Warm floor in the bathroom: electrical and water heating systems, a necessary equipment kit and materials. Description of mounting work.

Layout diagram and connecting two-core cable

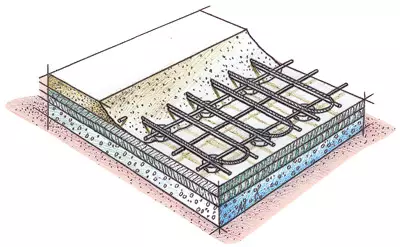

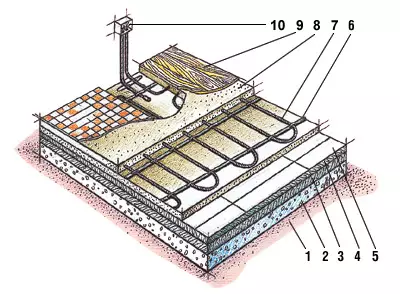

1. Soil

2. Sealing gravel

3. Heat insulation

4. Plastic film

5. Reinforced concrete plate

6. Mounting Planca

7. Heating cable

8. Aligning concrete

9. Surface material

10. Thermostat

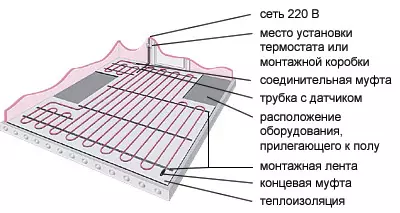

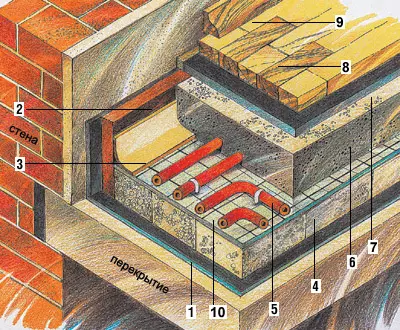

1. Waterproofing

2. Thermal-linguing gasket

3. Isolating film

4. Thermal-linging plates

5. Tubes of heating circuit

6. Concrete screed

7. Mastic

8. Clean flooring

9. Plinthus

10. Heat Cotor Foil

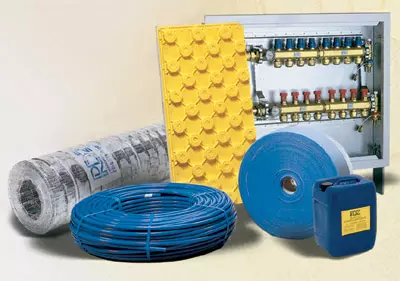

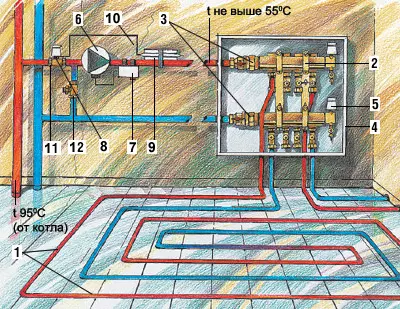

1. Heating contour

2. Ring distribution

3. Ball crane

4. Distributor cabinet

5. Air road

6. Circulating pump

7. Electric pump thermostat

8. Thermostat

9. Foreign temperature sensor

10. Capillary tube

11. Thermost-ticial valve

12. Bypass valve

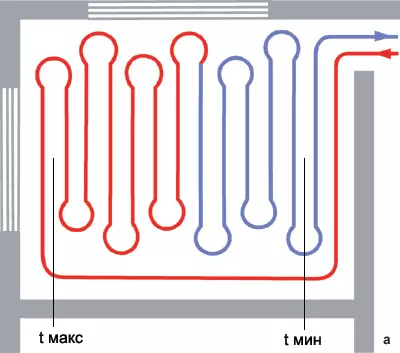

a - Meandar;

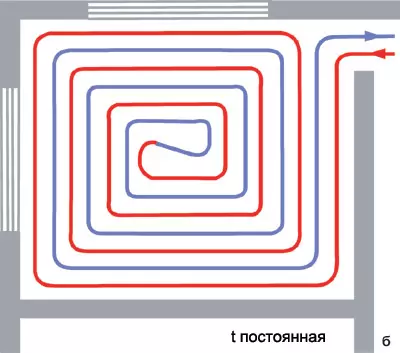

b - spiral

The floor heating system in the bathroom is needed, perhaps, like any other room at home. Together with the heated towel rail, it supports the most comfortable microclimate in the most wet dwelling zone. The temperature on the floor surface is + 26c, and at the head level +22 ... + 24c. According to experts, such a temperature distribution in the height of the room is optimal and very difficult to achieve the use of other heating devices.

Chewned with a heating system even very cold in winter does not feel drafts. The splashes that hit the floor quickly dry out, so it always remains dry and warm and it is difficult to slip on it. In addition, the cleaning of the room is facilitated and the likelihood of the appearance on the surfaces of the walls and the floor of the walls is almost eliminated, often detecting in wet places at home.

Varieties of floor heating systems

Today, electric and water heating systems are most popular in Russia. They are installed both in urban high-rise buildings and in country houses, there would be electricity and funds to pay for utilities. For a small bathroom with an area of 2-4m2, a separate wiring is required with its machine and the RCD, the power of about 0.2-0.5kW. Civil buildings that were erected more than 10 years ago and where substations and eyeliner are designed for old standards (approximately 2,5kW per apartment), we can only talk about the heating of floors only as an additional heating. Yes, and it should be used carefully, since there is a possibility of overloading the feed cable (if all neighbors simultaneously include numerous household electrical appliances). But even when the power is necessary for connecting power (in modern apartments, it is 7kW), it is necessary to check whether the existing wiring allows the connection of the warm floor to the current load. If not, you can recommend installing a system with a power of more than 2kW through a separate wiring and a separate machine.As for the water system, it requires a source of hot water for this type of heating of floors: a boiler for gas, diesel fuel, angle, electricity (in the regions with a warm climate to this list, you can add solar collectors and thermal pumps). Therefore, it is more often used in cottages with an autonomous water heating system, where, in addition to the bathroom, heated floors and in other rooms. For the water heating floor, in the urban model apartment, it is necessary to obtain the resolution of DEZ to connect to the network of hot water supply or install a small electric boiler specifically for feeding the heating system, which is unnecessary.

Maulro burls

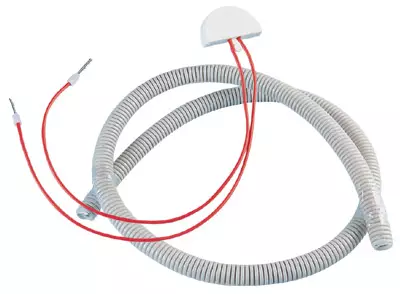

The heat source in the bathroom electrical system system is a heating cable, which turns the surface into a large heating panel, evenly emitting heat. The cable is connected to the automatic thermostat, due to which the system is controlled. The thermostat is fixed on the wall (if it has a waterproof design, then directly in the bathroom, if not, beyond it, for example, on the lighting switches panel) and is the only visible part of the system. Temperature readings come to it from the temperature sensor installed, as a rule, in a special corrugated tube in the plane of the sealing of the cable (so that it can be changed during the breakdown).

All necessary equipment for the electric heating system is sold composed of heating cable, thermostat, temperature sensor and corrugation. Completed sets for mounting in thick or in a thin screed. When choosing equipment, it is necessary to proceed from how the mark can be raised in the bathroom, how urgently need to put the system into operation and how much burdens for the customer the economic aspect of its use. Install the warm floor during the repair of the bathroom can be independently or using the services of specialists (to whom to contact, the vendors will be prompted). At the same time, it is necessary to strictly follow the technological recommendations of the manufacturer. Avot connect the system to the power supply and grounding should be only with a qualified electrician.

The thickness of the concrete screed depends on the alleged mechanical loads. For a uniform temperature distribution over the floor surface, the German standards of DIN4725 are recommended to perform a screed with a thickness of at least 65mm. According to the requirements of Russian SP41-102-98, its thickness should be at least 30mm. Punching flooring in the bathroom should be used ceramic tiles, marble or other material with an indicator of thermal resistance R = 0.02M2K / W.

Montage in thick screed

When there is no significant restrictions on the height of the ceiling in the room, it is possible to resort to the traditional scheme, which involves the most efficient energy-saving transformation of electricity to the heat for the bathroom, is to install the heating system in the thick screed. If the floor in the bathroom is earthen (in the cottages it is often located in the basement floors), the pillow is stacked from thoroughly rammed gravel and waterproofing. On the ready-made concrete base of gravel, naturally, it is not used, in this case the "lining" for the system is a well-purified and aligned slab overlap. On top lay a layer of hard heat-insulating material with a thickness of 50-100mm, on which the first screed is performed. The segments of the mounting ribbon or the reinforcing design of the wire that have not yet frozen until the end of the concrete surface, which substantially facilitate the cable layout (by a predetermined track). Next comes the second concrete screed, its thickness with direct heating ranges from 30 to 50-70mm. On the perimeter of the room, in the lower parts of the walls, the insulation strips are arranged, preventing floor deformation when heated as a result of a thermal expansion of concrete. The floor, built with cement mixtures, dries at least 28 days, made using self-adjustable mixtures - 2-3 days. Finally, the finish coating is placed on the tie, such as ceramic tiles.Buying a set of equipment for mounting the electrical heating system in a thick screed, it is necessary to keep in mind some features of the base elementary cable. By diameter and power cable power (that is, by its ability to give the surrounding space, this or that amount of heat expressed in watts for each meter of length) there are no restrictions. For laying in a thick screed, cables can be used with a diameter of 5-10mm with a pole power from 17 to 21W / m, as well as "thin" 2-3 mm cables with a capacity of 5-12W / m. Cable coils with less routing power are closer to each other, in strict accordance with the manufacturer's recommendations. It is important that the power of the entire cable is enough for a comfortable heating of a particular room (approximately determine the required power, multiplying the room of the room 100W).

It is not essential that the cable is available in a complete or dwended (the difference between them is that the dwellings are practically not created the electromagnetic background and are 10-20% more expensive). The presence of single-core systems of an electromagnetic background, which in any case is no more than the hair dryer or hidden wiring, is not dangerous, besides, a person comes into the bathroom several times a day, and that is not long.

When choosing a heating cable for the "wet" zone, it is necessary to pay attention to the fact that it necessarily had a screen from steel or copper wire, aluminum foil or lead, which serves primarily security goals. Listening to the damage to the cable or the water hitting on it, the screen plays the role of "grinding", moreover, it significantly reduces the electromagnetic radiation created by the cable. Extracting systems with shielded single-core cable, the screen is used both as a feed (reverse) wire, but only located coaxially with a heating residential, due to which the resulting electromagnetic radiation decreases significantly.

It is characteristic that the cable in the set of floor heating system is not as a piece of wire, but in the form of a complete product-section with a certain length of heating veins and thermal power. For the convenience of mounting and increasing the service life of the entire design to the segment of the heating cable in the factory conditions, the so-called cold ends of the power conductors are attached, which, unlike the cable itself, can be led or shortening if necessary. The section of a single-core cable contains two couplings and two cold end, while a section of a two-housing cable at one end is rejected by a terminal cap, and on the other-coupling and two cold ends to connect to the network (thanks to such a device to lay sections from a two-core cable easier ).

The quality of the coupling is one of the most important criteria for successful system selection. The coupling must provide reliable electrical contact for many years of cable and tightness of the connecting unit. Different firms use various options for compounds (soldering, welding, crimping) and sealing (the use of heat shrink plastics, filling with polymerizing compounds). Reliability and durability are determined by both the perfection of technology and the quality of the assembly of the assembly, therefore the best indicator here is the long experience of the manufacturer's firm in the market of warm floors and the period of free warranty service.

Dozens of companies are engaged in the production of heating sections on the basis of single and two-core cables, among which Ceilhit (Spain), Alcatel (Norway), Kima (Sweden), Devi (Denmark), Siemens (Germany), Ensto (Finland), as well as Russian firms "WST", "ChuVashkabel", "Terma" and "Eltech Electronics".

Thin screed

Recently, for heating the floor in the bathroom, the cable is practiced in a thin screed (0.5-1.5 cm) - right on top of the old tile or concrete floor. From the use of thermal insulation, as a rule, refuse. Without it, heating the bathroom will not be so economical as with a thick screed, but it will not be necessary to sacrifice 5-10 cm of the room height, which is especially important for a larger number of city apartments. Yes, and the timing of the system is reduced several times. The cable is folded with a snake or spiral and fix on the former tiled facing. From above, instead of a screed, a layer of glue is applied to which (depending on the technology cable proposed by the manufacturer) gives drying for 1-2 days, and then the finish coating is already assembled. Or put a new tile immediately, on just applied glue.

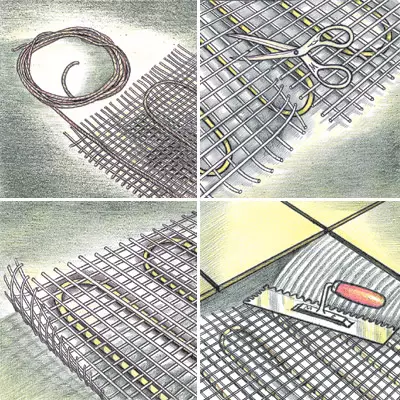

Thin single and two-housing heating sections can be supplied to the customer in bays or in the form of mats, which are laid by a snake cable attached to the carrying fiberglass grids with a width of 50 or 90cm and length from 1 to 10m (the length is proportional to the power). If the thin cable, as already noted above, is quite suitable for installation both in thick and in a thin screed, then the heating mats are manufactured specifically for the premises, where it is impossible to raise the floor level by more than 0.6-1 cm without taking into account the finish coating ( There are only for a thin screed). The grid can be easily cut into fragments without disturbing the integrity of the cable, which allows you to decompose mats on an area of any configuration (including the obstacle).

Heating mats and sections based on sintering thin single-core and dwelling cables produce Ceilhit (Spain), Devi (Denmark), "CST" (Russia), Alcatel (Norway), Ensto (Finland), Siemens, Arnold Rak and Stiebel Eltron (Germany), Kima (Sweden).

Electronic thermostators

The thermostat with the floor temperature sensor, along with the heating cable, is an essential element of the electrical heating system. Such instruments produce OJ Microline (Denmark), Eberle (Germany), Devi (Denmark), Ensto (Finland), "CST" and "Eltech Electronics" (Russia) and others.It is hardly justified by buying a set of equipment with a programmable thermostat for heating the floor of a small bathroom in an urban apartment. It is quite a fairly traditional unprogrammed model worth from $ 40 to $ 120. Such a thermostat can easily cope with the maintenance of a fixed temperature for a long time - up to the next adjustment of the user parameters. By sposing the temperature of the floor to the mark, which is lower than 0.1-2C (depending on the model), the instrument commutes the system, with an increase of the same value, turns off. The temperature setting on unprogrammed thermostats is done step by step, using a multi-position switch, or smoothly, by means of an alternating resistor. The color indication reports the user that the heating system is under voltage.

Of course, if the bathroom in size resembles the Throne Hall of the Royal Palace, you can also purchase more expensive (2-3 times), but also a more economical programmable thermostat. It is capable not only to maintain the specified temperature, but also to change it on the algorithm installed by the user: for example, heating the floor to a certain temperature only in the morning from 7 to 9 hours and in the evening from 18 to 23 hours. Increased time the system will be in the disconnected state. Such devices allow you to extract the maximum benefit from the two-year electricity payment scheme, automatically including heating and accumulating heat during the topics of the cheap tariff.

Permissible electrical hardware loads (according to PEU)

| Explorer material | Number of housing, mm2 | Maximum load current, and | Maximum total power, kW |

|---|---|---|---|

| Copper | 21. | nineteen | 4,1 |

| 21.5 | 27. | 5.9 | |

| 22.5 | 38. | 8.3 | |

| Aluminum | 22.5 | twenty | 4,4. |

| 24. | 28. | 6,1 |

It's all in warm

According to most professionals, the right choice of thermal insulation leads to a noticeable economy of electricity during the operation of the floor heating system, and its initial cost increases slightly. The heat insulation reduces the useless spending of heat to heating overlapping, soil and other structures underlying the heated room. When the floor is arranged in the ground floors and on the ground, it is recommended that the heat insulation is recommended to use solid types of polystyrene 50-100mm thick. Heat insulating plates with a layer of foil with a polymer coating are often used. Foil, if it is in contact with the concrete screed, due to thermal conductivity, heat from the cable over the entire floor surface, and also reflects part of the thermal radiation back to the heated room. In addition, foil is a good vapor polypoletor. The polymer film protects it from alkaline destruction as a result of interaction with the concrete tie.A very effective heat insulator for the floor heating device in a thick screed is cork slabs with a thickness of 2 to 10 mm.

The selection of heat-insulating materials is quite wide. Among the manufacturers should be noted LLC PKP Stroy-Plast, Dow Chemical BASF, (high hardness polystyrene floors Floormate), Hanalon (South Korea), Bubble Foam Industries N.V (Belgium, foil and laminated focus). Domestic foil foam polyethylene is manufactured at the LIT-Isolation plant. The average price is 1m2- from $ 2 to $ 4.

How much is comfort?

The minimum cost of a set of equipment and materials (for a device in a thick screed) for heating the floor in a 3m2-order bathroom with an area of system of domestic production and 120-140 using imported products. The choice of equipment is great enough.

Complete price (mat or section, thermostat with floor temperature sensor, a corrugated tube for a sensor) for a bathroom with an area of 3m2 is about 90-130.

Underground "Rivers"

The water heating system in the bathroom is environmentally friendly (there is no emission at all) and economical (warm hot water is usually cheaper than electricity, except for the case when an electrocotel is used as a heat generator). The main heat transfer elements in the water system are durable and easy-to-install polymer pipes (from stitched polyethylene, metal-polymer IDR.). Cut pipes (they are also called contours) do not have joints (whole pieces cut off from the bay). They are located in the form of coils in the body of a cement tie of the floor and are connected to the feed and reverse collectors of the heating system. In general, the case of contours (one by one, two or three on the room) connected to one collector may be several. The collectors, in turn, are mounted in the collector cabinet installed on the wall or flush with the wall in the bathroom or beyond (if the water heating is arranged in several rooms).When the pipes laid in the floor circulates hot water, the surface of the floor radiates heat. Since, as already noted above, in urban houses with central heating, water can not be directly taken from the heating system, nor from the DHW system, this installation is recommended to be mounted in country housing. There, in addition to the equipment for a warm floor (cutting of a polymer pipe, a collector kit, thermal insulation, fasteners and other elements), a boiler, circulation pumps and an expansion tank, as well as a control device are used.

The main control unit of the water system serves as a multi-part crane with the thermostat. It adjusts the heating of the floor, mixing water in the desired proportions, coming from the boiler or other source of heating and returning from the warm floor system with water temperature in the circuit 35-50c. It is convenient to use the finished node of the thermostat with the already assembled faucet, mixing and irrigation valves and circulating pump. Additional amenities for the user provides a combination of a thermostat with a timer that provides work on a day or a week a week ahead.

Make the selection and installation of equipment for water heating of the floor in the bathroom with its own forces is unlikely to be advisable - this requires computer calculations, specific knowledge and tools. It is better to resort to the services of firms officially representing products and technology of leading manufacturers of Water Systems of Warm Paples OVENTROP, REHAU, Unicor, Aquatherm (Germany), Henco (Belgium), Purmo, Pexep (Finland), Wirsbo (Sweden), "Ghent" (Russia) and others. The cost of arranging water heating in the bathroom with an area of 3-4m2 can easily exceed the amount of 1000. However, if there is a water heating of the floor in a country house in several rooms, this will cost the user at 40-60 for each meter of heated area.

According to many experts, the environmental safety of electrical heating is not doubtful. According to the sanitary standards and rules of Russia (SanPine2971-84), the electric field strength in residential premises cannot exceed 500V / m, and the level of induction of the magnetic field of industrial frequency (by SanPiN2.1.2.1002-00) should not reach 10 mkl. The actual values of these parameters of electromagnetic fields above the gels with shielded cables are below several times. Manufacturers Indicate Electrical Stress from 10 to 300V / m. APO testimony of the employees of the Electromagnetic Security Center of the Ministry of Health of the Russian Federation, made by them in the residential premises of the measurement showed that the tensions and induction values created by the floors do not exceed the background. It is also important that the materials used in the device are less susceptible to fire than the usual electrical wiring.

Wet

Leaving beyond the framework of this article about the arrangement of the heat supply system and on the conjugation of the heat source with the floor heating system in the bathroom, consider the actual installation of pipes in the floor design. At this stage, the wizard often make mistakes, but the customer may well monitor the process and make their comments.

The most common technologies used today implies the so-called wet installation when the heating pipes are paved in the body of a concrete screed. A similar system can be arranged in the bathroom, the overlap of which will withstand an additional load of 250-300kg per 1 m2 premises. Saying the manufacturer of equipment for water heating of the floor has its own developments for the implementation of the procedure of wet mounting, but the principal technological discrepancies are probably not.

Actually, the installation of the system is often preceded by a rather long preparatory period during which the base surface for the water heating device is strictly horizontal and smooth. If necessary, it is covered with a thin concrete screed, minor potholes (no more than 0.5 cm) in some cases can be embedded with dry sand.

If the aligned base plate comes into contact with the ground, waterproofing from waterpress or other material is placed on it. Next comes a layer of thermal insulation, the thickness of which is calculated when designing the system. In the device of water heating to thermal insulation, it is resorted not only in the bathrooms, bordering the ground and cold undergrounds, but also in the rooms of the upper floors. Compliers' systems suppliers include ready-made leaf and rolled heat insulating materials. Sheet insulation is a plate or polystyrene panel, basalt fiber or foamed polyurethane with a thickness of 30 to 70mm. They can be covered with heat-reflecting foil with a markup in the form of a mesh or supplied with bosses for laying and fixing pipes. On top of the heat insulation layer, it is recommended to lay a polyethylene film so that the cement solution does not penetrate between the plates and did not create temperature and acoustic bridges.

In order to prevent deformation, cracks and swelling of the floor covering as a result of the temperature expansion of concrete, as well as to protect against the appearance of thermal and sound bridges, after installing the thermal insulation, it is necessary to make an edging of the future heated screed. It is performed by the edge ribbon of foam polystyrene or other material, which is stacked along the walls and other building elements. It follows the temperature seams in the rooms of a complex form and in the case when one of the sizes of the ceiling slab exceeds 8m.

After laying auxiliary materials (thermal insulation, vaporizolation, edging, temperature seams IT.D.) You can start the main phase of work. First of all, you must install the feed and reverse collectors. The pipe is connected to the feed collector, after which they begin to unwind the bay and form the heat circuit on the prepared surface. When the water heating device is used, one of the three main options for laying the pipe is used. Schema "Single Snake" provides easy installation and most uniform temperature distribution over the surface. This technology can be applied to heating oblique areas. The parallel location of the supply and return pipes guarantees a uniform middle temperature. Well, the parallel spiral is recommended for bathrooms with large heat lines.

When choosing a method of laying the pipe, it should be remembered that heat loss is distributed on the area of the room unevenly. For example, the outer walls are higher. Waich places should arrange pipes closer to each other than in the rest of the sections.

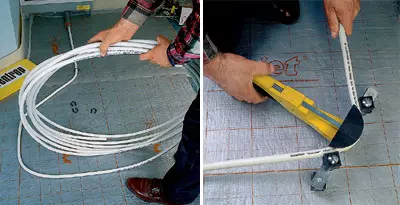

The fixation of pipes on the prepared base is carried out using the reinforcement grid and wire, with the help of mounting brackets, rails, between elements of profiled heat insulation (bobbs) IT.P. The first option is characterized by simplicity, since the reinforcement grid is also graphic, and therefore it does not have to spend time on the markup of the floor, and the concrete screed due to reinforcement it turns out more durable. In addition, due to the grid, the heating tube is completely (the entire surface) contacts the material of the floor screed, ensuring maximum heat transfer. The grid is made of a metal bar with a diameter of 3 to 6 mm. The cell size is usually 150150mm, less often 225225 or 300300mm. The pipes are attached to the grid at least by 0.5-1m with the help of plastic clips, fastening wire, twisted with a special hook, or plastic fastening tape.

Installation must be performed at an air temperature not lower than + 10c. Each warming circuit should consist of one whole piece of pipe, without crossings, twisting and overlap, as well as squeezing and other damage. It is important to apply only the fittings and tools certified pipe manufacturers. Cut the pipe from the bay follows only after laying the loop and supply it to the reverse collector. With a large number of pipes close to each other, for example, near the collector, you need to isolate some of them, preferably feeding, in order to prevent local overheating.

The next stage of the warming contours of the concrete, which is aimed at ensuring uniform warming up the floor surface. However, before forever hide polymer pipes under the layer of concrete, it is necessary to conduct hydraulic tests of the system. According to the construction rules, the inspection of floor heating for tightness is carried out at a pressure, 1.5 times higher than the working (but not less than 0.6 MPa), and at a constant water temperature. Under the operating pressure, the pipe must be at the time of the fill, it will reduce the likelihood of in the system of unwanted mechanical stresses.

Typically, companies supplying professional equipment and materials for the installation of water heat floors provide accurate proportions of the preparation of a screed solution, which depends on the execution of warranty providers. Summarizing data from various manufacturers, it can be said that a cement-sand mixture of a brand should be applied for the device not lower than 400. The dormitory is often added to the so-called plasticizer that improves fluidity. Due to this pipe covered with concrete more tightly, the thermal conductivity and the strength of the screed increases. So that there are no air pockets in the floor, concrete around the pipes must be carefully tumped. In concreting, it is important to avoid displacement and vertical bending of pipes.

The supply of hot water into the system should be made no earlier than in 3 weeks. During this time, the concrete screed will type the necessary strength. In no case cannot be allowed in the system of floor heating hot water with the design temperature until the screed is hardening, for its heating will result in the formation of cracks. After the specified period, the coolant with a temperature of + 25c can be submitted, and in the next 4 days it should be gradually raised to the calculated one.