The history of the construction of the house with a total area of 163 m2 using a glued timber for imitation of log walls. Properties of material and assembly technology.

Cut in size

Probably, many of us in the depths of the soul lives a dream of a small village house - a log and without fail. Is it possible to embody such a fantasy into reality using the most modern technologies? Answer to the question you will find in this article

Tale of wanderings

He lived on white light Ivan-Tsarevich. Not young, not old, and most of the most mature age. He managed to get a man and his wife-beautiful, and three kids. Asseta with them lived Mom Ivan-Tsarevich, in which he himself, and his homemade souls did not care. Balleling grandmother all seven pieces and pancakes, as well as dishes different, both dietary and not very. He taught (and taught) she prepare and Ivan-Tsarevich, and he loved this thing is hot and passionately. Asseta grandmother walked and engaged in grandchildren, told them the stories of various vital. They show her kids with mutual love, and were ready to go with her to the edge of the world, if only on the way the fairy tale said.

In general, they lived well and friendly. Only one thing was not evolving, did not have the dacha family. That houses in the village, where carrots and repka grow on the beds. Where is the beautiful nature, fresh and clean air, and not nasty gases, sprayed from the Nutra of the evil mandes named the car. Where you can safely release a walk, without fear that they, having won, inadvertently fall under the wheels of this monster. For a long time, a family could only dream about such a summer cottage.

|

|

|

Foundation home-combined. For its device, testers tear down the depth below the drainage point in which they made sandy and then the gravel pillow. Over the trenches set a milking formwork, put the reinforced frame, poured concrete, thus created the tape of the foundation. In the entire area of the house, a non-removable formwork was mounted and the monolithic reinforced concrete plate was cast over the foundation ribbons (1). A collaborated place in the stove was placed by an electric cable and a tube coupling, through which water and sewer (2) -trubs will be put into the house for them in the trench (3) later

But the fate decided to smile to our Ivan-Tsarevich. Whether the treasure he found, or in business, he became interested in Tom unknown, and there is no relation to our fairy tale. It's at least I came home, I gathered a family in the biggest hill and announced: "Scream" Hurray ", Favorite Chad and Households! I bought a little from Moscow, in a picturesque place" Meshcherskaya Polesie "a bit of land. Ibud. We are building a cottage! Spacious and Light. From a new material called Foam concrete .- "Hurray!" - shouted everything. One wise grandmother for some reason he sirred. "Well, Ivan-Tsarevich turned to her?" Is it really not happy to news? "-" What are you, Ivanushka, "Mom answered," as not happy! Only, you already sorry, I'm afraid, I will be hard in a new house. On the floors, they are running. We have dreamed about what house? About a little, log. Spidder - so that there is a pancake yes pies for you, your spouses and kids oven. Yes, you and the guests are not averse to me to pamper Furnaces are awesome. Attut immediately on the foam concrete palace, you wake up. Is it in him a stove? Let's start with a small house, and you will build a palace for yourself. "The children and wife the grandmother came to taste, and they got up on her side.

Listened by Ivan everyone and Mili: "Well, if you think!" And the chibanko himself thought. Log house building is not a problem. Although from pine, at least from larch or even from cedar. Only the soul lies with modern technologies, in particular, to glued brustees. After all, it seems too, a tree, and build a house completely different from it. Avdrug there is a new miracle material on white light, in which the resistance of larch and the healing properties of the cedar are combined, and build from it just as simple as from the glued bar, and the house looks like a log?

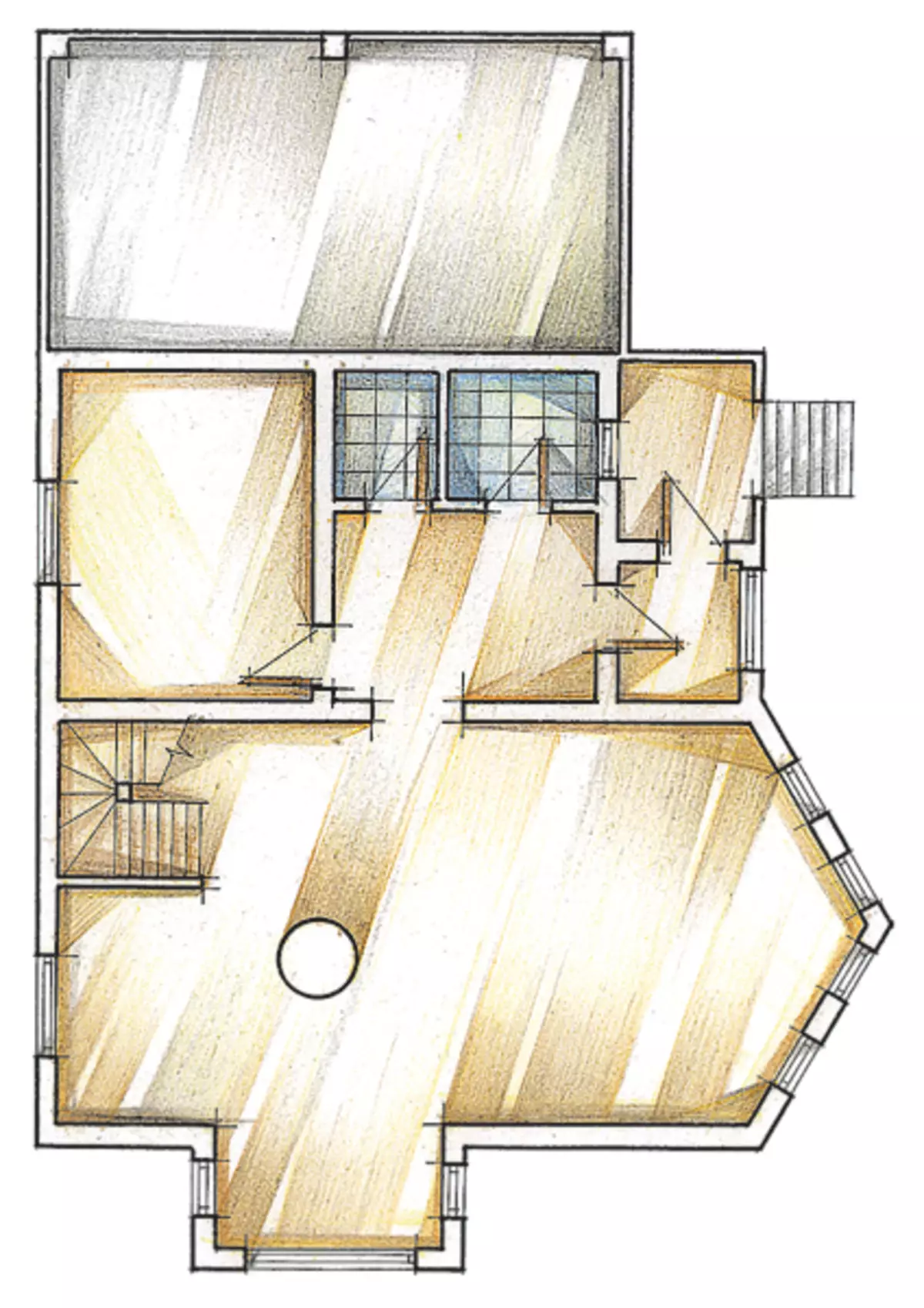

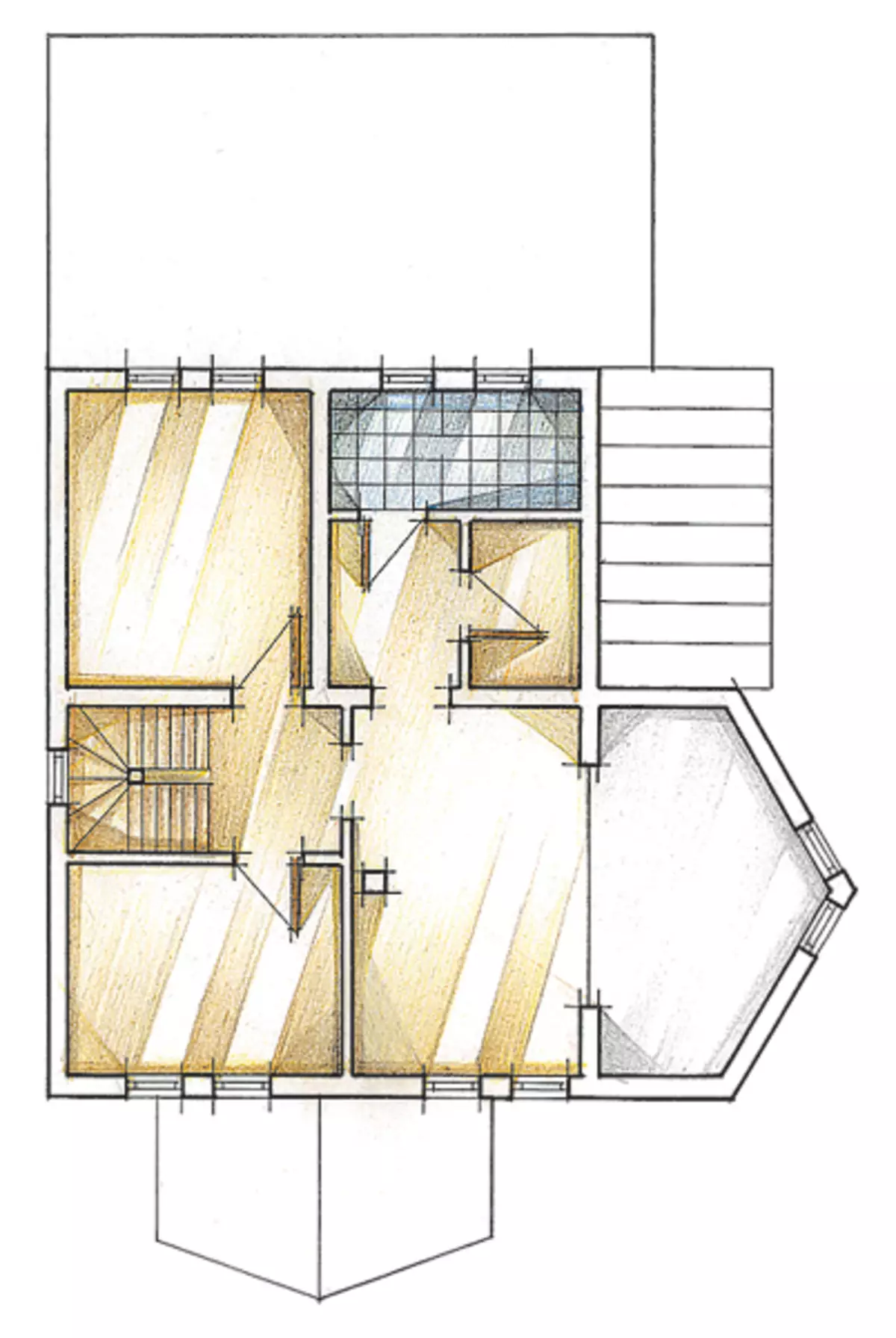

Yes, Ivan-Tsarevich set himself a difficult task. I was looking for where I could have everly traveled for a thirty lands, flew over the thieves of the seas. Own! Not outside the sea, not in foreign states, but in the glorious Russian city of Biysk, which in the Altai Territory. Found a firm called "Kadrin", which produces the desired material. "Thank you, kind well done, for the trust and for what I turned to us, and not to someone else!" Said Ivan the director of the company. "We will find you the project, and build a house. But I mean. Although the glued bar we are. We release, and long, but it was exactly the one that you failed to taste, we started to produce only a day. Ascertaining my own at home and never tried. First you will be. But you, dove, do not be afraid! Building brigades will find the best . Bar to you directly from the plant with powerful trailers to deliver. " Satimi said the director before Ivan-Tsarevich the first project. As he saw a future house (and by that time he was a construction certificate trained, this is another useful side of his wanderings) and measurement. It seems like a small (only 169m2), and the roomy- all children and households on the room will receive. Akaka Hall for receptions of expensive guests, combined with the dining room and kitchen, is at least dances!

In general, Ivan did not even watch other projects. They hit the director of hand, made Ivan a copy of the project - and for a while they broke up. Tsarevich finally home went home to please and start the foundation for future choirs to erect. Director - Production: Give the team to preparing a new miracle material for an expensive customer. Well, we are with you, dear reader, it's time to move from the fabulous presentation to prose. Prose construction.

Miracle Bar

Wooden house- special. We make a special smell, special energy. You feel in such a house completely different: and the strength he helps to restore, and the mental balance to save. It is not by chance that in our days, the volume of construction of wooden houses grows simply with mad pace. Iodine from the reasons for this is the active use of glued profiled timber.

|

|

|

1. Equally made connecting bowls in additional seal elements do not need.

2, 3. Sounds "Schip-PAZ" condensed with narrow ribbons of foamed polypropylene 2mm thick. Under the load, this material is compressed to 0.2-0.3 mm.

In detail about the process of making glued timber, we were told quite recently (see article "Oh, the crowns glued!", "IVD" N 5 for 2007). Recall that this material produced according to a special technology, firstly, is more durable than the usual tree, secondly, with a reduced level of internal stresses (it means less likely to appear cracks and other defects, as well as deformations, as separate parts, So the design as a whole). Thirdly, a special profile allows you to customize bars sufficiently tightly, the wall is obtained as close as possible by heat insulating properties to a solid wooden. But the most important vertical shrinkage of the glued bar design does not exceed 1-3% (the shrinkage of the house from the tree of natural humidity is 3-10 times higher). Consequently, there is no need to wait for the end of the shrinkage of a cut, and his finish can be done immediately.

|

|

|

For the ceiling device, glued beams were used with a cross section of 220160mm, the ends of which were inserted into special grooves in the wall timber. Wrestling beam spans have intermediate supports

Machine bar is produced mainly from pine and ate, and only a few firms make it from larch. Cadrine's bar of the company, from which the house we have built, gloves from larch and cedar lamellae. Moreover, the external ("street") side is made of larch bars as radial cut (without defects) and tangential (tobacco bitchs that have franticed the bitch with a diameter of no more than 3 cm, resin "pockets", no longer powder less than 5 cm). The inner side (facing room) is collected from cedar radial or tangential lamellas. (It is necessary that neither on that nor on another front surface there was no obol, crook, rot, blue, etc.) Thus, a person who is in the house, sees the walls of a cedar beam, and the one who is outside, from larch.

But this is not the only feature of the bar. Its height does not exceed 135mm, while the height of the glued bar from the pine may well reach 180mm. Why so few? To answer this question, we will deal with some properties of larch wood. Let's start with the fact that in structure it is more dense, and the pores in it, than pine. This determines the specificity of the drying process: it should be very soft (low-temperature) and long (the material dries 3 times longer than pine). It is worth trying to intensify the process, and the bounded resin "seals" the pores, after which the rate of evaporation of moisture from the board will become much lower and the drying period will increase.

But this is if we consider the differences of larch from pine in general terms. There are also a lot of growing conditions. So, the larch from the Krasnoyarsk Territory the density of the annual rings is almost 2 times lower than that of larch from the Altai Territory, where it grows in more severe conditions and therefore 2 times slower. As a result, if the density dried to 8% moisture content of the Krasnoyarsk larch is 650kg / m3, then Altai- 720kg / m3 (for comparison: the density of the pine of the same humidity is 500kg / m3, oak-750-800kg / m3).

Looking at the Altai larch even longer than Krasnoyarskaya. Judge in the dried state, the first behaves not as the second, and even more so, not as pine. The lobster lobs (160-180mm) needed to obtain a bar of the same height, after drying, quite significant internal stresses are formed, which can lead to cracking of the already glued bar. Output one: Sew a plate width no more than 135 mm and glue them into a bar. Well, to make a built of such a bar, the house did not look like a clapped, the Kadrin officers applied the original reception: they gave the outer surface of the bar the shape of a quarter of the cylinder. If, when assembling at home, lay a timber in the wall so that the "cylindrical" surfaces are directed towards each other, it creates a complete impression that the wall is assembled from a diameter of 220mm (timing width - also 220mm). From the inside the wall "flat". The original appearance is primarily attracted to Brusa, not only our fabulous Ivan Tsarevich, but also the author of these lines. I must say, the price of such an unusual timber is sufficiently high: 1 m3-18.5-23.5 thousand rubles.

It is clear that only outer walls are collected from the "rounded" bar. For the inner walls there is a bar of the same height, but less width (160 or 200mm) and with flat side faces.

Fundamental basis

Long before the start of the assembly of the house made its foundation: it is a monolithic reinforced concrete plate with a thickness of 200mm (inside the two layers of the reinforcing lattice from the rods with a diameter of 12mm). The slab was put on concrete tapes, the lower point of which is below the drainage depth. From the construction of a "full-lifted" basement, the basement was abandoned due to the fact that on the construction site, the groundwater is fitted close to the surface, which means that the basement of the house constantly remained dry, it would have to invest a lot of money. "Nothing," the future owners decided, "so far, and then build a cellar near the house, if, of course, there is something to hide in it." In general, to the beginning of the assembly of the walls concrete foundation managed to dial full strength.Mainly, start!

And then the day came when a brigade of builders arrived at the site and the first trailer came with a miracle timber. Unloaded manually: Since the bar is thin, it is relatively light. They brought him to the construction site in the form of blanks with a length of 9m. Already on the spot they were cut in size, fastened in packs, and then on side surfaces, using a special compact manual machine, cut the connecting bowls. This builders devoted the first four days, laying ready-made elements with stacks opposite those places where they will be installed. When accumulated about half the height of the first floor, started assembling.

Started from a strapping crown: it was placed on a lining larch board treated with antiseptic composition. The process took almost two working days of laying geometry checked very carefully. When the strapping crown was assembled, its parts were lifted and placed under a lining board as waterproofing ruberoids, before the start of the assembly did not do this, fearing to damage the material.

|

|

|

1. With the bottom side to the rafters, Brukes 5050mm were knocked out, to which a layer of vaporizolation was pressed using a edged board.

2. The insulation was covered between the rafters, the insulation was covered with a layer of moisture insulation, which pressed the counterclaim, the boards of the crate was attached to it.

3. The river "pie" covered the solid flooring.

Reliable walls

Vertical bars are connected by means of grooves and ridges. Moreover, on each bar, it is not one such compound, and three, as a result of which the horizontal seam is not blown in principle. WHATS These joints additionally constructed using a foamed polypropylene 2mm thick, sliced on thin tapes. Two such tapes were laid in extreme grooves.

Vertically the crowns were pulled by steel studs with a diameter of 18mm and a length of 80cm, located in the corner releases of the bar (outside), in technological rearrangements (outside and inside), on the sides of the window and doorways, in front of the IT.D., - we described in detail In the "IVD" N 5 for 2007. The student was that the studs did not interfere with the threaded bushings (as a result, the rod would be obtained, as it were, perpetrating the wall to the bottom), and installed each heel separately, tightened "package" from eight The bars forming four "logs" in the outer wall. Each subsequent stud was inserted not strictly over the previous one, but with a shift of 15-20 cm, and its installation began simultaneously with the laying of the last two bars of the previous "package". In other words, before collecting and pulling in the "package" of the two top timber, at a distance of 15 cm from the already existing studs in them drilled a hole in which a new stilette was inserted, having a fixed nut with a washer under the lower plane of the penultimate timber. The collected "package" of eight Bruusyev was tightened, and another six bars were sitting on a new stud. Next, the process repeated. Thus, the wall turned out to be pulled by the studs to the bottom.

The intergenerational overlap with the help of glued beams, on top of which the boards immediately put, creating a solid flooring, significantly simplifying the construction of the walls of the second floor.

Roof of my house

The rafters were made using the edged boards with a cross section of 15050mm. The cubous walls were attached to metal corners and self-drawing. The reduced side to the rafters perpendicular to them, knocked wooden bars, and they recorded a layer of vapor barrier, held below the unedged boards (so as not to provis). Why do you need transverse bars? They allowed to increase the thickness of the insulation between the rafters from 150 mm (the height of the rafter feet) to 200mm. Naturally, the "solid" is only the top layer of 150mm, which is the 50-millimeter layer under it under it, only between the transverse bars, such ruptures will not be very little on the heat-saving characteristics of the roof as a whole.

The underlined insulation was covered with a layer of vapor-permeable moisture insulation, pressing it to the rafters of the counter tests (5050mm), which determined the magnitude of the future ventilation gap. Perpendicular to the counterclaim, crossed the edged plates with a cross section of 8020mm, and they were attached oriented inlet stoves, creating solid flooring. On him, with compliance with all the recommendations of the manufacturer, a soft bitumen tile was placed.

|

|

|

Rustic house without stoves- like an airplane without wings. It was put on all the rules - using cast-iron mortgage elements, "accurate" bricks IT.P. The stove on a powerful concrete base, made simultaneously with the fill of the floor screed in the kitchen zone. This furnace and heated the whole house in winter, allowing to lead finishing work

Final stage: outside and inside

Floor floors are on top of a solid reinforced concrete plate. Discovered as follows. A layer of claymps was poured on the plate, then poured a concrete tie. In all rooms, except for the kitchen, bathroom and boiler room, laugs were recorded on the screed, while the plates of extruded polystyrene foam 50mm were laid between them. Then the flooring was created from the trooped firboard, it was polished and covered with varnish. Wook, the bathroom and the boiler room on the concrete tie sticked a porcelain tile.

Insulated ceilings of both floors and sites of the attic of the attic was triggered, after that it, together with the brusched walls, was covered with decorative and protective composition: Light planes, ends with a bruck. Town openings were installed windows with frames and flaps from glued larch bars (he also produces Cadrine, painted in the same color as the ends of the wall timber.

The short side of the ends of the bar was closed by gearboxes, thus providing protection against atmospheric influences, and then the walls were also treated with a decorative protective composition that emphasized the larch texture.

That's, perhaps, all that we wanted to tell about an unusual house built by a loving father, husband and son for expensive households, and first of all for Mom. Akak also a fairy tale? Perhaps we can finish it with you. Well, for Ivan Tsarevich, she continues, his family is just beginning to make a built house.

The enlarged calculation of the cost * construction of the house with a total area of 163m2, similar to the submitted

| Name of works | Number of | price, rub. | Cost, rub. |

|---|---|---|---|

| Foundation work | |||

| Handling axes, planning, soil removal | 76m3 | 700. | 53 200. |

| Sand base device, rubble | 30m3. | 220. | 6600. |

| The device R / B foundation tapes and plates | 78m3 | 2830. | 220 740. |

| Waterproofing horizontal and lateral | 250m2. | 170. | 42 500. |

| Cargo removal by road | 50m3. | 520. | 26 000 |

| TOTAL | 349 040. | ||

| Applied materials on the section | |||

| Concrete heavy | 78m3 | 3100. | 241 800. |

| Crushed stone granite, sand | 30m3. | 1100. | 33,000 |

| Hydrosteclozol, Bituminous Mastic | 250m2. | - | 17 600. |

| Armature, Formwork Shields and Other Materials | set | - | 90 700. |

| TOTAL | 383 100. | ||

| Walls, partitions, overlap, roofing | |||

| Preparatory work, installation of forests | set | - | 10 300. |

| Build the walls and partitions from a bar | 104m3. | 6000. | 624,000 |

| Assembling overlaps with a stitching of rough floors | 163m2 | 490. | 79 870. |

| Assembling roof elements with crate device | 180m2. | 680. | 122 400. |

| Hearth roofing and overlap | 342m2. | 80. | 27 360. |

| Hydro and vaporizoation device | 342m2. | fifty | 17 100. |

| Bitumen Tiles Coating Device | 180m2. | 390. | 70 200. |

| Eaves Bearing, Svezov | 45m2. | 400. | 18 000 |

| Installing window and door blocks | set | - | 40 500. |

| Device of finishing floors, ceiling liner | 300m2. | - | 117 600. |

| Grinding of walls, protective composition | 800m2. | 420. | 336,000 |

| TOTAL | 1 463 330. | ||

| Applied materials on the section | |||

| Cleaning ram | 104m3 | 18 500. | 1 924,000 |

| Sawn timber | 20m3 | 4500. | 90,000 |

| Paro and waterproof films, insulation | 342m2. | - | 55 600. |

| OSB-3 stove | 180m2. | 195. | 35 100. |

| Bituminous tile, components | 180m2. | - | 50 400. |

| Wooden window blocks, window sills | set | - | 480,000 |

| Neck-protecting compositions | set | - | 29 000 |

| Floor board (spruce), lining (larch) | 300m2. | - | 183,000 |

| Ceramic tile, staircase, dry mixtures IT.P. | set | - | 140,000 |

| TOTAL | 2 987 100. | ||

| Engineering systems | |||

| Installation of boiler room, plumbing and electrical equipment, including its cost | set | - | 731,000 |

| TOTAL | 731,000 |

* - The calculation is made without accounting of overhead, transport and other expenses, as well as profit firms.