to creak. To align the lags, it is necessary to join, or pour sand under them (the space between lags is also falling asleep by sand by 0.5 of their heights), or pour the cement-polymer solution onto the slab. Wooden lags need to be treated with an antiseptic and provide ventilation of the underground space so that they do not rot. On top of the lag usually put one or two layers of sheet material: osp, plywood (under the coatings of wood) or GVL (under the tile). To reduce the index of the given shock noise under the overlap, under the lags, and sometimes they laid the DVP, Poly Penopo Foam or Technical Cork.

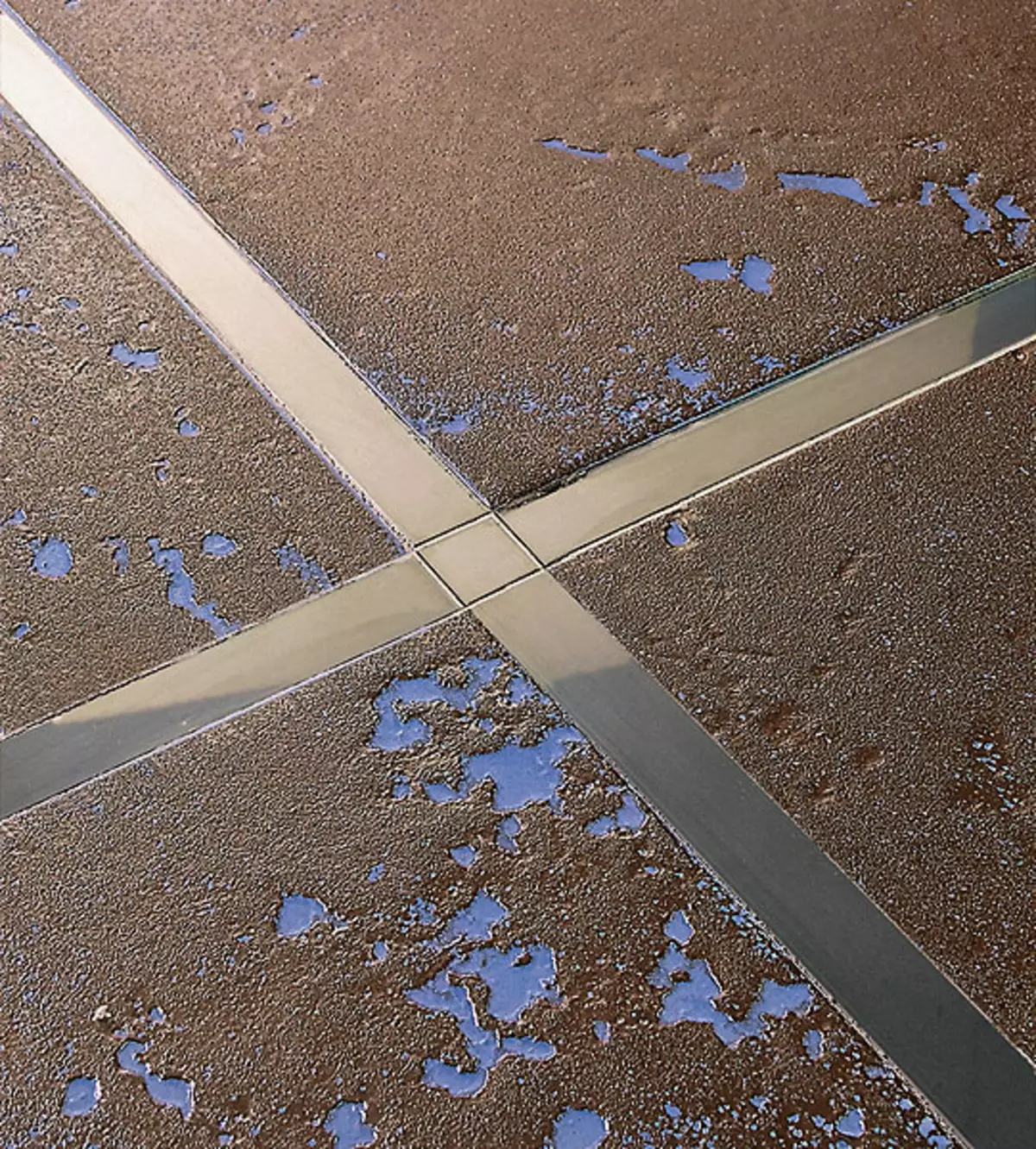

I joke, compensate, decorate

Where the flooring of a tree or laminated HDF is adjacent to the walls and resting on overlapping elements of the interior (racks, columns IT.D.), as well as in places of joints with other coatings should be left cleaners. For a piece parquet and a massive board, they must be at least 10mm; For coatings laid by the "floating" method, not less than 15mm. Eliminated the clearance is closed by a plinth, which can be hard to fix only to the wall. Extremely practical removable plastic or aluminum plinths with internal cavity (cable channel). The joints of different floor coatings can be decorated with two methods - with the help of decorative thresholds (wooden, metal, from PVC IT.D.) or cork compensators. The latter are not towering above the floor, which means that fully correspond to fashion trends. But the boards allow you to visually smooth the small height differences, which sometimes still fail to avoid, and also indispensable when using rolled coatings (linoleum, carpet). Cork compensators and wooden thresholds are always available with major firms selling parquet, parquet and massive board: "Parquet Hall", Tarkett Rus, Trade Forest (all- Russia) IDR. A wide range of plinths and metal orproofing products offer "World Profile" (Russia), Bona (Germany), Duuri (Finland), Pergo (Sweden), Neuhofer Holz (Austria), ASPO, Darek, Polmar (All Poland) and etc.

Adjustable floors There are two types: adjustable lags and adjustable plywood. Such floors are based on the slab overlap through frequently located threaded racks, which allows "output horizontal" with significant irregularities of the supporting surface. If you need, using adjustable lags, you can raise the level of the first floor to a height of up to 220mm from the overlap, it is sometimes equipped with low podiums, hiding under them communications (for example, leading to the kitchen "island"). Plywood is regulated in much more modest limits - 30-70mm, but the "eats" less than the height of the room. The market presents two large supplier of regulated sex systems - Nivell System (Sweden) and "Department of New Technologies" (Russia). The price of material with installation is about 750 rubles. For 1m2.

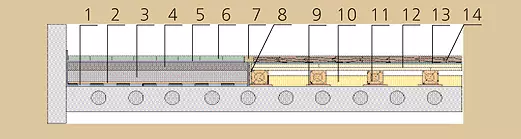

The device and docking of the tiled floor by screed and parquet for lagas

2- sand reproduction (2mm);

3- Ceramzite concrete (40mm);

4- Cement-sand tie (30mm);

5- Tile glue (2mm);

6- tile (2mm);

7- cork compensator (15-20mm);

8- Technical cork (5mm);

9 - strip of soft fiberboard (5mm);

10 - polystyrene (25mm);

11- Lagged (4545mm);

12 plywood, 2 layers (20mm);

13- Glue parquet (1mm);

14-Parquet (16mm)

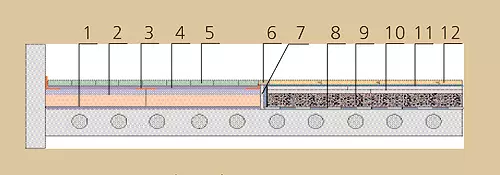

Device and docking of tile and laminate flooring on the national bases

2 NBSP /> - extruded polystyrene sandwich panel (50mm);

3-tape sealing waterproofing;

5- tile (12mm);

6- cork compensator (15-20mm);

7- GVVL (band);

8 - waterproofing, 2 layers (3mm);

9- Ceramizitic crumb (30mm);

10-GVVV, 2 layers (24mm);

11- filled PE (1mm);

12- Laminate (8mm)

Points on the plane

Since you have gathered to do a single-level floor, at the stage of preparation of the base, it should be borne in mind the thickness of the finishing coating, taking into account the method of its laying (even the drop in 2-4mm, which gives a substrate or adhesive mastic, can later create a serious problem). Solve this task during repair in the entire apartment in the presence of a complete project is not so difficult. If you plan a "wet" screed, after the height of the draft floors is determined using the level and the walls are applied to the walls, the latter are adjusted, taking into account the thickness of the coating. The screed is cast plots (for each type of coating), which are limited to removable formworks. It is also permissible to make an aligning screed at one level at once in the entire apartment, and when it can be walking, install formwork and create the necessary differences, pouring cement-polymer solution. The last method does not require such an accurate calculation, however, it leads to an excess of an expensive finish mixture. Sometimes the necessary points of the base level are made, fastened on the screed sheets of plywood, GVL, chipboard, fiberboard, extruded polystyrene of the corresponding thickness.Stages of laying piece parquet

|

|

|

|

|

|

"Parquet Hall"

Often, for saving money or time combine various types of bases under the coating, for example, lags and tie. The order of work is determined individually (as a rule, first of all create the basis for the coating occupying a large area). But in any case, you first need to set the overall floor level for the entire apartment and calculate the load on the overlap. Height in practice quite often one floor is customized under the other, which is called, in fact, it should be avoided- a preliminary assessment on the eyes is almost always inaccurate.

If the repair is carried out in stages in populated housing, a room at the room, it is much more complicated as a result of a smooth, without ledges. It is not always enough to know the design of the overlap, to choose materials for the first floor of different rooms and clarify their thickness. Best of all before starting work to order in the construction company the expertise of the foundation. It requires a partial dismantling of the floor covering, but it allows you to install the maximum level drops, find out the state of existing screens and other hidden structures, evaluate the possibilities of saving them and thus avoid errors and unnecessary spending.

Possible combinations of floor coatings with different types of base

| Type of flooring | Type of foundation | Method of laying |

|---|---|---|

| Laminate | "Wet" or "dry" screed, waterproof plywood in two layers of total thickness of at least 20mm by lagas, adjustable plywood | "Floating", for laminates without a lower noise absorbing layer - an elastic substrate. Special sealant apply for joints |

| Piece parquet | Waterproof plywood in two layers of total thickness of at least 20mm on lags, plywood 10-12mm thick on a screed, primed "wet" screed, "dry" screed | On bitumen mastic, polyurethane glue with studs |

| Parquet board | The same as for a piece parquet | Preferred "floating" method of laying. Possible polyurethane glue either mastic |

| Massive board | With the thickness of the board up to 20mmm plywood in two layers of lags, plywood in one layer on the "wet" screed, "dry" screed; With greater thickness, lags (step lag depends on the thickness of the board) | On glue with additional fixation by nails or screws |

| Linoleum | "Wet" screed using a self-refined mixture (desired-primed) | On bitumen or polymer mastic |

| Carpet | Printed "Wet" screed | For flu, double-sided scotch, glue (with or without a substrate) |

| Ceramic tile, porcelain stoneware, natural stone, mosaic | "Wet" screed; Possible laying on adjustable Phaneur, on lags and "dry" tie (except for bathrooms) | On tile glue |

The editors thanks the company "Ark-Parquet", "World Profile", "Parquet Hall", "Trade Forest", "Ekostroy Design", Kronospan, Tarkett Rus, Weitzer Parkett Rus, Representative Office of QUISK-STEP, Trade and Economic Department of the Embassy of Spain For help in preparing the material.