For the operation of electrocotes do not need chimneys and fuel reserves

Warmosqx boiler can be programmed to "Summer" mode. Management is carried out using a programmable room thermostat.

The inner view of the Warmos boiler from "Evan"

The Tennic Cotele of the EU Series ("Galan") is supplied with an electronic control unit "Navigator" of the same manufacturer

Electric boiler "Foci" ("Galan")

Boiler room with electrocottal

Solid fuel boiler "Don" ("Condord")

Kotel "Ziosab-45" from "Ziosab"

Model Dord.

OPOP solid fuel boiler

Cast iron solid fuel (operating on the corner, coke, wood fuel) The Solitech series boiler can be equipped with gas and liquid fuel. Power models - from 10 to 81,4kW

Photo of Karen Manko

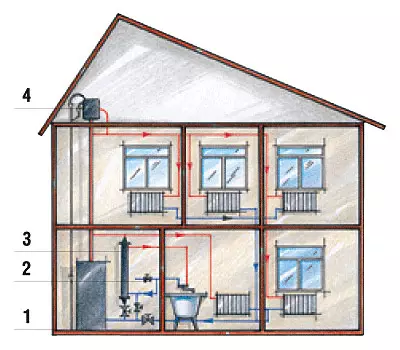

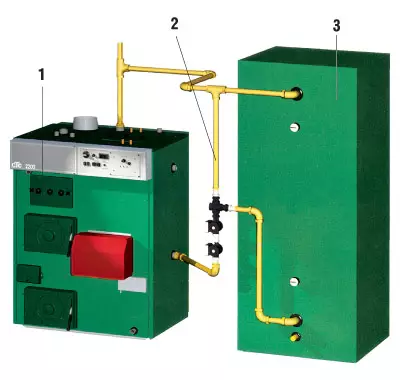

Option of strapping boiler room with electrocottal. When installing electrical models, the main problem is to achieve permission to supply the desired power power (with the power of more than 15 kW, it is quite difficult to do)

The heating is an ordinary open expansion tanks can be replaced by membrane. The latter are issued different volumes.

You can install the membrane expansion tank at any point of the system, for example on the inverse pipe near the boiler.

Heating the room of a country house or cottage is a challenge. It is possible to solve it for a different way. Inters with the help of a boiler operating on electricity or solid fuel

Choosing a boiler for heating a cottage or country house, first of all, it should be analyzed by the availability of this or that type of fuel, its price and delivery uninterruptedness. Then it is necessary to estimate the cost of installing and operating boiler equipment, as well as the organization of the fuel warehouse. It is possible to approximately determine the required power of the boiler necessary in the conditions of the middle strip of Russia, it is possible to simply: for every 10m2 area of heated insulated room (with a ceiling height of 2.5-3m) 1kW of the boiler power is needed. Of course, this is conditional data. Alternatively, the individual features of the building (thermal conductivity of enclosing walls, windows, doors, gender and ceiling) play a major role. For heating an individual house, boilers are usually used with a capacity of 5-6 to 30-240kW. When there is no possibility to damn rooms with natural gas, install the boiler with the most affordable source of energy. For the conditions of the middle and northern band, the system with two boilers is economically justified: one works on electricity, and the other is solid fuel. Moreover, one of them plays the role of a reserve or additional heat source connected to the main (low power) in the peak of cold.

Electric boilers

Tanic boilers. The most common electrocurceptors on the Russian market for heating individual home-based liquid, consisting of tanks with Taneans, controls and control units. The liquid in the heating system can circulate either naturally (at the expense of gravity forces) or forcibly with the pump. It is heated to a temperature of + 80-95s. The tank is usually made of stainless steel and has a cylinder form. Cast iron does not apply for such purposes, as this would lead to a significant increase in the weight of the equipment.

Single-circuit and double-circuit models. A single-mounted boiler has one pipe system with a coolant and serves only for heating. A two-circuit boiler is usually called such a heat generator, in the housing of which two heat exchanger: one provides heating, and the other is a hot water supply. If necessary, you can connect a separate water heater with a coil to ensure hot water supply to a single-circuit boiler.

To power the electrocallors, as a rule, you need a separate entry with grounding. When installing the instruments are guided by the N42-6 / 8-ET21Mart in 1994, Glavgosenergoneadzor Document. "Instructions for the power supply of individual residential buildings and other private structures."

The boilers at 10-12 kW are single-phase and three-phase, feed from the network with a voltage of 220 and 380V, respectively. Devices of greater power are only three-phase. Mostly in electrocouplers with a capacity of over 8kW, its stepped adjustment is provided, which allows not to use the device to fully power, when there is no need and, therefore, save electricity. Adjusting the boiler power can be carried out both in manual and automatic mode. A number of companies, such as Evan "(Russia), Kospel (Poland), are laid in the design of some of its models the possibility of smooth control of the coolant temperature within each stage of the power. As a rule, boilers are equipped with thermostats, pressure gauges and thermometers. Many manufacturers provide devices with protective automation. Thus, in the boilers STIELEBEL ELTRON, KOSPEL has a built-in temperature limiter and overload protection machines. Control the work of the boiler both manually and by automatic control of the temperature of the coolant or indoor air temperature. Available devices in wall and outdoor versions.

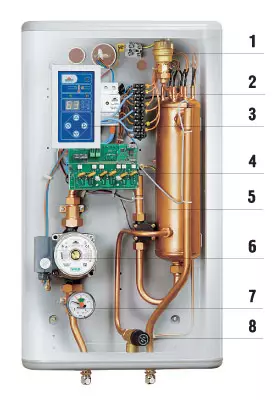

1. Automatic airlock valve

2. RemediesTeerWT3, protecting boiler from overheating

3. Electronic control panel

4. Powerful knot on semiconductors

5.Prothing water heater

6. Congulates

7.Nometer

8. Clap Safety

The Russian market is widely represented electrocallors of both import and domestic producers. Among them are Stiebel Eltron, Wespe Heizung (Germany), CTC (Sweden), Dakon, Protherm (Czech Republic), Elbeva (Slovakia), "Evan", "Eleurium", "Saturn", "Galan" (Russia). The cost of foreign products, depending on the power varies from 15300 to 56000 rubles, domestic analogs can be purchased at a price of 5600-43795 rubles.

Electrode boilers. There is another variety of electrocottable electrodes. They have not yet received a lot of distribution due to the fact that the requirements for the coolant used in them are very tough: it must have a strictly defined conduction and at the same time resistance, since its heating occurs with the help of two electrodes, charged to the boiler. Punching of the coolant in such devices is used either special liquids or distilled water, putting it up to the necessary concentration. Electrode devices with power from2 to 30kW produces, for example, the Russian company "Galan" (Series "Foci", "Geyser", "Volcano"). The boiler is a metallic cylinder with a diameter of 40-100mm and a length of 310-350 mm, which is included in the closed circuit of the heating network. Despite its compact sizes, the devices are capable of damping the room from 120 to 850m3. When heating the coolant, the pressure in the heating network rises to 2ATM, and the coolant begins to circulate. For a faster heating in the strapping of the boiler room, a circulation pump can be mounted. The cost of electrode boilers is 2100-16 2210 rubles. Mass - from0.5 to 6.5kg. Due to the fact that the coolant is heated by the "direct" method directly from the electrodes, and not from the TAN, the devices are quite economical, according to some sources, they consume 20-30% less electricity than the bean.

The problem when using electrocotals can be high cost of electricity and, especially in rural areas, its lack, as well as interruptions with the supply of electricity. This case will help an additional or reserve boiler. For example, a traditional solid fuel boiler.

Pukayev T. V., Director of the Representative Office of Evan in Moscow:

Traditional solid fuel boilers

The main advantage of solid fuel boiler is a low price of fuel and its availability. They are ideal for those places where the branches of gas pipelines and power lines have not reached. The same in Russia there are truly huge reserves of coal, forests and peat. Solid fuel is primarily wood, coal, peat briquettes, sshy IDR. Actual strip drowning the boiler with solid fuel cheaper than using for heating diesel or electricity. In addition, the work of a traditional solid fuel boiler does not depend on the availability of electricity. The main disadvantage of this type of instruments is the need to quite often load the fuel portion in the furnace (for coal it is usually 6-8h, for firewood - 2-3h). It burns unevenly, with variable intensity, burns not completely, highlighting soot. Chimneys are clogged and deteriorated due to corrosion. Ash is formed a lot, and it must be possible to periodically delete. The same boiler power is obtained by 25-30% less than when using gas or diesel fuel in them. Usually in the cottages apply apparatuses are not more powerful 30kW.

Steel boilers are not afraid of the temperature of the coolant temperature, but they are more corrosion. A special danger for such devices is the so-called low-temperature corrosion-on the cooled surface of the boiler firebox condenses moisture, which is in chemical reactions with the combustion-present acids present in the combustion products. This "acid" condensate and "eats" gradually walls. The cause of its appearance is admitted to the boiler (from the inverse pipe of the heating system) of the coolant having a temperature below the one to which the device is designed. Low-temperature corrosion can be prevented by maintaining higher temperatures, and therefore less economical than it is required directly for heating, work.

Steel boilers are demanding of cast iron to the type of fuel. Not in all models can burn coal. For this, they have to equip them with cast iron, as in domestic boilers of the COP series, or water-cooled, as in Junior (Jaspi, Finland), grate. Another option is made of boiler steel. Verner P45 (Verner, Czech Republic) was made of steel furnace coated from the inside with refractory reinforced concrete. Steel boilers equip the built-in coil to prepare household hot water (Senior 1040 KS, Junior K, KS-TGV, ATV-23G IDR.). In addition, the devices provide for the installation of Tan (N6-12kW) to heal water in the off-season or to help the furnace with cooling.

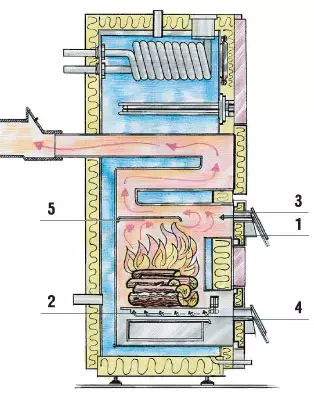

1.Read Luc

2. Kolyasnik

3. Forset of secondary air

4. Place of primary air

5. Gas turbulence adjustment

Modern solid fuel boilers can automatically maintain the specified coolant temperature. A sensor-regulator registers the temperature of the coolant is installed on the outlet nozzle of the device. It is mechanically connected to the damper pissed the boiler. If the temperature of the coolant becomes higher than the specified, the damper is automatically covered, the air supply to the combustion chamber stops, and the burning process slows down. When the air temperature decreases, the flap is opened, and the incoming air contributes to more intensive burning of fuel.

All boilers on solid fuel on a constructive feature can be divided into two groups: with one heat chamber and with two. Those and others are still divided into one and dual-circuit. The first provide only heating, and the second can still provide household hot water.

A feature of single-use combined boilers is that to transition from one type of fuel to another they need to be reconfigured. After all, each fuel has its own character of combustion, and to make it so that in the same chamber gas, diesel fuel and firewood with high efficiency, it is objectively very difficult. Say, the fire chamber for wood should be volumetric and without multi-turn chimneys that reduce the thrust. The use of blowing burners dictates completely different parameters of the camera. They do not need a thrust from the chimney, but the smoke channels to increase the heat of heat "shirt" are required. These restructuring are easy and forces by the owner of the equipment. Somewhere you need to remove (put) chammed boards (as in FB from Dakon), somewhere - turbules (model JAMA). DOR (DAKON) and V25 UB (CTC) and V25 UB (CTC) even provides for the transition from the upper (surface) combustion mode to the bottom when the firewood changes to coal. Sometimes the reconfiguration is reduced only to the installation of the burner to the lower door of the furnace, where the desired mounting hole has already been made (domestic models of the COP series and CCM or JAMA boilers). But only a specialist with a relevant license has to put or remove the gas burner. Two-pitching devices have two separate heat chambers: for burning solid fuel and to install a blowing gas or liquid fuel burner. Each furnace has its own design that ensures the best combustion of fuel. It is not necessary to rebuild anything in such boilers (as in one-window), everything is collected at the factory and ready to work at any time. The furnaces are connected only in the zone of the total smoke collector, which goes out to the chimney, so do not affect each other. Cameras are performed from steel. Printing models provides for the possibility of installing the Tan (1-3CTCs with a capacity of 6-18kW). All devices can supply the house with hot water. Bosch (Germany) Polyflam TC35 is used for this, a built-in 120l boiler is applied, and in the remaining devices, flow water heater. Hot water consumption depends on the power of the device. But for a good shower and washing the dishes of water, 600-1200l / h).

1.Choto

2. Cold water

3. Water heater

4.Clocked expansion tank

Solid fuel boilers, presented on the Russian market, produce Dakon, Opop, Atmos, Viadrus (Czech Republic), Buderus, Viessmann (Germany), Fondital (Italy), "Konord", "Kirovsky Plant" (Russia) IDR. Range of price - from4000 to 108000 rub. When choosing a solid fuel boiler, it should be borne in mind that it will require a sufficiently large length of the chimney. For example, with the power of the device 16kW, the length of the pipe must be about 6-12m, and at 40-45kW it can reach 20m (depending on the diameter or section of the pipe and the specific type of boiler). Common diameters of pipes - 150, 200mm. If a pipe of a square or rectangular shape, then the area of its cross section is usually from 100 to 400cm2.

Gas-generator boilers

In these boilers, gas is burning, released by adding fuel. Since either wood chip (no more than 5 cm long, and 3 cm thick), or pellets (wood pellets), that is, environmentally friendly fuel, boilers do not pose people's health and do not pollute the environment. Extract models can also be applied and firewood as fuel.

2.Winevik GVS.

3. Flood gases

4.Prust camera

5.Derova

6.Force

7. combustion centers

8.Camer after afterburning combustible gases

9. Fractional "Shirt"

10. Solnikom

11. Loading Luc

The combustion process takes place in two phases: in the load chamber, with a lack of oxygen, it is at first a dry sublimation of wood with the formation of hot generator gas. Next, this gas burns with high efficiency in the furnace chamber, both at partial and rated power. The boiler power is smoothly adjustable in the range of 40%. Laying a lion to 50 cm long can be launched (with the power of the model from 18 to 40kW) and up to75cm (with a power of 60-10kw). The solid volume of the chamber allows you to load the boiler with fuel no more than once in 12 hours. Regulatory efficiency of the device - 85%.

Compared to traditional solid fuel boilers, gas-generating rates are isolated less ash and soot, but when they are processed, condensate is formed (D1l per day). Therefore, with a device for such a chimney equipment, manufactured, as a rule, from stainless steel, in its lower part it is necessary to install a discharge nozzle to remove condensate. Boilers with pyrolysis fuel combustion are very sensitive to its humidity (it should not exceed 20%). Therefore, only dry fuel should be applied. With increasing its humidity, the efficiency of the device decreases, more ash and condensate is distinguished. If the boiler is incorrectly configured and the chimney device can fall to 7-10l condensate per day. During the ignition, the boilers consume up to 1.2kW of electricity, and in operating mode, 0.1-0,3CW.

Gas generator pellet boilers are usually single-mounted, with forced circulation of the coolant. They are two types - with a torch burner and volumetric. Users equipped with a torch burner, a burner fan, creating airflow, drive pellets into the burning zone, where they, trees, distinguish a combustible gas that form a flame torch to 1200s. The resulting ash sat down in the ashpan, from where it is subsequently removed manually or automatically.

Plots equipped with bulk type burners, fuel, droplet inside the burner, highlights gas, which, passing through a special nozzle, is lit with a bright flame. Inside the fuel burner is supplied by a special auger mechanism. There, to maintain the mode of fuel and separation of combustible gases, the fan is inserted through a special flap of fresh air. The temperature in the central part of the burner reaches 1200s. The operation of such boilers usually occurs with the help of automation, which, depending on the temperature of the coolant, opens and closes the air damper, turns on and off the fan and the fuel supply mechanism. The efficiency of such devices is slightly higher than that of boilers with flare burners.

In the Russian market, gas-generated boilers are presented by a number of models. Thus, the company Viessmann (Germany) produces the Vitolig150 boiler in several modifications (nominal power from 18 to 80kW). Massive-from377 to 1075kg. The price is 47,000 to 113000 rubles. The KPPYRO boiler company DAKON also has several versions of from7.5 to 40kW. The mass of the device depending on the model - from240 to 300kg, and the price is 53000- 62000 rubles.

Combined boilers

The main advantage of combined (sometimes called them is called universal) boilers in the fact that they can work both on all four types of fuel (gas, solid and liquid fuel, electricity) and two to three in different combinations. Universal systems operating on four types of fuel, set a universal gas-liquid burner, tanes and a flue chamber. Such models produce Jaspi, CTC and some others. Tan inserted into boilers can be programmed to work at night (when there is a cheap electricity charge rate). In addition, electricity can also be used as backup fuel.

Single-mount boilers operating on three types of fuel (gas, liquid and solid fuel), Dakon, Demir DKM (Turkey) are supplied to the domestic market. Dual-circuit devices manufactures Jaspi. Breaking models are provided by two coil chambers - one for solid fuel, and the other is for gas and liquid fuel. The STS company produces boilers operating on two types of electricity and gas. Combined devices have a large mass and are produced in the outdoor option. Here are the characteristics of some of them. The FB model (Dakon) has several modifications, works on solid fuel and gas (or liquid fuel). Instrument capacity - from 20 to 40kW, Massay210 to 350kg. The price is from 33,000 to50000rub. The jamajunior double boiler can work on any kind of fuel. The boiler (with strapping and automation), working on solid fuel and electricity, costs about 145000 rubles., And on four types of fuel- about 195000 rubles. Cost 1200Family from CTC (electricity, gas, liquid fuel) - 150000 rub. Domestic analogues are much cheaper. So, the model KS-TG-16 "Don" (solid fuel and gas) costs about 12000 rubles.

|

|

|

|

Modern automation is able to effectively manage the work of the equipment, which increases the safety of its work, reduces the cost of fuel and improves comfort in the dwelling; Allows you to set the daily and weekly mode of operation.

Bottle block

In order to properly operate the boiler, it is necessary to competently make his strapping, equip modern automation and install heating devices. The capping of the boiler implies the installation of an expansion tank, the circulation pump (if the heating system provides forced circulation of the coolant) and the so-called security group. Many patterns of boilers are supplied to the consumer already with an expansion tank, a circulation pump, as well as a safety valve, filter, and air ventilation vehicle.

The expansion tank is necessary because the coolant, changing its temperature, changes the volume. Therefore, when excess the coolant is formed in the heating network, it is extruded in the expansion tank, and when the coolant cools and its volume decreases, it returns from the tank to the heating. The circulation pump is set to enhance the circulation of the coolant in the heating network. It is usually necessary if it is sufficiently branched to heating and consists of a number of heating devices. The security group includes a safety valve that is triggered if the pressure of the coolant in the network exceeds the allowable level. Through the valve, the coolant is removed into the sewer, and does not break the closed heating network. Electrocotels still equip the RCD (protective shutdown device), disconnecting the power supply of the device at emergency, not allowing a short circuit (for example, in the event of a battery breakdown or an occurrence of any malfunction in the power supply of the boiler). The security group also includes an air vent - the nozzle through which the air has been removed in any way. The filter cleans the medium circulating in the heating network from various impurities. The process of heating device in the house can be divided into three stages: installation of the boiler, pipe wiring and heating devices, the cutting of the boiler and its connection to heating pipes. Of course, the layout of pipes and heating devices can be made according to the project, the first stage, and then install the boiler, tie it and connect it to the pipes.

The tube of boiler automation includes appliances controlling and regulating boiler equipment. Automation can be both mechanical and electronic. For example, the operation of the electrode boilers manufactured by Galan can manage the Navigator electronic unit, manufactured by the same company (the price of different models ranges about 5000 rubles.). The operation of some devices can be controlled by the programmer, setting the daily and weekly temperature modes. Thus, the Warmosqx boiler ("Evan") can be controlled using the IMIT programmer (Italy, price is about 1500 rubles). More and more manufacturers equip the heating boilers with microprocessor devices, allowing to more accurately monitor and regulate the specified parameters in automatic mode. This makes it possible to significantly reduce heat loss, and therefore the cost of heating a house or cottage.

The installation of the boiler house is started after performing the wiring, the installation of sewage taps and connecting cold water. The boiler must be installed on the floor with a non-aggravated coating so that sufficient air access is provided to it, as well as a free approach for inspection and maintenance. Ventilation holes should be done with limited space. When air from the street, the inlet should be of the size that provides the necessary air exchange. The outlet chimney of the boiler is connected by a removable chimney with chimney of the building. Installation of pipelines start after fixing the boiler and expansion tank. Plongs are mounted pumps, air and dirt discharges. Safety and drain cranes are installed on the boiler and the boiler. Pipelines are fixed on the suspension holders so that the weight of the pipes used in the stroke has not been transmitted to the boiler. Then the pressure gauges, thermometers, thermostats and temperature sensors are installed.

How to reduce heat loss

Even the most primitive solid fuel boiler can be dried more than a few hours in 2-3 days. Then it will be possible to use the fuel to use the fuel as efficiently, get a small amount of soot and clean flue gases. To do this, you need to connect the heat insulated tank battery of hot water sufficiently large volume (500 liters or more). The tank takes water from the boiler when fuel is on intensely, highlighting a lot of heat. When the fuel burned and the boiler cools, the battery feeds the water "shirt" of the boiler and the hot water heating system. Vitoga Smooth temperature in the house is supported for a longer time, and conditions are saved in the boiler for better fuel burning. In addition, the boiler can be made less frequently, which gives fuel economy. Connect the battery with a boiler in two ways: directly, without shut-off valves, as is done in Jaspi models, or with the help of a controlled bypass circuit with a forced circulation, as the STS offers.

1.Choto

2.Baypas line with hydraulic pump

3. Hot water accumulator

The editors thanks Buderus, Viessmann, Protherm, Jaspi, Demir DKM, "Evan", "Diathon B.", "Forsterm" and "Galan" for help in preparing the material.